Hollow forging method of nuclear power main pipeline

A main pipe, hollow technology, applied in the field of forging, can solve the problems of high manufacturing cost and long processing time, and achieve the effects of reducing machining, high utilization rate of raw materials, and shortening manufacturing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

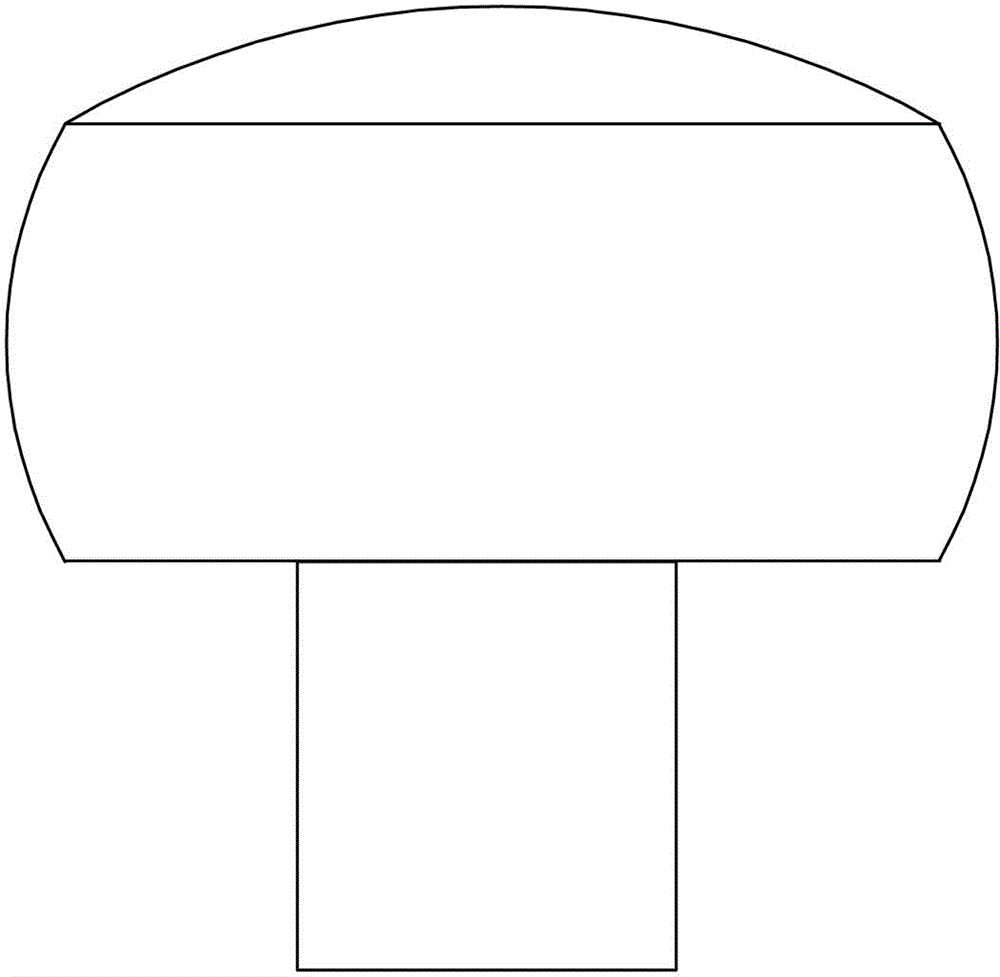

[0022] The first forging: heating the steel ingot to 1250°C, keeping it warm for a certain period of time, and upsetting to figure 1 shape, return to the oven for reheating;

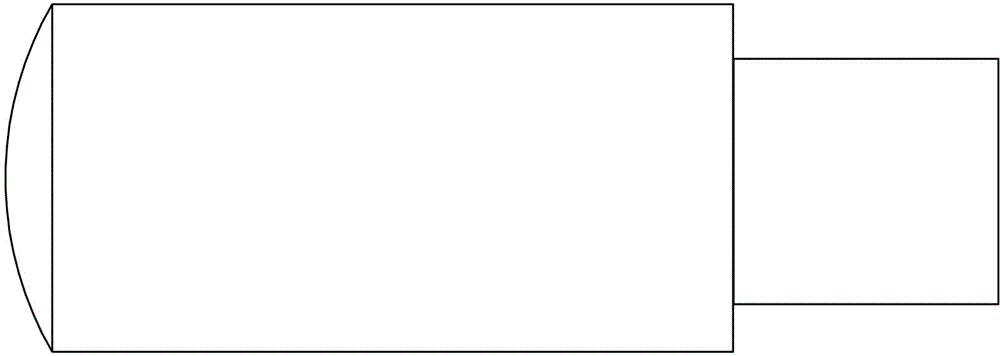

[0023] The second forging: heat the above-mentioned forging to 1240°C, keep it warm, and stretch it to figure 2 shape, return to the oven for reheating;

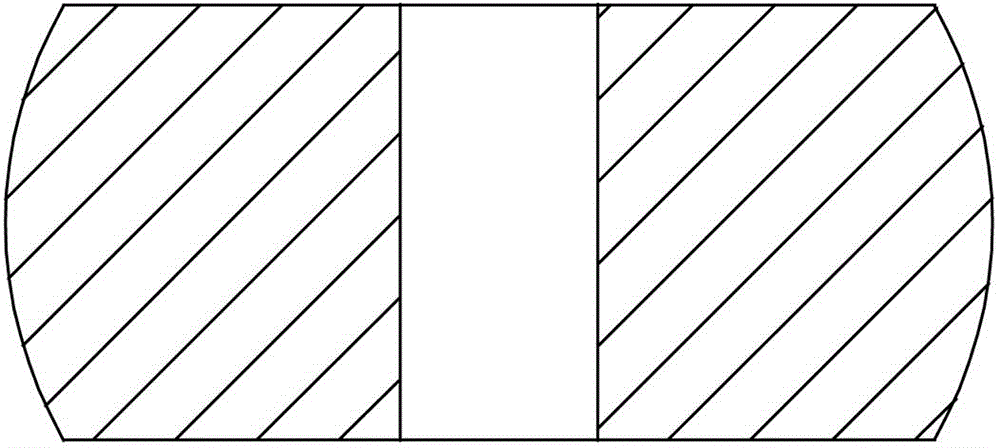

[0024] The third forging: heat the above forging to 1220°C, keep warm, upset and punch to image 3 shape, return to the oven for reheating;

[0025] The fourth forging: heating the above forging to 1200°C, keeping it warm, reaming and pulling out the mandrel to Figure 4 Shape, cut shoulders, pull out the mandrel and grow out of the ring belt boss, return to the furnace for reheating;

[0026] Fifth forging: heat the above forging to 1200°C, keep warm, and pull out the mandrel to Figure 5 shape, pipe wall thickness t 0 =2t f , t f The wall thickness of the final shape hollow forging is returned to the furnace for reheating;

[0027] The sixt...

Embodiment 2

[0029] The first forging: heating the steel ingot to 1240°C, keeping it warm for a certain period of time, and upsetting to figure 1 shape, return to the oven for reheating;

[0030] The second forging: heat the above-mentioned forging to 1240°C, keep it warm, and stretch it to figure 2 shape, return to the oven for reheating;

[0031] The third forging: heat the above forging to 1220°C, keep warm, upset and punch to image 3 shape, return to the oven for reheating;

[0032] The fourth forging: heat the above-mentioned forging to 1220°C, keep it warm, ream the hole and pull out the mandrel to Figure 4 Shape, cut shoulders, pull out the mandrel and grow out of the ring belt boss, return to the furnace for reheating;

[0033] The fifth forging: heat the above forging to 1220°C, keep warm, and pull out the mandrel to Figure 5 shape, pipe wall thickness t 0 =1.2t f , t f The wall thickness of the final hollow forging is returned to the furnace for reheating;

[0034] T...

Embodiment 3

[0036] The first forging: heating the steel ingot to 1220°C, keeping it warm for a certain period of time, and upsetting to figure 1 shape, return to the oven for reheating;

[0037] The second forging: heat the above-mentioned forging to 1220°C, keep it warm, and stretch it to figure 2 shape, return to the oven for reheating;

[0038] The third forging: heat the above forging to 1220°C, keep warm, upset and punch to image 3 shape, return to the oven for reheating;

[0039] The fourth forging: heat the above-mentioned forging to 1220°C, keep it warm, ream the hole and pull out the mandrel to Figure 4 Shape, cut shoulders, pull out the mandrel and grow out of the ring belt boss, return to the furnace for reheating;

[0040] The fifth forging: heat the above forging to 1180°C, keep it warm, and pull out the mandrel to Figure 5 shape, pipe wall thickness t 0 =1.6t f , t f The wall thickness of the final shape hollow forging is returned to the furnace for reheating;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com