Patents

Literature

214results about How to "Reduce machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

3D (Three Dimensional) forming method for large-sized porous amorphous alloy part of complex shape

ActiveCN104399978ASolve difficult-to-machine defectsOvercoming the Deficiencies of Difficult ChoicesSelective laser sinteringAlloy

The invention discloses a 3D (Three Dimensional) forming method for a large-sized porous amorphous alloy part of a complex shape. The method comprises the following steps: preparing amorphous alloy powder through mechanical alloying pulverization in combination with plasma spherizing or atomization; then sintering metal powder by using selective laser so as to prepare the large-sized porous amorphous alloy part with the complex shape. The method has the advantages that the problems such as small critical dimension of amorphous alloy formed by a water quenching method and a copper mold casting method and difficulty in selection of a pore forming agent are solved, the 3D preparation and forming of the large-sized porous amorphous alloy part are realized, the part with the complex shape can be prepared, the defect of difficulty in machining of the amorphous alloy material is overcome, the amorphous alloy part of the porous structure can be conveniently formed, the pore size and the volume fraction can be flexibly adjusted, and the method has the advantages of raw material saving, high efficiency, low cost and the like and is suitable for industrialized preparation of the amorphous alloy part.

Owner:SOUTH CHINA UNIV OF TECH

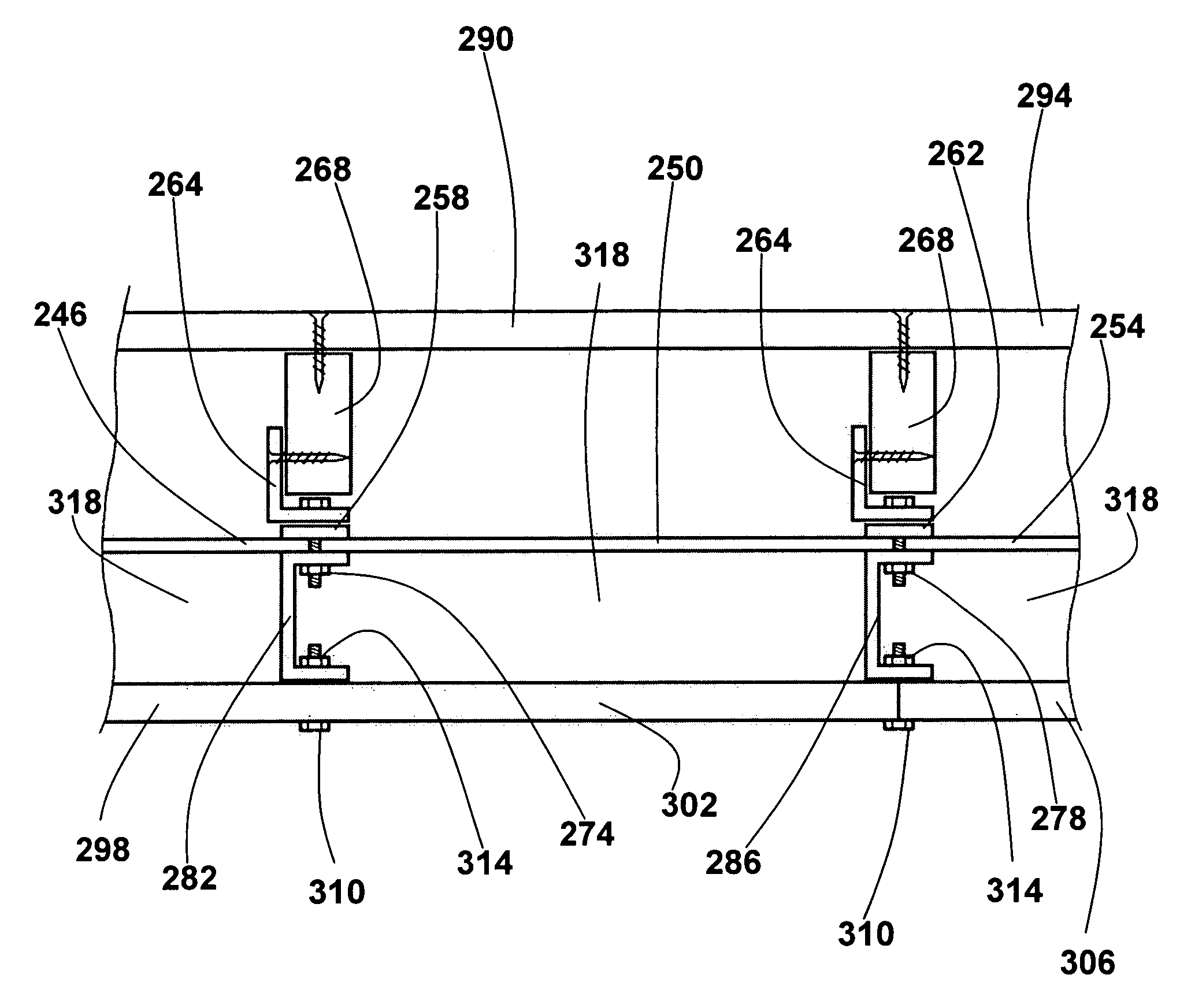

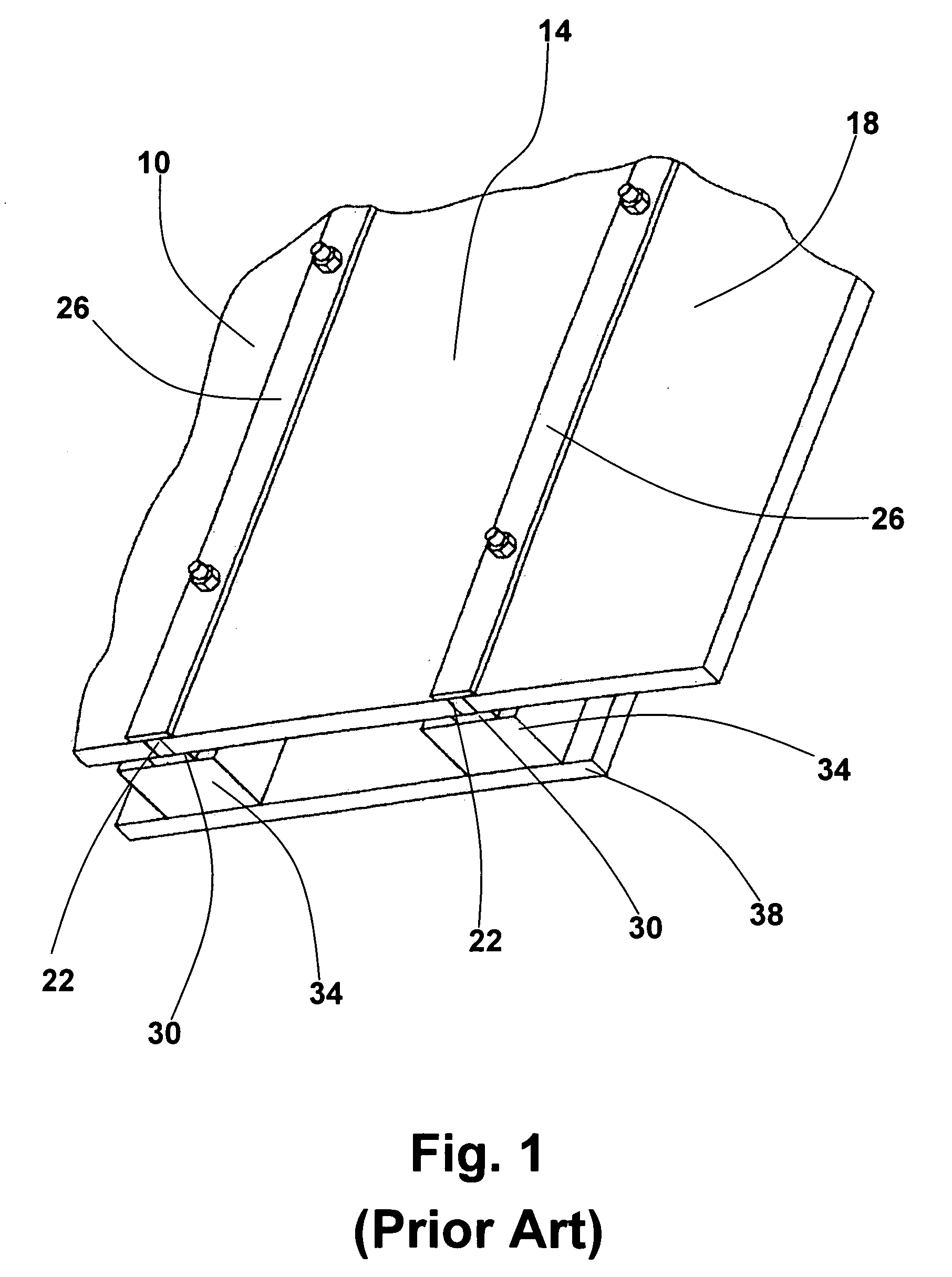

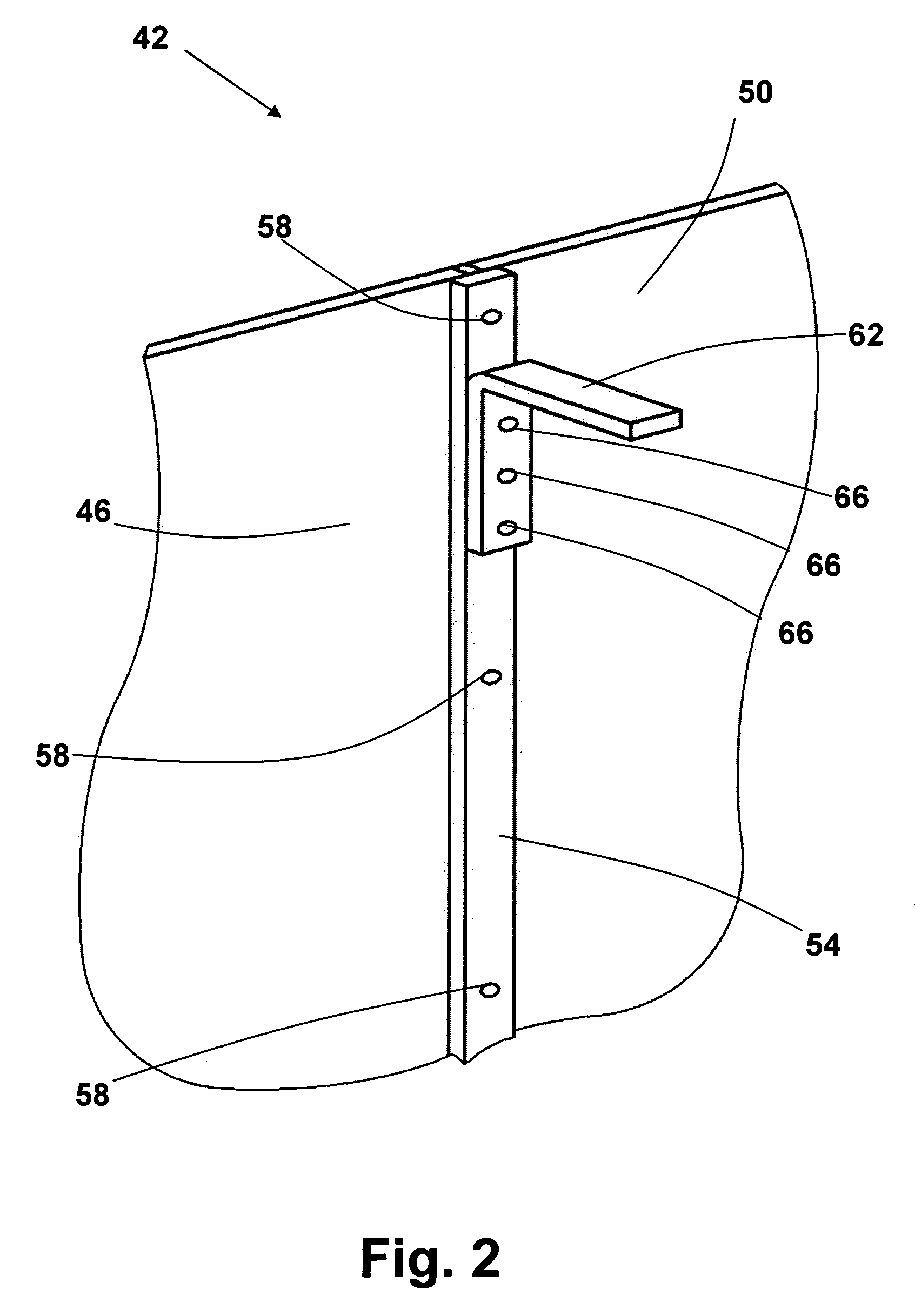

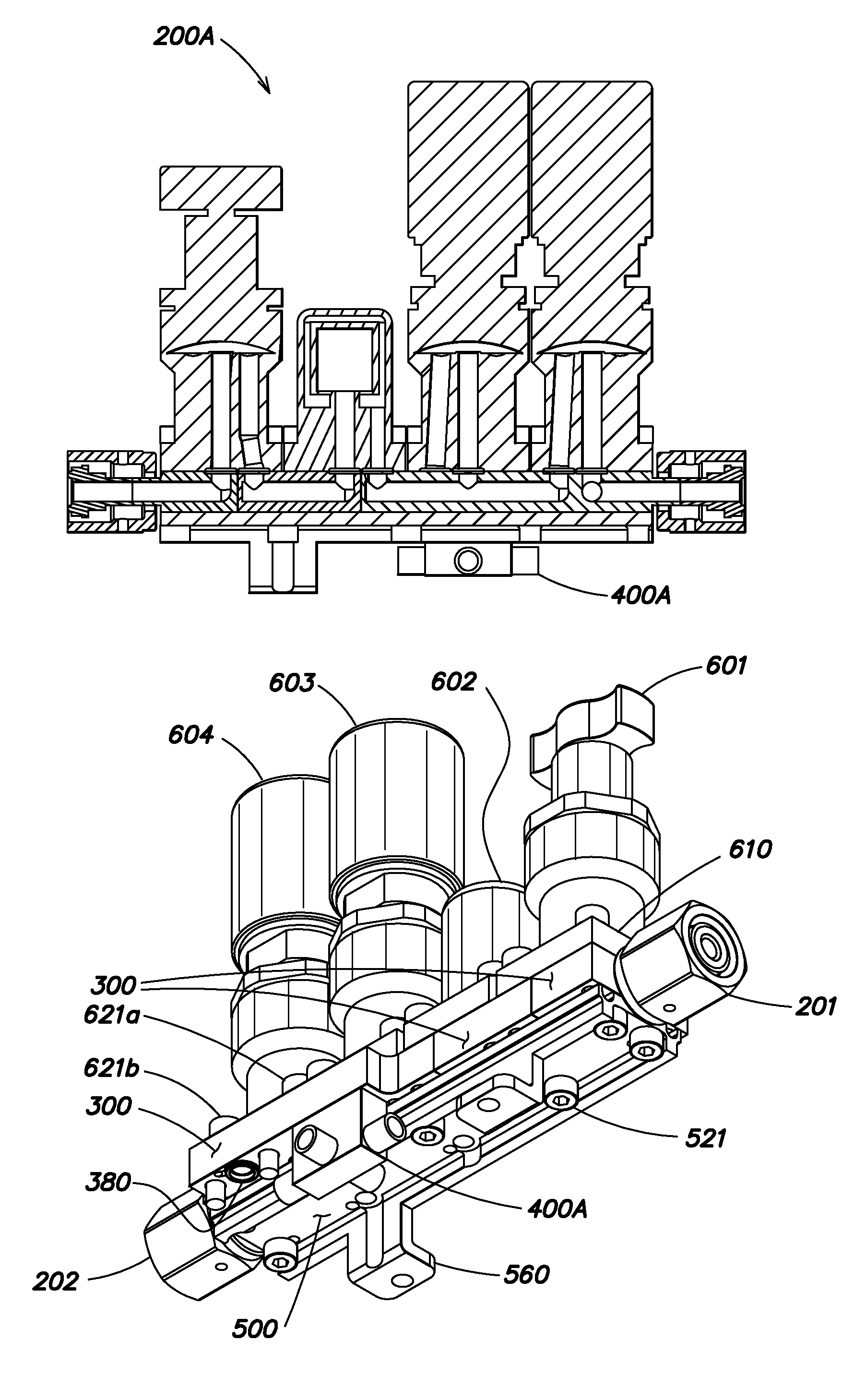

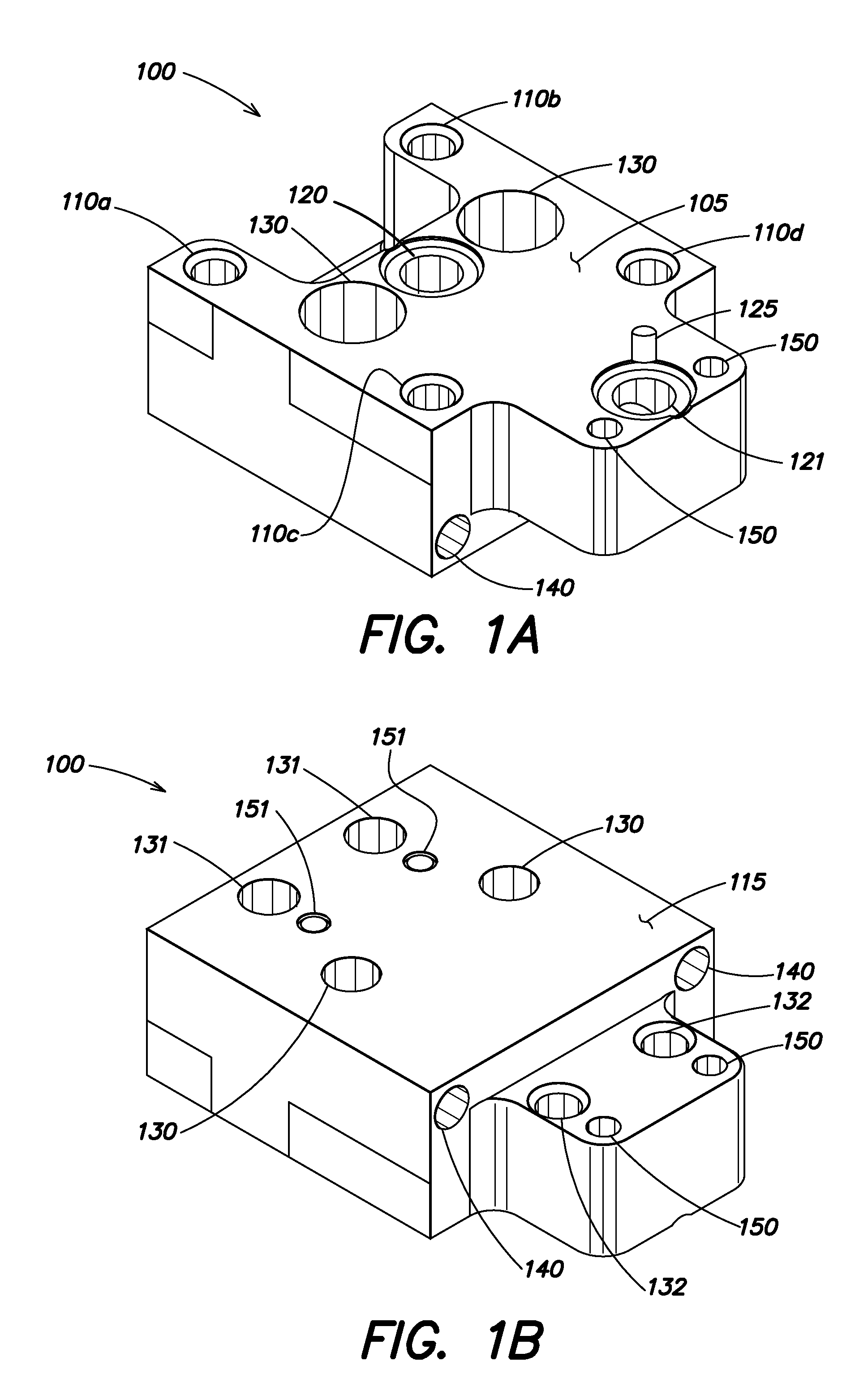

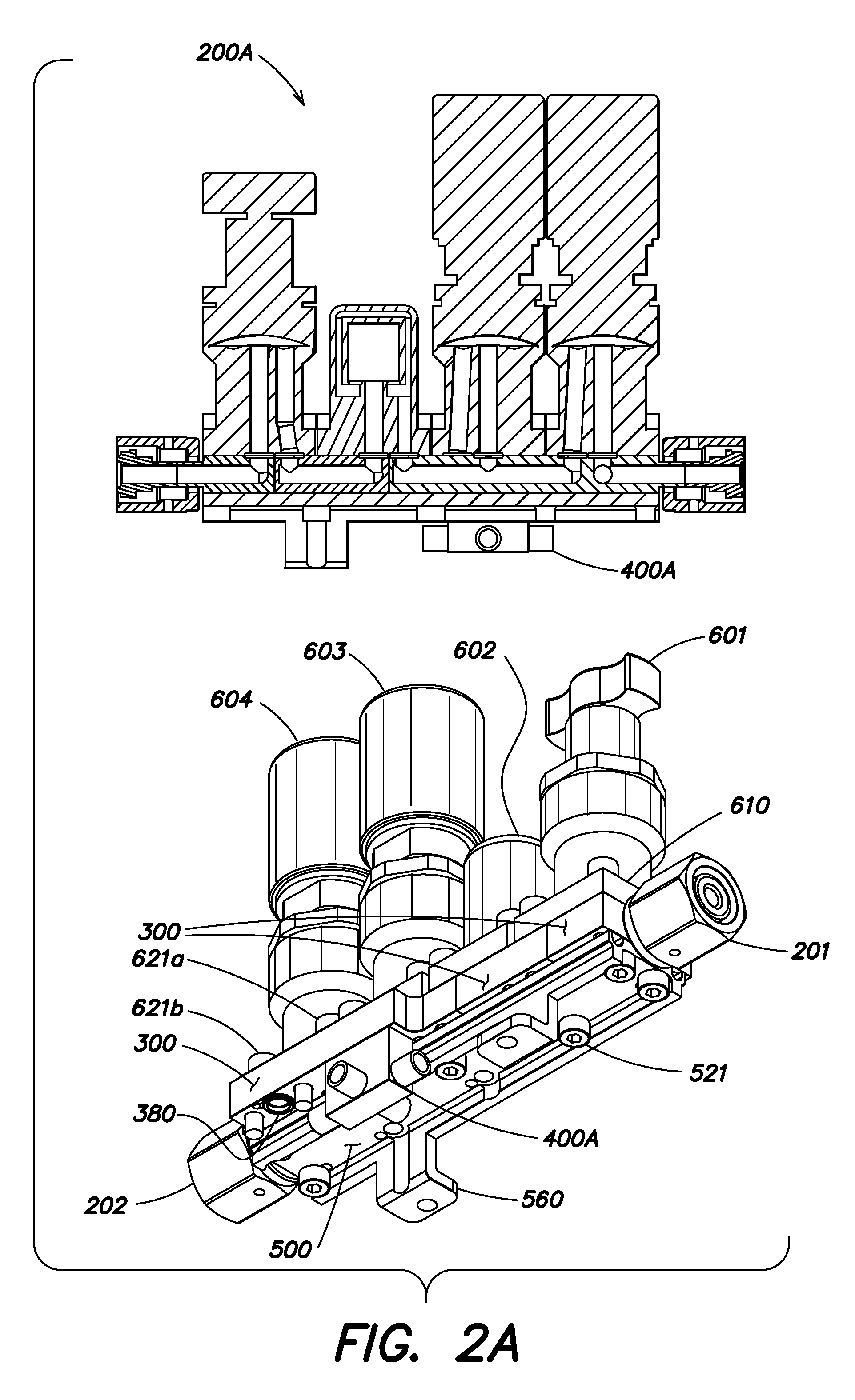

Fluid delivery substrates for building removable standard fluid delivery sticks

ActiveUS8307854B1Minimize the numberLow costServomotor componentsMultiple way valvesCatheterBiomedical engineering

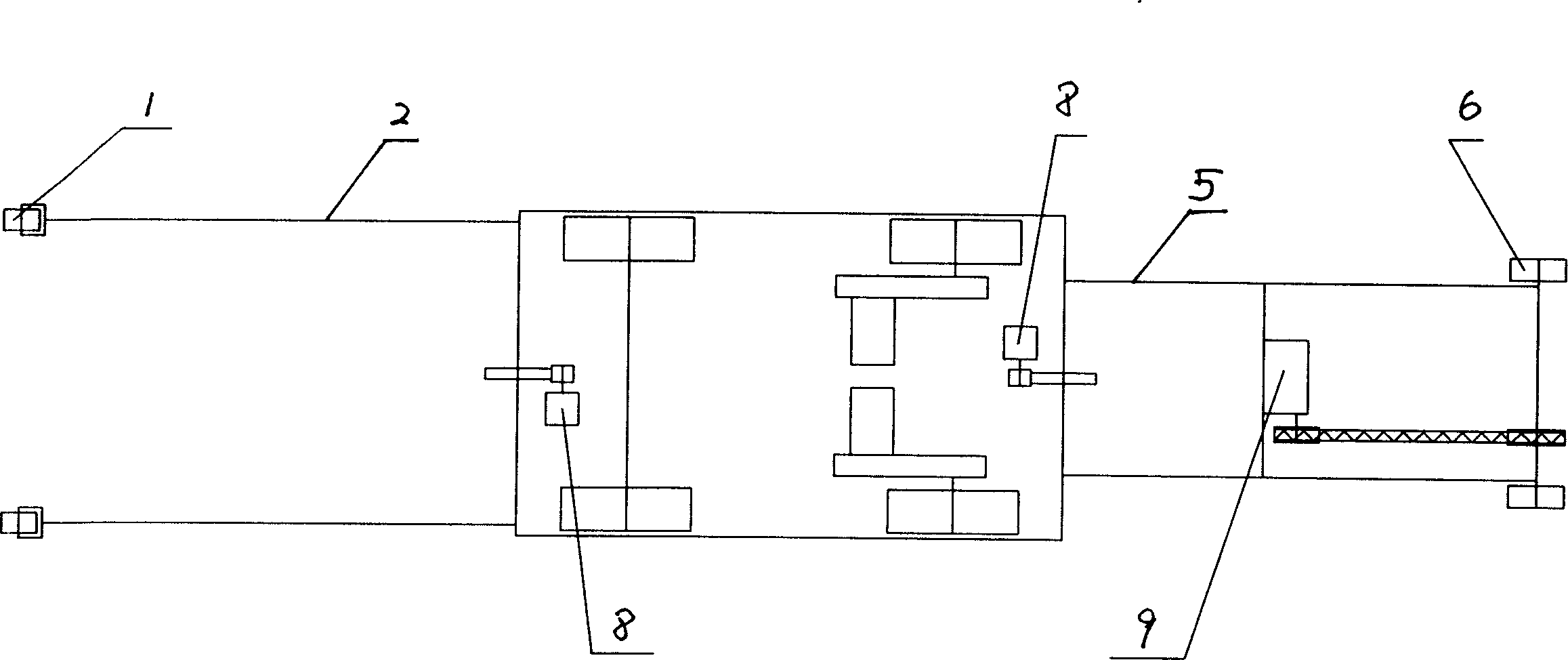

A fluid delivery system that includes flow substrates and manifolds that minimize the number of fluid conduit ports and seals needed to build standardized fluid delivery sticks. Each flow substrate has a component attachment surface with one or more component conduit ports and an associated plurality of fastener apertures. Some flow substrates incorporate a transverse manifold connection conduit port on a surface opposite the component attachment surface. Fastener apertures associated with the transverse manifold connection conduit port are accessible adjacent to installed fluid handling components. Transverse connection between fluid delivery sticks use a welded assembly of fluid conduits to provide a transverse connecting lower layer which is sealingly retained by fasteners inserted from above through apertures associated with the transverse manifold connection conduit port. Flow substrates for each fluid delivery stick are fastened to a standardized bracket and each fluid delivery stick arrangement can be assembled and tested as an integrated subassembly.

Owner:COMPART SYST PTE LTD

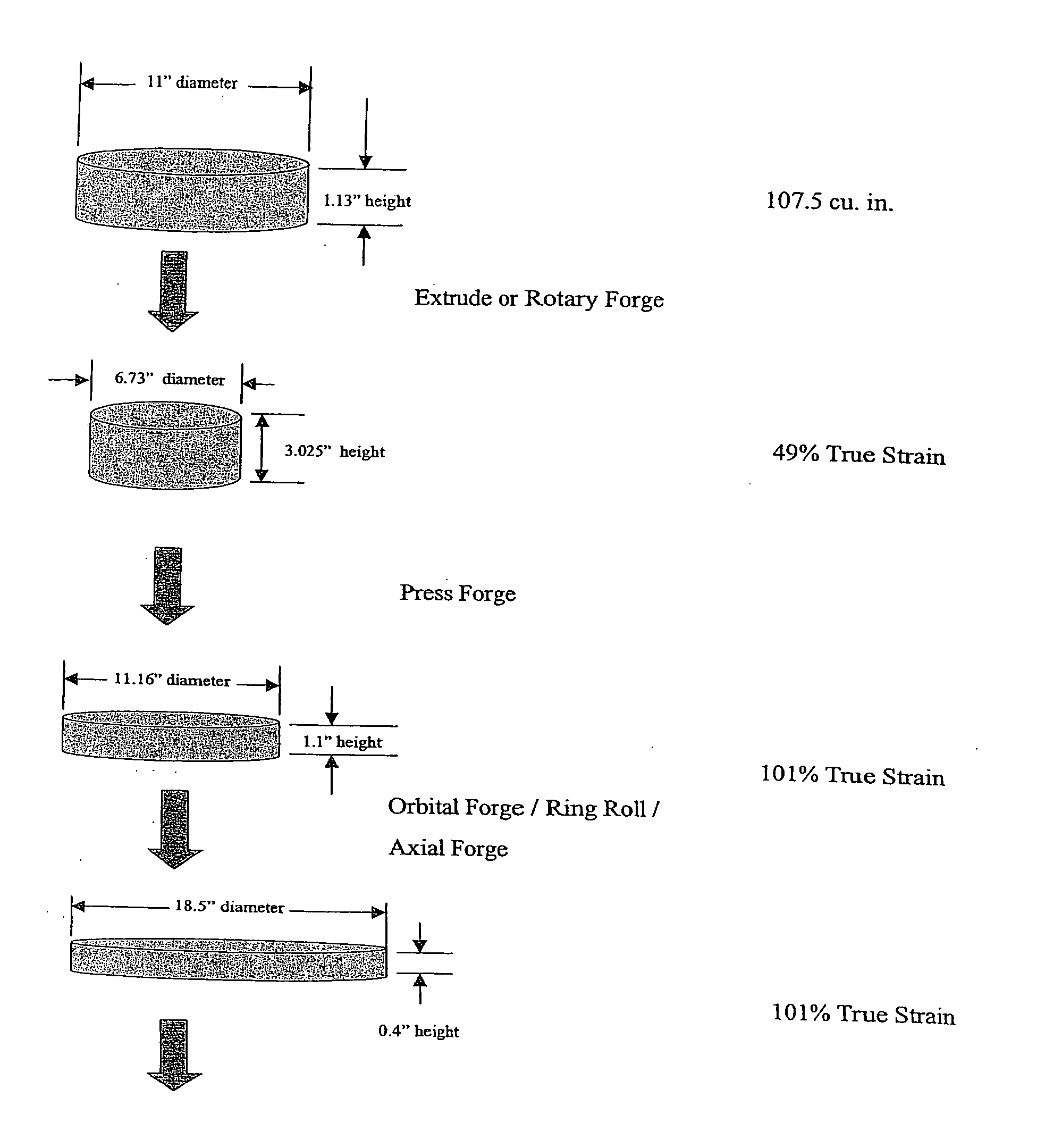

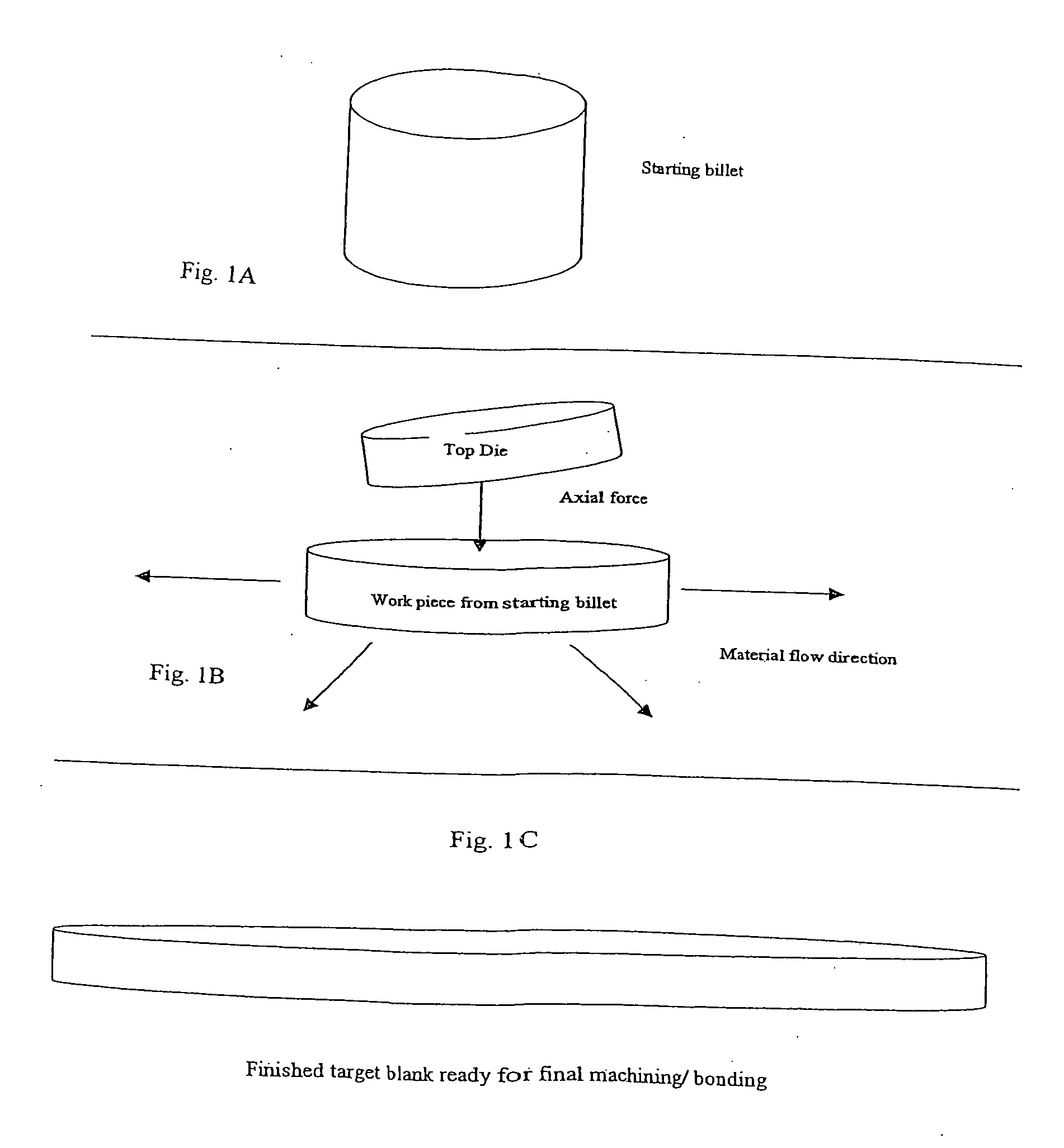

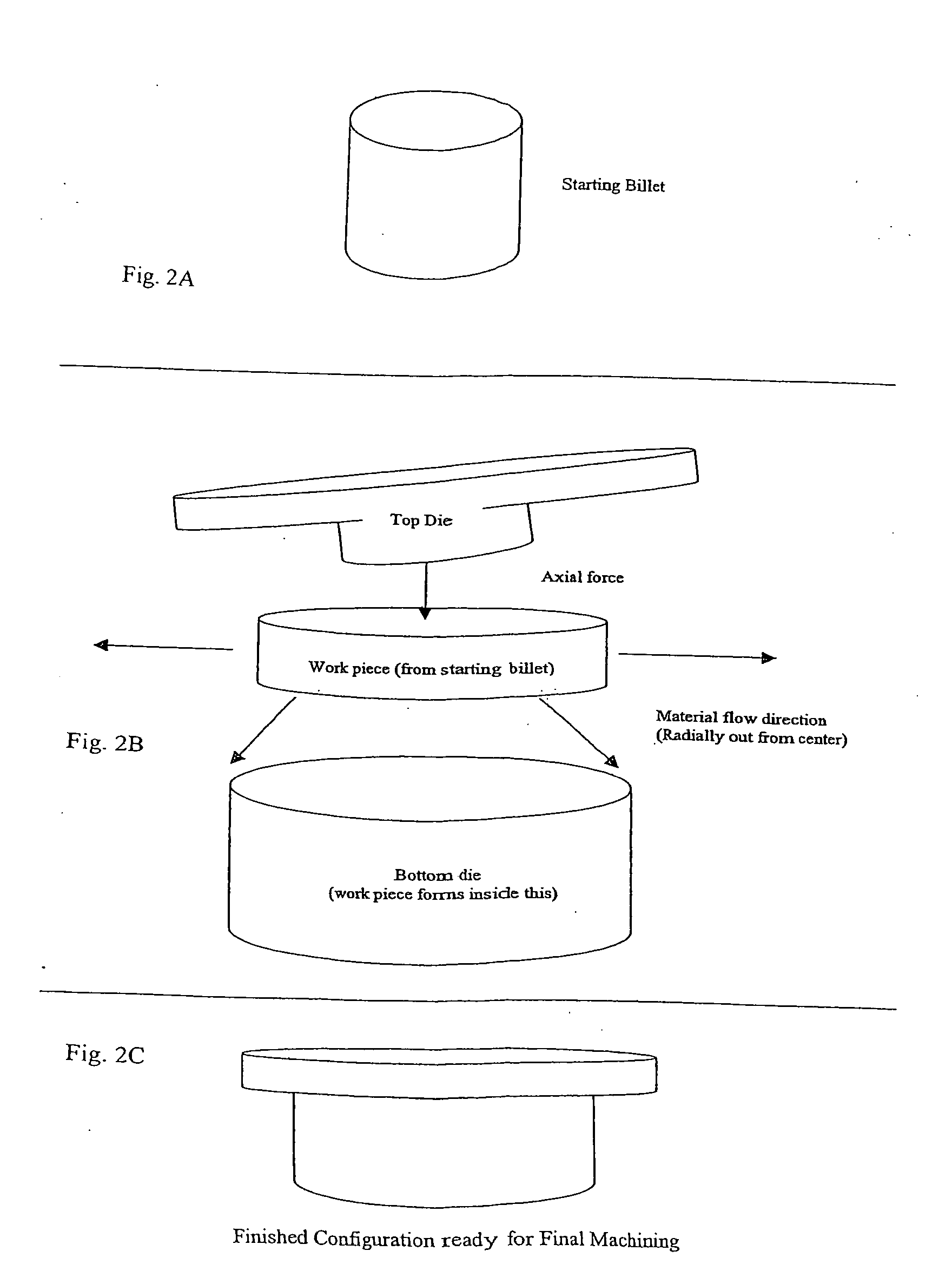

Sputter targets and methods of forming same by rotary axial forging

ActiveUS20050247386A1Low costLess labor intensive operationVacuum evaporation coatingSputtering coatingCrystal structureMachining

Owner:GLOBAL ADVANCED METALS USA

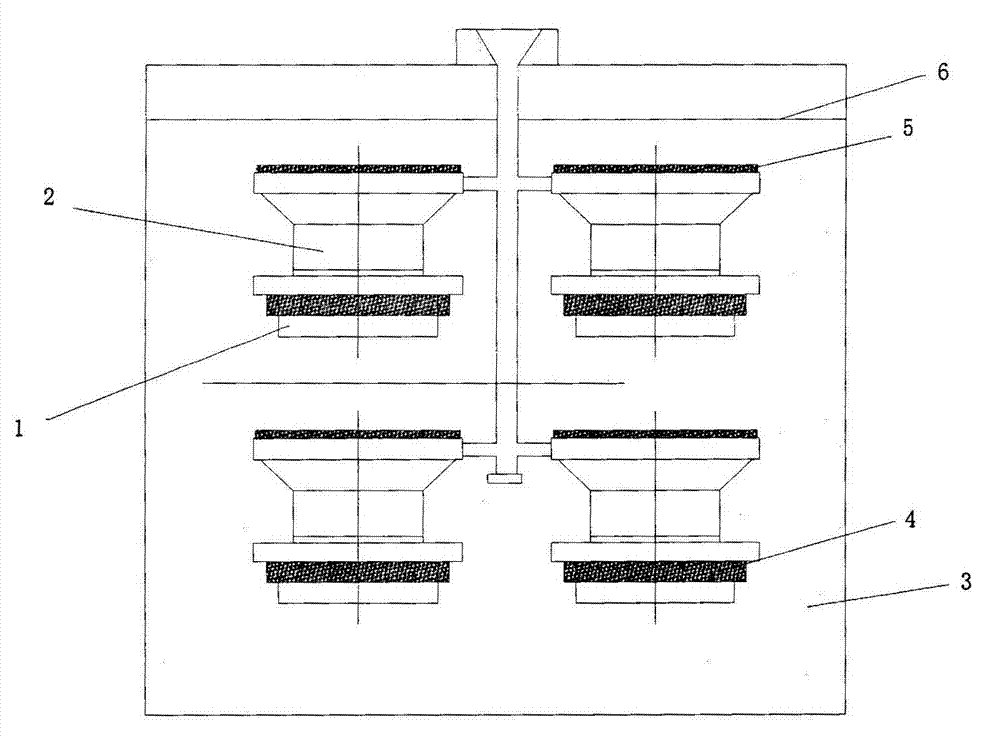

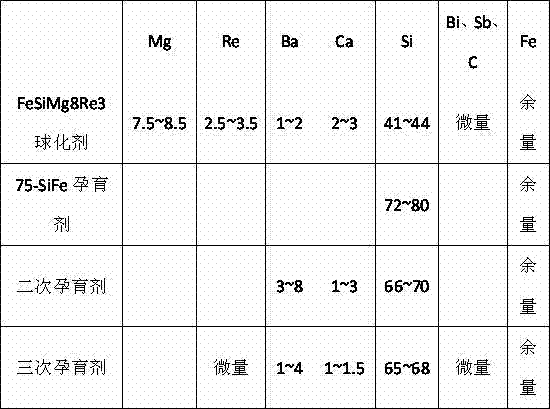

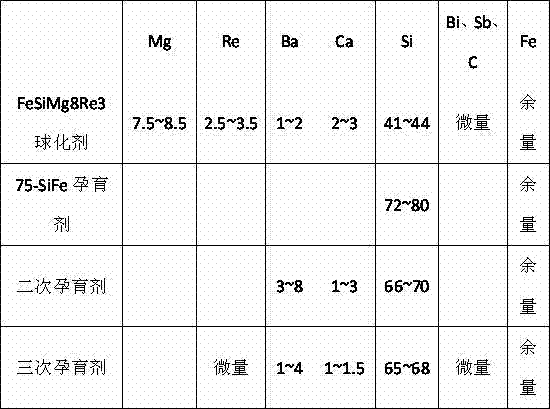

Manufacturing method of spheroidal graphite cast iron casting of wind power yaw variable-pitch device

The invention discloses a manufacturing process of a spheroidal graphite cast iron casting of a wind power yaw variable-pitch device. The process comprises the following processes of mould making, foaming and moulding, paint brushing, boxing and shaping, electric furnace smelting, tundish-covering nodulizing treatment, vacuum-assist pouring and three-time inoculation treatment, wherein the boxing and shaping process is a layered assembling process, so that the production efficiency can be improved and the process yield can be increased; cold iron is vibrated and reasonably arranged, so that the compactness of tissues in the casting can be improved and the defect of shrinkage porosity can be avoided; by virtue of the processes of electric furnace smelting and tundish-covering nodulizing treatment, the nodulizing rate of the casting can be stabilized and increased and the mechanical properties of the casting can meet the technical quality requirements of wind power castings; the spheroidal graphite cast iron casting manufactured by the process is compact and uniform in tissue, hardly has defects, has good surface quality and high size precision; the casting forming of multiple layers of castings can be realized; and the production efficiency and the process product yield are improved.

Owner:CHTC HEAVY IND

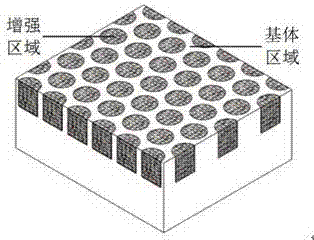

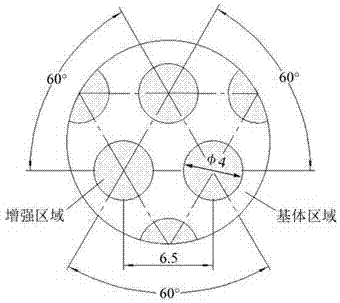

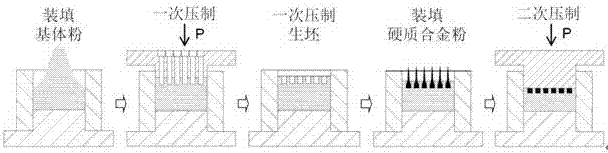

Powder metallurgy preparation method of localization reinforced composite

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

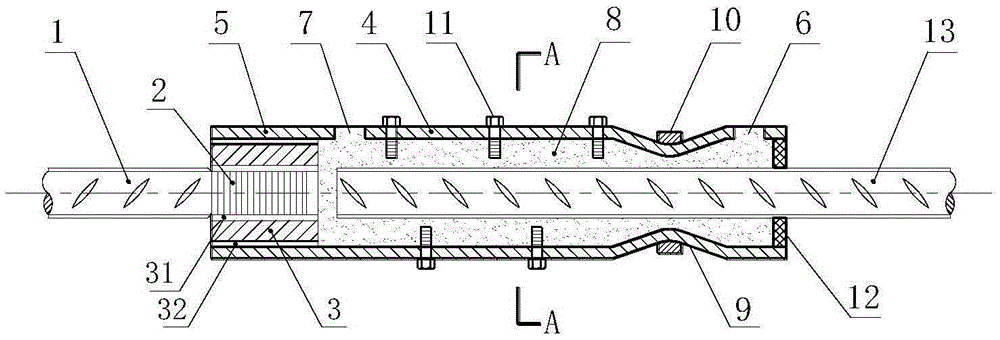

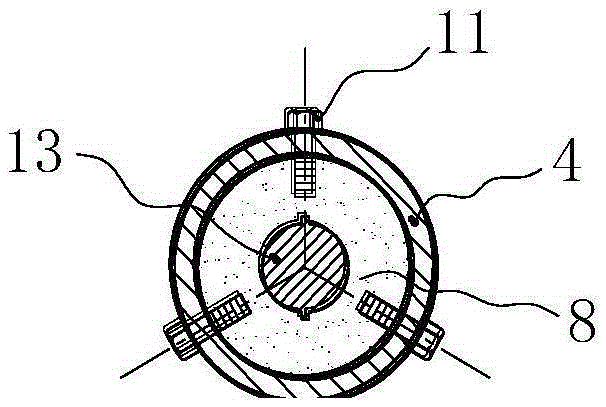

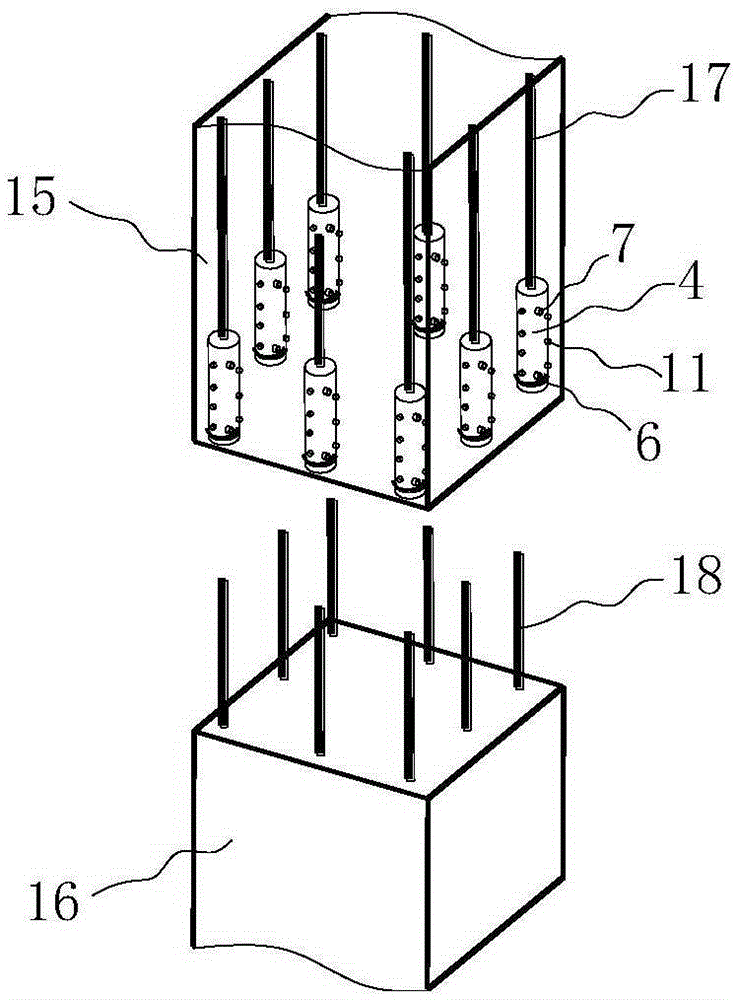

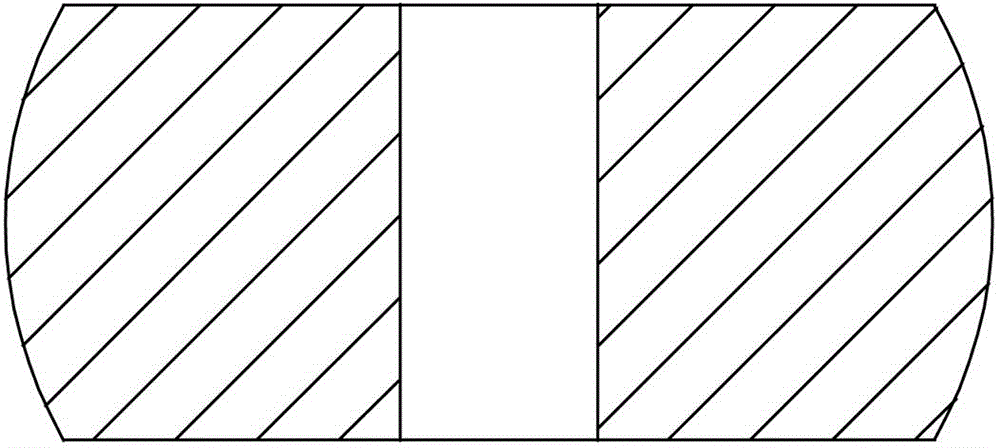

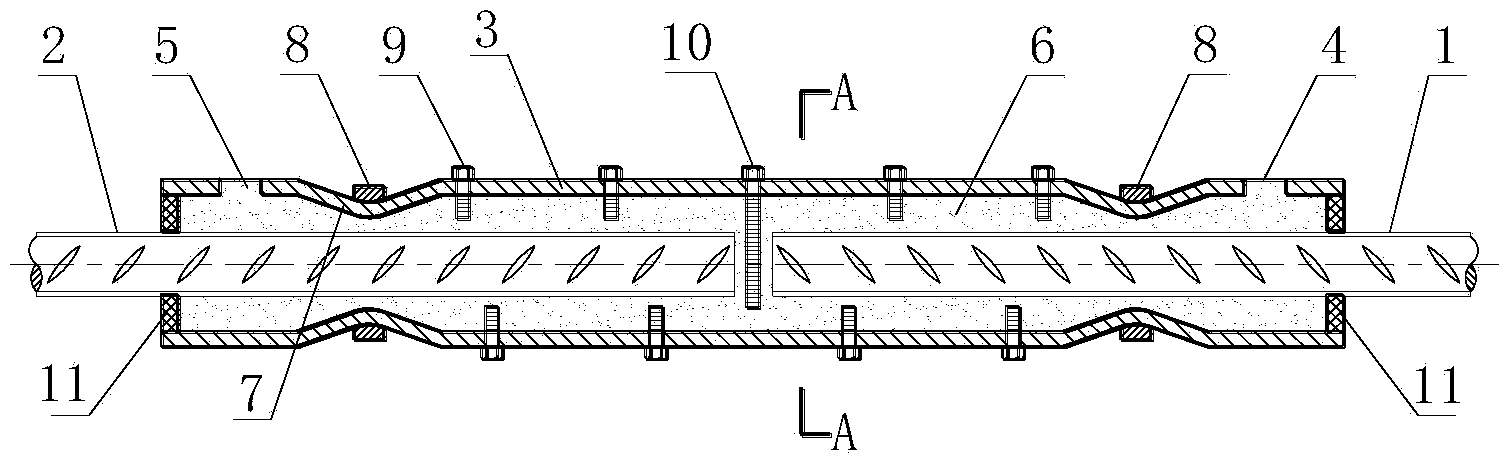

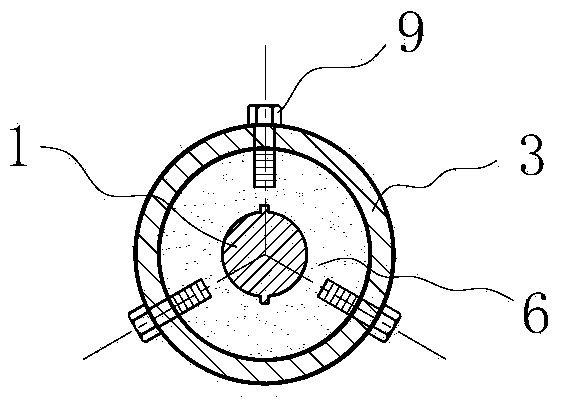

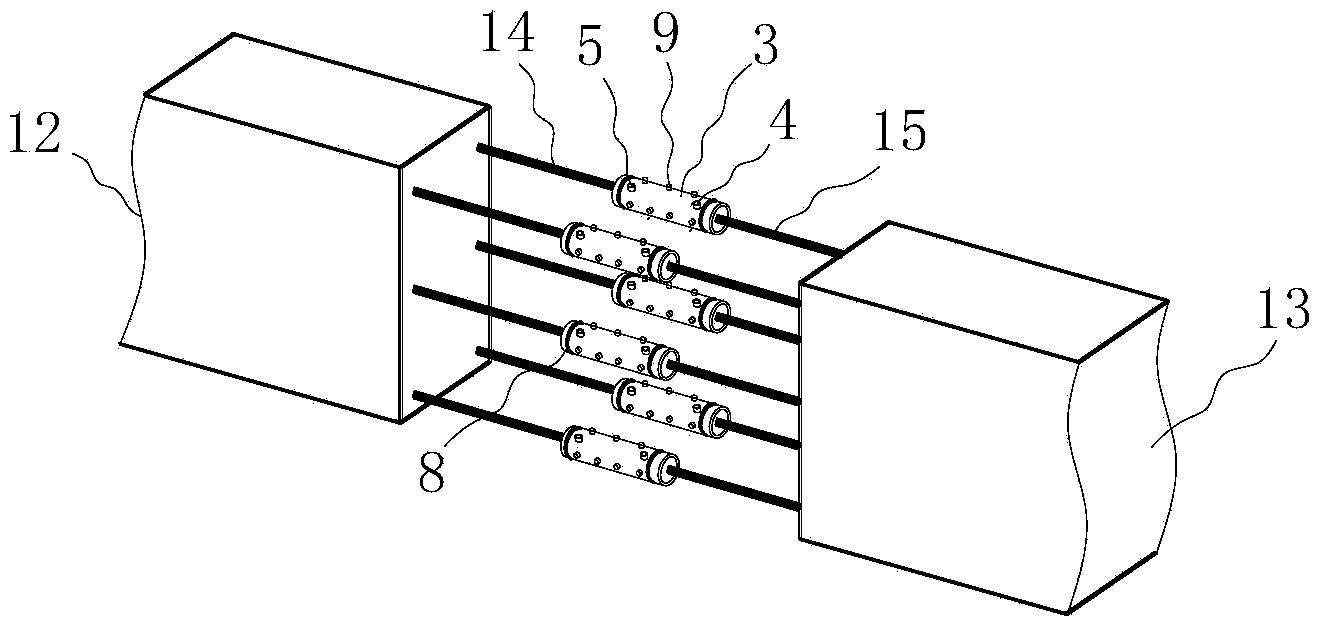

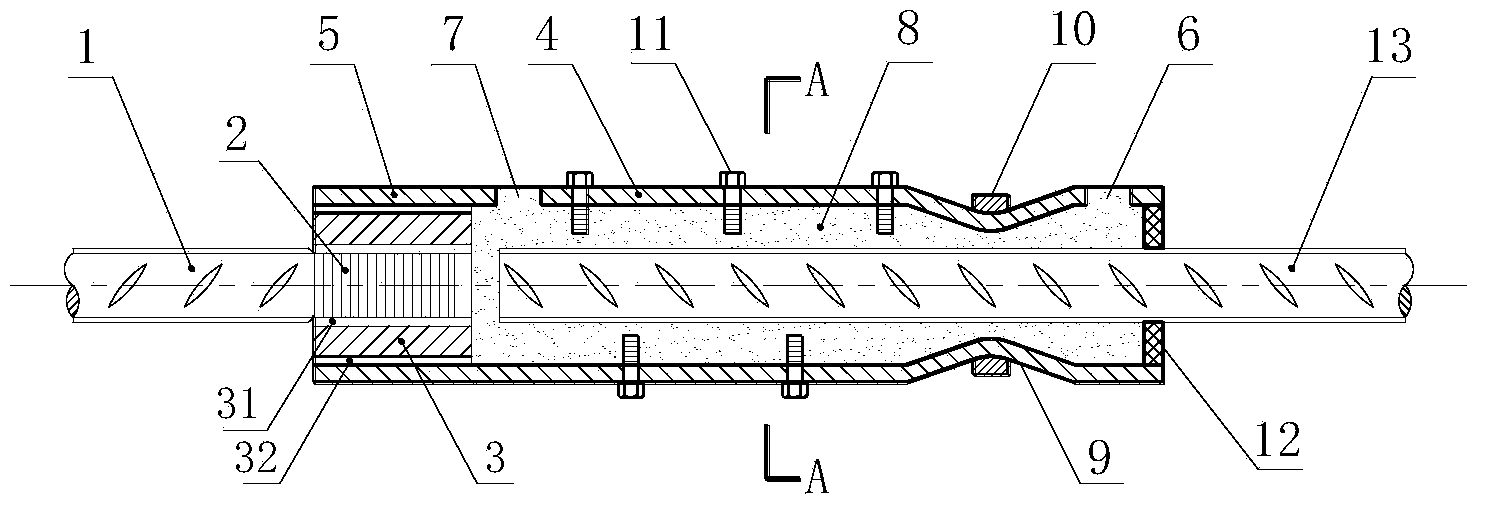

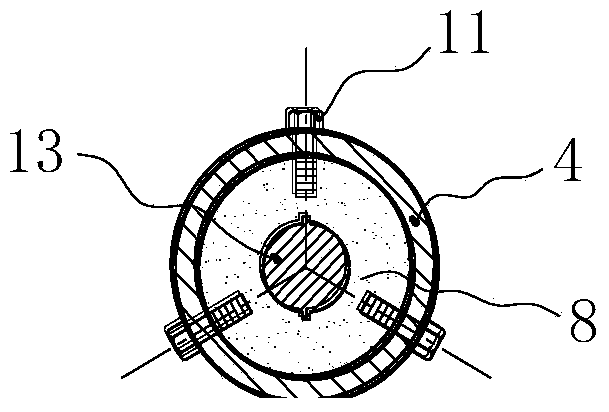

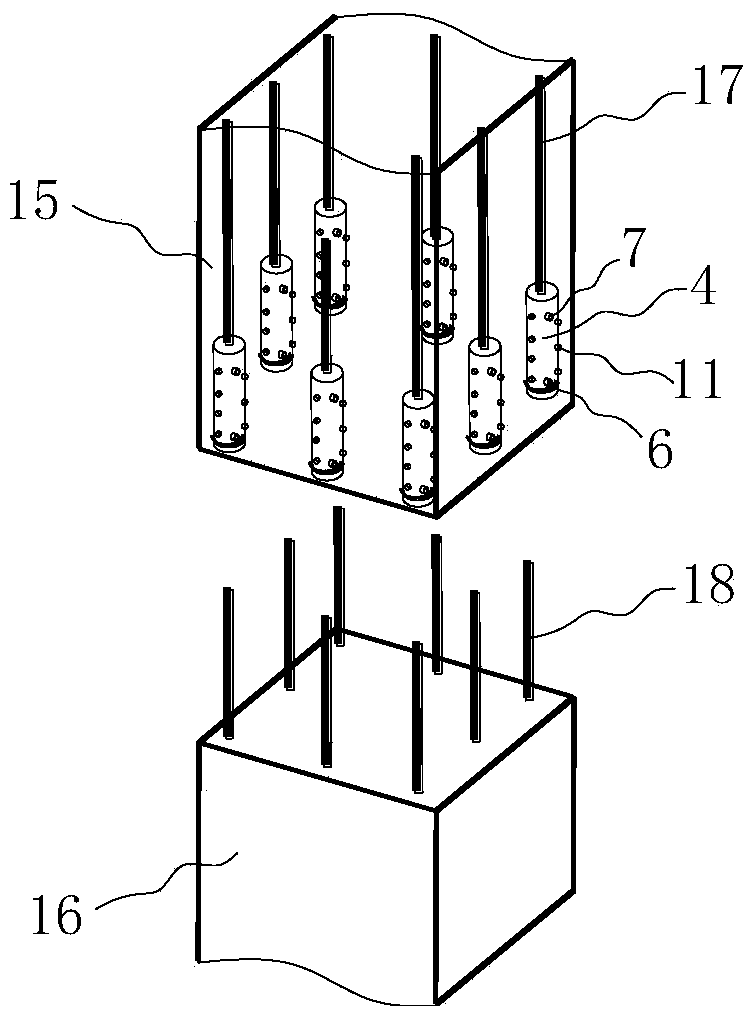

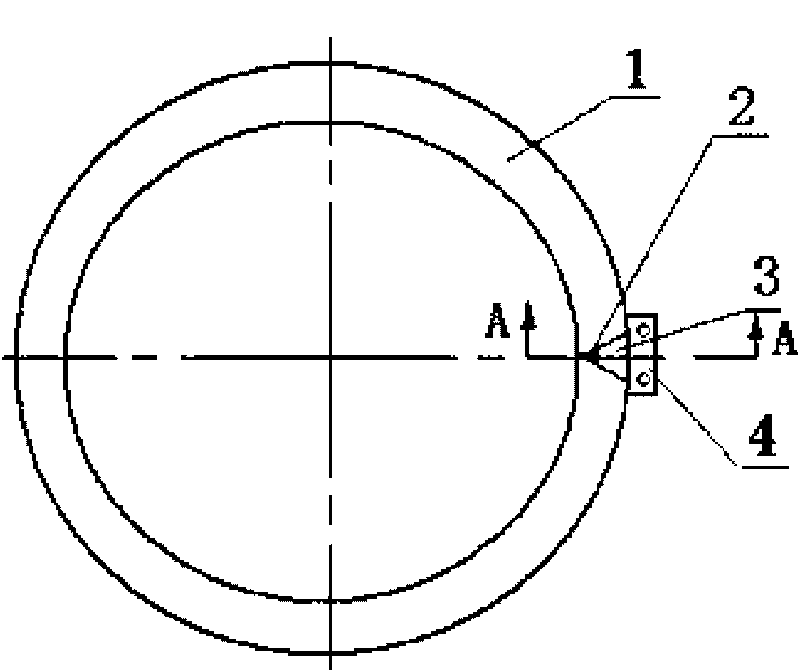

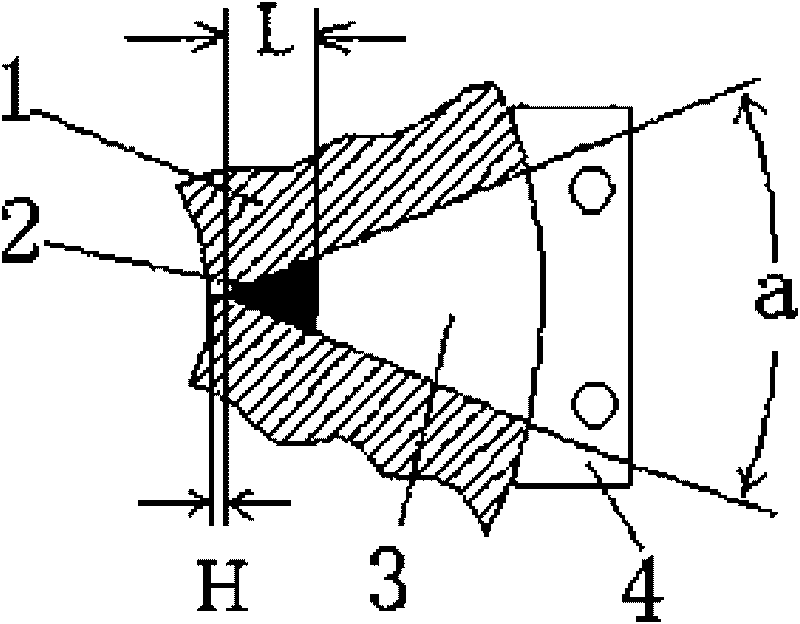

A Shear Enhanced Semi-grouting Sleeve

ActiveCN103758291BReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type semi-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; an elastic rubber sealing ring is arranged at the opening of one end of the sleeve body; a threaded connecting piece is arranged at the opening of the other end of the sleeve body; a grouting hole and a discharge hole are formed in side walls close to the end parts of the sleeve body; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type semi-grouting sleeve has the advantages of wide material resource, simplicity in machining and manufacturing, reliability in property and the like, can greatly overcome the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

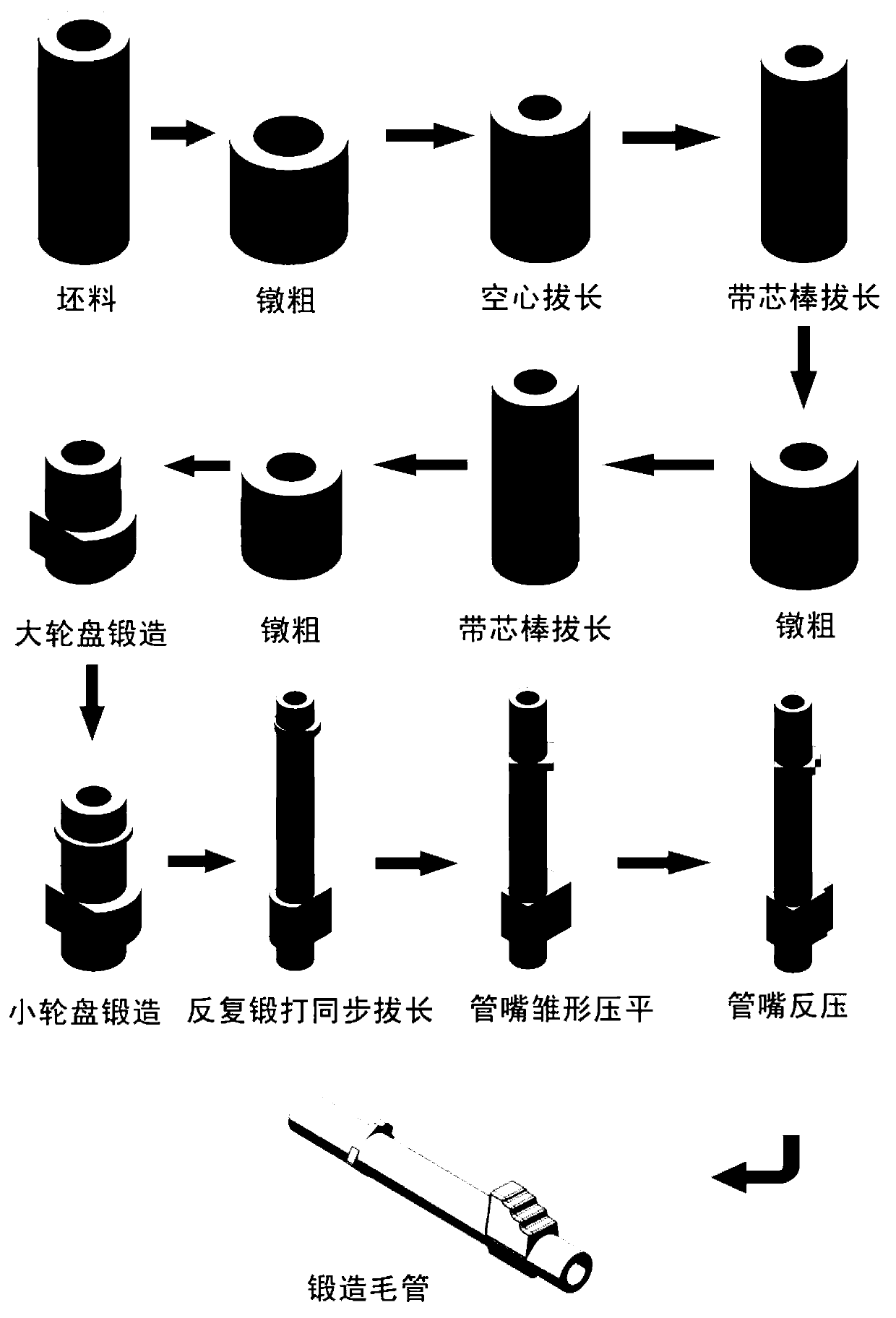

Hollow forging method of nuclear power main pipeline

ActiveCN103143659AMeet technical requirementsIncrease profitMetal-working apparatusPunchingNuclear power

The invention relates to a hollow forging method of a nuclear power main pipeline, and belongs to the technical field of forging. According to the forging method, hollow forging is carried out in a free forging manner, a boss part is formed in an annular belt manner, and the deformation is reserved before a core rod is drawn out to be in a final shape. The forging method comprises the following processing steps of: (1) upsetting; (2) drawing out; (3) upsetting and punching; (4) chambering and drawing out the core rod; (5) carrying out shoulder feeding; (6) carrying out shoulder splitting; (6) drawing out the core rod: heating a hollow forged piece obtained in the step (5) till 1000-1050 DEG C, and drawing out till a final shape is formed; heating multiple times till 1000-1050 DEG C if the shape cannot be formed after one heating number, and drawing out till the final shape is formed. The nuclear power main pipeline with the boss is forged in the manners of punching, chambering and drawing out the core rod, the boss part is forged into an annular manner, and the shape of the nozzle of the boss is ensured. The forged piece is directly forged into a hollow pipeline, so that the subsequent machining is reduced, and the manufacturing period is shortened. The technical requirement of the third generation forging main pipeline can be met, and the utilization ratio of raw material is high.

Owner:TONGYU HEAVY IND

Shearing reinforcing type full-grouting sleeve

ActiveCN103758292AReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type full-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; elastic rubber sealing rings are arranged at the openings of two ends of the sleeve body; a grouting hole is formed in the side wall close to the opening of one end; a discharge hole is formed in the side wall close to the opening of the other end; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type full-grouting sleeve is wide in material resource, simple to machine and manufacture and reliable in property, greatly overcomes the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

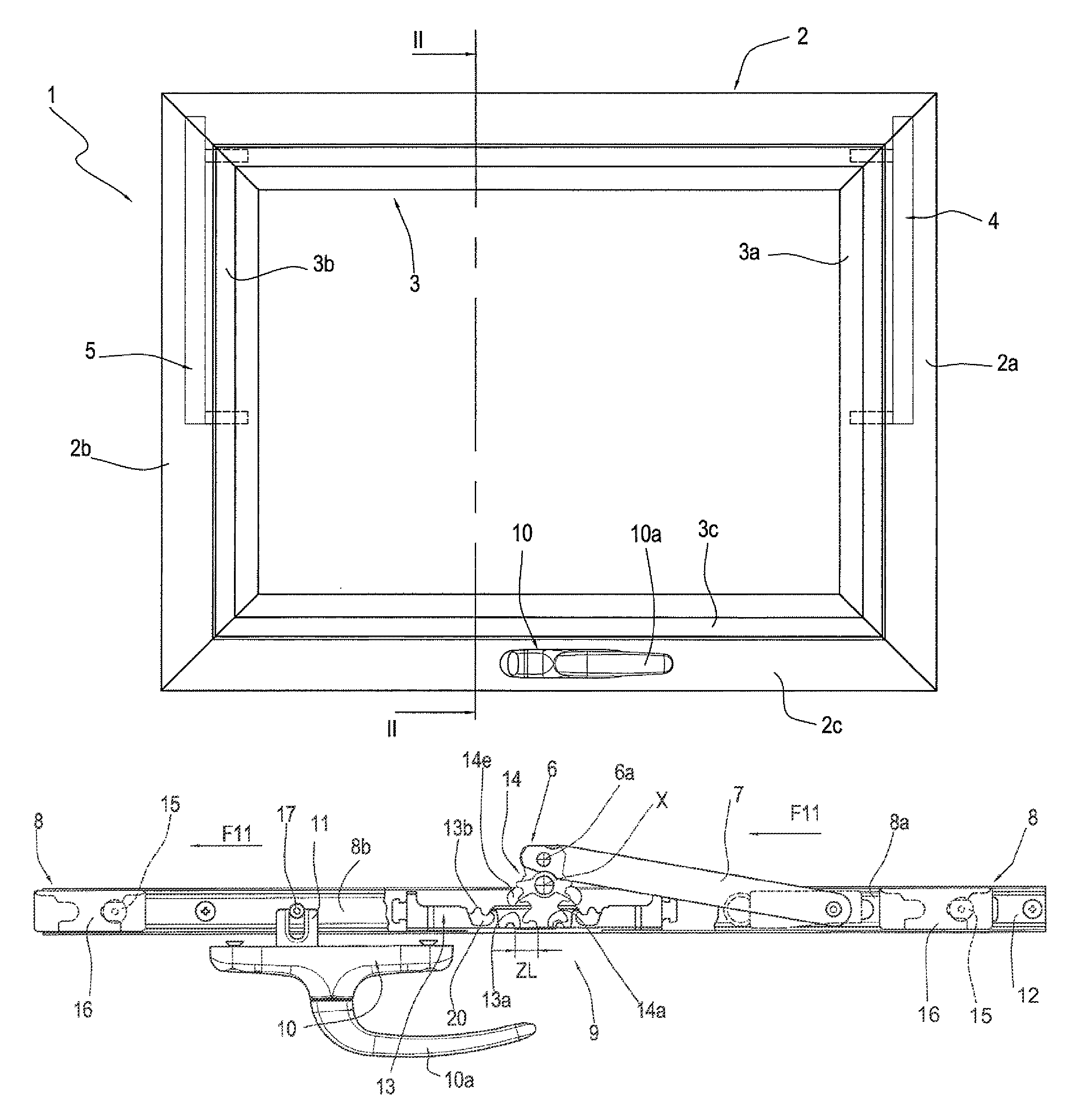

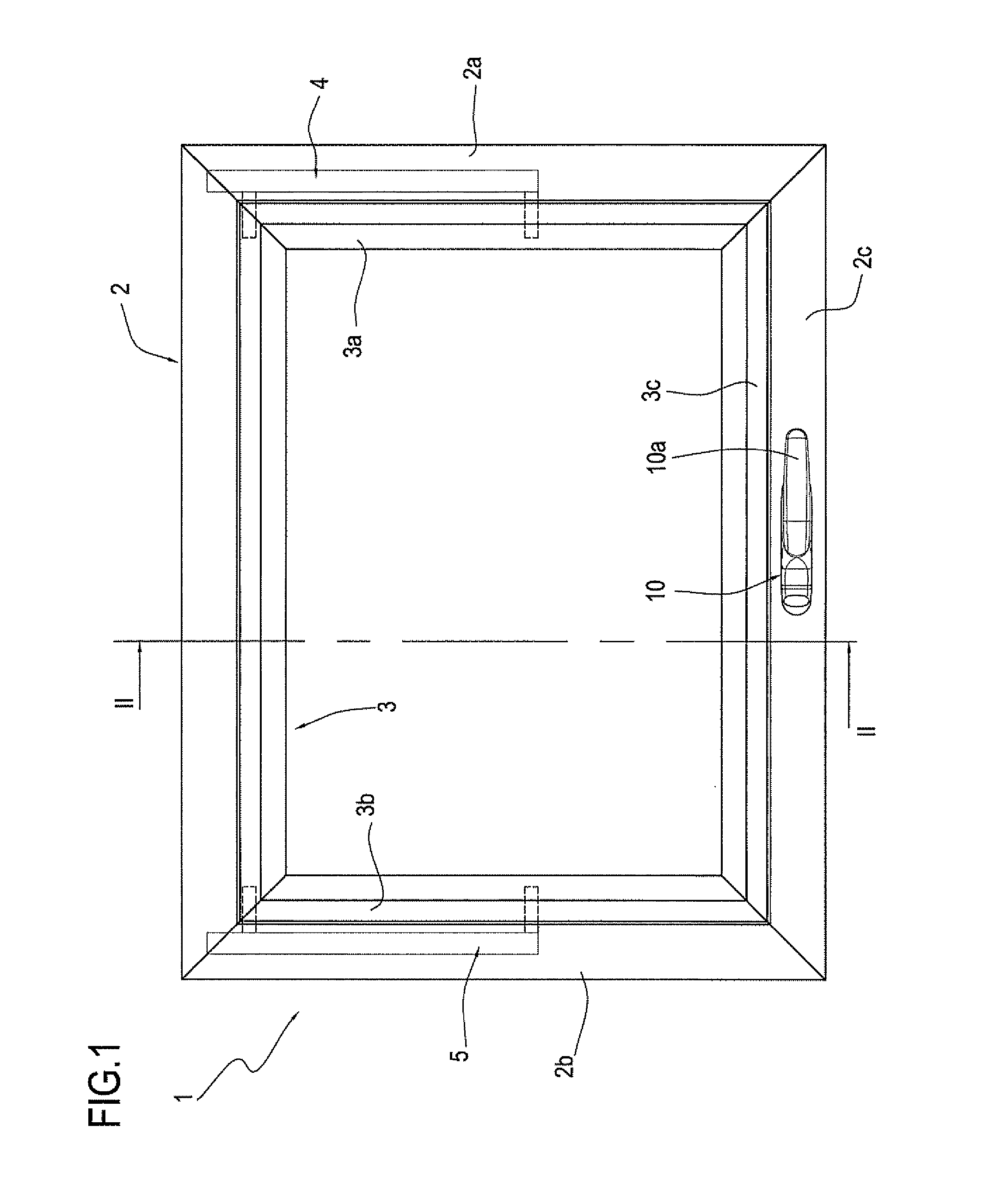

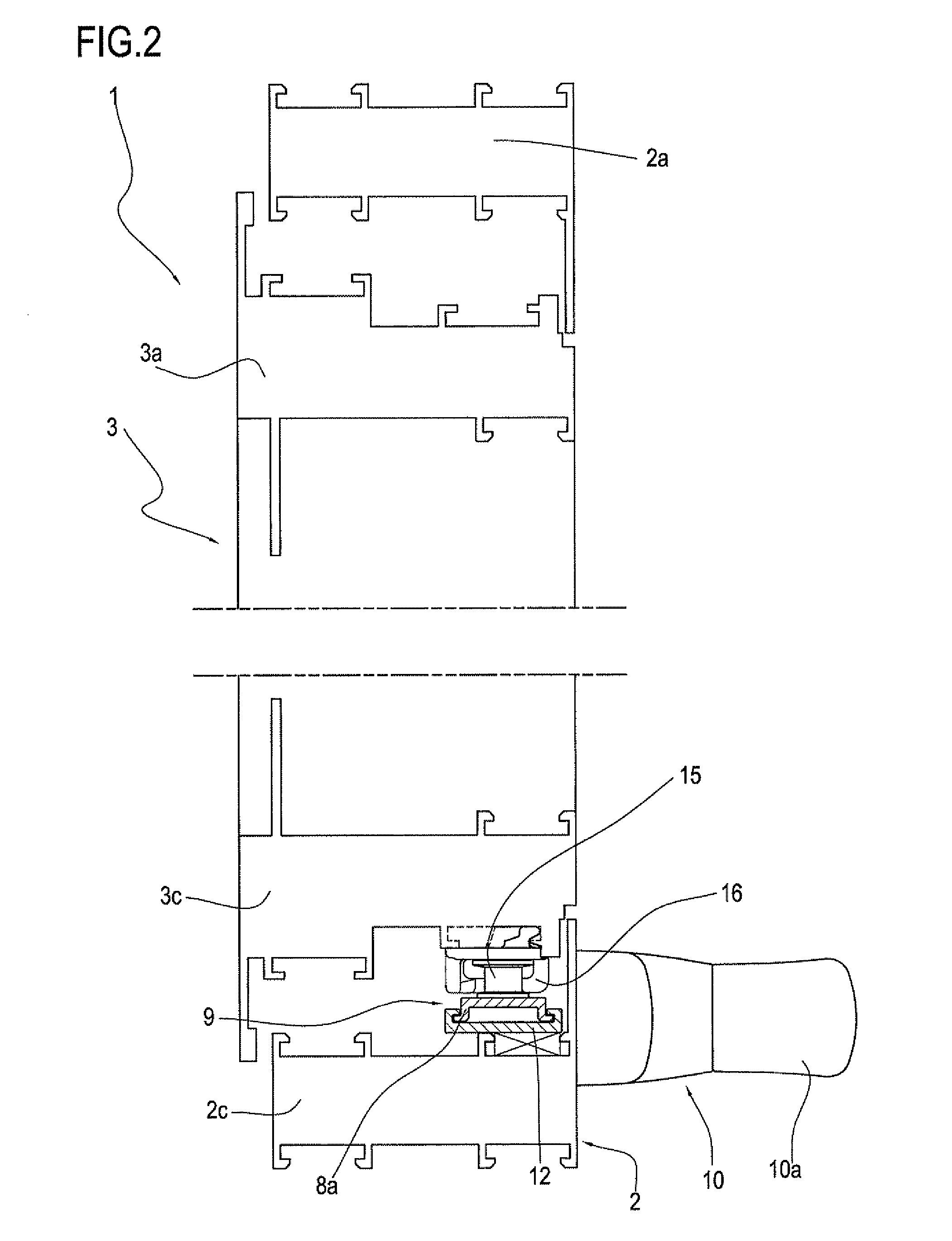

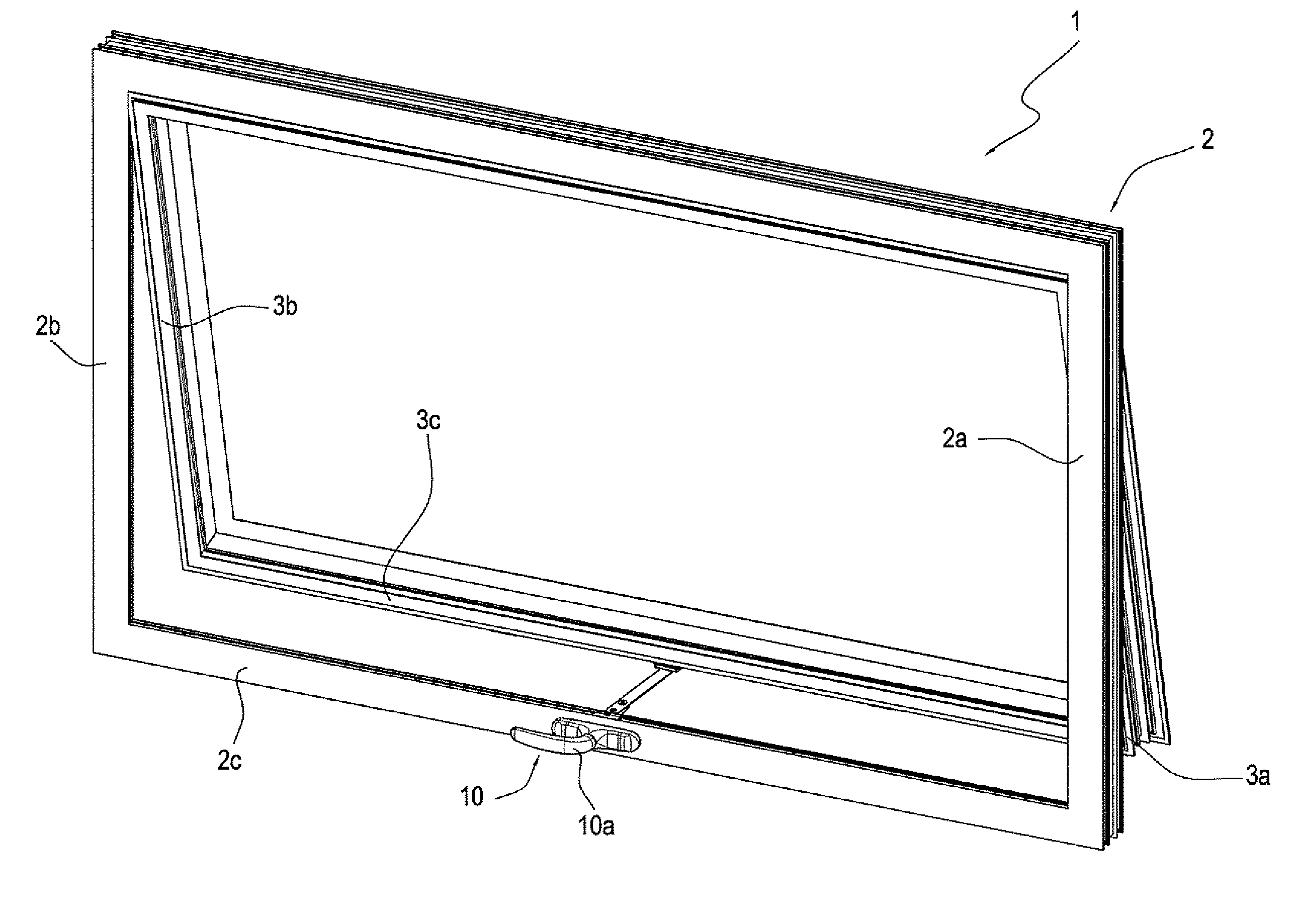

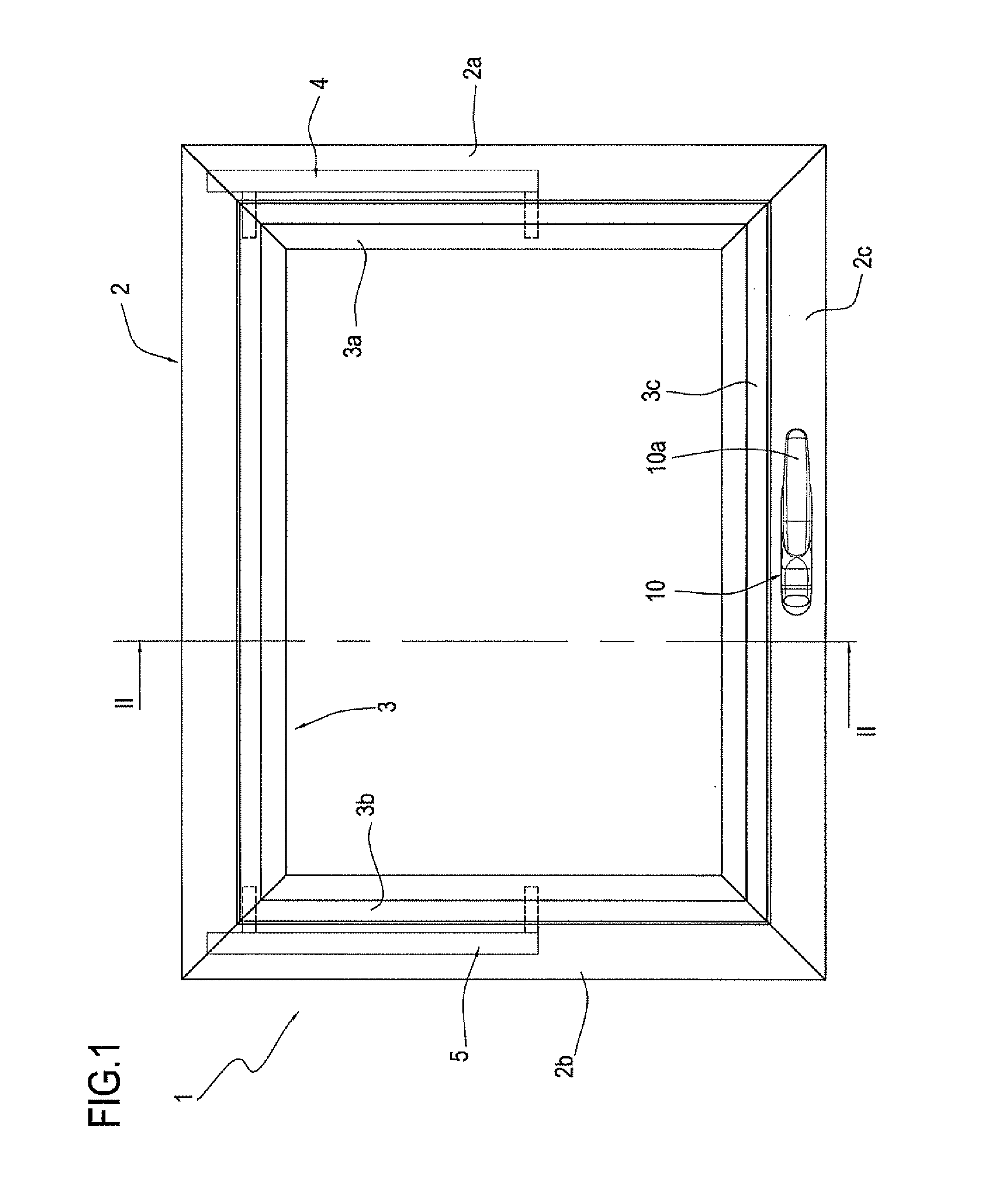

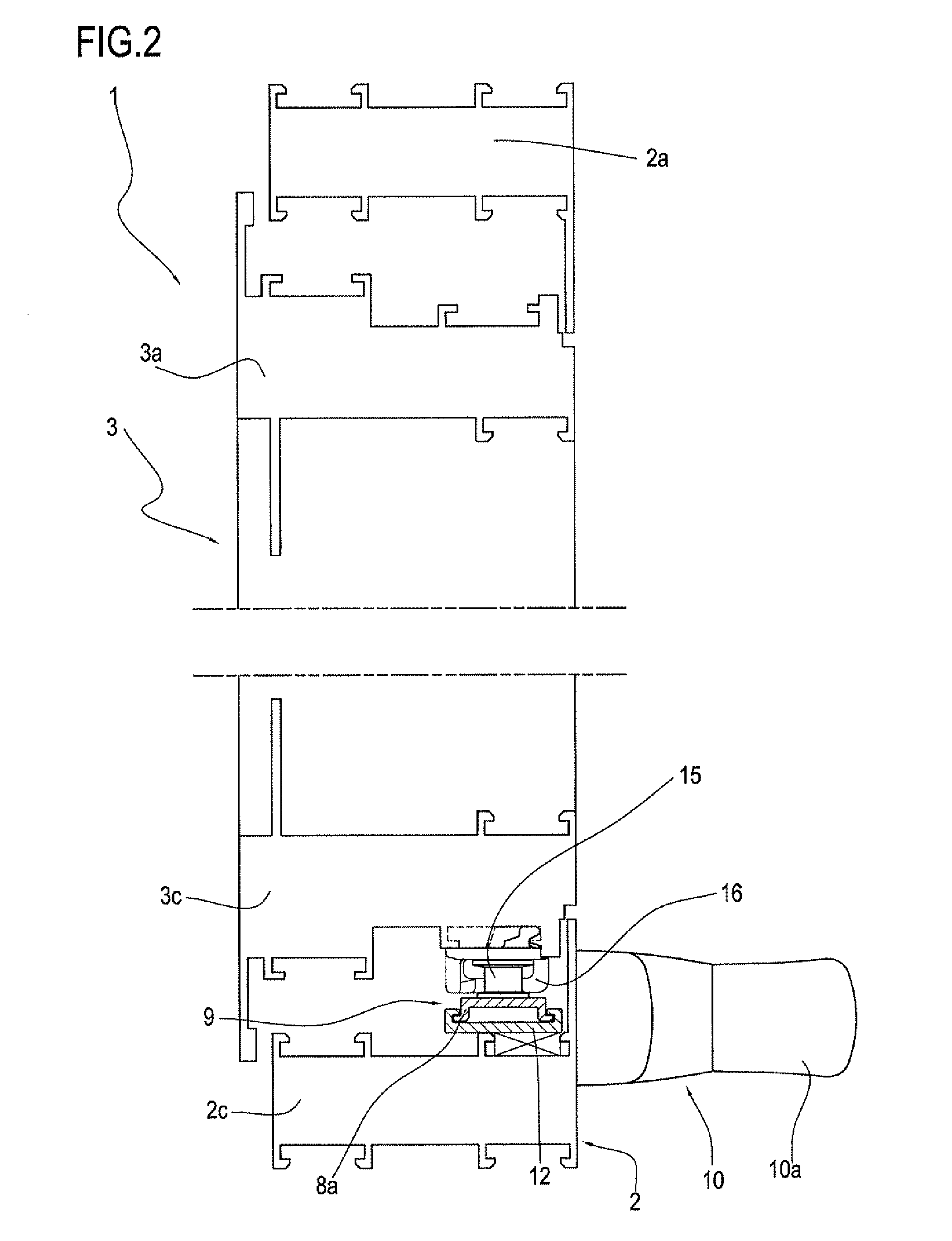

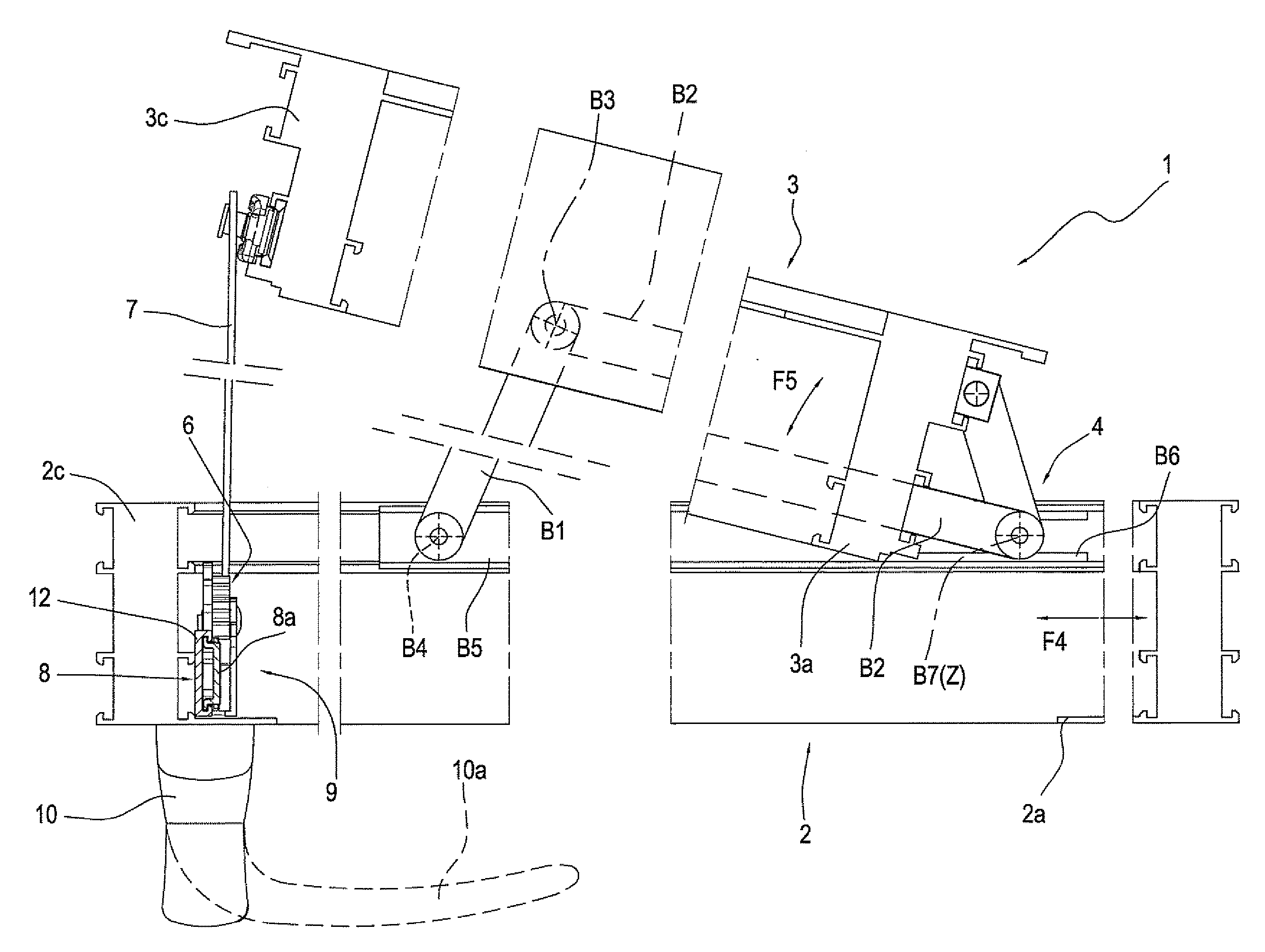

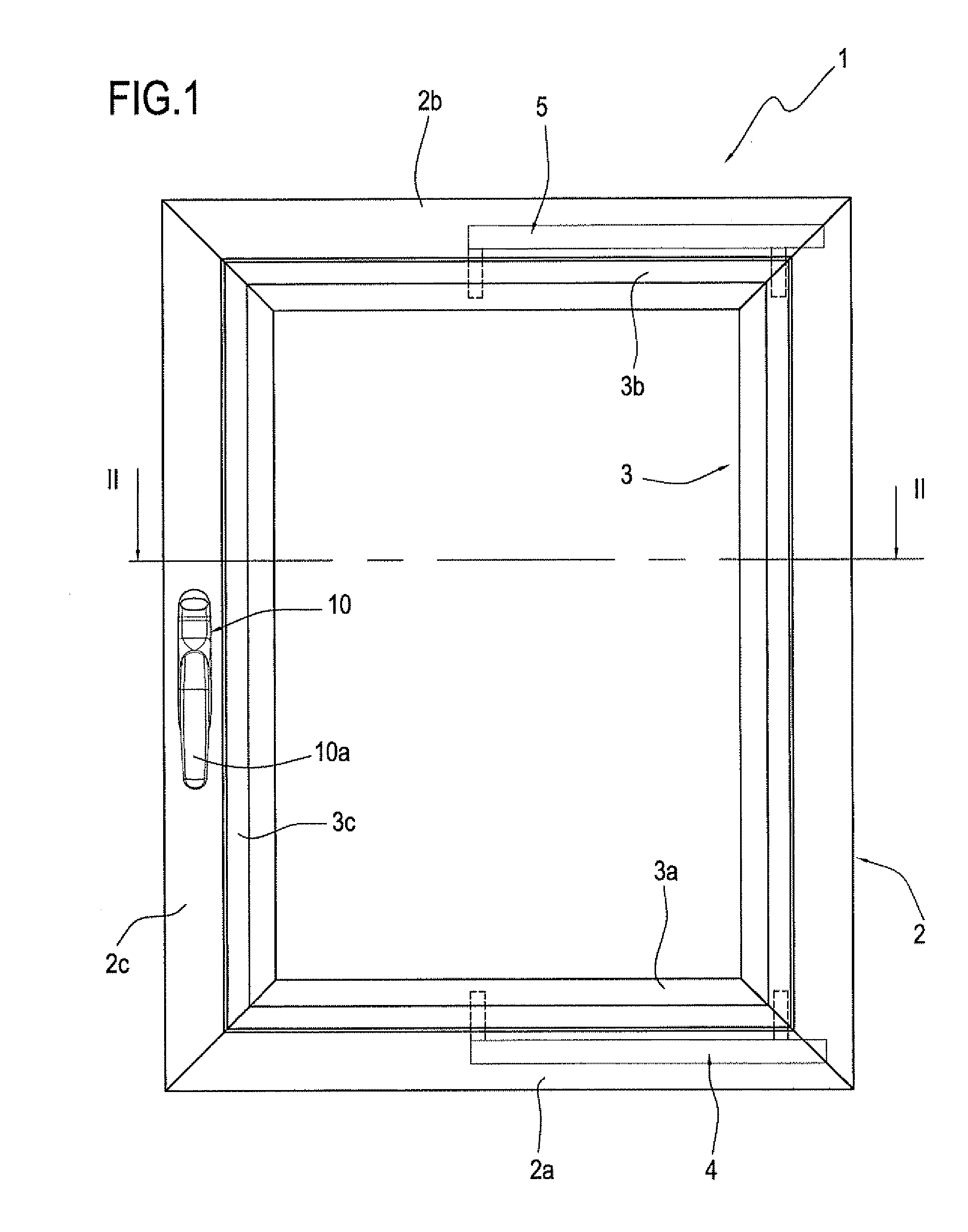

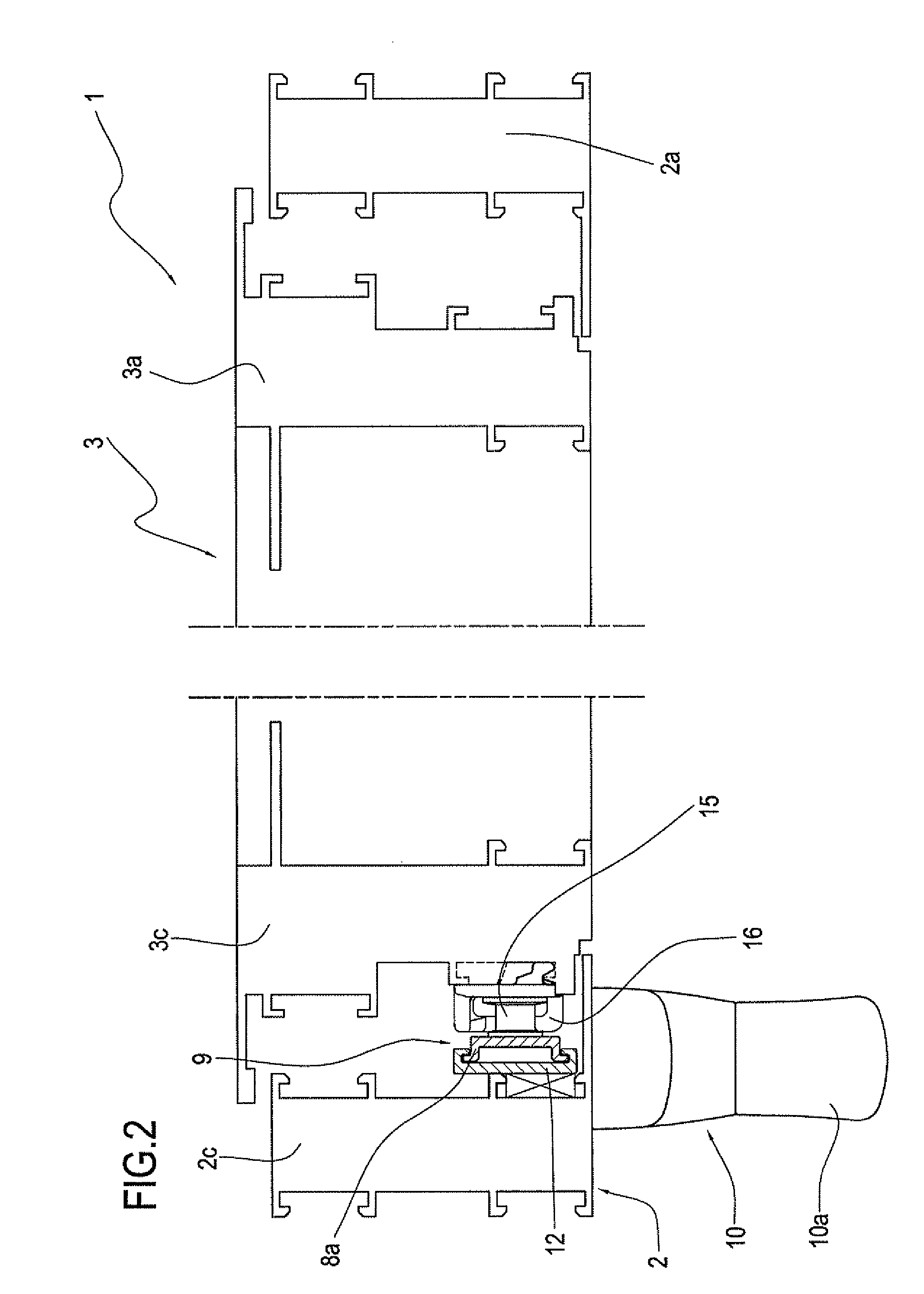

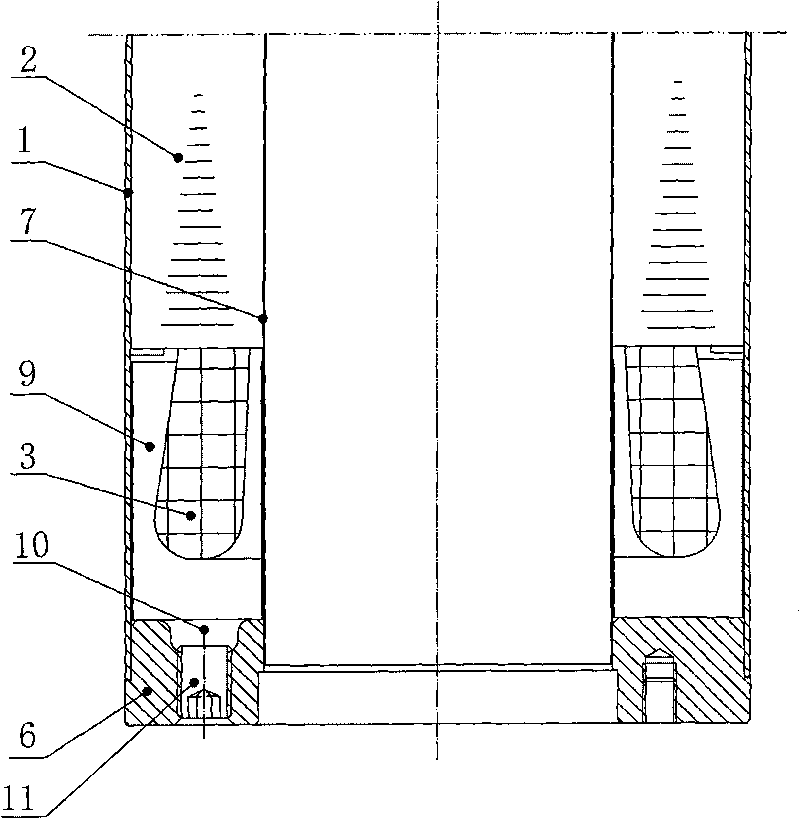

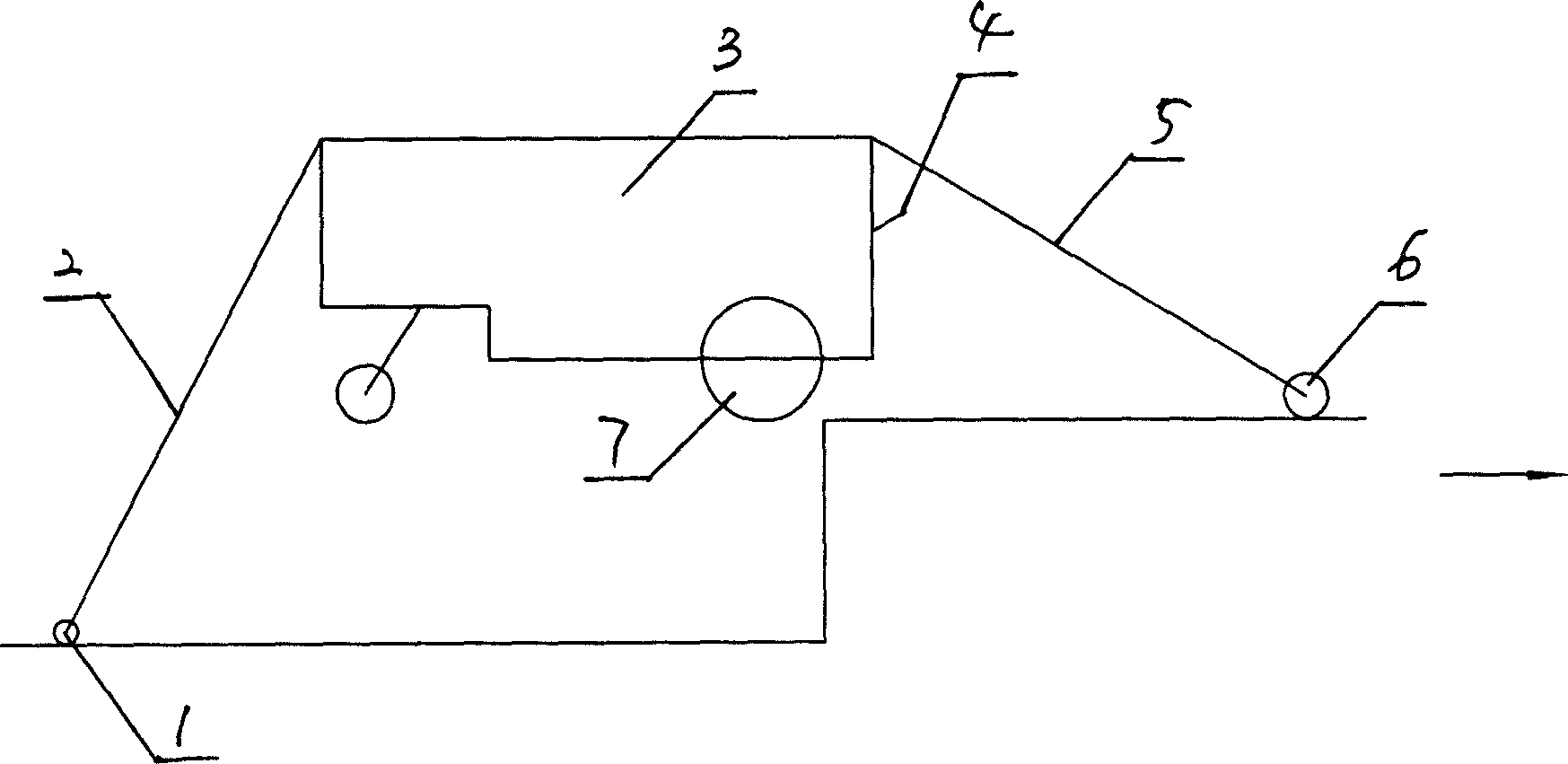

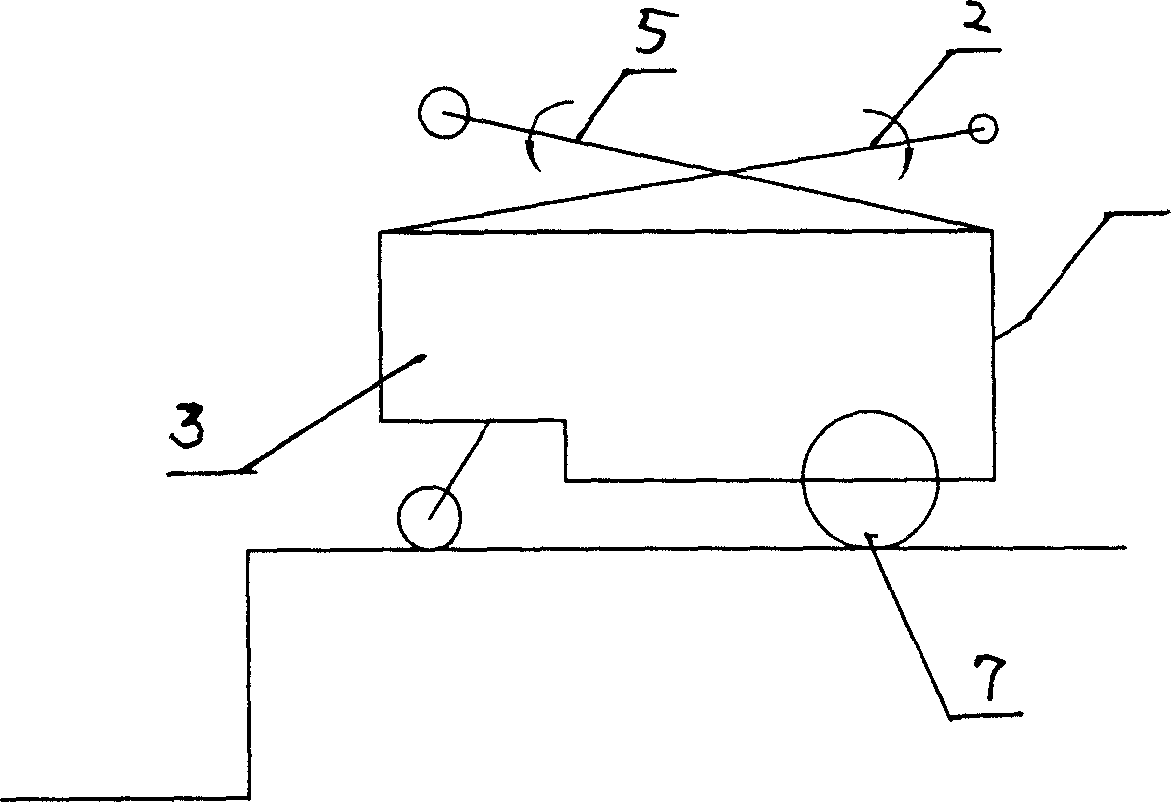

Awning window unit with an operating and closing slide unit for the movable frame of the window unit

An awning window unit which includes a fixed frame (2); a movable frame (3) connected to the fixed frame by a pair of hinged members (4, 5) joined to respective members of the fixed frame and of the movable frame so as to allow the movable frame to move between a closed position, where the fixed and movable frames are in contact with each other, and an open position, where at least one lower rail (3c) of the movable frame is at a certain distance from the fixed frame towards the outside of the room where the window unit (1) is installed, and vice versa; and a movement arm (7) configured to move the movable frame from the closed position to the open position, and vice versa.

Owner:GSG INT

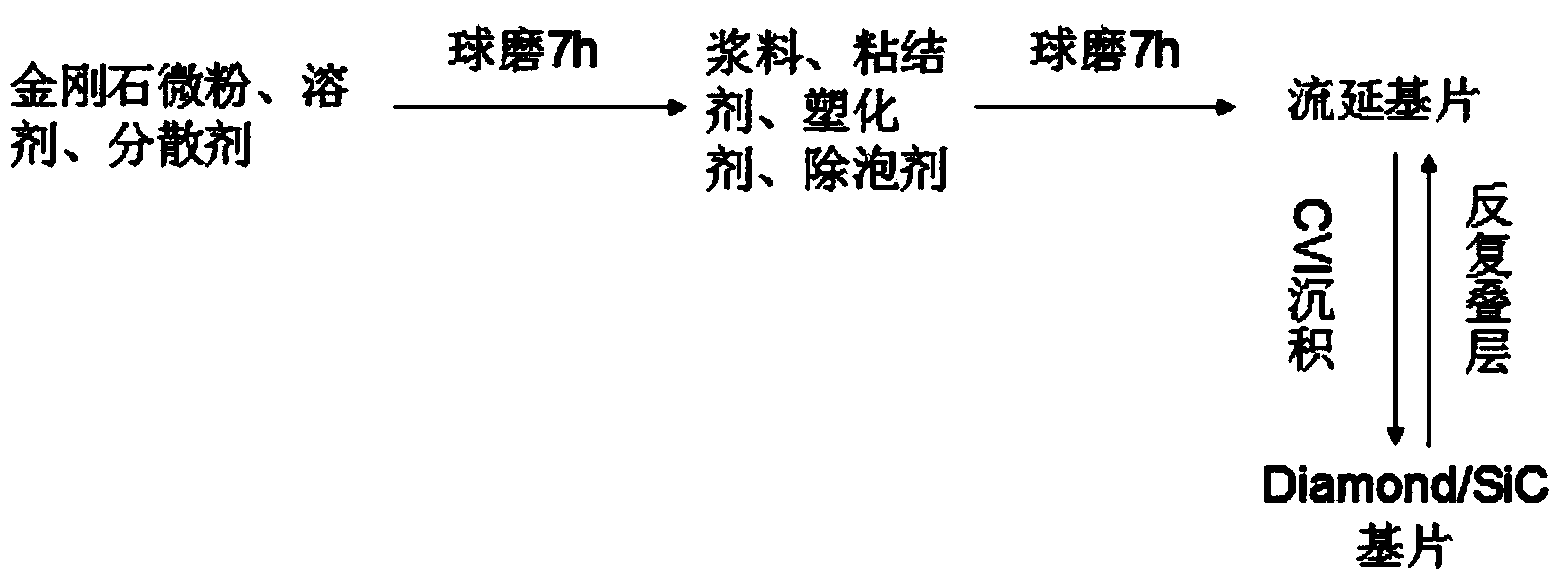

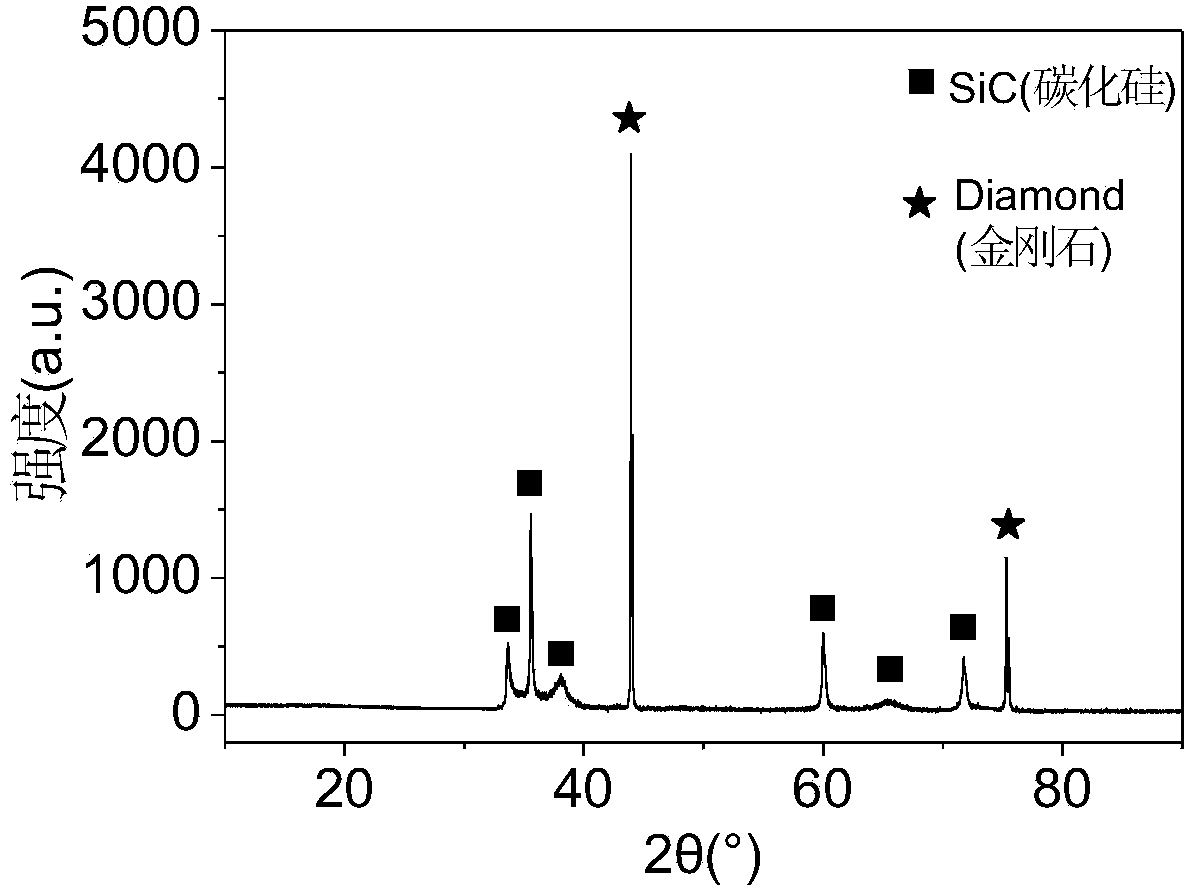

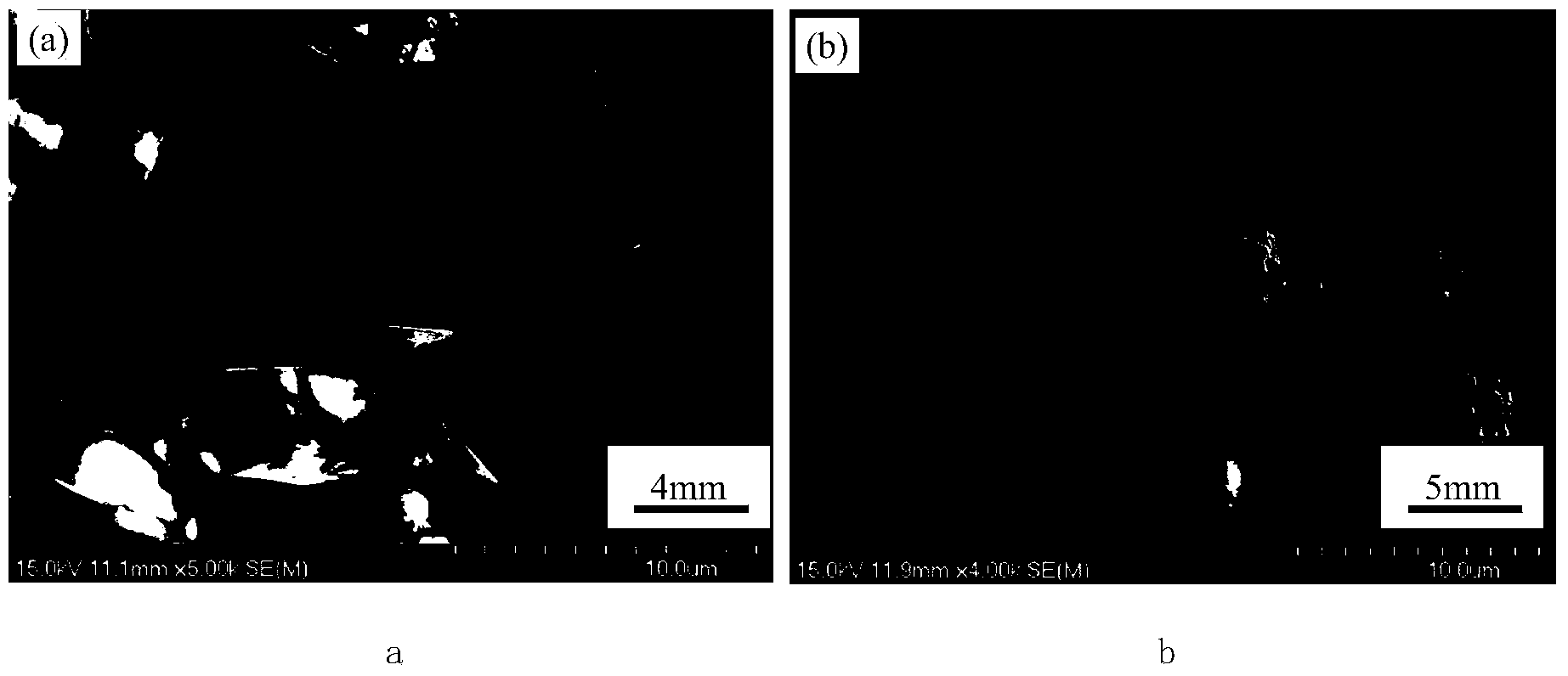

Preparation method of diamond doped silicon carbide (SiC) ceramics with high heat conductivity

The invention relates to a preparation method of diamond doped silicon carbide (SiC) ceramics with high heat conductivity. A silicon carbide base body is deposited in a porous diamond perform by a tape casting process combined with a chemical vapor deposition method; the method comprises the steps of preparing diamond slurry with different particle sizes (7-50mum) and then carrying out a casting experiment, drying a substrate formed by the cast diamond particles and polyvinyl butyral at room temperature and setting aside, placing into a CVI (Chemical Vapor Infiltration) deposition furnace for deposition of the silicon carbide base body to obtain a diamond / silicon carbide substrate, carrying out repeated casting and deposition on the surface of the diamond / silicon carbide substrate, and finally, obtaining the diamond / silicon carbide composite material sample. The prepared diamond / silicon carbide composite material has diamond and silicon carbide phases without other impurities, and the diamond is distributed uniformly in the composite material and can be well combined with the silicon carbide base body.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

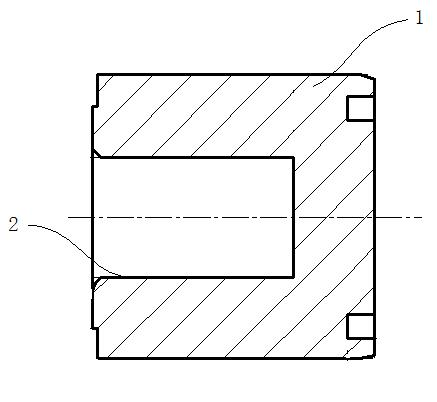

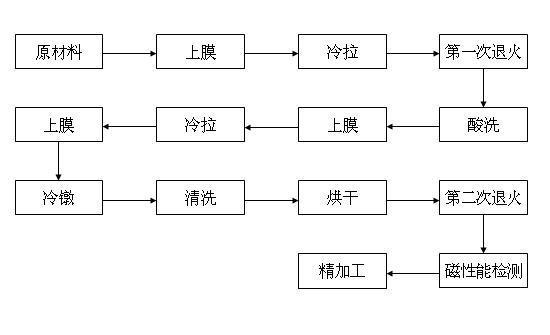

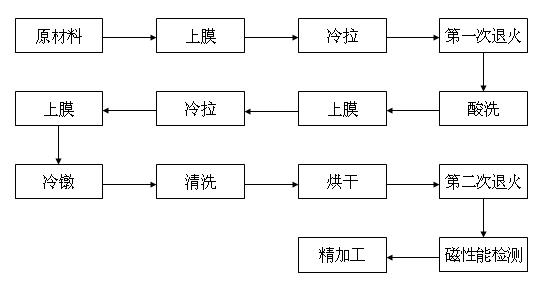

Processing technology of static iron core of electromagnetic valve

The invention relates to a processing technology of a static iron core of an electromagnetic valve, which has the advantages of reducing the material spillage and improving the magnetic performance of the static ion core. The technology comprises the following steps of: performing cold drawing, primary annealing treatment, secondary cold drawing on linear ferrite serving as raw material, and carrying out cold heading on the material to form a part blank; performing secondary annealing treatment on the part blank, detecting the magnetic performance of the part and performing surface finishing treatment if the part is qualified. According to the processing technology, cutting processing is replaced with cold drawing and cold heading, annealing treatment is performed after the part is formed, the magnetic perforamnce of the final part is enhanced, and the material utilization rate in the static iron core processing process is improved.

Owner:SHAOXING KANGJIAN PRECISION STAINLESS STEEL

Awning window unit

An awning window unit which includes a fixed frame (2); a movable frame (3) connected to the fixed frame by a pair of hinged members (4, 5) joined to respective members of the fixed frame and of the movable frame so as to allow the movable frame to move between a closed position, where the fixed and movable frames are in contact with each other, and an open position, where at least one lower rail (3c) of the movable frame is at a certain distance from the fixed frame towards the outside of the room where the window unit (1) is installed, and vice versa; and a movement arm (7) configured to move the movable frame from the closed position to the open position, and vice versa.

Owner:GSG INT

Process for manufacturing high-strength large-scale aluminum alloy plate

InactiveCN101712116AHigh energy consumptionImprove pollutionMetal rolling arrangementsHigh energyHigh intensity

The invention discloses a process for manufacturing a high-strength aluminum alloy plate, which comprises eleven steps of batching, smelting, checking, standing, casting, sawing and face milling, heat treatment, hot rolling, quenching, ageing and finished product shearing in turn. The manufacturing process radically changes the common phenomena of high energy consumption and high pollution in the conventional smelting furnace, meets the requirements of energy conservation and environmental protection, and the cast aluminum alloy plate has high mechanical property and good machining quality, and meanwhile the finished product rate and the production efficiency are effectively improved.

Owner:浙江顺虎铝业有限公司

Casement window unit

Owner:GSG INT

Shearing reinforcing type semi-grouting sleeve

ActiveCN103758291AExtensive sources of materialsEasy to processBuilding reinforcementsMechanical millingMaterial resources

The invention discloses a shearing reinforcing type semi-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; an elastic rubber sealing ring is arranged at the opening of one end of the sleeve body; a threaded connecting piece is arranged at the opening of the other end of the sleeve body; a grouting hole and a discharge hole are formed in side walls close to the end parts of the sleeve body; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type semi-grouting sleeve has the advantages of wide material resource, simplicity in machining and manufacturing, reliability in property and the like, can greatly overcome the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

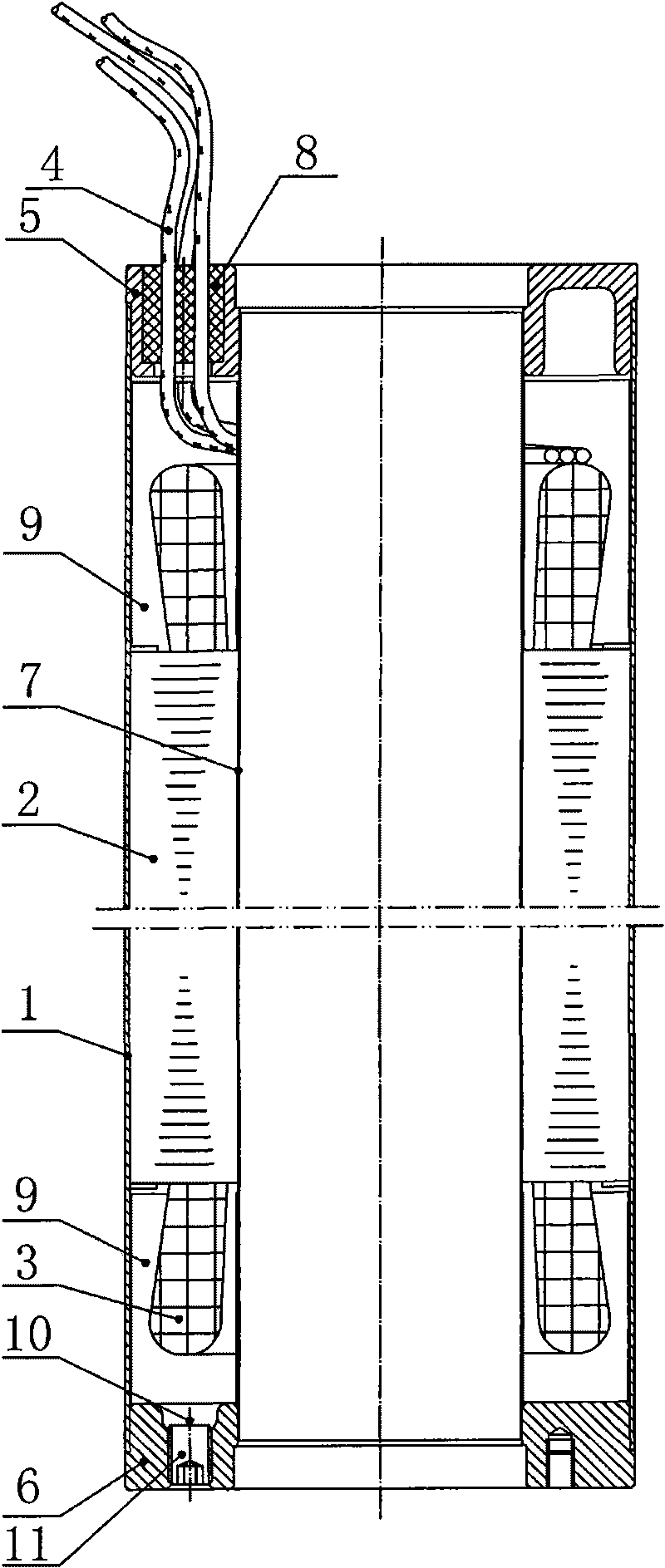

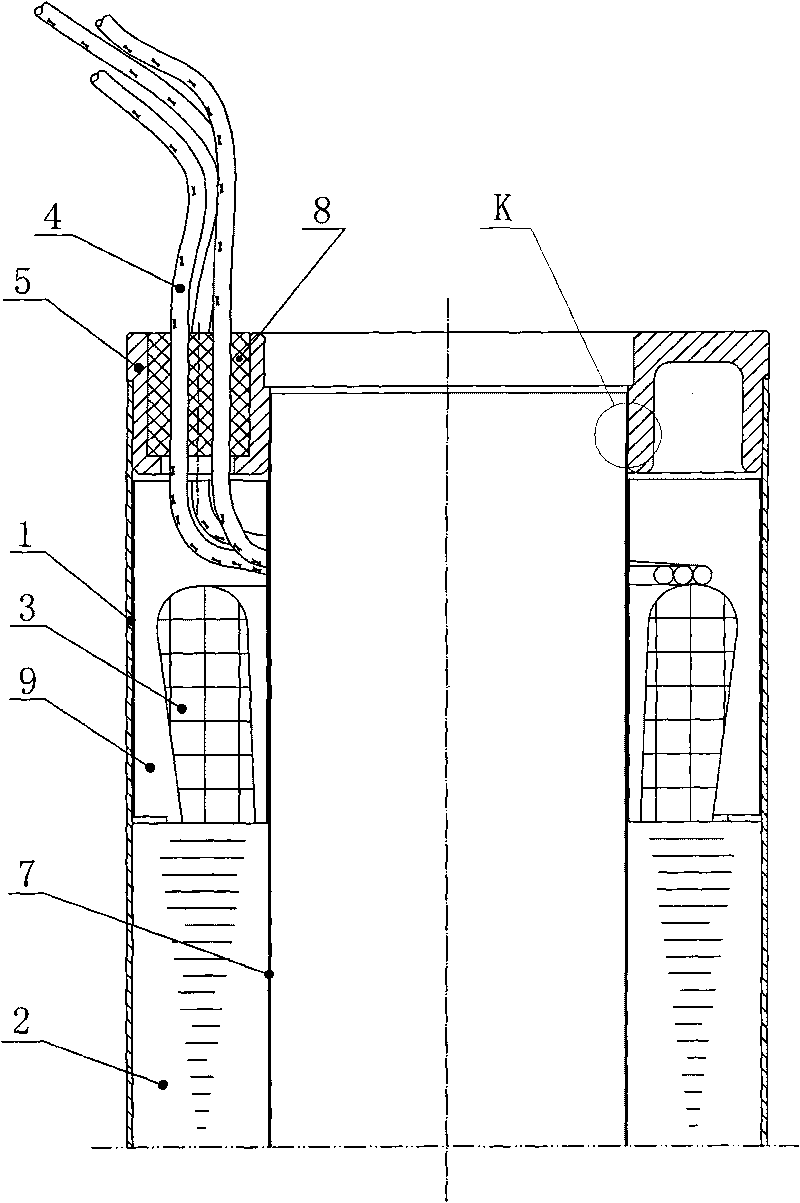

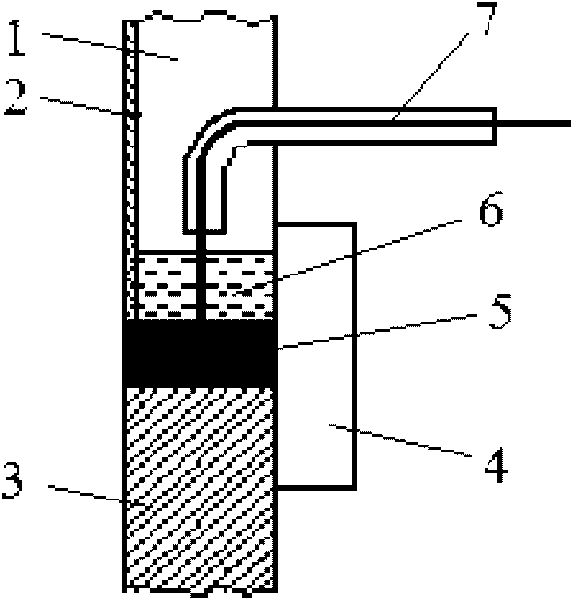

Stator structure of submersible motor and manufacturing method thereof

ActiveCN101764451AAchieve sealingImprove sealingWindings insulation shape/form/constructionMagnetic circuit stationary partsEngineeringConductor Coil

The invention discloses a manufacturing method of a stator structure of a submersible motor, wherein the stator structure comprises a stator case, an iron core, a stator winding and a winding lead wire; the upper end and the lower end of the stator case are respectively welded with an upper flange end ring and a lower flange end ring in a sealing way and also fixed with a stainless steel shielding sleeve and a lead wire sealing device that is used for sealing and wrapping the edge of the winding lead wire; insulating fluid sealant is filled in the clearances among the stator case, the stainless steel shielding sleeve, the upper flange end ring, the lower flange end ring, the iron core and the stator winding. The method for manufacturing the stator structure of the submersible motor includes the following sequential steps of manufacturing the stator case and the stainless steel shielding sleeve by rolling according to the argon arc welding means; manufacturing the stator winding and the iron core; lathing the upper flange end ring, the lower flange end ring and a small V-shaped convex ring; assembling, sealed-welding and reshaping; preparing the insulating fluid sealant; filling the insulating fluid sealant; and sealing. The stator structure has the benefits of complete sealing of the stator winding of the motor, high watertight and insulating performances, simple structure and safe and reliable operation.

Owner:GUANGDONG RUIRONG PUMP IND

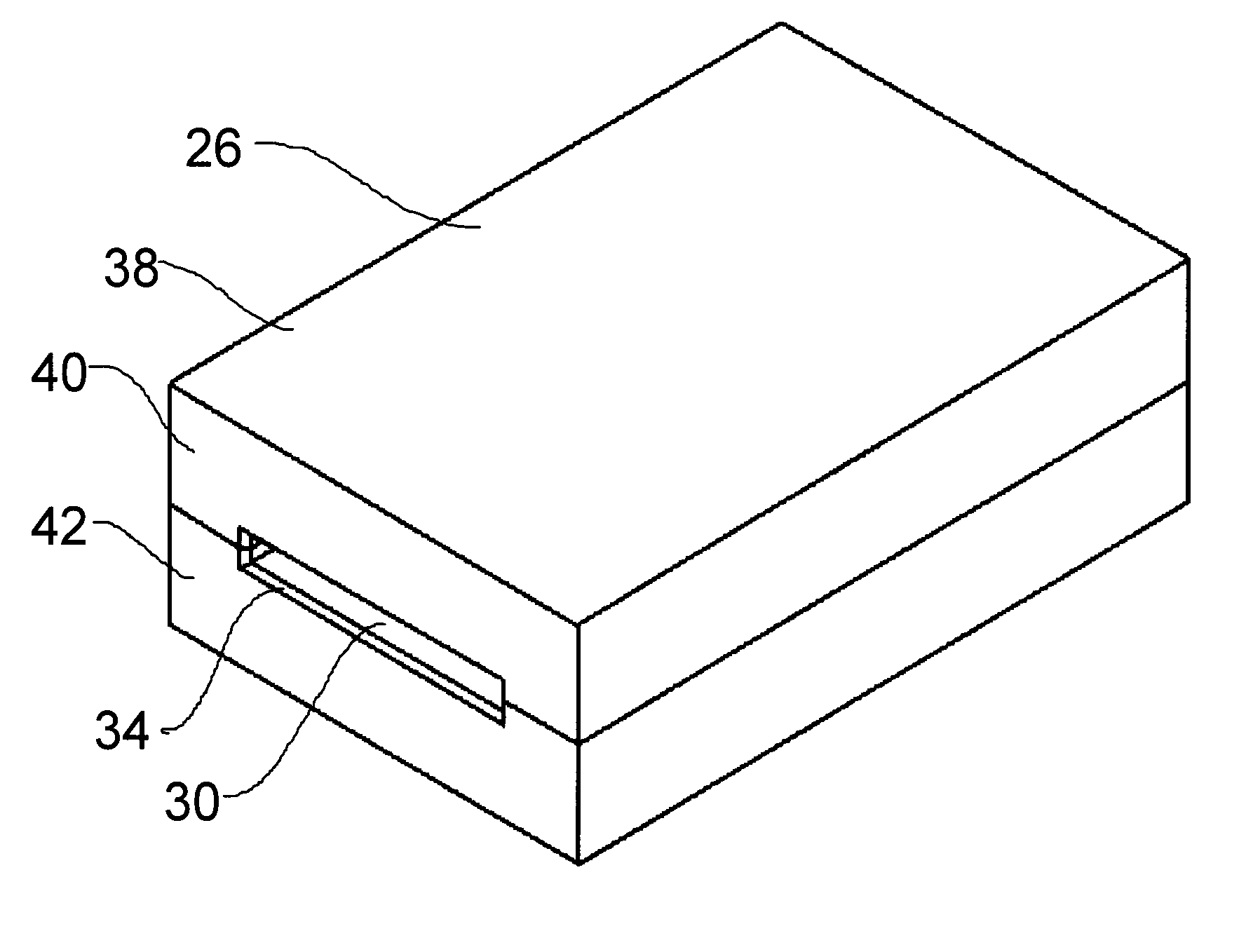

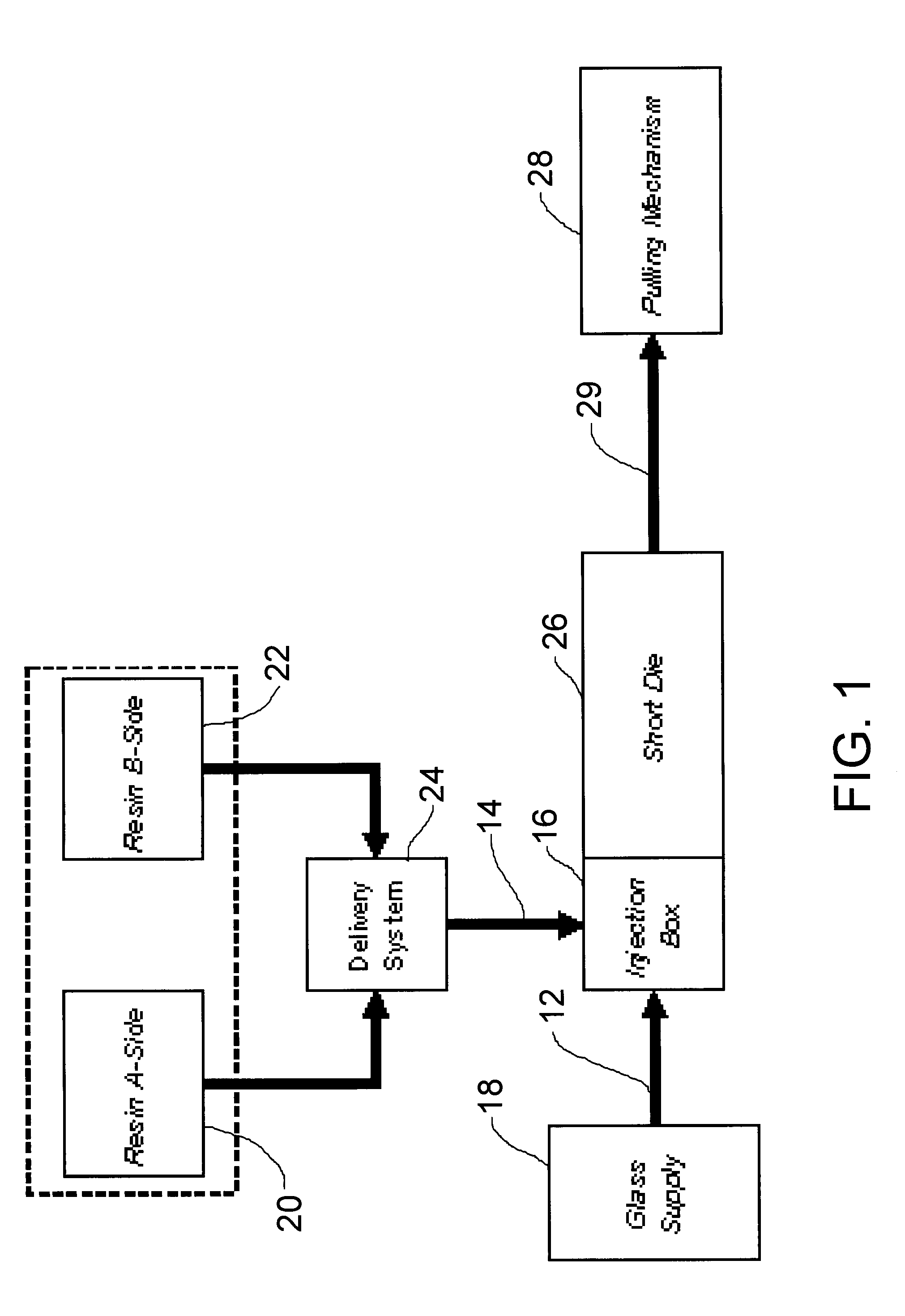

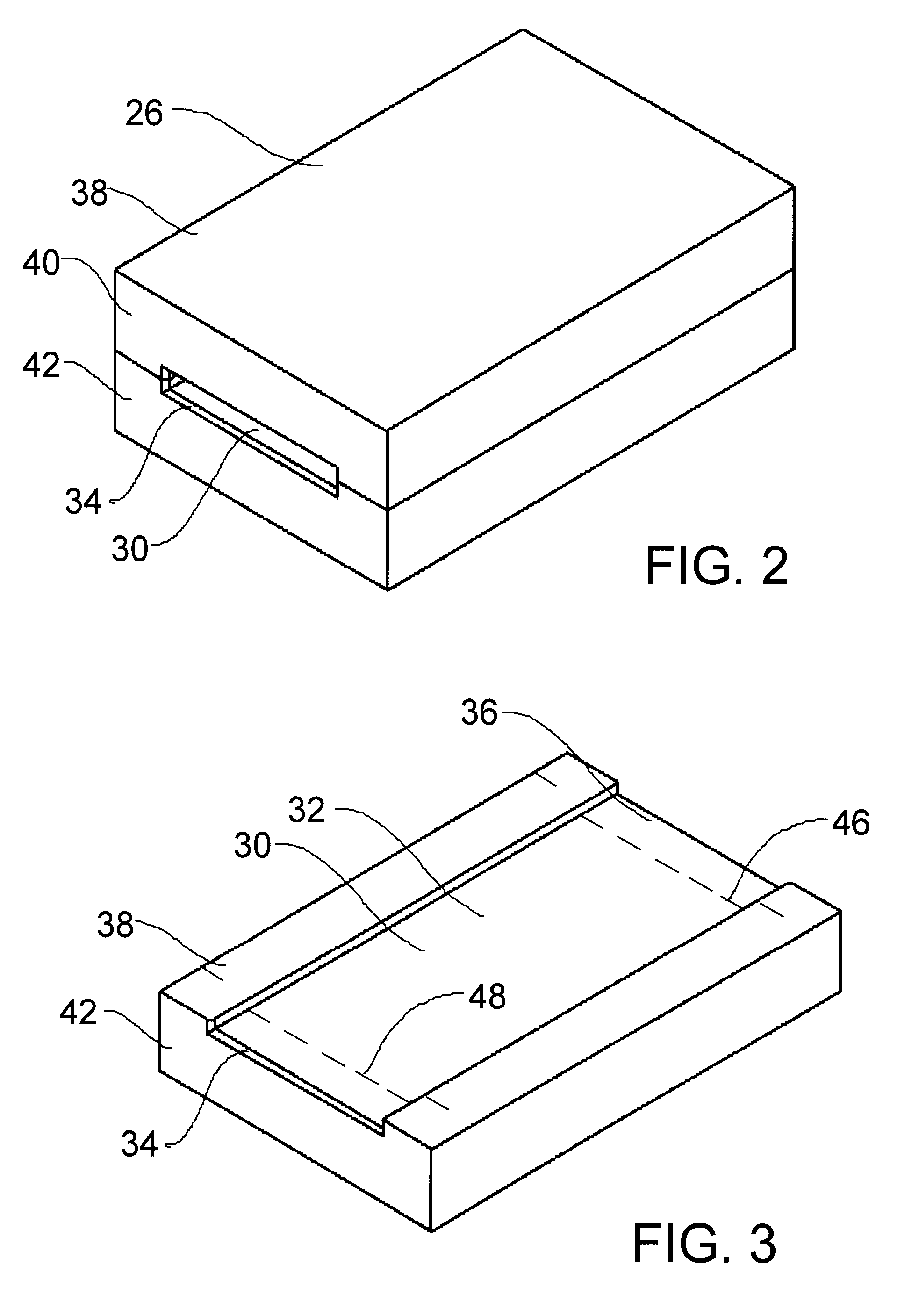

Pultrusion Apparatus and Method

InactiveUS20090071593A1Shorten the lengthImprove attributesLaminationLamination apparatusReaction zoneChemistry

A method and apparatus for pultrusion of polyurethane resin is provided. The method comprises impregnating fibres with polyurethane resin to produce polyurethane impregnated fibres, and then pulling the polyurethane impregnated fibres through a pultrusion die. The pultrusion die defines a pultrusion path with a heated reaction zone of from about 20 to about 60 cm in length. The apparatus comprises a pultrusion die in combination with a polyurethane resin, the pultrusion die comprising, a body defining a pultrusion path with a heated reaction zone from about 20 to about 60 cm in length.

Owner:RESIN SYST

Special alloy steel and method for high-speed rail turnout integral sliding bedplate

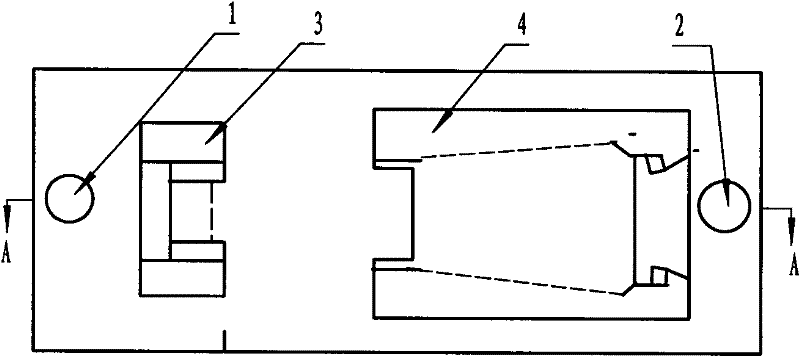

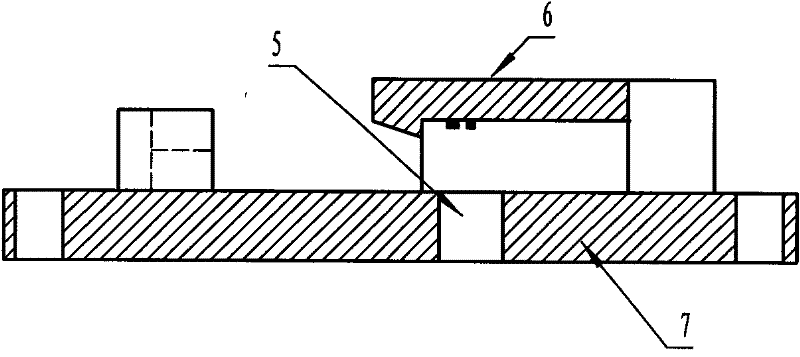

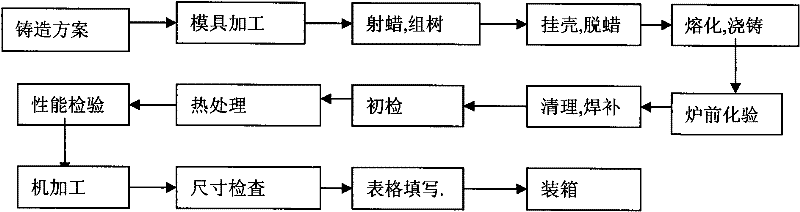

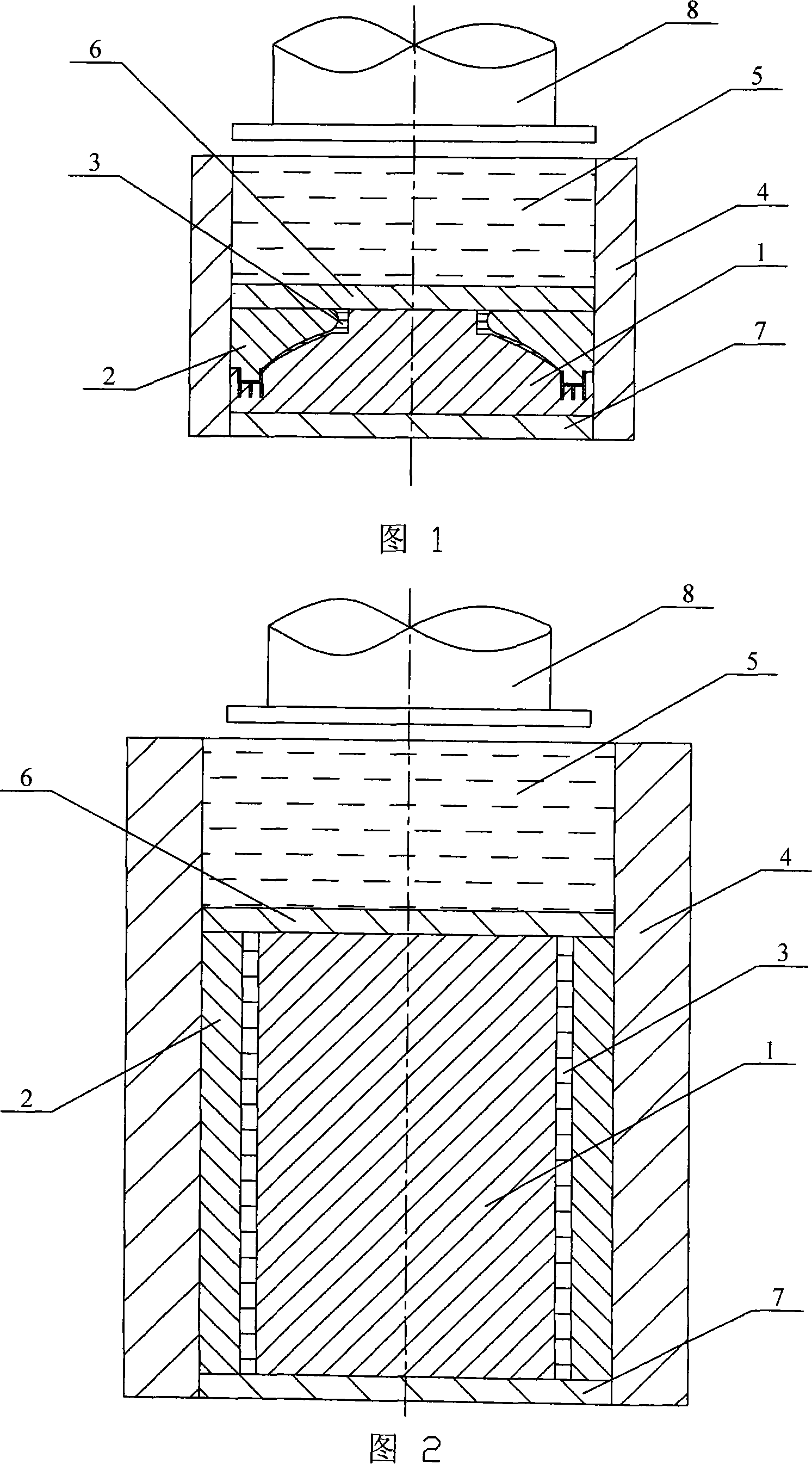

InactiveCN102453842ASolve the problem of precision and welding deformationSimple structureRail switchesFoundry mouldsCarbon steelCorrosion resistant

The invention which relates to novel special alloy steel, and concretely relates to special alloy martensite stainless steel and a method for preparing a high-speed rail turnout integral sliding bedplate from the stainless steel belongs to the technical field of novel material preparations and applications thereof. The special alloy steel comprises the following chemical components, by weight, equal to or less than 0.10% of C, equal to or less than 1.5% of Si, equal to or less than 1.5% of Mn, equal to or less than 0.03% of P, equal to or less than 0.03% of S, 12.5-15.5% of Cr, 1-2% of Ni, a certain amount of Nb, 0.05-0.2% of W, 0.0003-0.0005% of B, 0.02-0.04% of N, and the balance Fe, wherein the amount of Nb is 3-5 times the amount of C. The method is carried out with integral casting one-time forming. According to the invention, defects of the processing technology complexity and the short service life caused by the adoption of easily abraded common carbon steel and the welding of three parts in the prior art are offset. The integral sliding bedplate of the invention, which successfully replaces split-welded sliding bedplates, has the characteristics of high strength, good abrasion resistance, corrosion resistance and no rust, no deformation, and short production period. So, the method which can satisfy essential conditions for the streamline production is very suitable for the large batch production.

Owner:张佳秋

Fibre reinforced intermetallic compound composite material as well as preparation and forming method thereof

Owner:HARBIN INST OF TECH

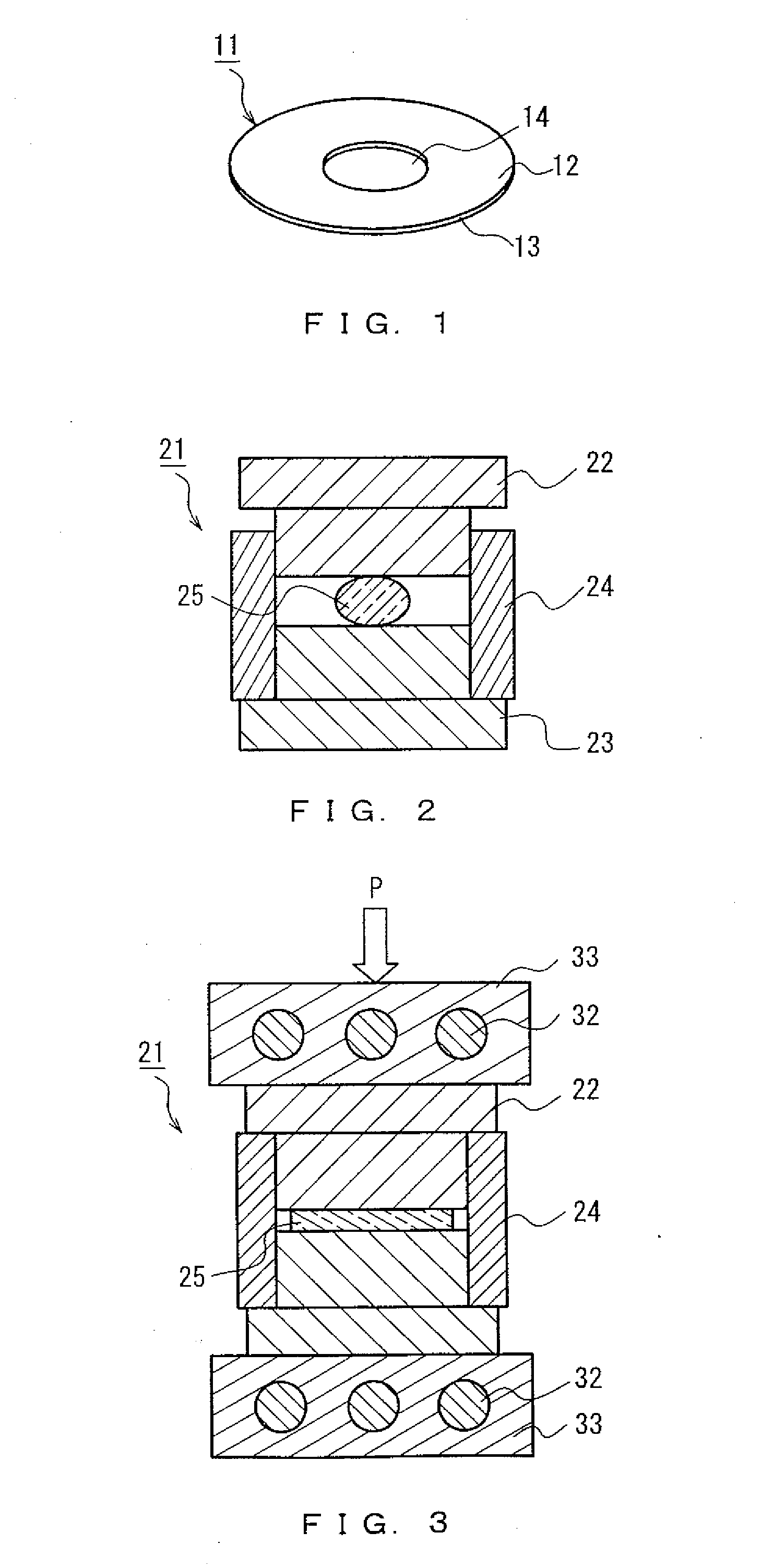

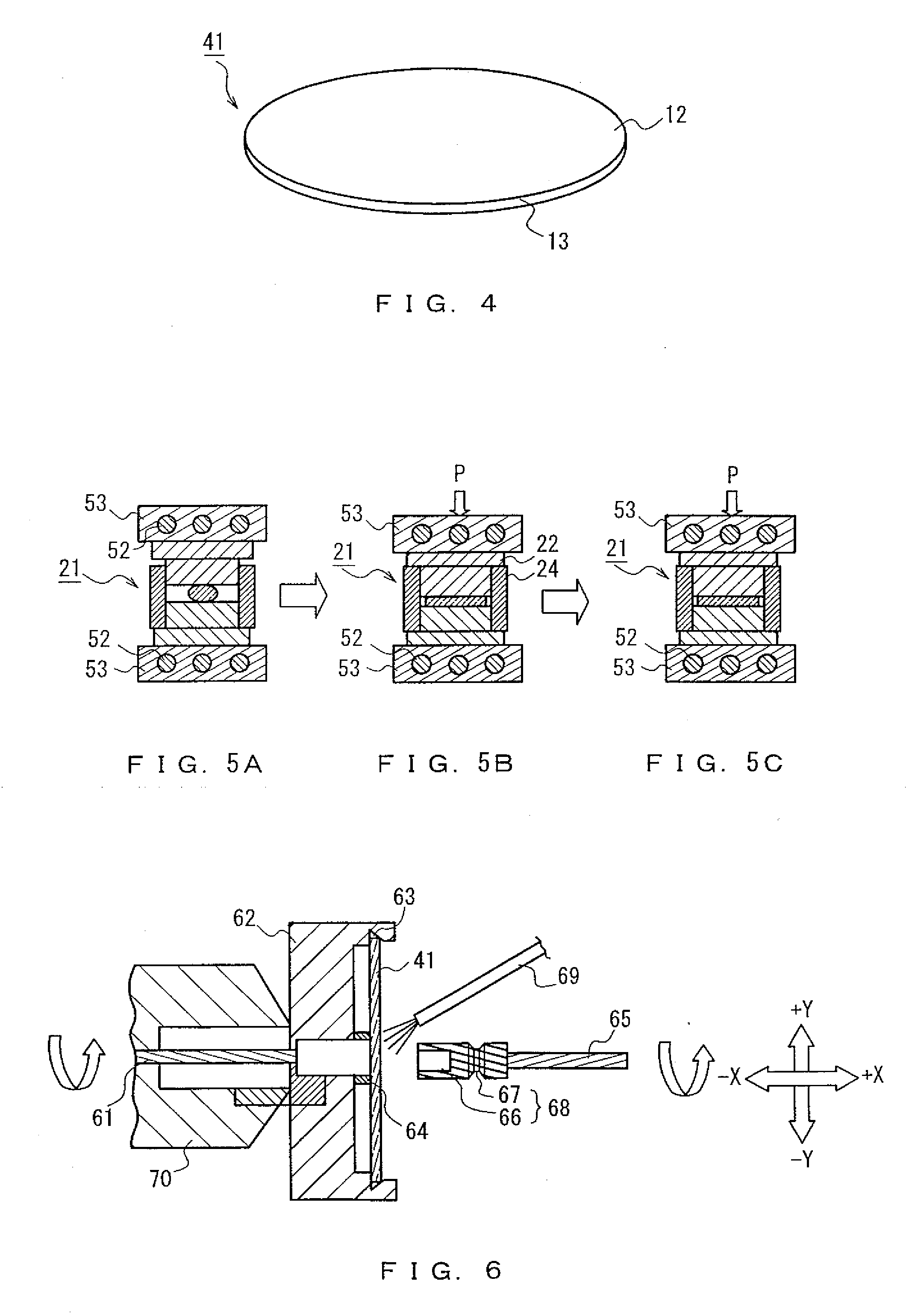

Molded glass substrate for magnetic disk and method for manufacturing the same

InactiveUS20070295030A1Reduce industrial wasteSuppresses generation of dustCharging furnaceBase layers for recording layersMaterials scienceGlass material

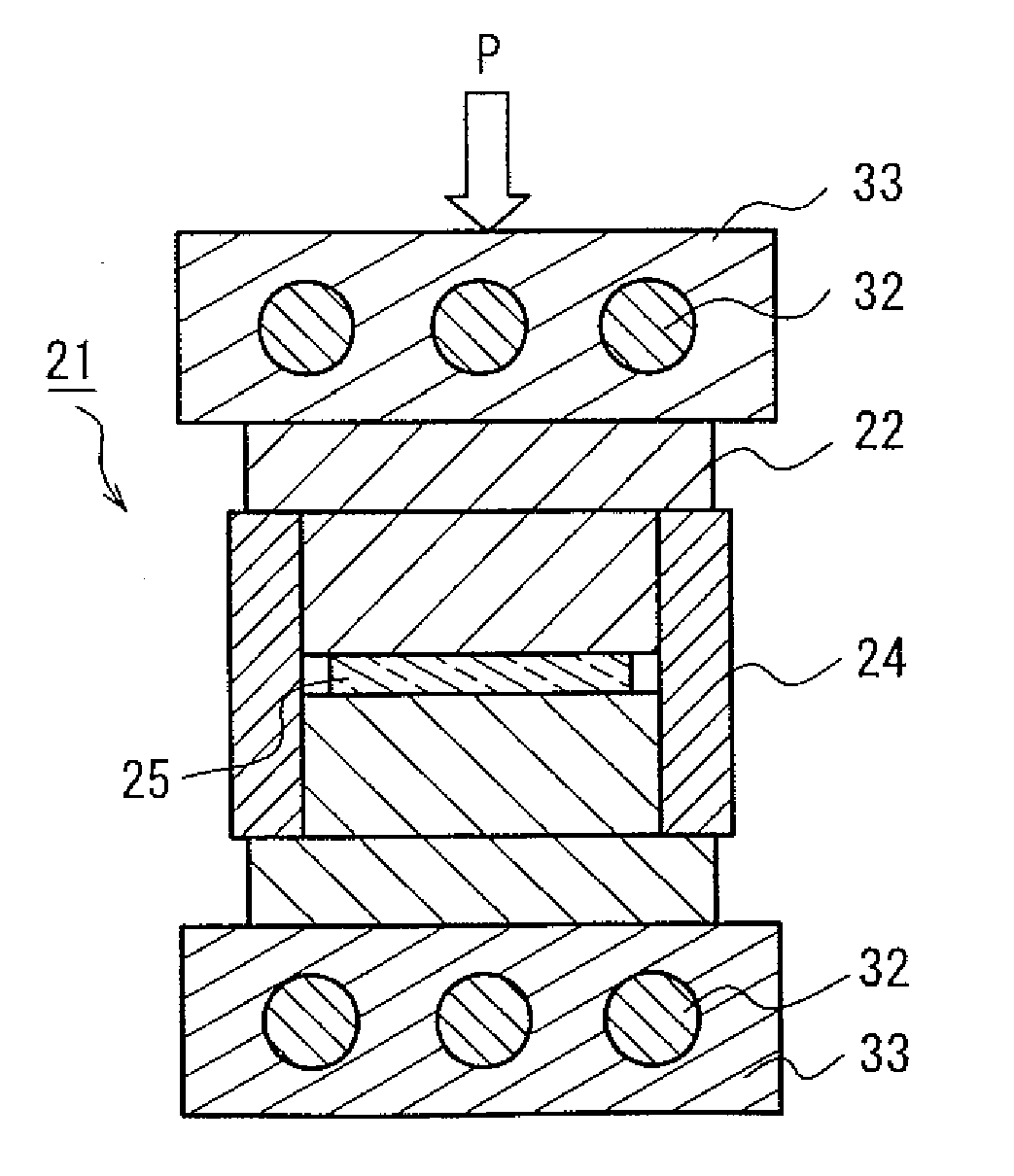

A method for manufacturing a glass substrate for a magnetic disk involving press-molding a heated glass material in an inside space of a molding die comprising a pair of dies, each having a predetermined processing plane, and a barrel die for slidably guiding the dies while forming an outer circumference of the glass material joined to both principal surfaces corresponding to the dies as a molding-free face, cooling the press-molded glass substrate and forming a predetermined through-hole in a central portion of the glass substrate.

Owner:PANASONIC CORP

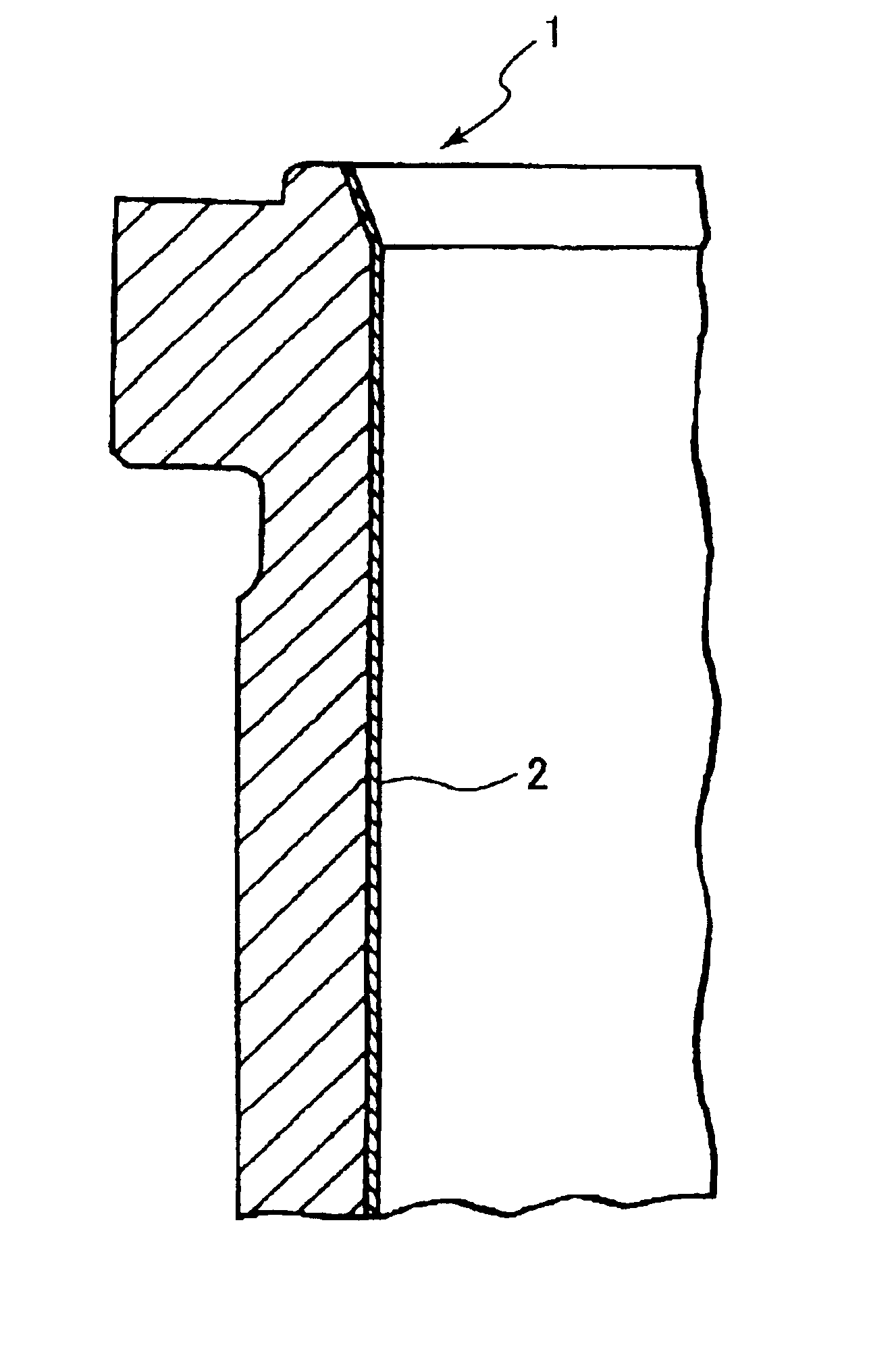

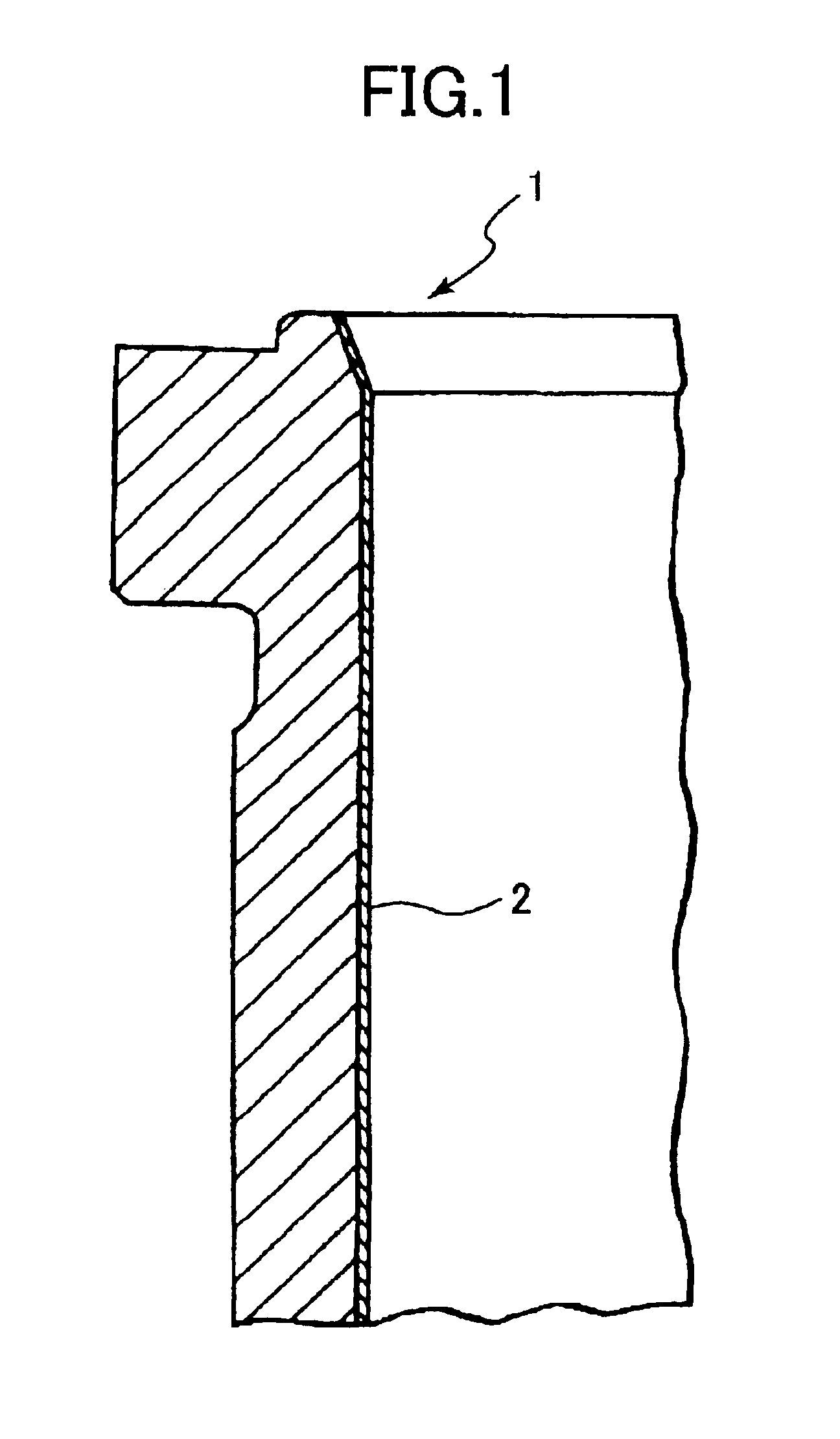

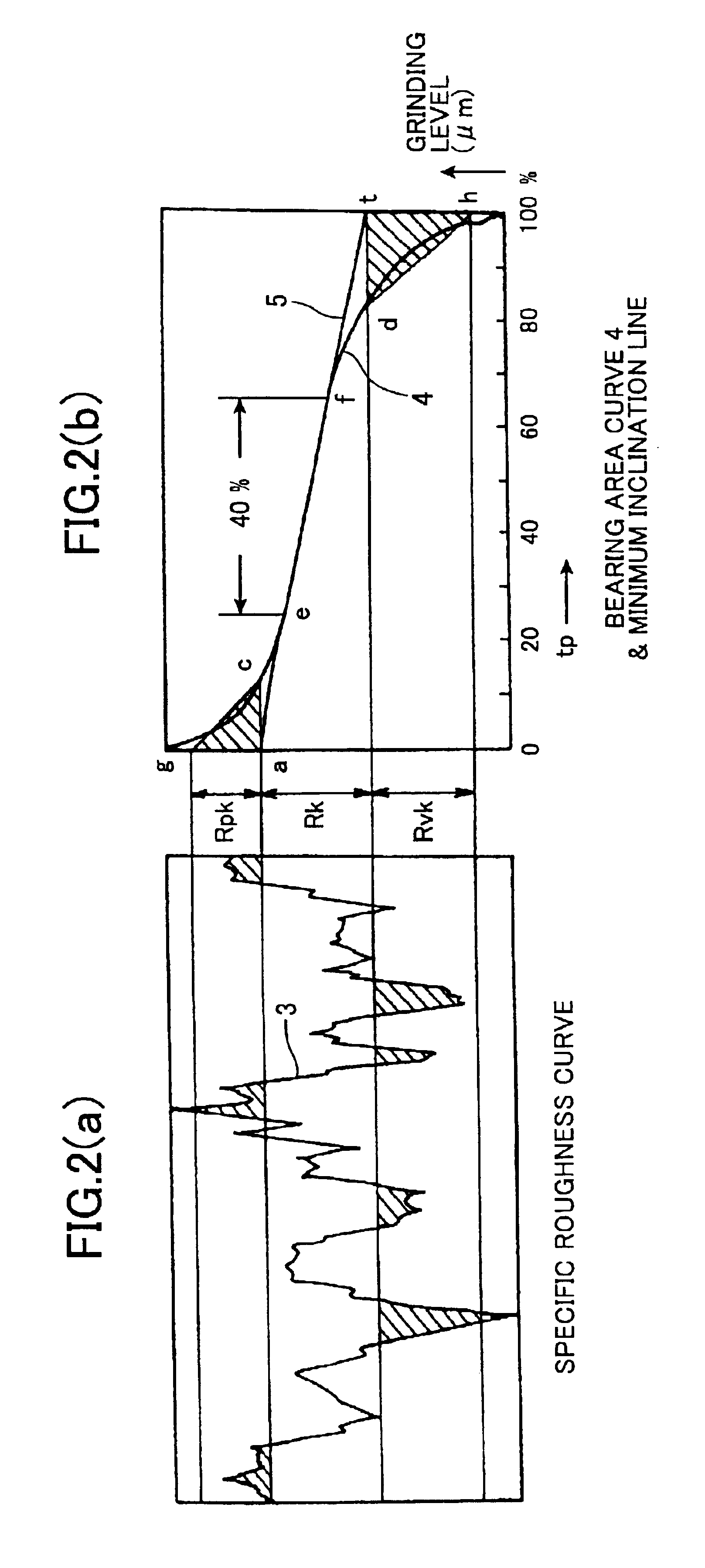

Cylinder liner with its inner peripheral surface formed with surface treatment layer, and method for machining to the surface treatment layer

InactiveUS7059290B2Improve grinding effectHigh hardnessCylinder headsCylindersHigh densityWater vapor

A cylinder liner for use in an internal combustion engine has an inner peripheral surface at which a surface treatment layer is formed upon water vapor treatment. The surface treatment layer has a surface configuration capable of providing excellent lubrication oil retaining function and initial break-in property as well as capable of being machined easily. The treatment surface of the cylinder liner has a plateau configuration providing a surface roughness Rz of 0.8 to 5.9 μm, and the plateau configuration is defined under DIN4776 by a reduced peak height Rpk of not more than 0.64 μm, a core roughness depth Rk of 0.05 to 1.8 μm, and a reduced valley depth Rvk of 0.15 to 3.3 μm. For grinding to the surface, a honing machine employs a grindstone containing metal bonded diamond grains at high density. Diamond grain size is not less than 4000.

Owner:NIPPON PISTONRING CO LTD

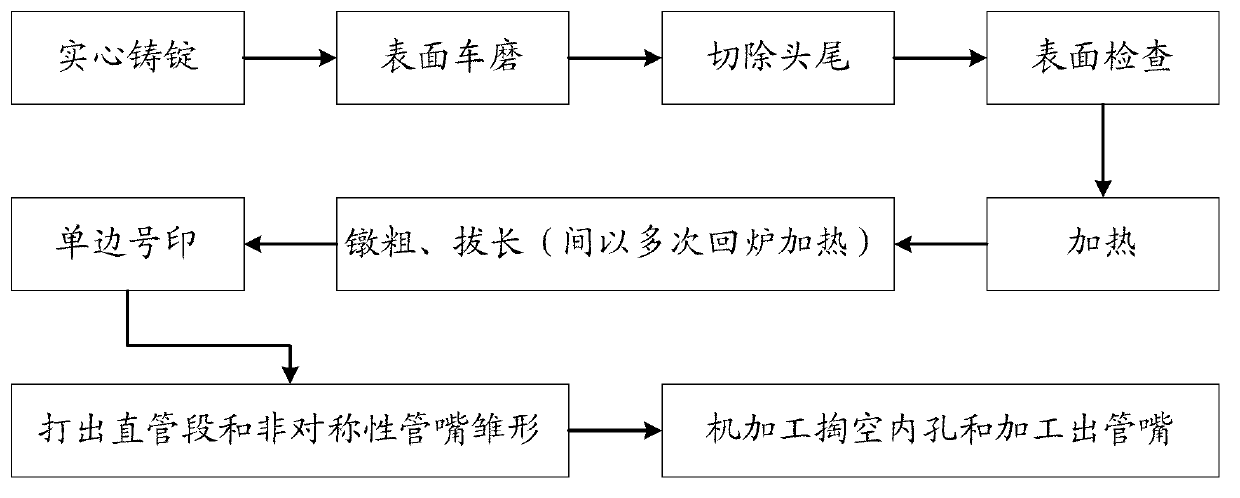

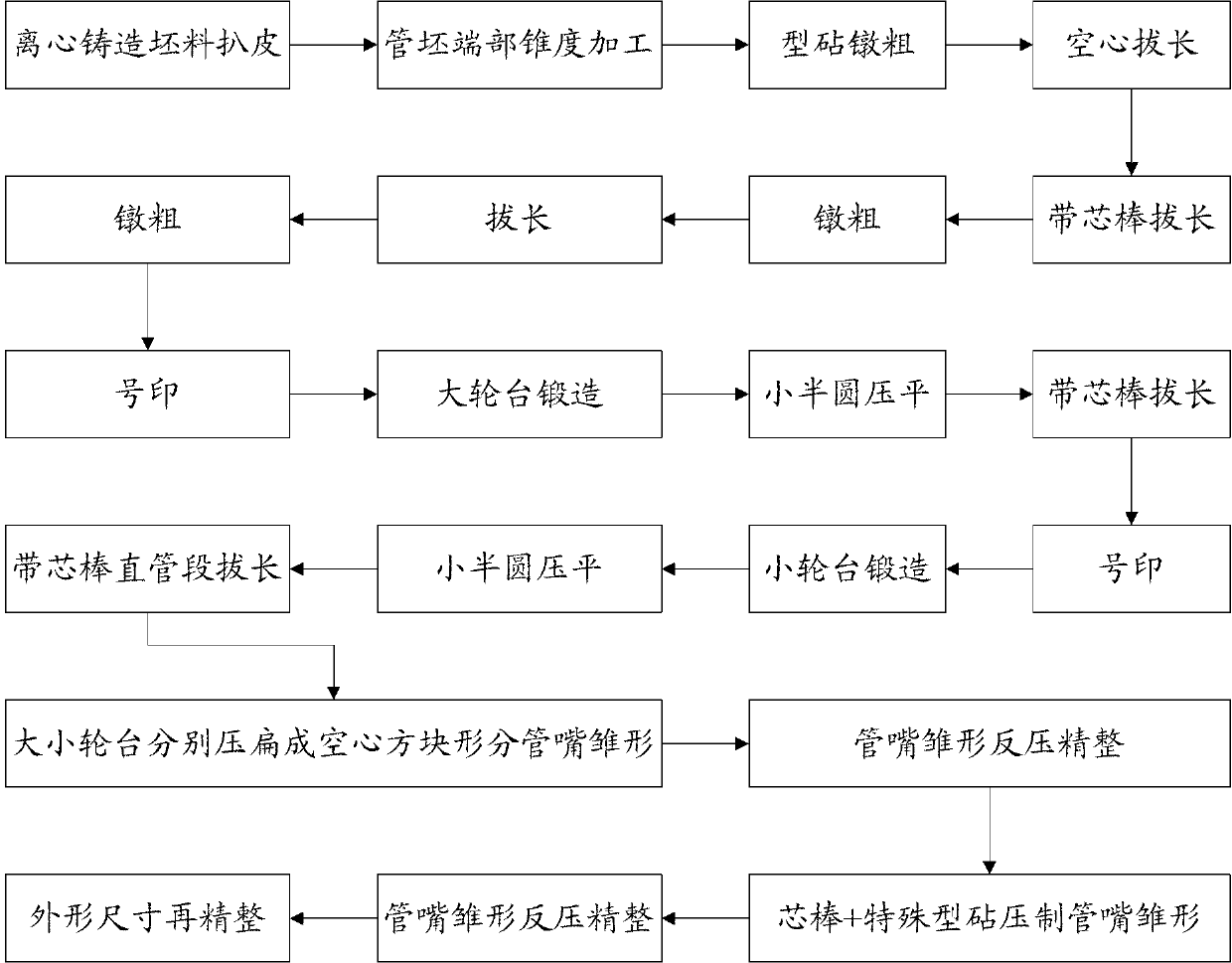

Process of producing nuclear power plant main pipeline forge piece through centrifugal casting hollow ingot

ActiveCN103341724AQuality assuranceHigh quality and precisionMetal-working apparatusBrickNuclear power

The invention discloses a process of producing a nuclear power plant main pipeline forge piece through a centrifugal casting hollow ingot, and belongs to the technical field of forging. After the centrifugal casting hollow ingot is reasonably heated and reheated, upsetting forming capable of avoiding serious instability is conducted on the centrifugal casting hollow ingot on a swage block with the cone apex angle ranging from 172 degrees to 178 degrees for at least twice, wherein stretching forming with an inner cooling core rod and stretching forming without an inner cooling core rod are conducted until a low diameter-wall ratio barrel-shaped forge piece with a required forging ratio and required sizes is obtained; barrel-shaped upsetting forge pieces are respectively forged through the swage block to form two hollow brick-shaped branch pipe nozzle rudiments with steps; all straight pipe sections are stretched through a long core rod with a specific diameter in succession until specified sizes are reached; redundant parts of the other side of each rudiment are removed in a machining mode, and therefore the required nuclear power main pipeline stainless steel forge piece is obtained. The process of producing the nuclear power plant main pipeline forge piece through the centrifugal casting hollow ingot has the advantages of being obvious in energy saving effect, consumption reducing effect, working hour saving effect and low-carbon discharging effect when being compared with a forging forming process where solid ingots are widely adopted.

Owner:CHINA IRON & STEEL RES INST GRP +2

Multifunctional obstacle-surmounting robot

InactiveCN1883886AFlexible controlImprove standardizationManipulatorElectronic controllerIntelligent control

The invention involves a multi-function obstacle-overcoming robot. The robot contains a vehicle body under which a walking mechanism is available. An obstacle-overcoming mechanism is equipped on the upper section of the vehicle body. The above mentioned obstacle-overcoming mechanism is equipped with two swinging arms which are ream jointed to the vehicle body. A following trolley is equipped on the outer side of the rear swinging arm and a driving wheel is mounted on the outer side of the front swinging arm. Inside the vehicle body, an intelligent control device and a handset control panel are available. The intelligent control device is equipped with the main control SCM. In the front of the vehicle body, an ultrasonic obstacle-overcoming probe and approximation contact switch are equipped. In the lower section of the vehicle body, a photoelectrical detection switch is mounted in the front and rear respectively. In the upper section of the vehicle body, a travel switch for the swinging arms is mounted. The invention involves the micro-electronic controller so that the control over the robot becomes more flexible. The utilization of software instead of hardware in the design makes technical alternations and upgrading more easy. Information exchange among environment-robot-human are realized through sensors and various controls and audio prompting devices. The robot has simple structure and low cost and can be applied on a robot which is intended for use in an occasion with road shoulders and wide sidesteps and other occasions.

Owner:HUAIHAI INST OF TECH

Device with a screw plug and a range of devices

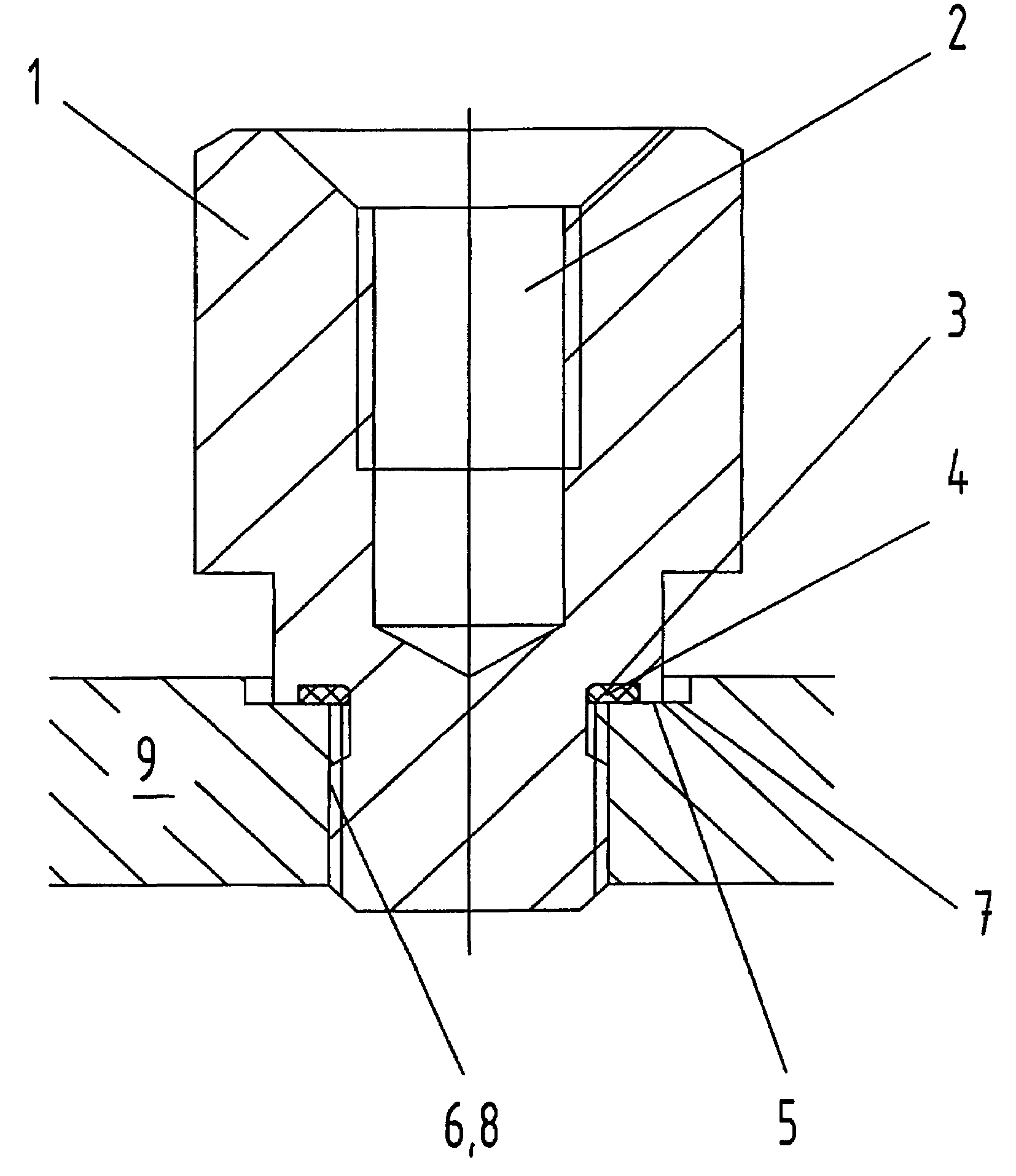

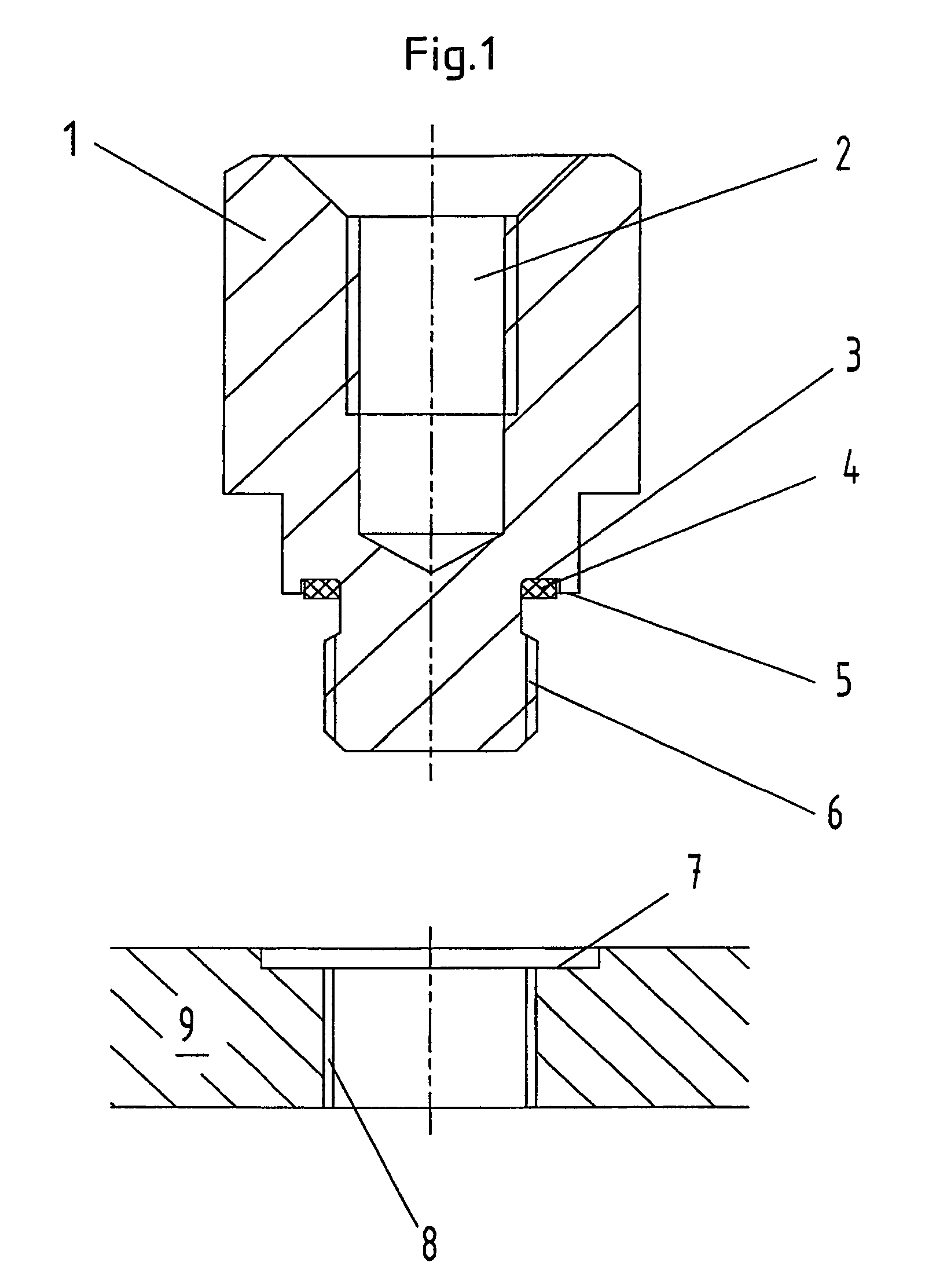

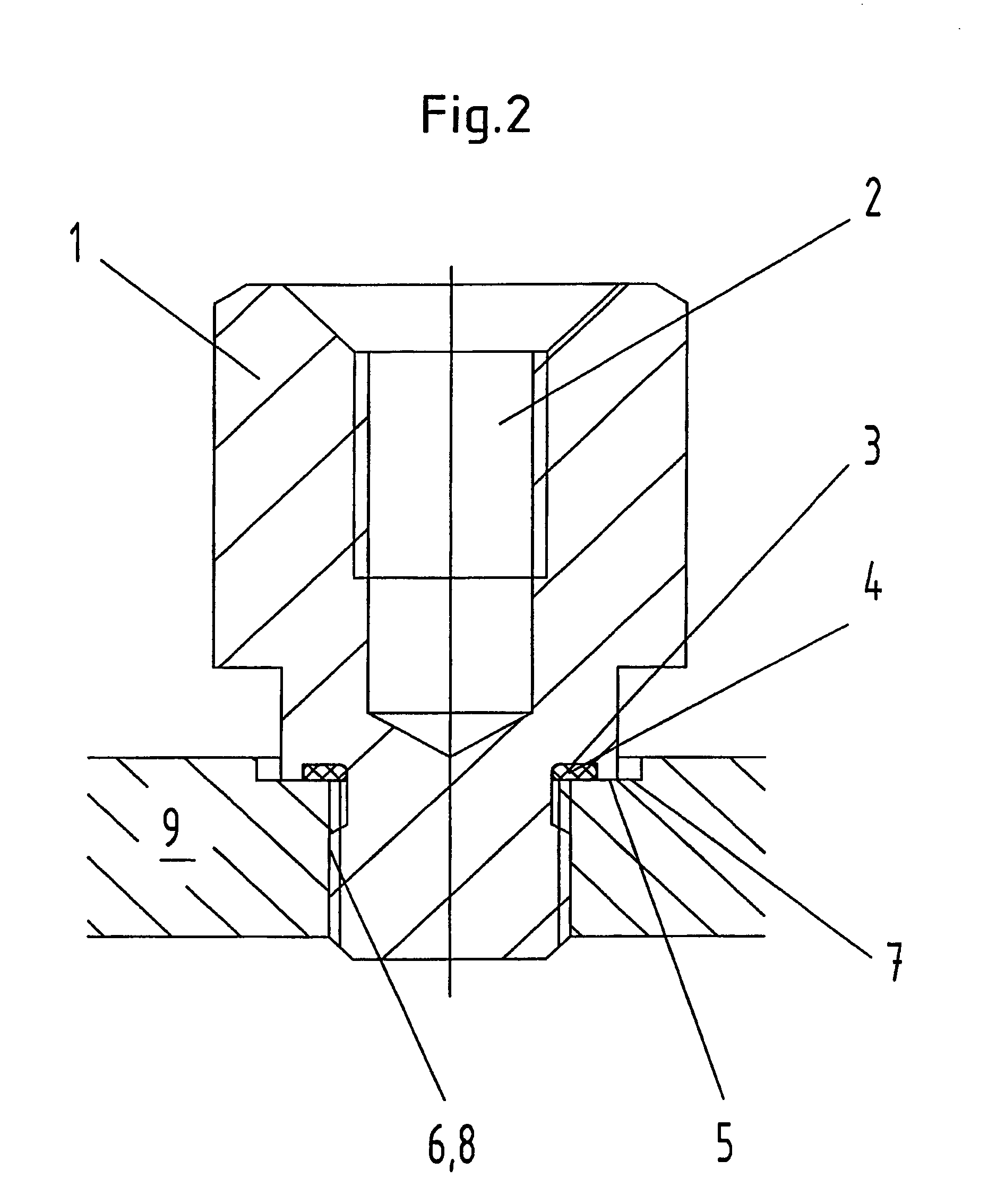

InactiveUS7624618B2Cost-effectiveGood flexibilityVibration measurement in solidsAcceleration measurement using interia forcesAcoustic waveEngineering

A device having at least one screw plug for screwing into a first tapped hole of a housing or housing part of the device, the at least one screw plug including a device for sealing, such as a sealing ring, for the connection to the housing in a manner forming a seal, e.g., against the escape of oil. Introduced into the screw plug is a second tapped hole by which a sensor is releasably connectable, e.g., is able to be screwed in. The screw plug includes an end stop for conducting acoustical waves and for the simultaneous mechanical limit for screwing in the screw plug.

Owner:SEW-EURODRIVE GMBH & CO KG

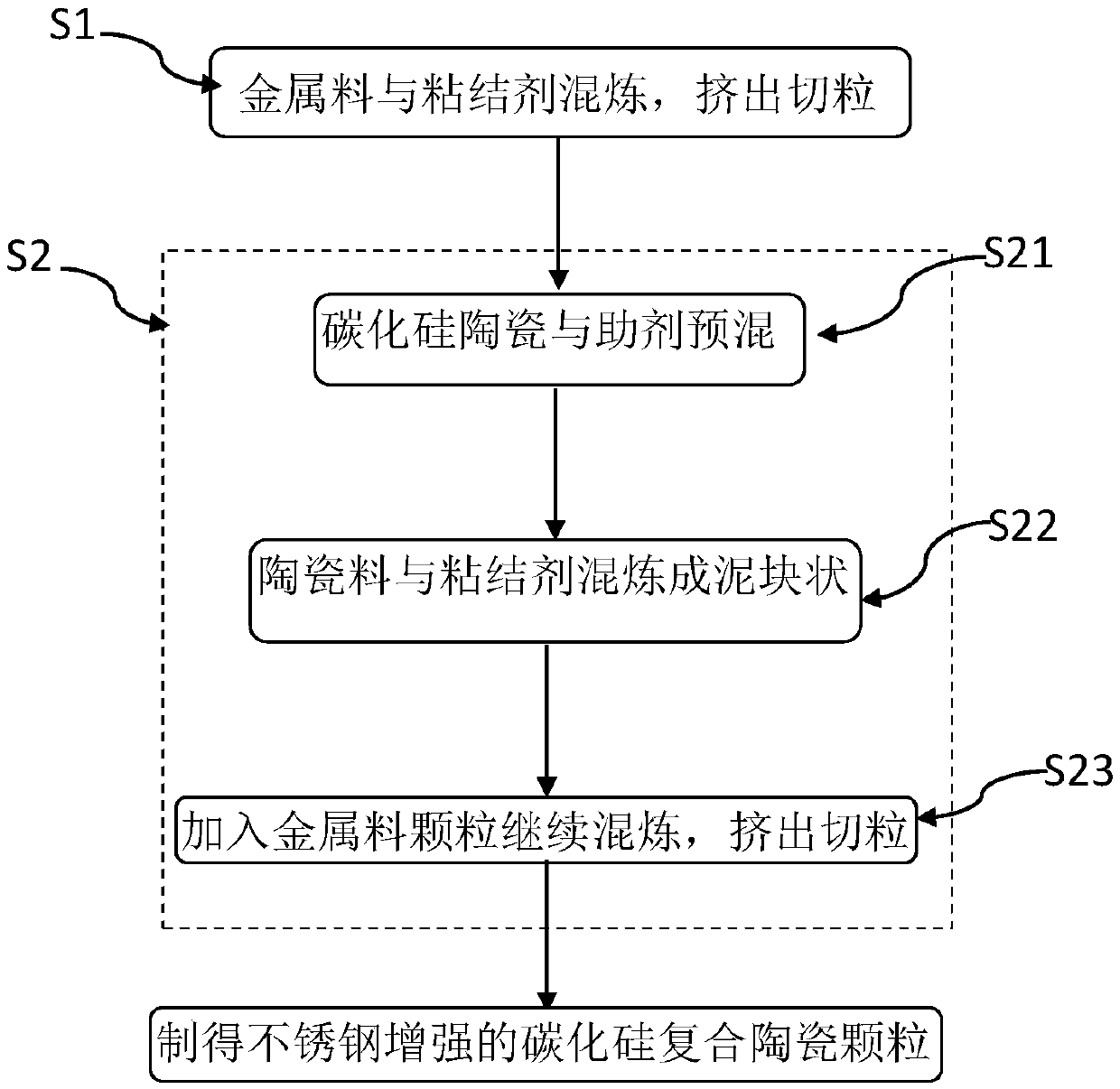

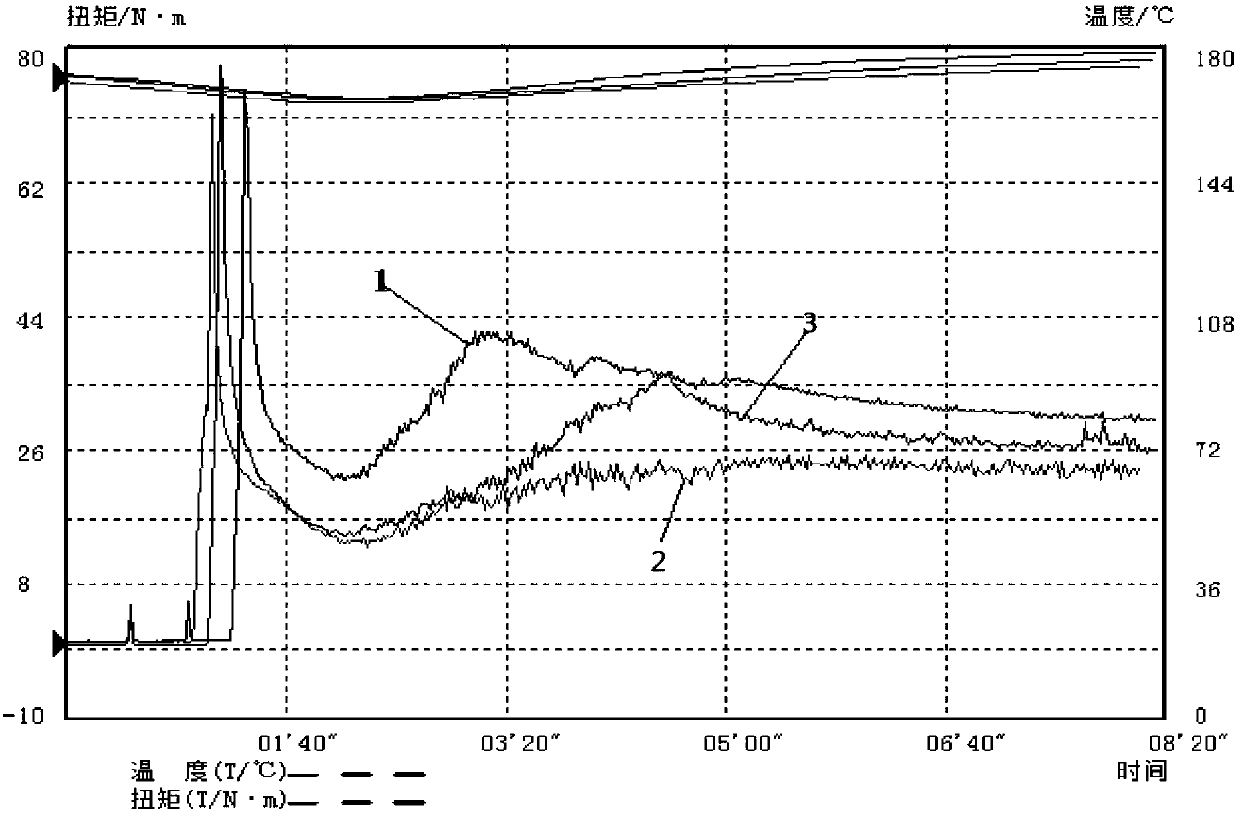

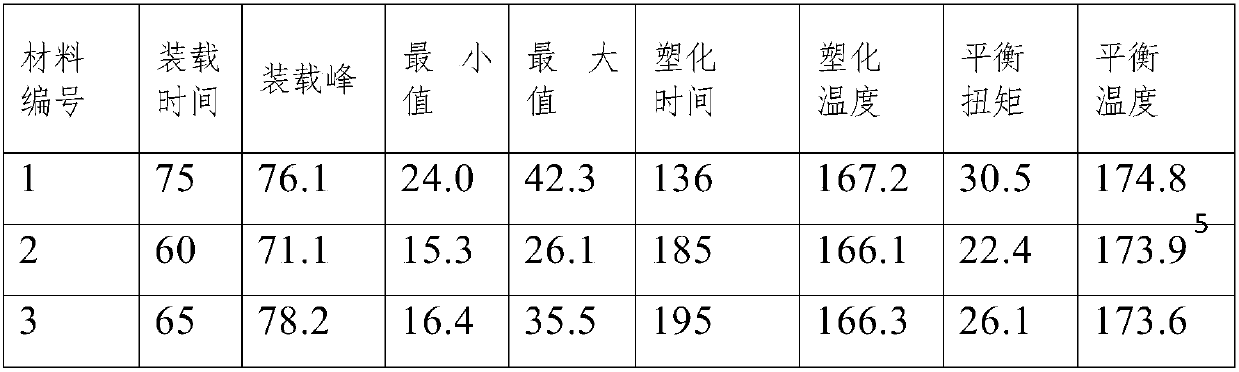

Granulation method of silicon carbide composite ceramic material

ActiveCN109534828AImprove toughnessHigh dimensional accuracy in productionComposite ceramicExtrusion Granulation

The invention relates to a granulation method of a silicon carbide composite ceramic material. The granulation method comprises the following steps: S1, a metal material is granulated, specifically, stainless steel powder and an organic binder are put into an internal mixer, mixing is conducted for 30-180 min, then squeezing and cutting into granules are conducted, and thus metal material granulesare prepared; S2, the silicon carbide composite ceramic material is granulated, specifically, ceramic powder and an organic binder are put into the internal mixer to be mixed for 30-180 min, then themetal material granules prepared in the step S1 are added into the internal mixer, thus the mass of the metal material granules accounts for 30-35% of the total material mass in the internal mixer, after mixing continues being conducted for 30-120 min, squeezing and cutting into granules are conducted, and thus the stainless steel reinforced silicon carbide based composite ceramic granules are obtained. According to the granulation method, the metal material is granulated separately firstly, the metal material, a ceramic powder material and the organic binder are mixed in the internal mixer and subjected to squeezing granulation, the problem that the difference between the stainless steel powder and the ceramic powder is large, and consequently even mixing cannot be conducted directly issolved, a granule material with good fluidity is prepared so as to be directly injected into a billet, and the size accuracy of the billet is maintained.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

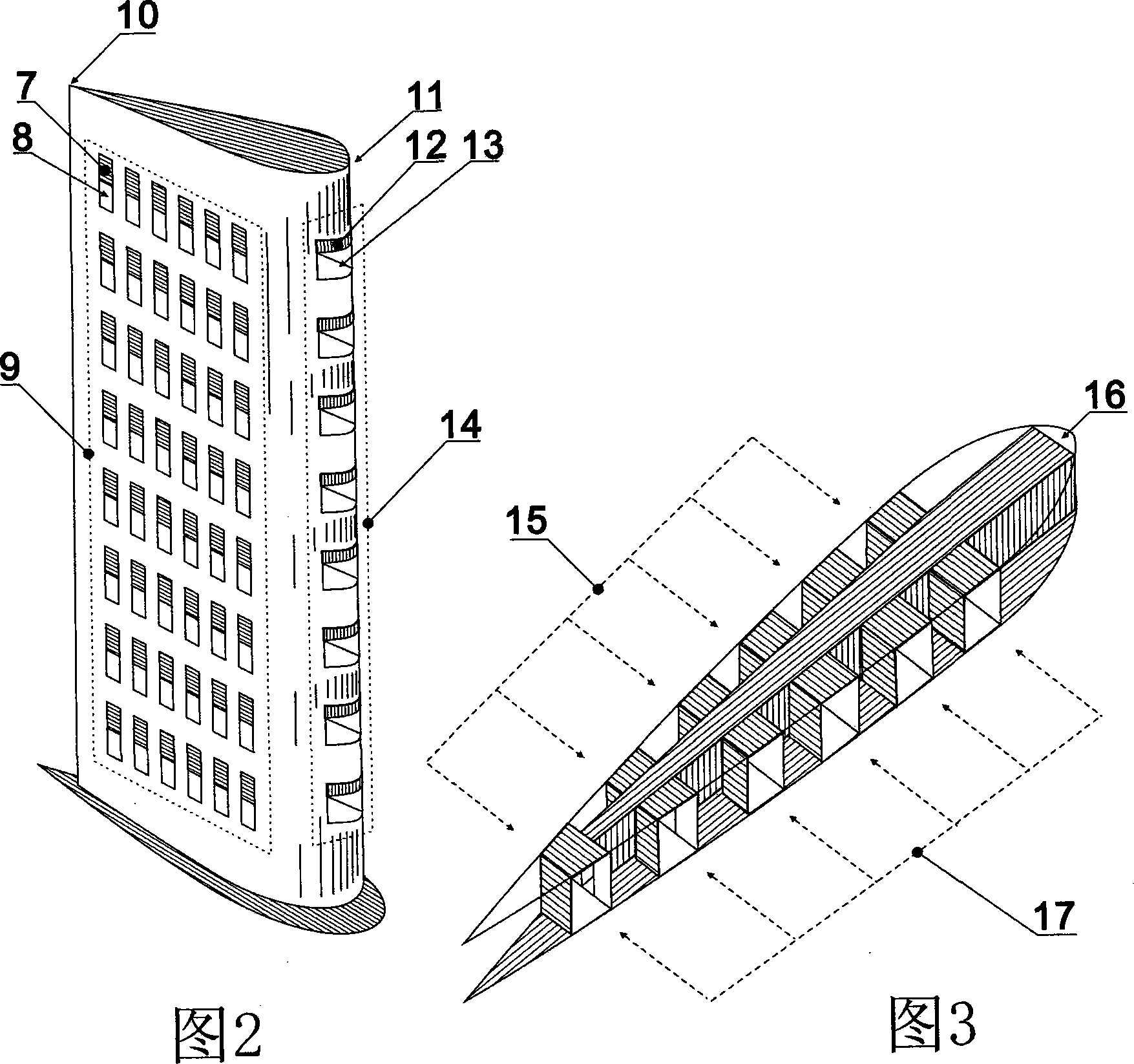

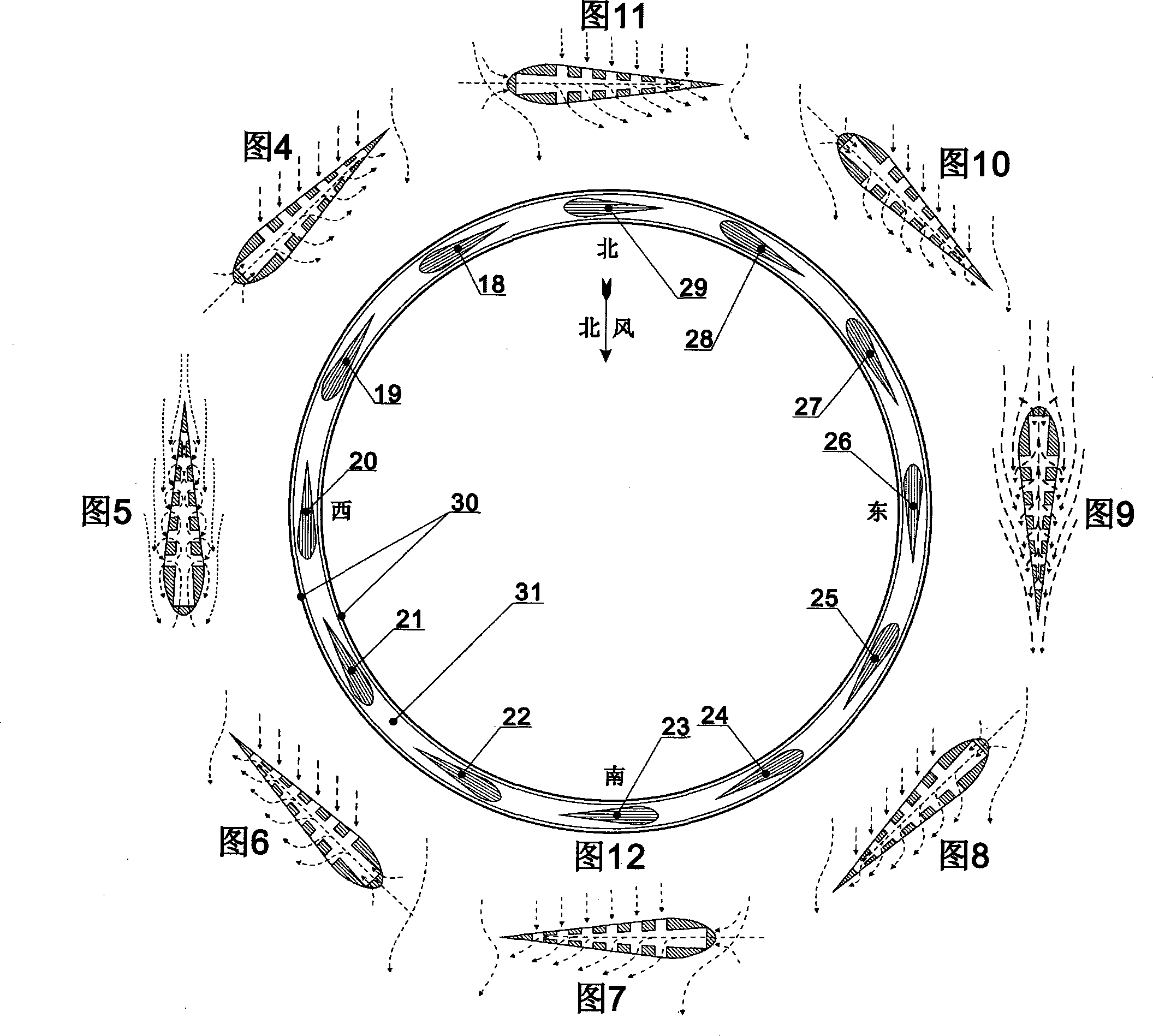

Magnetic levitation reinforced concrete built pressing jet type wing-shape sail wind power generator

InactiveCN101054950AIncrease power generationNo mechanical frictionWind motor controlFinal product manufactureReinforced concreteElectric control

The present invention relates to a stamping jet type wing shape wind sail wind generator made of magnetic suspension reinforced concrete. The generator changes the inner structure of the wind sail on the base of colligating the design idea of modern aerodynamics and retaining conventional wing shape wind sail. Because the generator adopts large area and the technology principle of the stamping jet type wing shape wind sail, it increases the area of practical wind arrest for the wind generator and also greatly improves the electricity generation efficiency for single wind generator. The present invention not only adopts the structure of the stamping jet type wing shape wind sail, but also combines the modern magnetic suspension groundsill track technology, machine-electric control technology and the conventional low cost and durable reinforced concrete structure producing technics. Thereby, the whole wind generator system not only is in favor for high efficiency big power electricity generation but also has no mechanical friction, no noise, no zoology pollution and long using life. Because the main structure of the stamping jet type wing shape wind sail wind generator is entirely made of reinforced concrete, thereby it omits complex mechanical machining and reduces the producing and manufacturing cost.

Owner:SHENZHEN WIND WATER WHEEL NEW ENERGY TECH

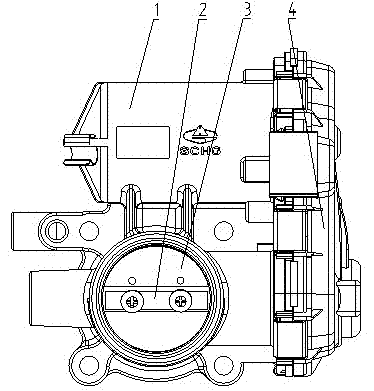

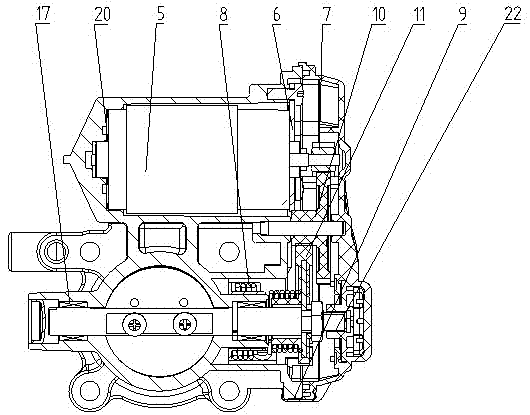

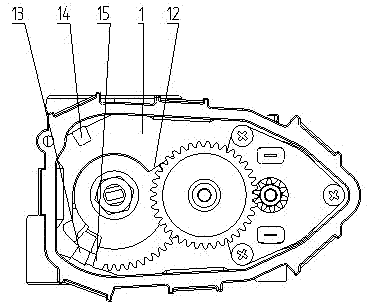

Electronic throttle body

InactiveCN102392742AExtend your lifeImprove securityEngine controllersMachines/enginesElectric machineGear wheel

The invention discloses an electronic throttle body which comprises a throttle body (1), a throttle shaft (2), a throttle plate (3), a position sensor (4) and a DC (direct current) motor, wherein a motor gear arranged on the DC motor is meshed with a middle gear arranged on the throttle body (1), the middle gear is meshed with a sector gear arranged on the throttle shaft (2), a limiting mechanism is arranged on the throttle body (1) and the sector gear, and a torsional spring is connected with the throttle body and the sector gear; when the DC motor does not output power, the throttle plate (3) is located at a high-idling position under the torsional action of the torsional spring; and the torsional spring is composed of a left torsional spring and a right torsional spring which are connected by a middle end. The electronic throttle body disclosed by the invention has the advantages that when one of the two torsional springs fails, the other torsional spring still can control the throttle plate to reset to the high-idling position, thereby improving the security.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Electroslag welding method for cylindrical longitudinal seam V groove

The invention discloses an electroslag welding method for a cylindrical longitudinal seam V groove, which is implemented by the following steps: gas-cutting a butted part of workpieces into a single groove, curling a workpiece into a cylindrical shape, making the single groove combined into a double V groove, and priming the bottom of the V groove to form a priming weld seam; and erecting the cylindrical workpiece on an electroslag welding fixed beam, attaching cooling copper sliding blocks to the excircle of a cylinder body on the outside of an opening of the double V groove, electrifying a filament to smelt a welding stick and metal on the V surface of the groove of the workpiece to form a weld pool, continuously sending filaments into the weld pool, introducing cooling water to the cooling copper sliding blocks outside the weld pool, spraying water to the inner wall of the priming weld seam, in the welding process, making the cooling copper sliding blocks synchronously raised along with a welding head, and making electroslag weld seam reliably welded with the double V groove and the priming weld seam to complete the welding. The method has the advantages of high welding quality and high welding efficiency.

Owner:MCC SFRE HEAVY IND EQUIP

Preparation method of high-fusion-welding-resistance copper-chromium fine-grain composite contact

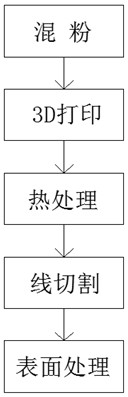

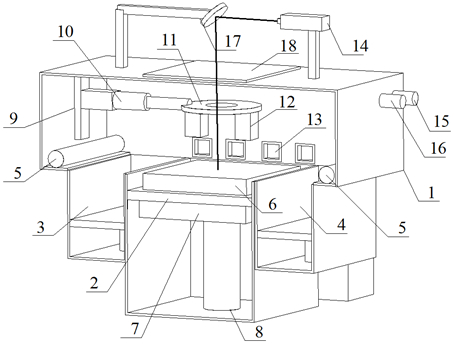

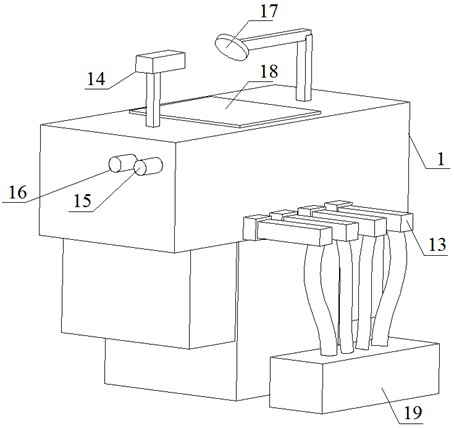

ActiveCN112091216AHigh densityImprove conductivityAdditive manufacturing apparatusIncreasing energy efficiencyWire cuttingAlloy

The invention relates to a preparation method of a high-fusion-welding-resistance copper-chromium fine-grain composite contact, and belongs to the technical field of copper-chromium contact manufacturing. The preparation method comprises the steps of powder mixing, 3D printing, heat treatment, wire cutting and surface treatment, wherein a composite layer is CuCr (0.5-2%) alloy powder, a contact layer is CuCr (10-50%) Te (0.2-1%) composite powder. The as-cast composite contact is prepared on the basis of a 3D printing process, and therefore, the interface between the contact layer and the composite layer can be flush, and the density is greatly improved. A Cr phase dissolved in Cu in a solid mode is separated out through shock cooling and heat treatment, the Cr phase is extremely fine, meanwhile, a CuTe phase is separated out, a CuTe brittle phase is formed, and the problem that the fusion welding resistance of an as-cast structure is poor is solved.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com