Preparation method of high-fusion-welding-resistance copper-chromium fine-grain composite contact

A composite contact, fusion welding technology, applied in the direction of improving energy efficiency, high-voltage air circuit breaker, process efficiency, etc. and other problems, to achieve the effect of improving electrical and thermal conductivity, improving electrical conductivity and hardness, and eliminating mechanical processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

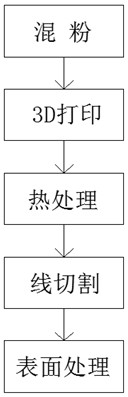

[0043] Such as figure 1 Shown, a kind of preparation method of high anti-welding copper-chromium fine-grain composite contact comprises the following steps:

[0044] S1: mixed powder

[0045] Proportion Cu powder, Cr powder and Te powder according to the weight requirements, among which Cr: 10%, Te: 0.2%, Cu: the balance, and the CuCrTe mixed powder after weighing is ball milled and mixed under the protection of argon. , the particle size mesh of the CuCrTe mixed powder is 200 meshes, what the ball milling medium uses are the copper balls for grinding, the weight ratio of the CuCrTe mixed powder and the copper balls for grinding is 1:1, the mixing time is 5 h, and the ball milled mixed powder is obtained CuCrTe mixed powder; CuCr alloy powder is prepared at the same time, wherein Cr: 0.5%, Cu: balance;

[0046] S2: 3D printing

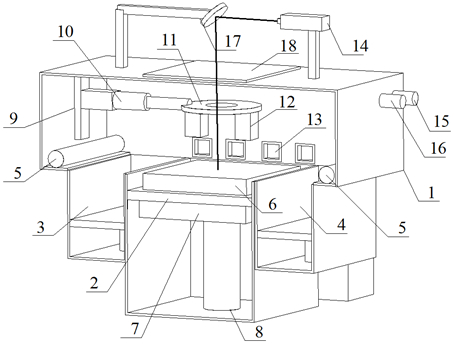

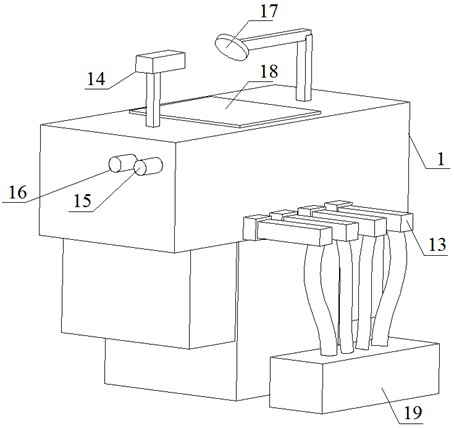

[0047] S2-1: Put the CuCr alloy powder obtained in step S1 into the first powder tank 3 of the 3D printing device 1, and put the CuCrTe mixed powder ...

Embodiment 2

[0059] This embodiment is basically the same as Embodiment 1, the difference is:

[0060] S1 mixed powder: mix Cu powder, Cr powder, and Te powder according to the weight requirements, of which Cr: 20%, Te: 0.4%, Cu: the balance, and weigh the CuCrTe mixed powder under the protection of argon Carry out ball milling powder mixing, the particle size mesh number of CuCrTe mixed powder is 200 orders, what the ball milling medium uses is the copper ball for grinding, the weight ratio of CuCrTe mixed powder and the copper ball for grinding is 1:1, and the powder mixing time is 5 h, Obtain CuCrTe mixed powder after ball milling; and prepare CuCr alloy powder, wherein Cr: 0.8%, Cu: balance.

Embodiment 3

[0062] This embodiment is basically the same as Embodiment 1, the difference is:

[0063] S1 Mixed powder: Proportion Cu powder, Cr powder and Te powder according to the weight requirements, of which Cr: 30%, Te: 0.6%, Cu: the balance, and weigh the CuCrTe mixed powder under the protection of argon Carry out ball milling powder mixing, the particle size mesh number of CuCrTe mixed powder is 200 orders, what the ball milling medium uses is the copper ball for grinding, the weight ratio of CuCrTe mixed powder and the copper ball for grinding is 1:1, and the powder mixing time is 5 h, Obtain CuCrTe mixed powder after ball milling; and prepare CuCr alloy powder, wherein Cr: 1.0%, Cu: balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com