Processing technology of static iron core of electromagnetic valve

A processing technology and static iron core technology, which is applied in the field of electromagnetic valve static iron core processing technology, can solve the problems of large material loss, low work efficiency, and large damage to the magnetic properties of products, so as to reduce the coercive force, improve the magnetic properties, The effect of grain uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

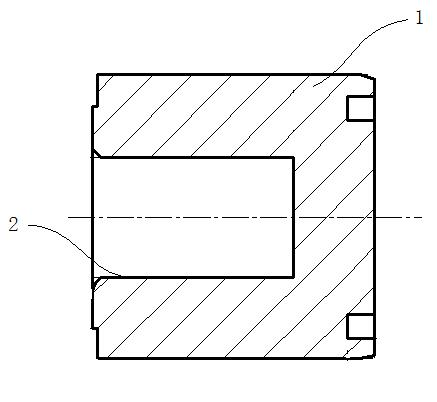

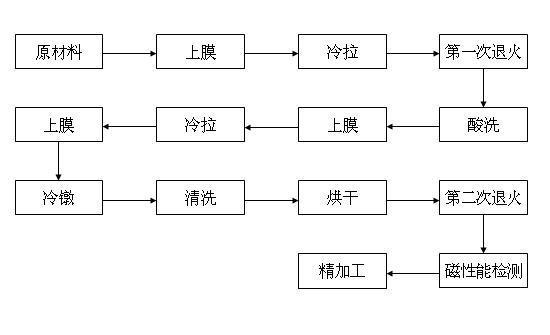

[0031] Example: A machining process for a solenoid valve static iron core, such as figure 2 As shown, the parts structure of the static iron core is as follows figure 2 Shown. The static iron core 1 has a cylindrical cap shape, one end of which is provided with an end hole 2 and the other end is provided with a ring groove.

[0032] The static iron core in this example is a ferrite material with a diameter of 10mm, and the processing technology is as follows:

[0033] a. The raw material is soaked in the film solution for more than 30 minutes and the film is applied, and the diameter is 9.85±0.02mm in the first cold drawing;

[0034] b. The material is first annealed after cold drawing. Keep the furnace temperature at 810±10°C for 4 hours. After the furnace is cooled to 450°C, open the furnace door to cool to room temperature and leave the furnace, and fill with nitrogen as protective gas during annealing;

[0035] c. The material is soaked in the film solution for more than 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com