Special alloy steel and method for high-speed rail turnout integral sliding bedplate

A kind of alloy steel, special technology, applied in the field of new material preparation and application, can solve the problems such as difficult to grasp, complex processing technology, short service life, etc., to solve the problem of precision and welding deformation, less machining process, strong integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

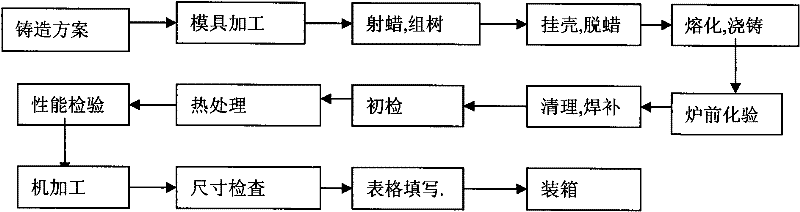

Method used

Image

Examples

Embodiment 1

[0049] Special alloy steel, composed of the following chemical composition (mass percentage, %): C 0.096; Si 0.624; Mn 0.611; P 0.026; S 0.007; Cr 13.05; Ni 1.87; The balance is Fe.

[0050] Put the castings and test rods with the above chemical composition into the box-type electric furnace for heat treatment:

[0051] (1) Normalizing treatment: heat in the furnace at 1080°C±10°C, keep it warm for 2-3 hours, and then put the test rod into the well-type electric furnace for tempering heat treatment after air cooling;

[0052] (2) Tempering treatment: heat in a furnace at 580°C±10°C for 4-5 hours, then air cool.

[0053] The mechanical properties are as follows;

[0054] Tensile strength: above 961Mpa

[0055] Yield strength: above 620Mpa

[0056] Elongation: 12.511.813 (for 3 test bars)

[0057] Hardness: 343HB

[0058] (3) Conclusion:

[0059] The performance is basically qualified, and the hardness is too hard to process.

example 2

[0061] Special alloy steel, composed of the following chemical composition (mass percentage, %):

[0062] C 0.081; Si 0.82; Mn 0.75; P 0.022; S 0.008; Cr 12.75; Ni 1.85; Nb 0.22; W 0.11;

[0063] Put the castings and test bars with the above chemical composition into the box-type electric furnace for heat treatment:

[0064] (1) Normalizing treatment: heat in the furnace at 1080°C±10°C, keep it warm for 2-3 hours, and then put the test rod into the well-type electric furnace for tempering heat treatment after air cooling;

[0065] (2) Tempering treatment: heat in a furnace at 620°C±10°C for 4-5 hours, then air cool. The mechanical properties are as follows;

[0066] Tensile strength: above 870Mpa

[0067] Yield strength: above 590Mpa

[0068] Elongation: 1313.213.9 (for 3 test bars)

[0069] Hardness: 283HB

[0070](3) Conclusion:

[0071] The performance is acceptable.

example 3

[0073] Special alloy steel, composed of the following chemical composition (mass percentage, %): C0.070; Si 0.86; Mn 0.91; P 0.018; S 0.006; Cr 12.75; Ni2.1; 0.03, the balance is Fe.

[0074] Put the casting test rod with the above chemical composition into the box-type electric furnace for heat treatment:

[0075] (1) Normalizing treatment: heat in the furnace (electric furnace) at 1080°C±10°C, keep it warm for 2-3 hours, and then put the test rod into the well-type electric furnace for heat treatment after air cooling;

[0076] (2) Quenching treatment: heat in a furnace at 650°C±10°C for 4-5 hours, quench into oil and cool to room temperature.

[0077] (3) Tempering treatment: heat in a furnace at 280°C±10°C for 4-5 hours, then air cool.

[0078] The mechanical properties are as follows;

[0079] Tensile strength: above 840Mpa

[0080] Yield strength: above 560Mpa

[0081] Elongation: 14 14.2 13.1 (make 3 test bars)

[0082] Hardness: 276HB

[0083] (4 Conclusion:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com