Patents

Literature

56results about How to "Guaranteed Grain Size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

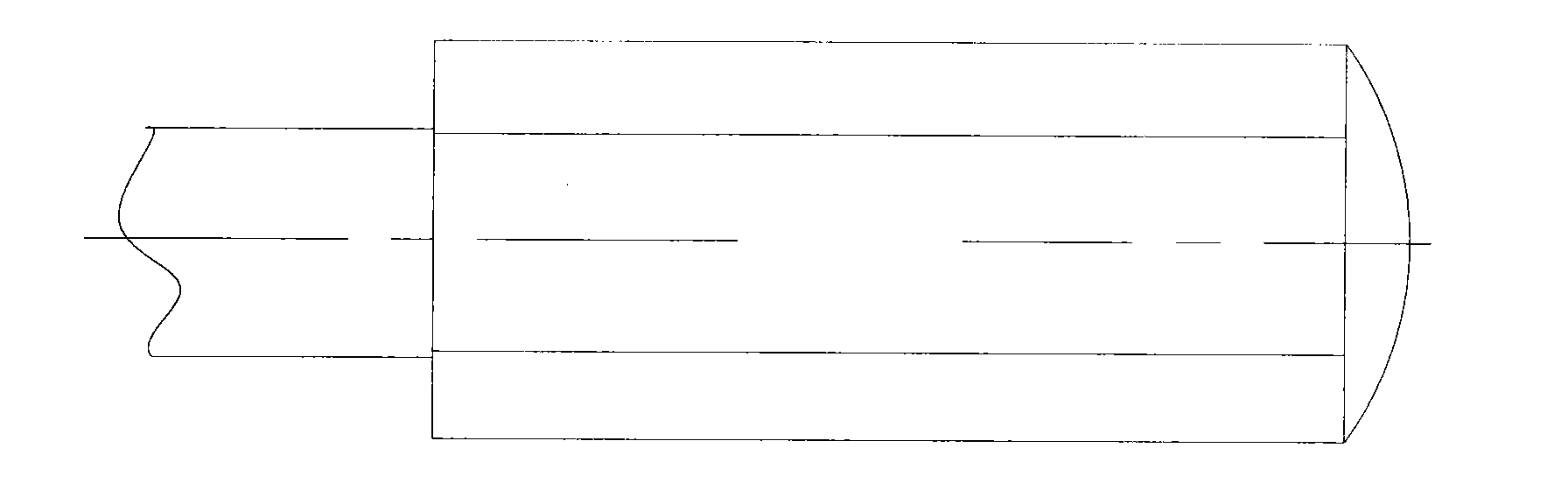

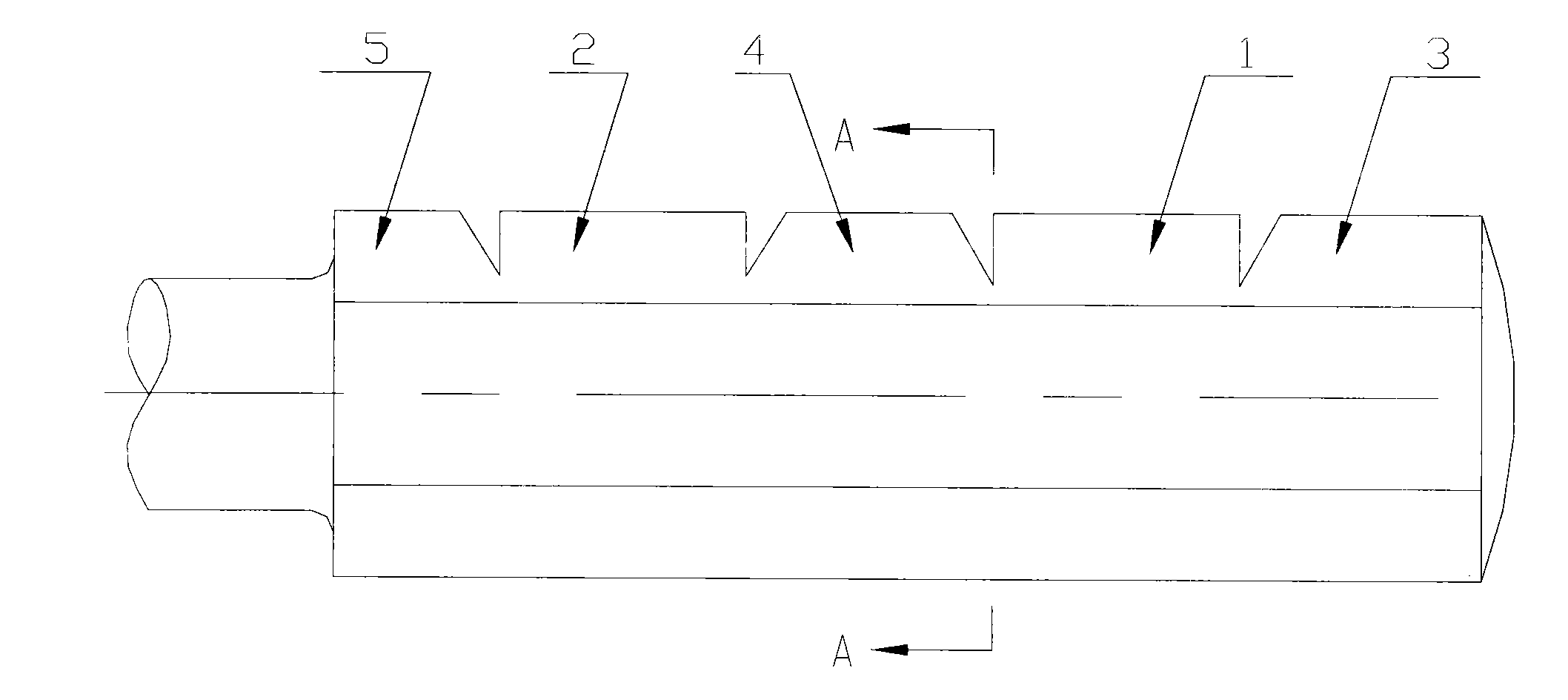

Forging molding method for million kilowatt nuclear power main pipe

InactiveCN101670416AReduce weightGuaranteed Grain SizeEngine componentsOther workshop equipmentNuclear powerIngot

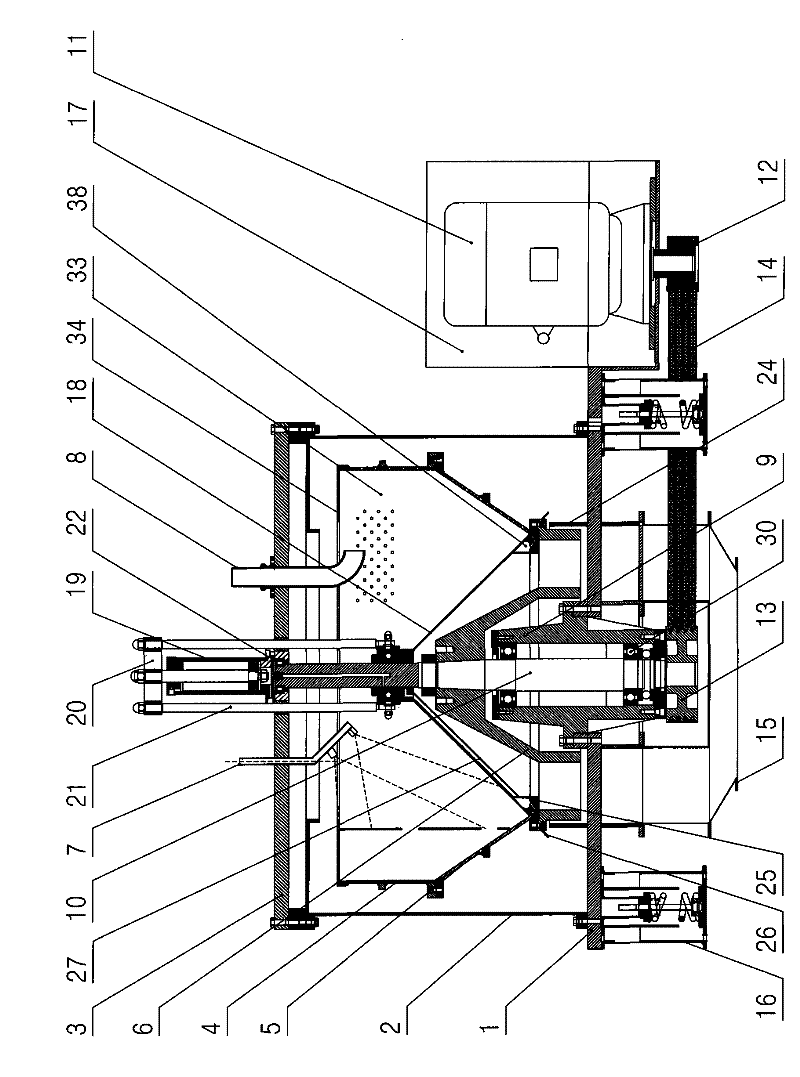

The invention discloses a forging molding method for a million kilowatt nuclear power main pipe. The forging process of the method comprises the following steps of a, upsetting; b, stretching; c, single-side marking; d, stretching at two ends and a middle part respectively; and e, final fire stretching. The method adopts the single-side marking technology in the forging process so that a forge piece has two-side asymmetrical deformation in the forging process and then a required eccentric shaft neck can be formed. The forge piece formed by the method can be forged on the main pipe in the forging process to form two joint pipes between which an angle of 45 degrees is arranged, so the processing quality of products can be ensured and the weight of the forge piece can be lightened. Because the size of the forge piece has deformation quantity in the final fire forging process, the grain size of austenitic stainless steel can be ensured. The forging molding method for manufacturing the million kilowatt nuclear power main pipe has the advantages of light required steel ingot weight, low cost and small processing allowance.

Owner:SHANGHAI HEAVY MACHINERY PLANT

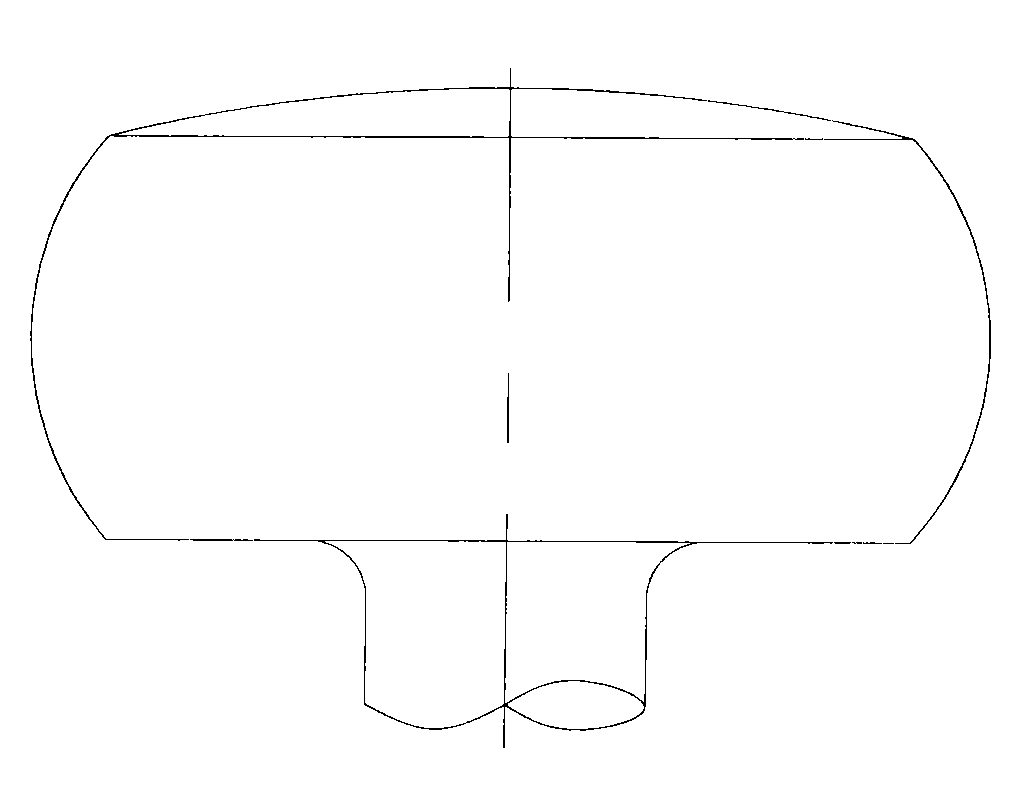

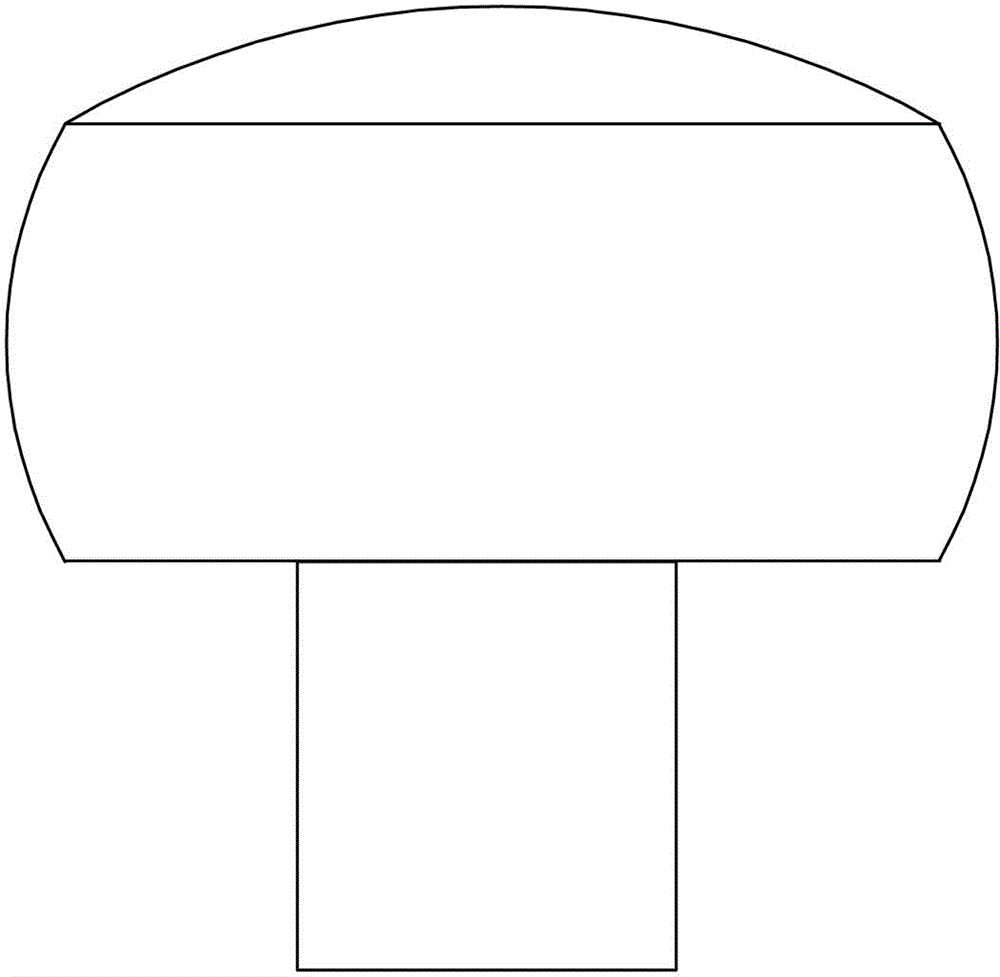

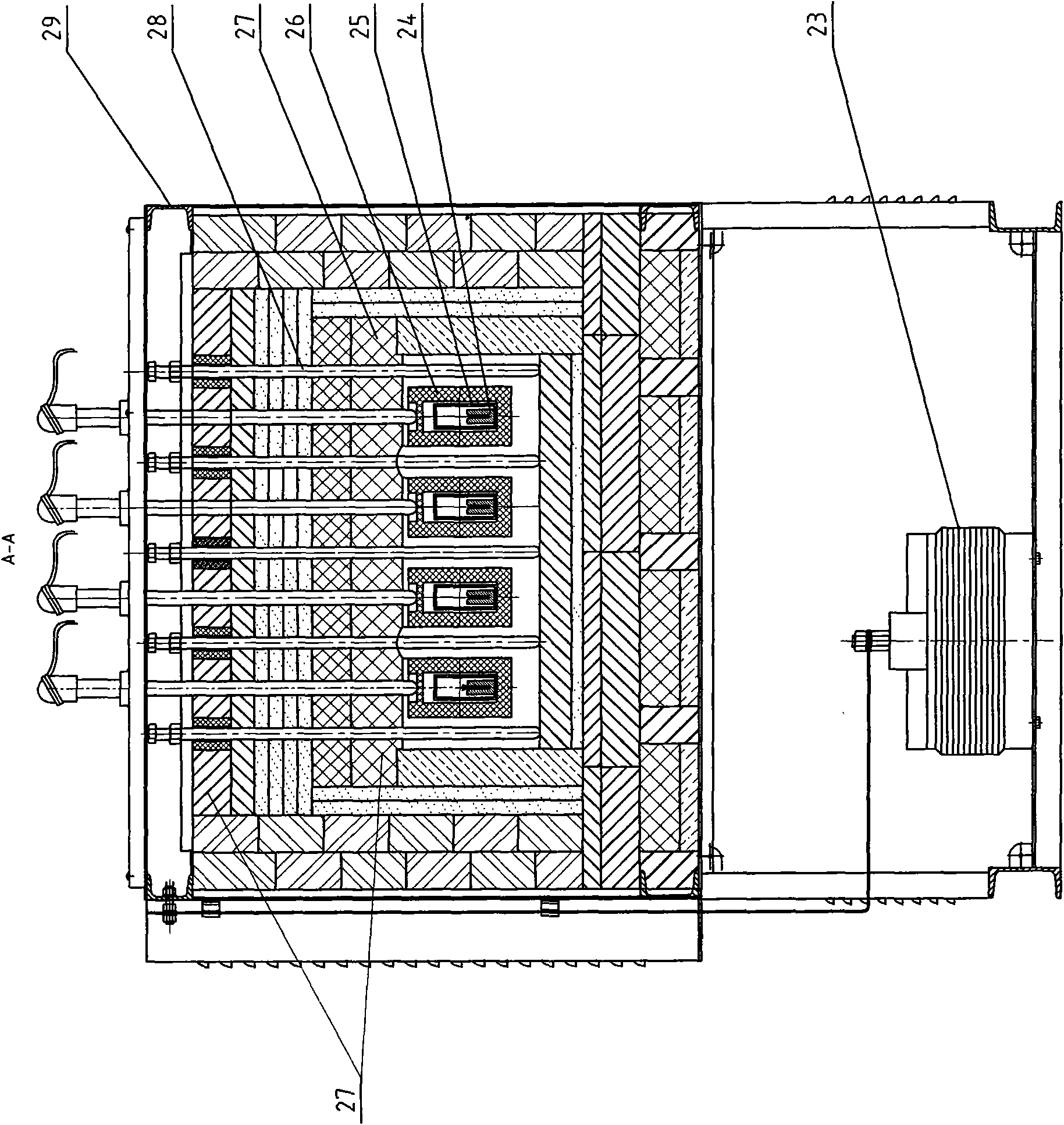

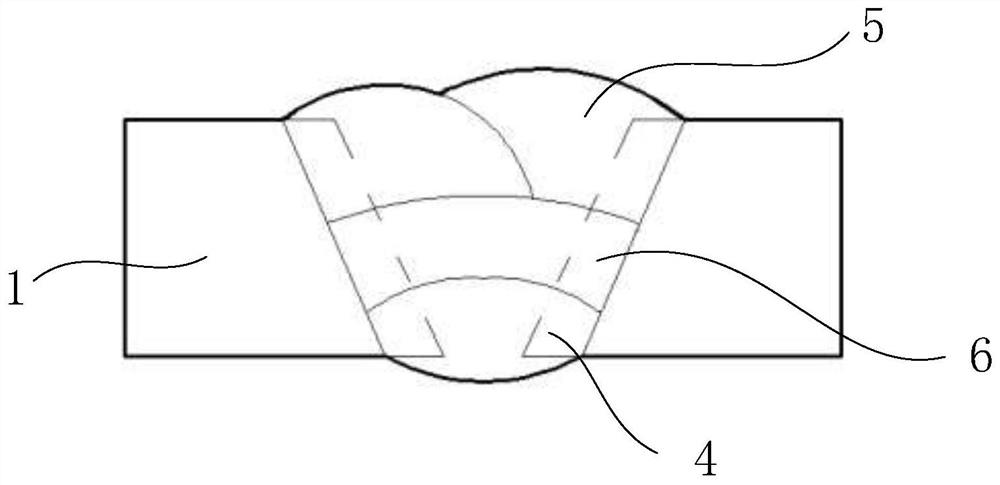

Hollow forging method of nuclear power main pipeline

ActiveCN103143659AMeet technical requirementsIncrease profitMetal-working apparatusPunchingNuclear power

The invention relates to a hollow forging method of a nuclear power main pipeline, and belongs to the technical field of forging. According to the forging method, hollow forging is carried out in a free forging manner, a boss part is formed in an annular belt manner, and the deformation is reserved before a core rod is drawn out to be in a final shape. The forging method comprises the following processing steps of: (1) upsetting; (2) drawing out; (3) upsetting and punching; (4) chambering and drawing out the core rod; (5) carrying out shoulder feeding; (6) carrying out shoulder splitting; (6) drawing out the core rod: heating a hollow forged piece obtained in the step (5) till 1000-1050 DEG C, and drawing out till a final shape is formed; heating multiple times till 1000-1050 DEG C if the shape cannot be formed after one heating number, and drawing out till the final shape is formed. The nuclear power main pipeline with the boss is forged in the manners of punching, chambering and drawing out the core rod, the boss part is forged into an annular manner, and the shape of the nozzle of the boss is ensured. The forged piece is directly forged into a hollow pipeline, so that the subsequent machining is reduced, and the manufacturing period is shortened. The technical requirement of the third generation forging main pipeline can be met, and the utilization ratio of raw material is high.

Owner:TONGYU HEAVY IND

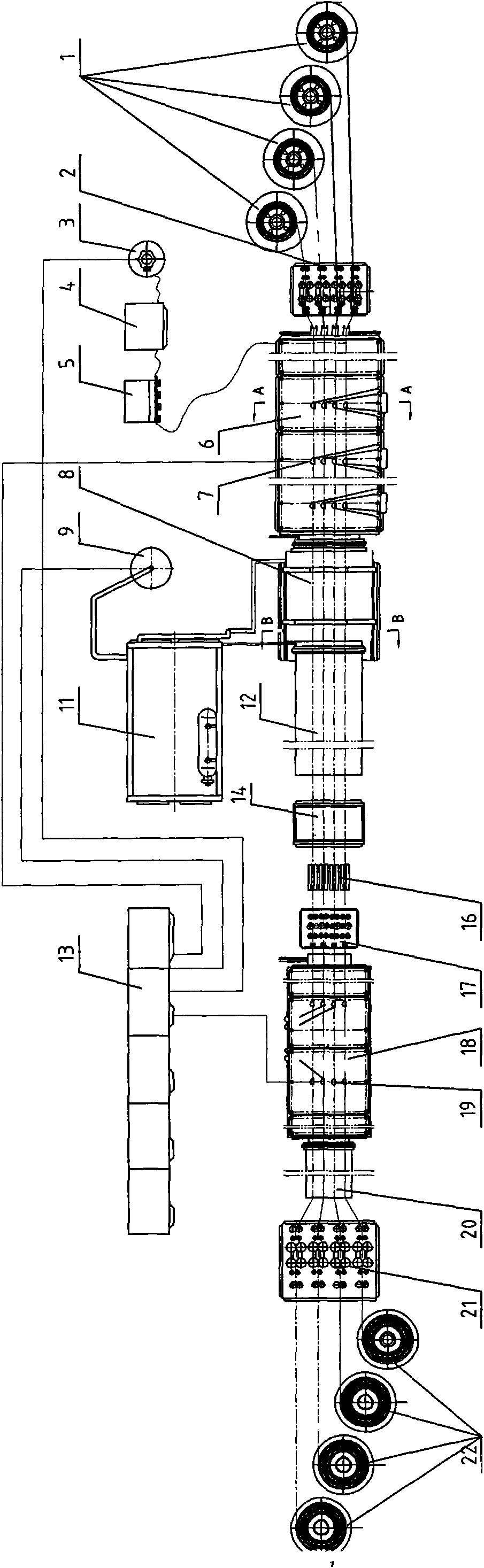

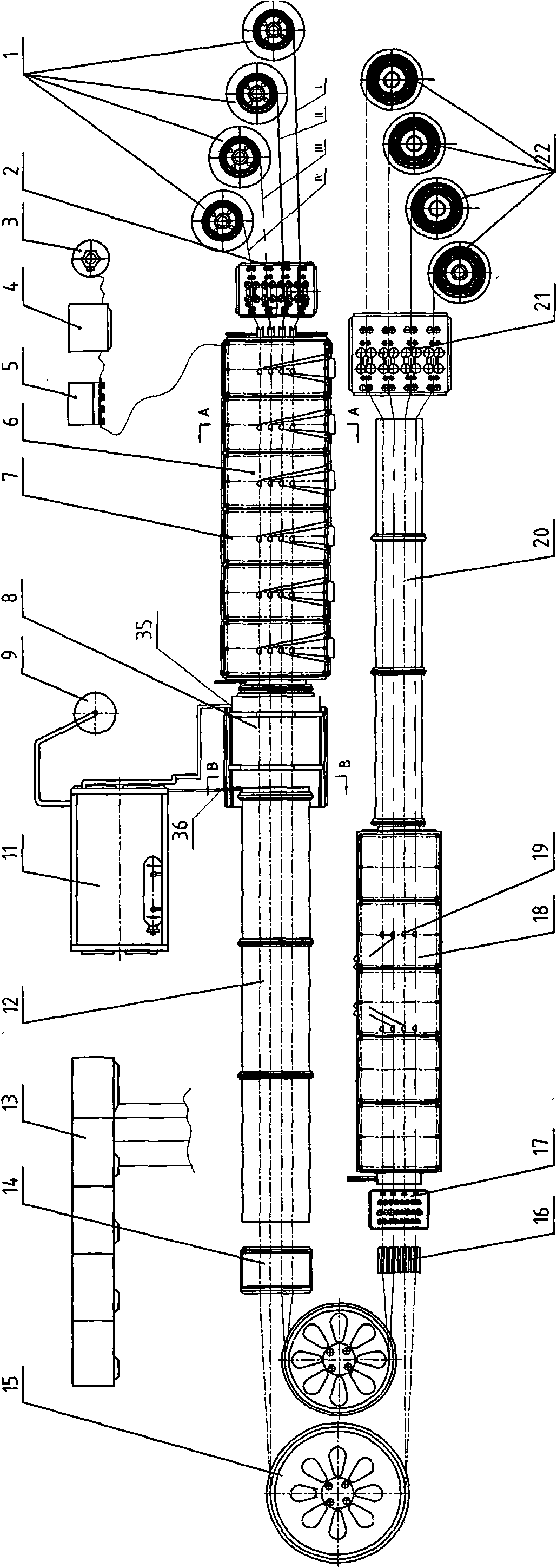

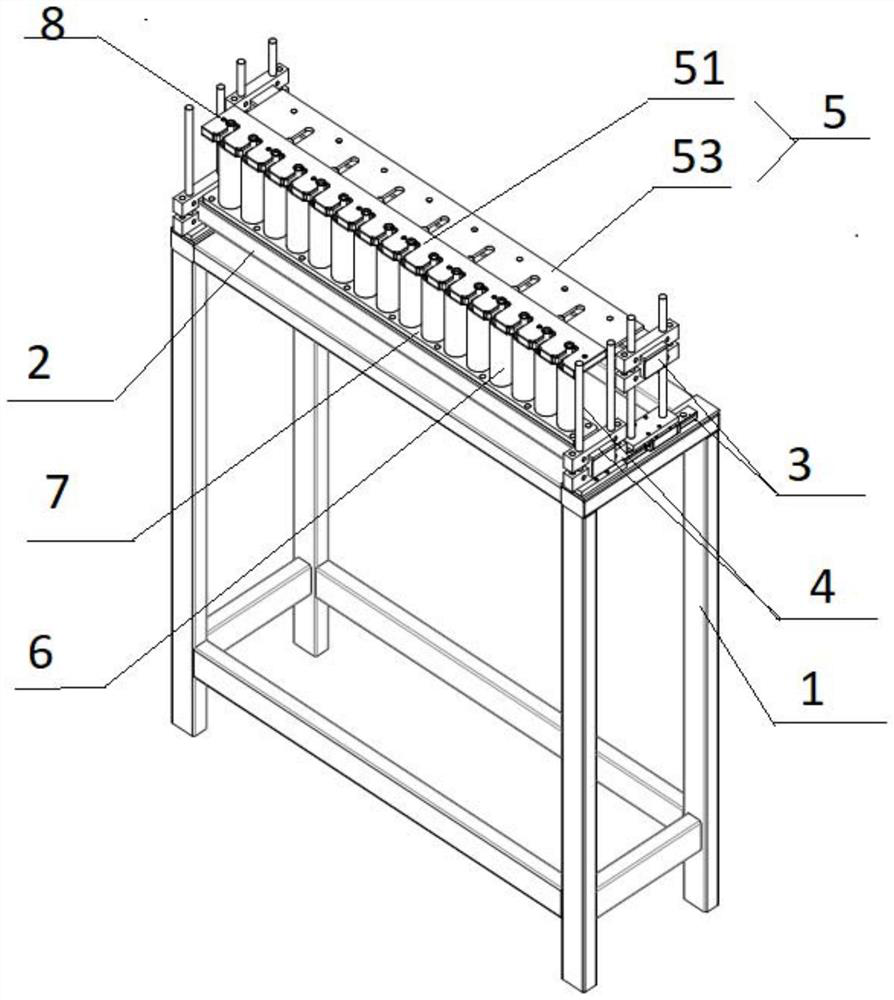

Full-automatic production line for synchronous furnace multi-band bright quenching of bimetal band saw blades

InactiveCN101654732AReduce in quantityReduce labor intensityFurnace typesHeat treatment process controlProduction lineMulti band

The invention discloses a full-automatic production line for synchronous furnace multi-band bright quenching of bimetal band saw blades and relates to the full-automatic production line for quenchingthe metal band saw blades. The full-automatic production line can solve the problem that the prior quenching device of the bimetal band saw blades can not realize the synchronous furnace multi-band quenching technology, thereby causing low production efficiency of the quenching technology of the metal band saw blades and waste of a large amount of energy. N heating units are arranged in a casing,a thermal insulating layer is arranged between the N heating units and the casing, and a plurality of silicon-molybdenum bar heating elements sequentially penetrate the casing and the thermal insulating layer and evenly distributed and arranged between each two heating units and between the thermal insulating layer and the heating units; and a channel of the metal band saw blades is formed in themiddle part of a main body of a chiller, and a plurality of side channels for arranging refrigerant flow channels are respectively arranged on two sides of the channel of the metal band saw blades. The full-automatic production line can realize the bright continuous quenching of a plurality of bimetal band saw blades and monometal band saw blades in the same quenching production line. The full-automatic production line has the advantages of high productivity, low comprehensive energy consumption, reasonable device structure and the like.

Owner:曹玉贵

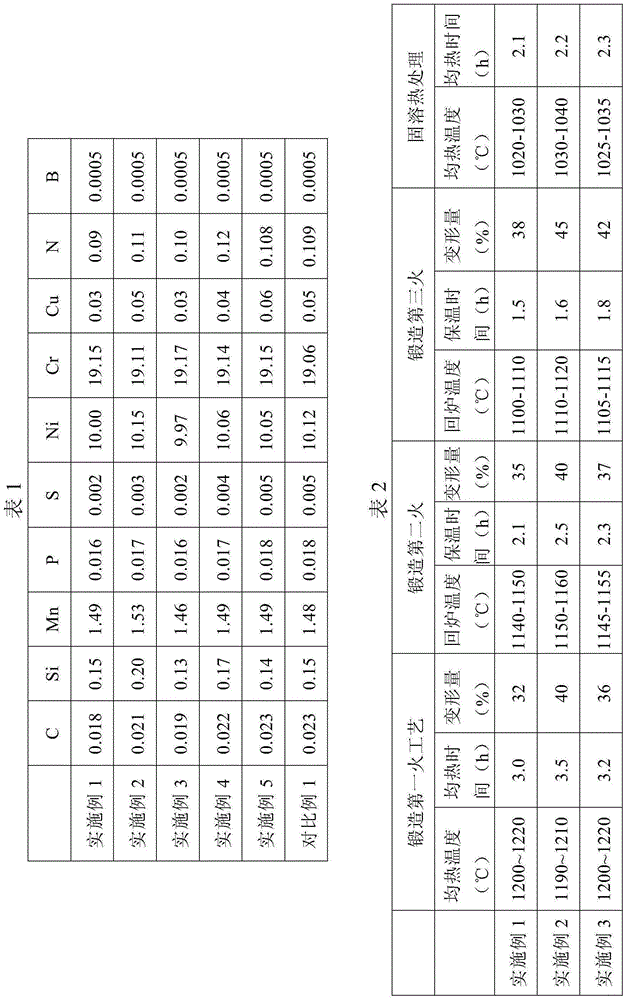

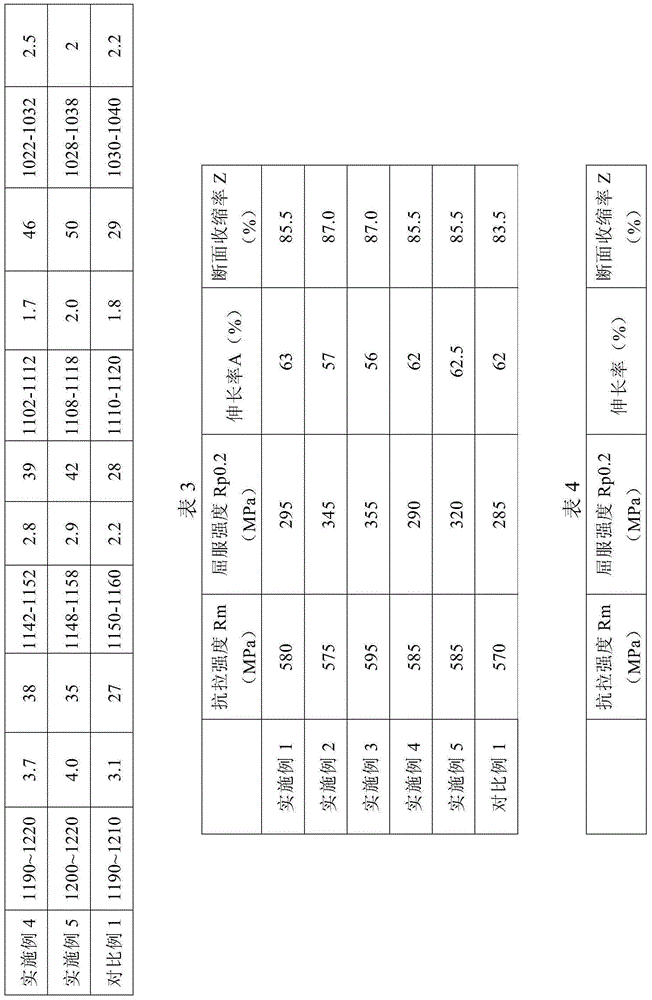

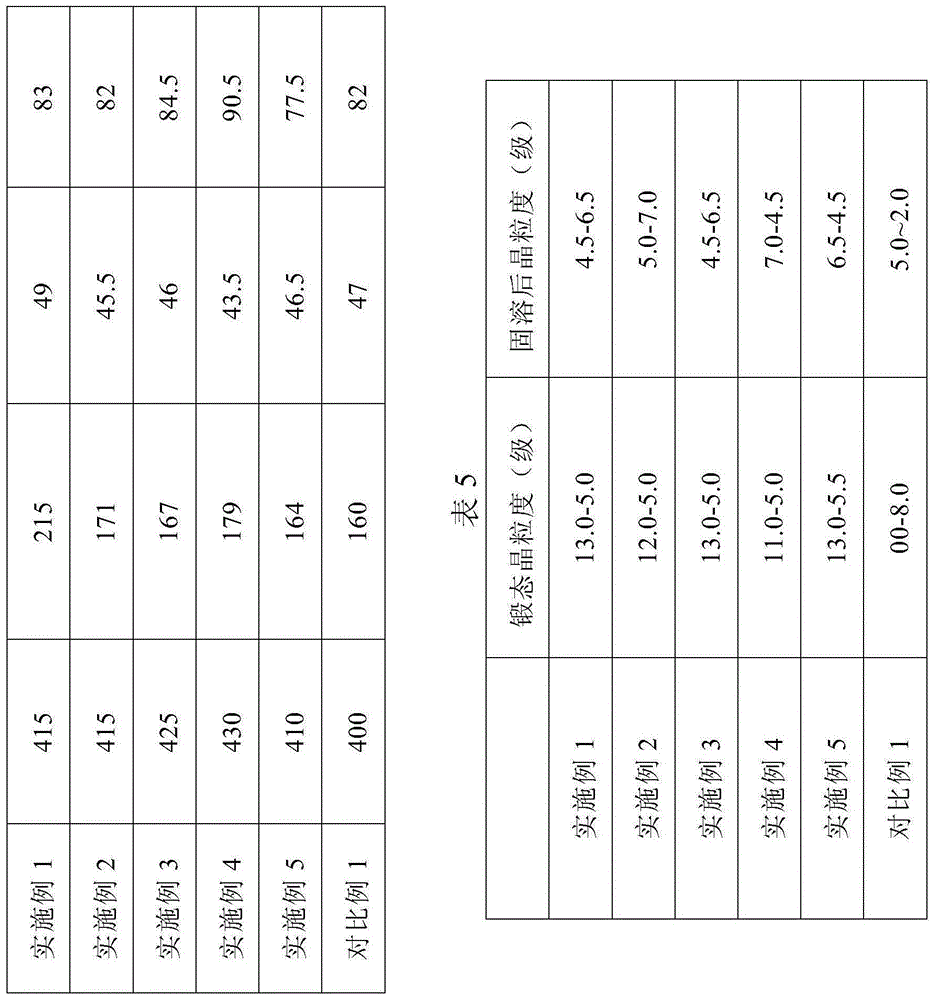

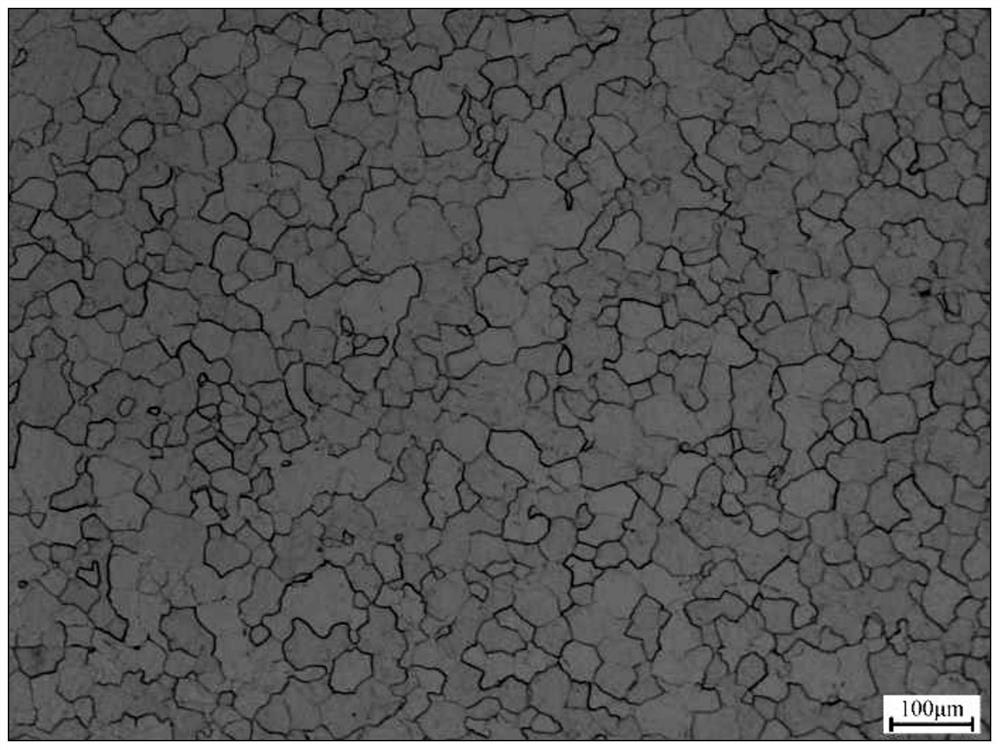

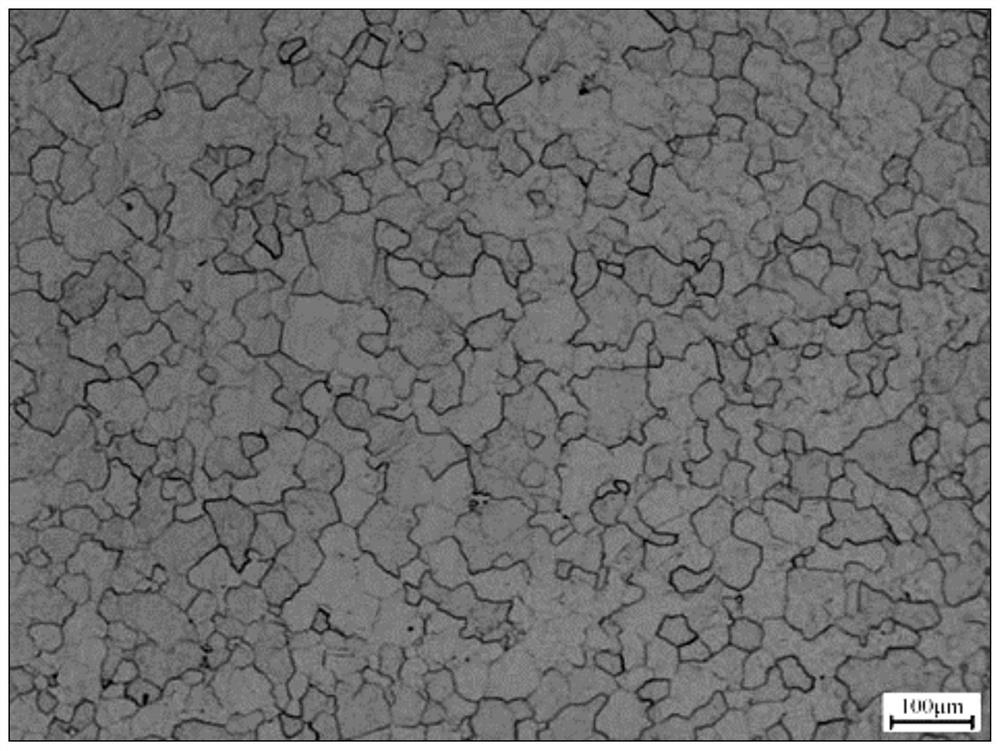

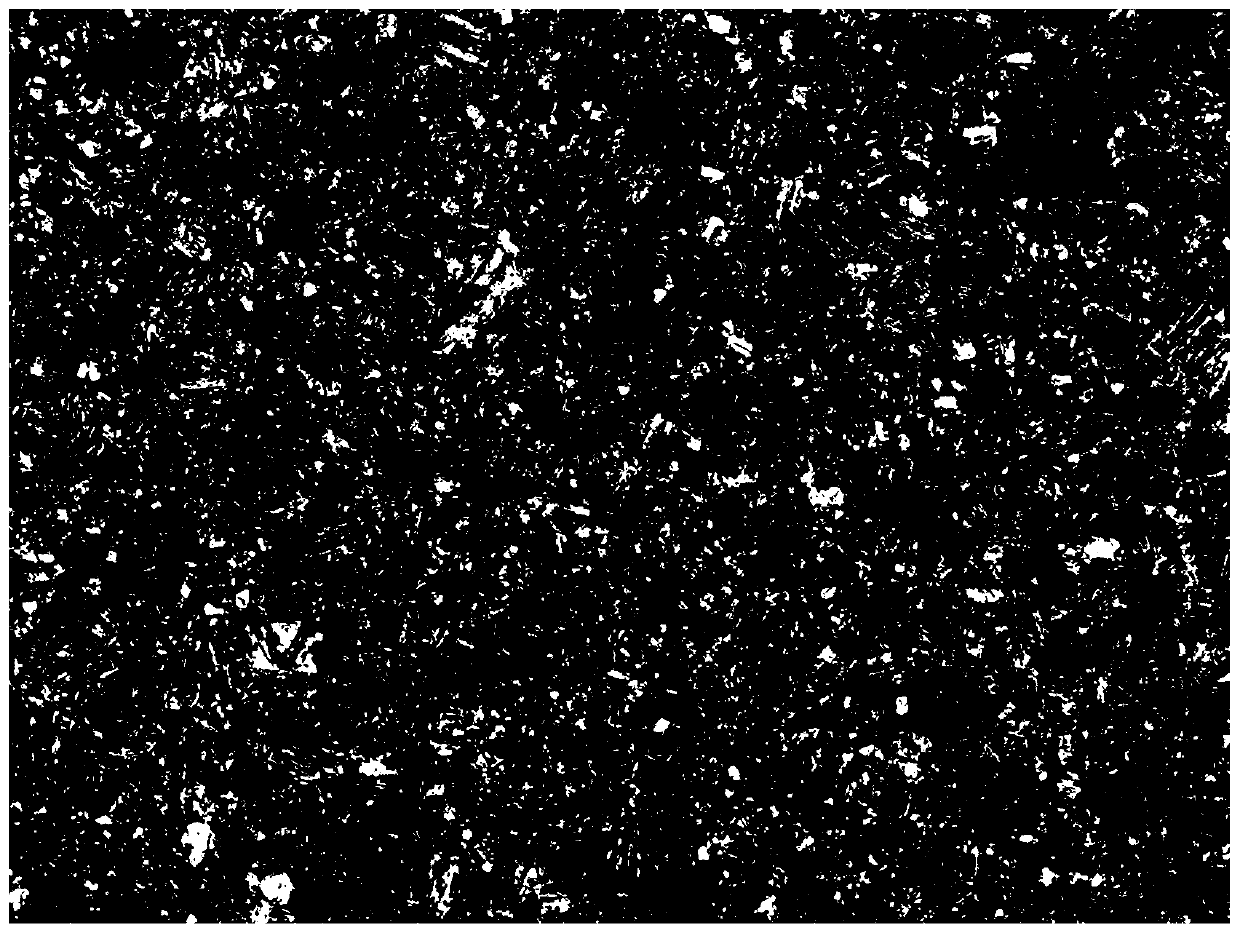

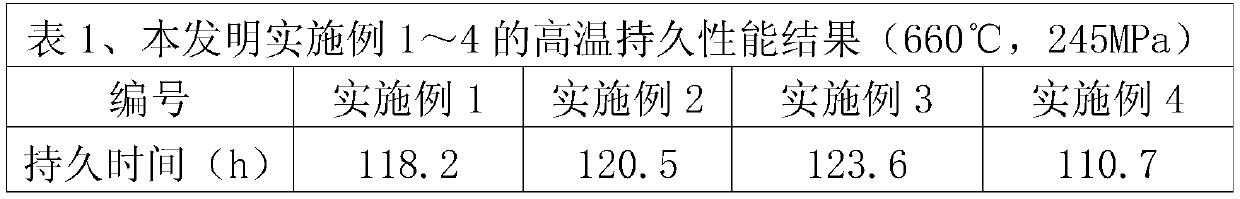

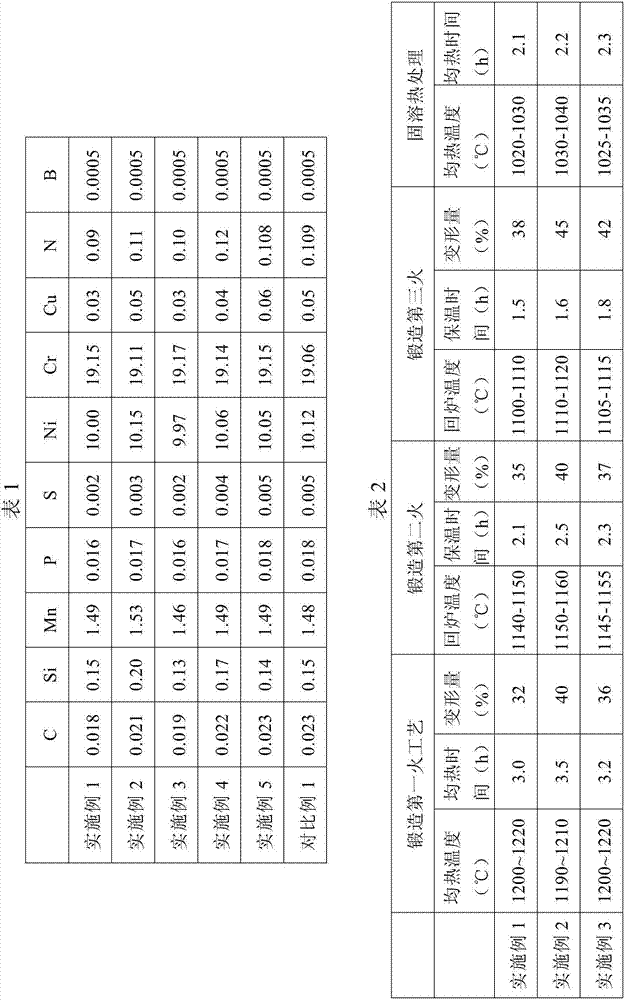

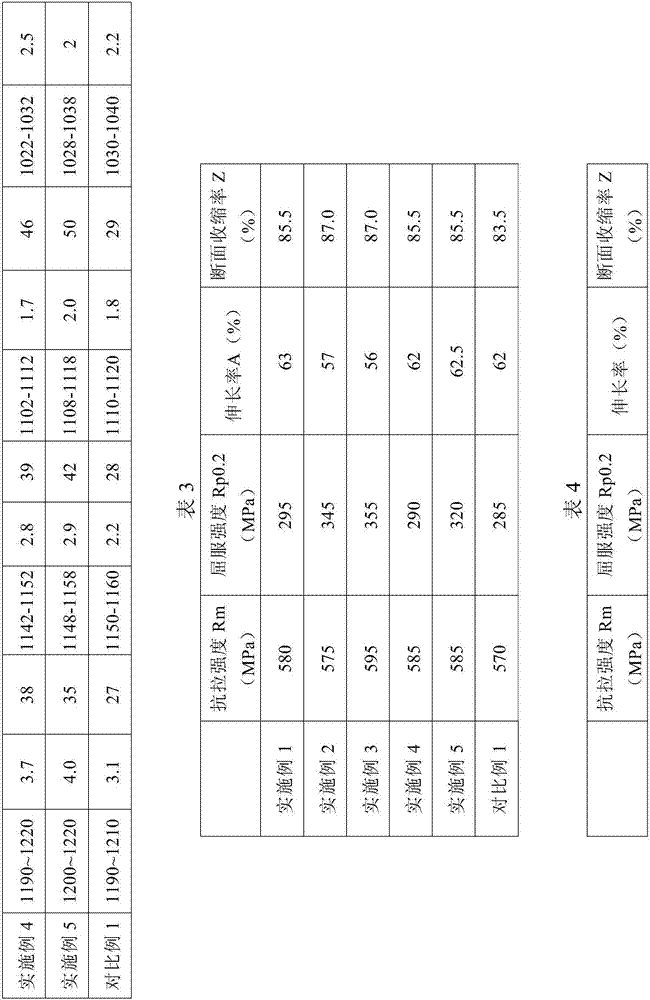

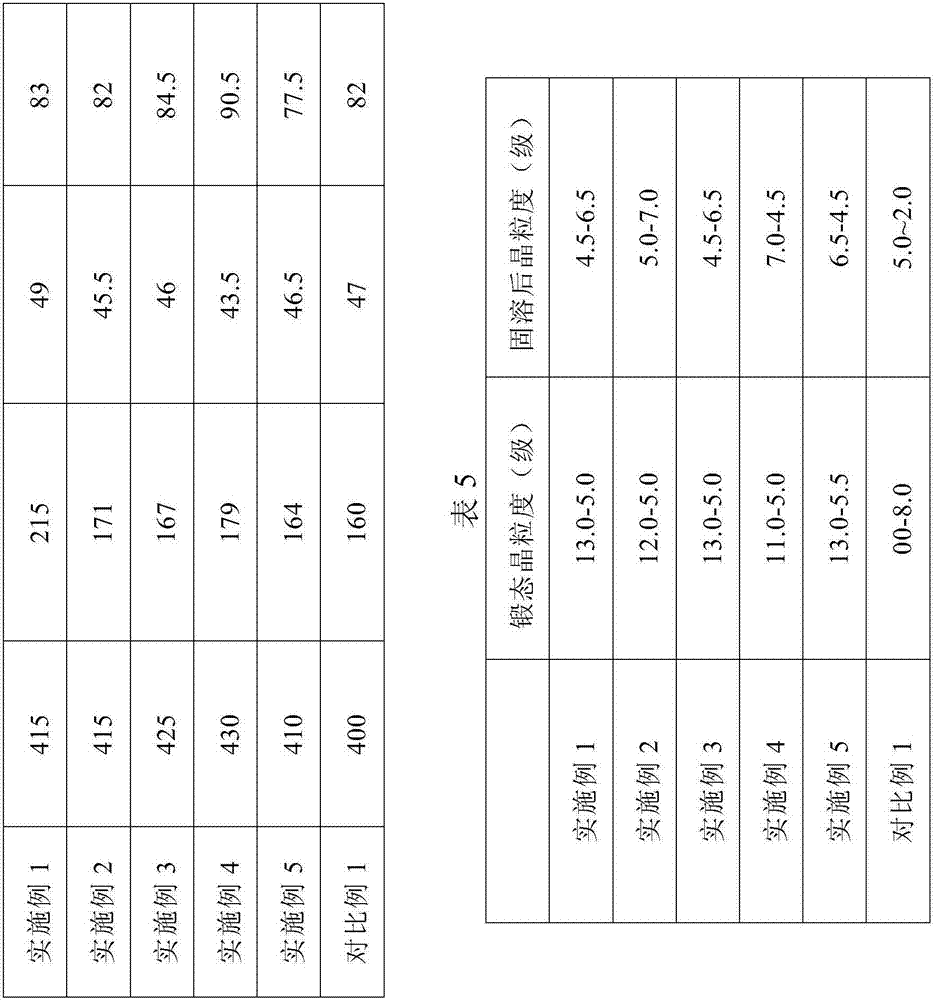

Manufacturing method of nitrogen-controlled austenitic stainless steel large forging piece

ActiveCN105088094AImprove performanceSolve the mixed crystal problemHeating/cooling devicesSlagNitrogen

A manufacturing method of a nitrogen-controlled austenitic stainless steel large forging piece comprises the following steps of electric furnace primary melting, AOD refining, LF refining, die casting pouring, electroslag remelting and forging. In LF refining, double deoxidizer with the mass ratio of Al to Si being 7:3 is adopted. In electroslag remelting, a quaternary slag system with the ratio of CaF2:Al2O3:CaO:MgO equal to 72:18:5:5 is selected as electroslag protection slag. In forging, a multi-time heading pulling manner is adopted, the first fire temperature, the second fire temperature, the third fire temperature and the deformation are all controlled to be larger than 30%, it is ensured that a large amount of recrystallization is generated in the post-forging cooling process, the grain sizes are all not thicker by 4 levels after products are in solid solution, and the problem of mixed crystals of the large forging piece is effectively solved; and the nitrogen-controlled austenitic stainless steel large forging piece has good comprehensive performance and can be kept with good performance under the condition of the temperature of 350 DEG C, and the using requirement of engineering structural pieces is met.

Owner:宝武特种冶金有限公司

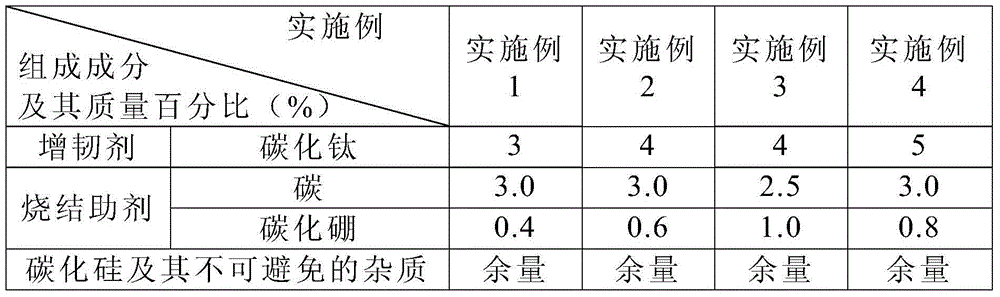

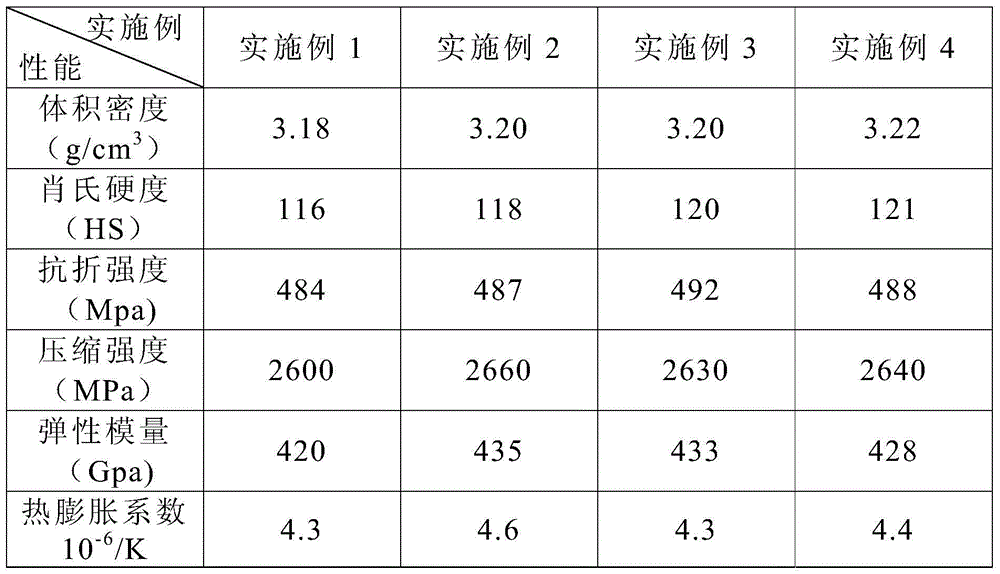

High-toughness silicon carbide ceramic and preparation method thereof

The invention relates to a high-toughness silicon carbide ceramic and a preparation method thereof. The high-toughness silicon carbide ceramic comprises 3-5% of a toughening agent titanium carbide, 1-4% of a sintering aid, and the balance silicon carbide and inevitable impurities, wherein the sintering aid comprises carbon and boron carbide according to a mass percentage ratio of 1:(0.6-8). The preparation method of the ceramic comprises the following steps: uniformly mixing silicon carbide with the toughening agent titanium carbide and the sintering aid comprising carbon and boron carbide, adding the obtained mixture into a ball mill, adding water-soluble resin and distilled water, carrying out ball milling, drying, adding the dried mixture into a steel mold, carrying out compression molding, sintering the molded mixture in a vacuum furnace, and carrying out surface grinding to prepare the high-toughness silicon carbide ceramic. The addition of the toughening agent titanium carbide into a silicon carbide matrix makes the fracture mode of the silicon carbide ceramic change from intergranular fracture to transgranular fracture, and improves energy required by the transgranular and intergranular fracture in order to enhance the flexural strength.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

Small-size LED copper strip production process

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

High strength steel bar for pre-stressed concrete and production technology thereof

ActiveCN104404380AImproved resistance to hydrogen-induced delayed fractureAvoid inhalationSpinningChemical composition

The invention discloses a high strength steel bar for pre-stressed concrete. The steel bar is composed of the following chemical components in percentage by weight: 0.20 to 0.25% of C, 1.50 to 1.85% of Si, 0.20 to 0.50% of Mn, 0.07 to 0.09% of Cr, 0.30 to 0.35% of Mo, 0.25 to 0.35% of V, 0.05 to 0.08% of Nb, 0.42 to 0.61% of Ti, 0.15 to 0.25% of Ni, 0.25 to 0.40% of Ca, not more than 0.025% of S, not more than 0.025% of P, not more than 0.20% of Cu, 0.15 to 0.30% of composite rare earth, and the balance being Fe. The invention further discloses a production technology of the steel bar. The production technology comprises the following steps: smelting to obtain a steel blank, rolling the steel blank, cooling the rolled steel blank, rolling the steel blank for a second time, carrying out a thermal treatment and a stabilizing treatment, performing a gas nitrogenation treatment, spinning, winding, bundling, and storing the bundles in a warehouse.

Owner:溧阳市万兴特种建材有限公司

Forming method of precise high-temperature alloy pipe with small caliber and thick wall for aviation

The invention discloses a forming method of a precise high-temperature alloy pipe with small caliber and thick wall for aviation. The forming method comprises the following steps: S1: cold rolling: carrying out multi-pass cold rolling on a qualified seamless tube to obtain a tube blank in transitional specification, wherein the outer diameter of the tube blank in the transitional specification is 1.14-1.17 times of that of a finished tube, the wall thickness of the tube blank is 0.97-0.985 times of that of the finished tube, and the dimensional deviation is controlled within a range of plus or minus 0.03mm; S2: manufacturing a pointed end: carrying out degreasing, heat treatment, acid cleaning, straightening and UT (ultrasonic) flaw detection on the tube blank with transitional specification sequentially, selecting the qualified tube blank obtained after UT flaw detection, and welding a pointed end with conicity at the end part of the qualified tube blank; S3: empty sinking: drawing the tube blank by the pointed end and deforming the tube blank under the extrusion of an outer mold to obtain a finished tube. The forming method makes up the technical gap of domestically producing the precise high-temperature alloy pipe with small caliber and thick wall, and has important economic benefit on the research and the production of a domestic aero-engine.

Owner:宝武特冶航研科技有限公司

Low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and preparation method thereof

ActiveCN105648322AReduce contentGuaranteed timelinessHot-dipping/immersion processesChemical compositionNitrogen

The invention discloses a low-cost extra-deep-drawing-quality cold-rolled galvanized steel strip and a preparation method thereof. The steel strip is prepared from, by mass percent, 0.001% to 0.005% of C, 0.07% to 0.12% of Mn, not larger than 0.012% of S, not larger than 0.012% of P, not larger than 0.03% of Si, 0.010% to 0.060% of Als, not larger than 0.0040% of N, 0.0015% to 0.0030% of B and the balance Fe and inclusion within an allowed range. According to the galvanized steel strip, the reasonable carbon content is controlled to reduce the content of free carbon in steel as much as possible; and meanwhile, a certain amount of boron is added to fix interstitial nitrogen and part of carbon, and therefore the timeliness of an extra-deep-drawing-quality galvanized product can be guaranteed. According to the galvanized steel strip, boron is used for fixing carbon atoms, so that the cost of an alloy material is greatly reduced, meanwhile, the heating temperature and soaking temperature of a galvanization procedure can be greatly reduced, and therefore production difficulty and energy consumption are effectively lowered.

Owner:唐山钢铁集团高强汽车板有限公司 +2

Method for preparing large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate

ActiveCN107185961AGuaranteed bonding strengthGuaranteed stretching effectRoll force/gap control deviceTemperature control deviceReduction ratioAlloy

The invention discloses a method for preparing a large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate. The method comprises the following steps that 1, a nickel-based alloy plate serving as a composite layer and a pipeline steel plate serving as a base layer are composited to prepare composite board blank through explosion welding; 2, a leveling treatment is carried out on the composite board blank, and then a heating treatment is carried out on the composite board blank; 3, a cooling treatment is carried out on the heated composite board blank; and 4, the composite board blank which is subjected to the cooling treatment is fed into an asynchronous rolling mill for asynchronous rolling to obtain the nickel-based alloy and pipeline steel composite plate, wherein the shearing strength of the nickel-based alloy and pipeline steel composite board is not less than 210 MPa, the total rolling reduction ratio of asymmetrical rolling is 50%-90%, and the different speed ratio of each pass of the asynchronous rolling mill is 1.05-1.30. According to the method for preparing the composite plate, the corrosion resistance of the nickel-based alloy plate serving as the composite layer is ensured, and the tensile property and the impact toughness of the pipeline steel plate serving as the base layer are ensured; and the bonding strength and other properties of the composite plate can meet the requirements specified in the NB / T47002.2 standard, and even the requirement for rolling force of the rolling mill is reduced.

Owner:XIAN TIANLI CLAD METAL MATERIALS

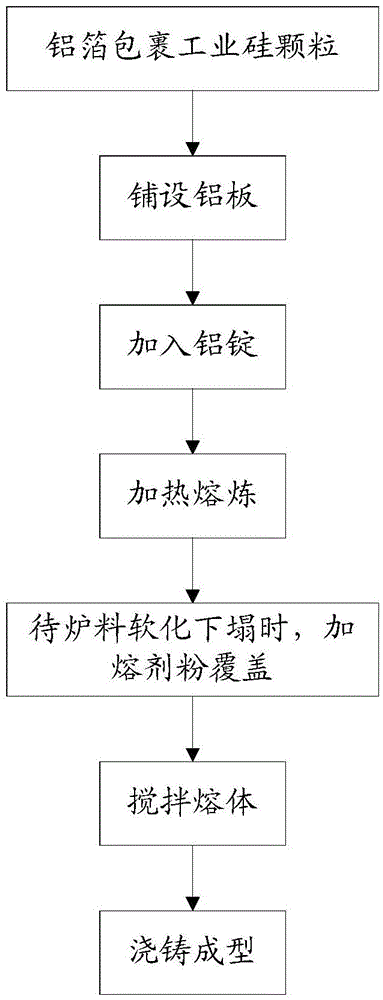

Preparation method for aluminum-silicon intermediate alloy

The invention discloses a preparation method for aluminum-silicon intermediate alloy. The preparation method comprises the steps that (1) industrial silicon particles are wrapped in aluminum foil and placed at the furnace bottom of a smelting furnace; (2) according to the matching ratio of the aluminum-silicon intermediate alloy, aluminum ingots are added into a furnace chamber of the smelting furnace and placed on the industrial silicon particles wrapped in the aluminum foil; (3) heating smelting is conducted, and when the furnace burden is softened and sinks, a layer of flux powder is scattered on the surface of molten liquid for covering; (4) after the furnace burden is molten completely, melt is stirred; and (5) after the melt is fully stirred, casting molding is conducted. Thus, it can be seen that in the scheme, the aluminum foil is used for wrapping the industrial silicon particles, with temperature increasing, the aluminum foil and the aluminum ingots begin to melt, and the industrial silicon particles are covered rapidly, thereby being protected against oxidation. In this way, a layer of silicon dioxide can be effectively prevented from forming on the surfaces of the industrial silicon particles, and the smelting temperature and the energy consumption are lowered. In addition, due to drop of the smelting temperature, aluminum-silicon intermediate alloy grains can be refined, and thus the grain size of follow-up casting ingots is ensured.

Owner:SOUTHWEST ALUMINUM GRP

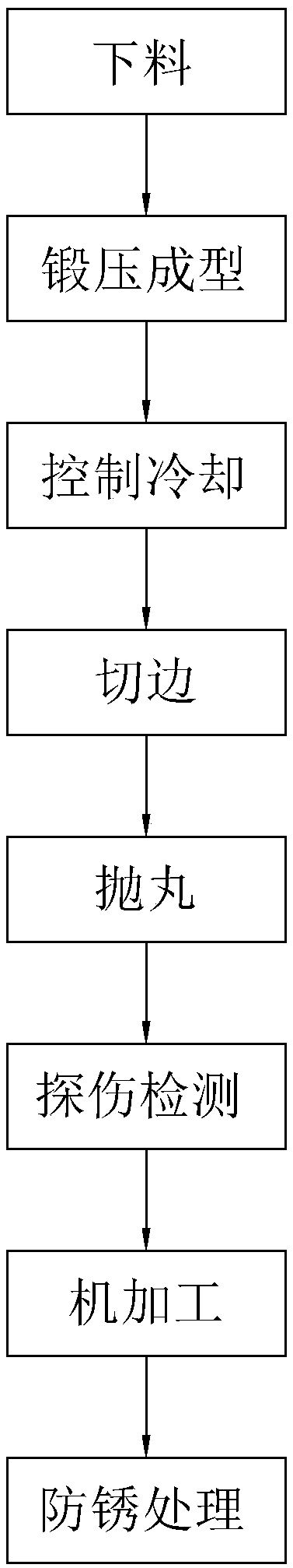

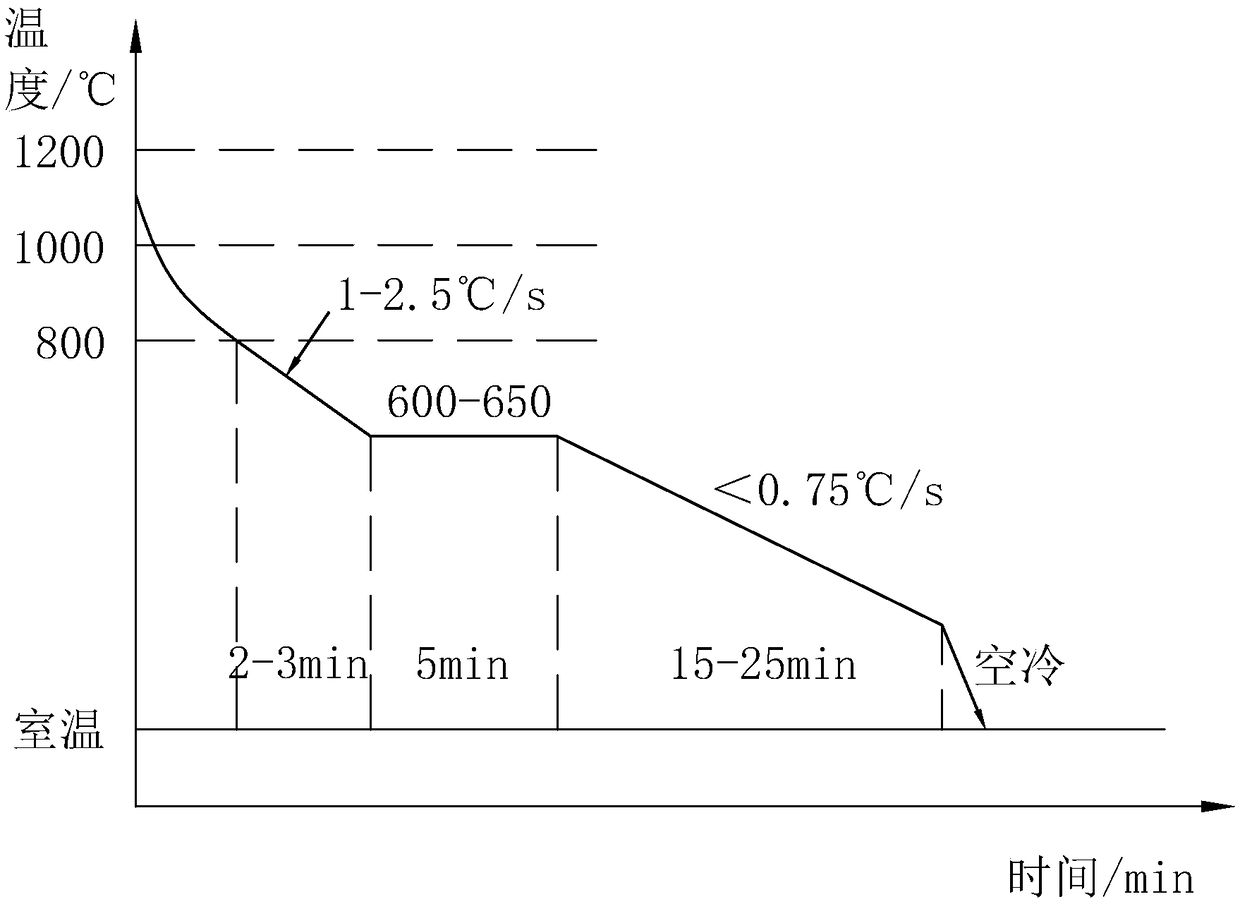

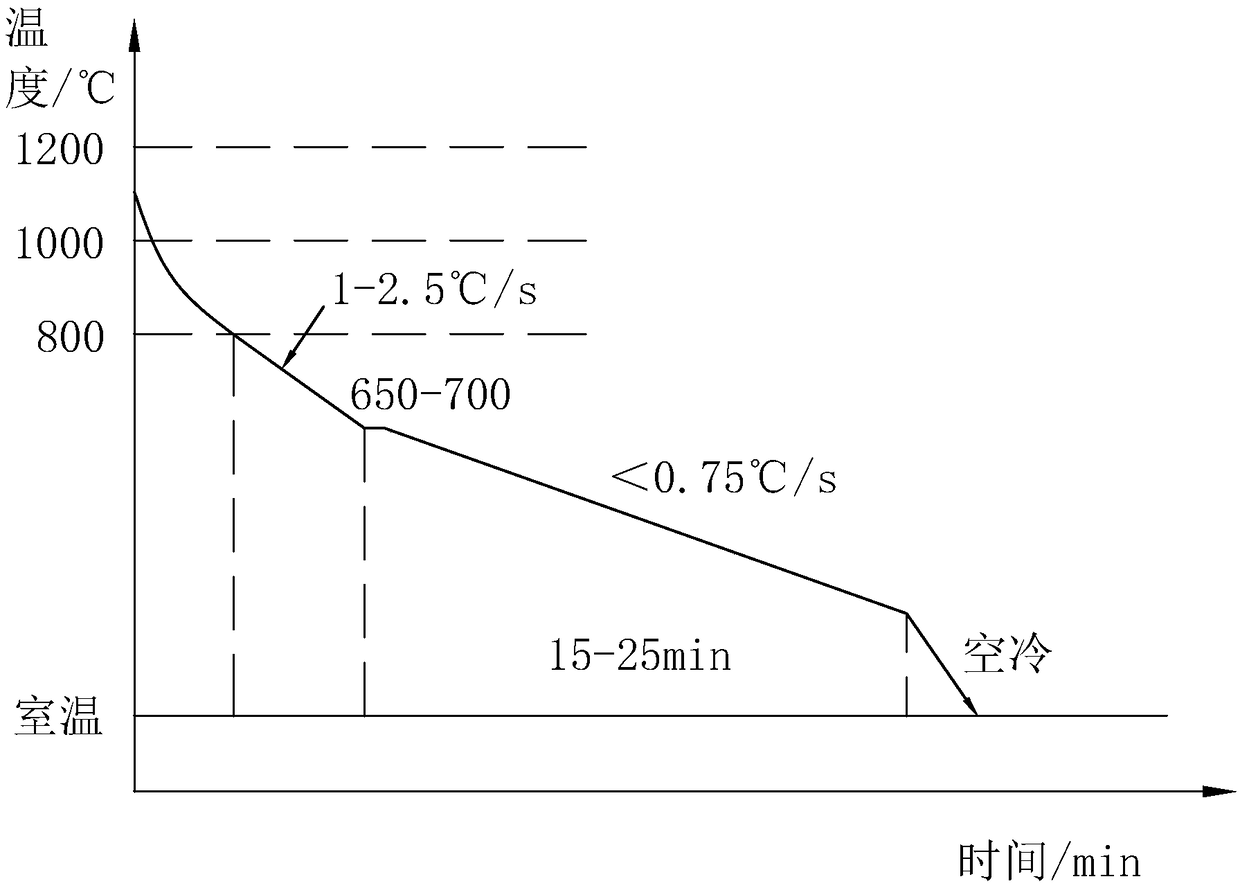

Processing technology for production of steel forgings

ActiveCN109266964ASufficient precipitationFully analyzeMetallic material coating processesRoom temperatureRoughcast

The invention discloses a processing technology for production of steel forgings, and relates to the technical field of heat treatment of metal. The processing technology is technically characterizedby comprising the following steps: (1) blanking of a material; (2) forging and forming: heating round steel to the temperature of 1080 to 1150 DEG C, forging and pressing in a mold to form a steel forging blank, and controlling the final deformation temperature to be 800 to 900 DEG C; (3) control on cooling: putting the steel forging blank in step (2) into cooling equipment, quickly cooling to thetemperature of 600 to 700 DEG C at the rate of 1 to 2.5 DEG C / S, slowly cooling for 5 to 25min at the rate less than 0.75 DEG C / S, and discharging out of a furnace; (4) cutting of edges: cutting an excessive material of the steel forging blank after heat treatment in step (3); (5) shot blasting. The processing technology has the advantages that the problems of waste of energy sources and low production efficiency due to cooling to room temperature and then heating for tempering after forging in the production process of a traditional steel forging are solved; the residual heat of the forgingis utilized, the cooling speed is controlled, and the heat treatment is performed, so that the energy source is saved, and the processing efficiency is improved.

Owner:QINGDAO TIANYING IND

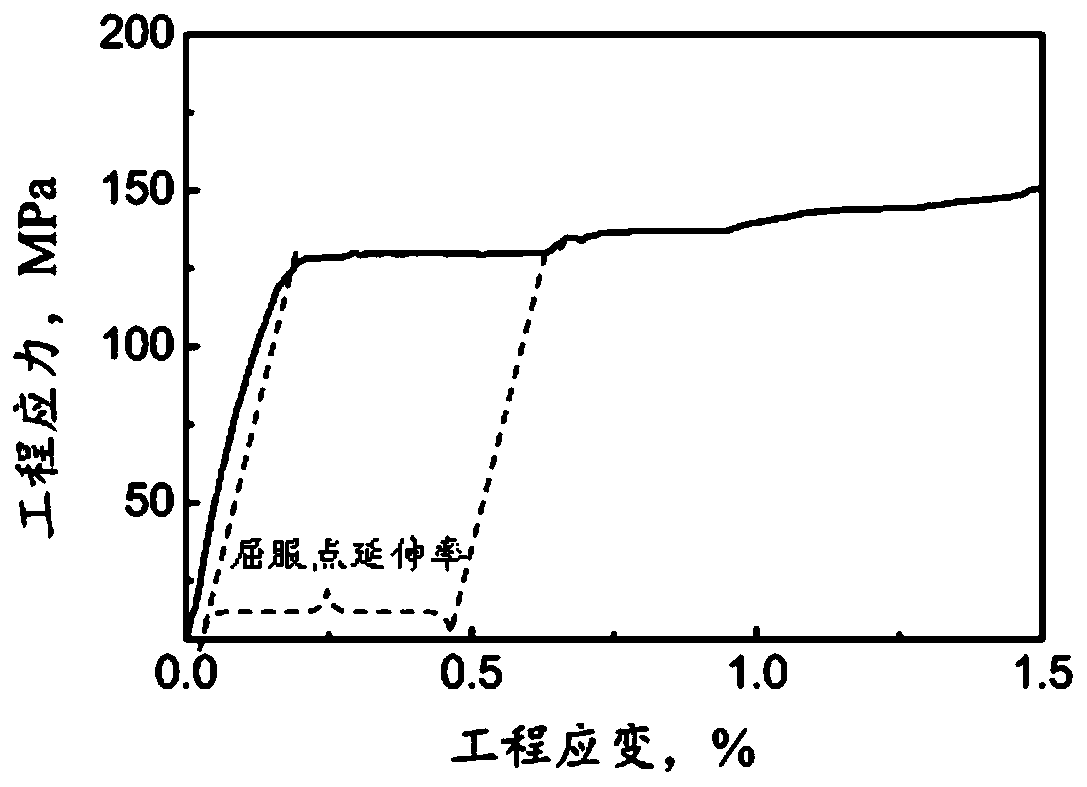

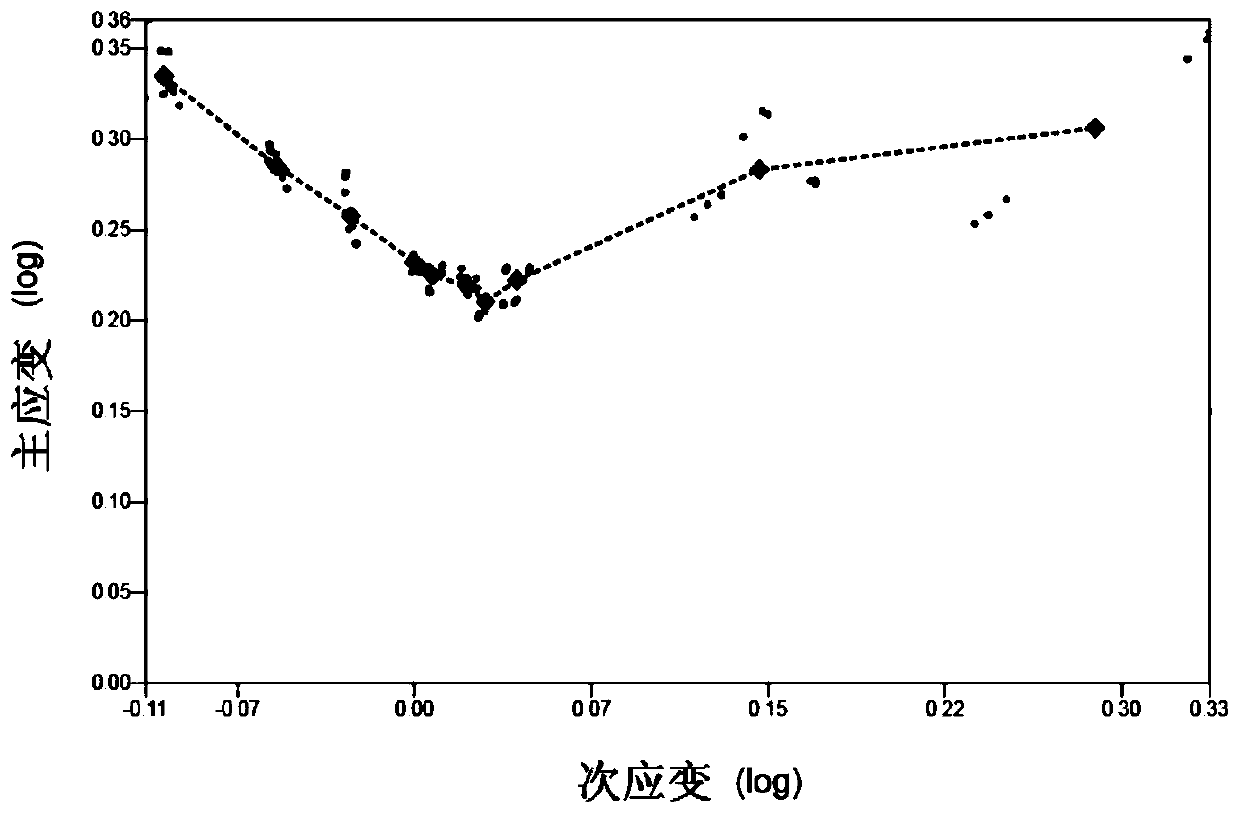

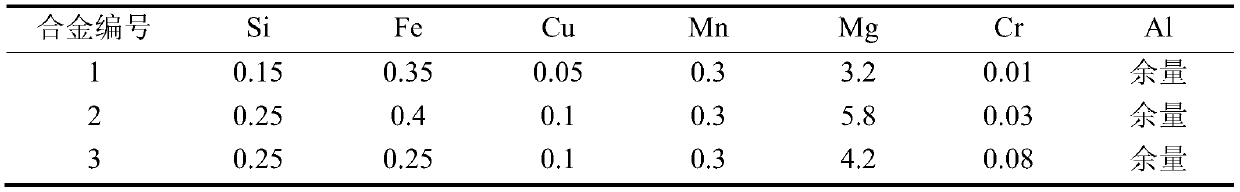

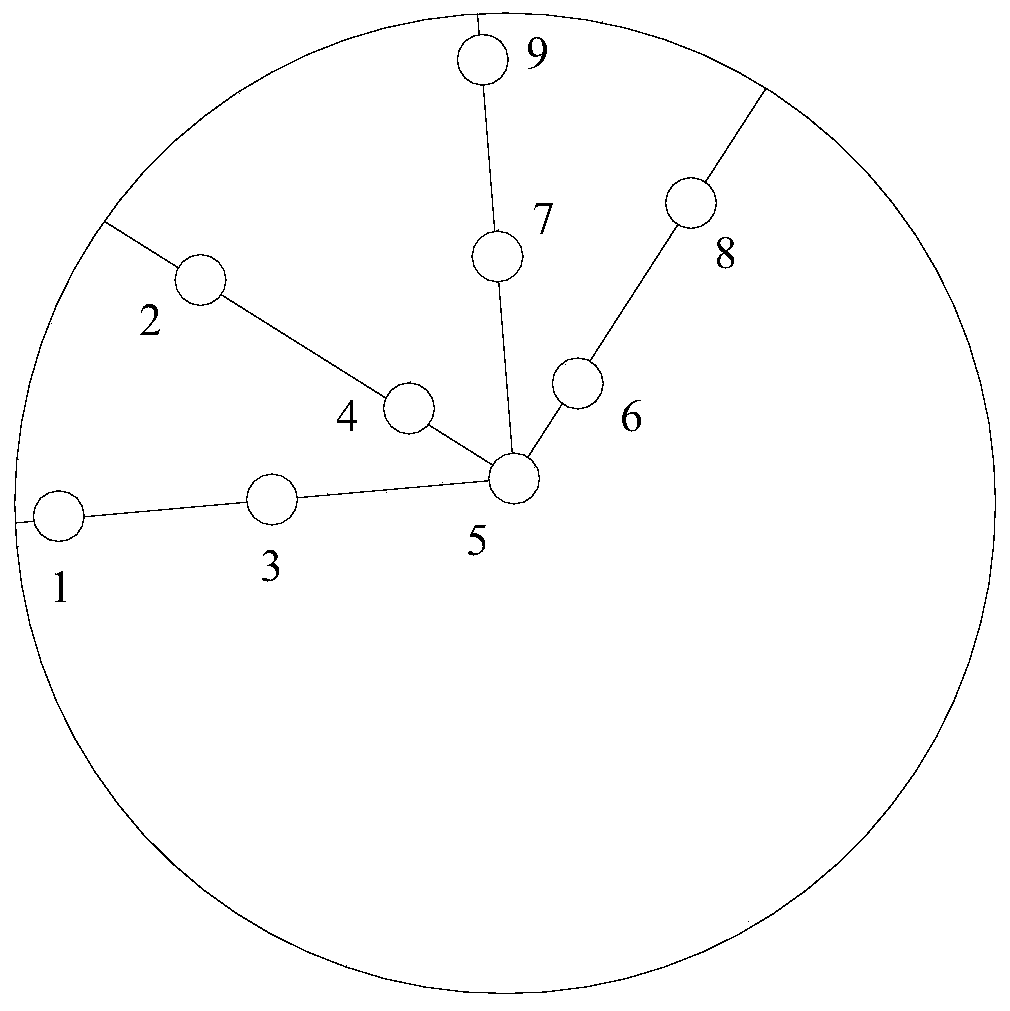

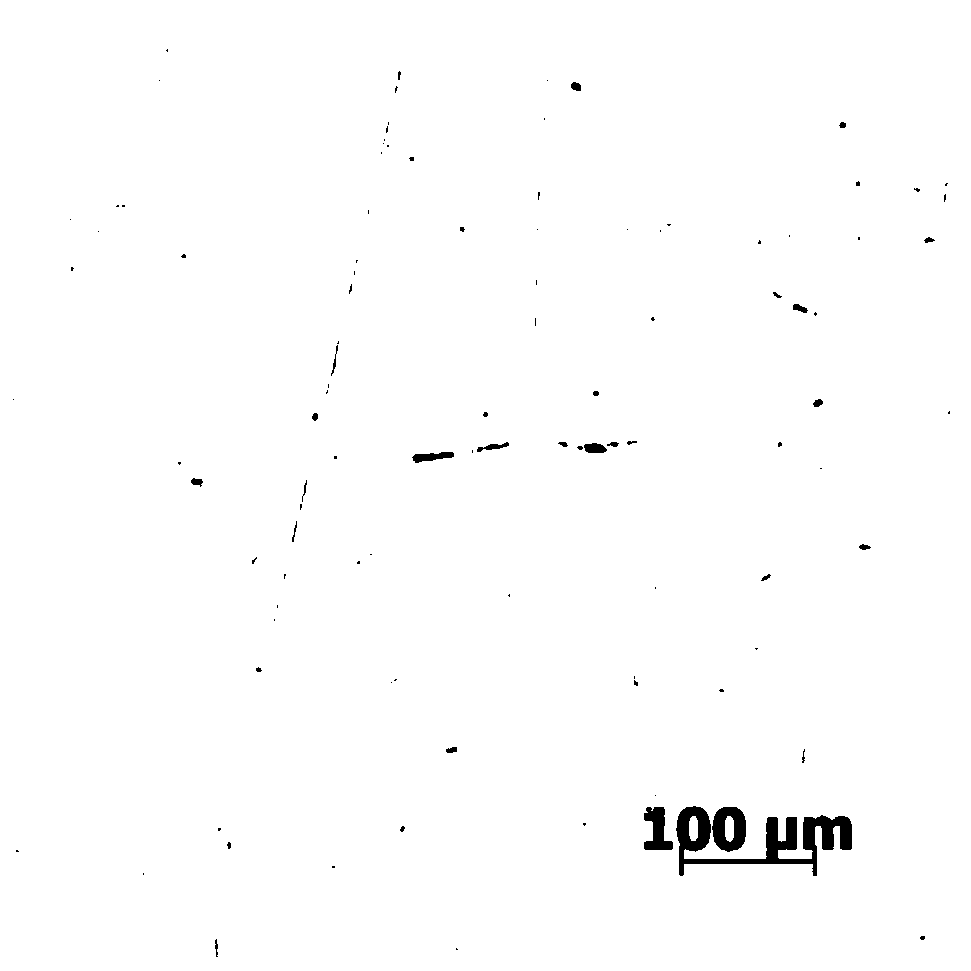

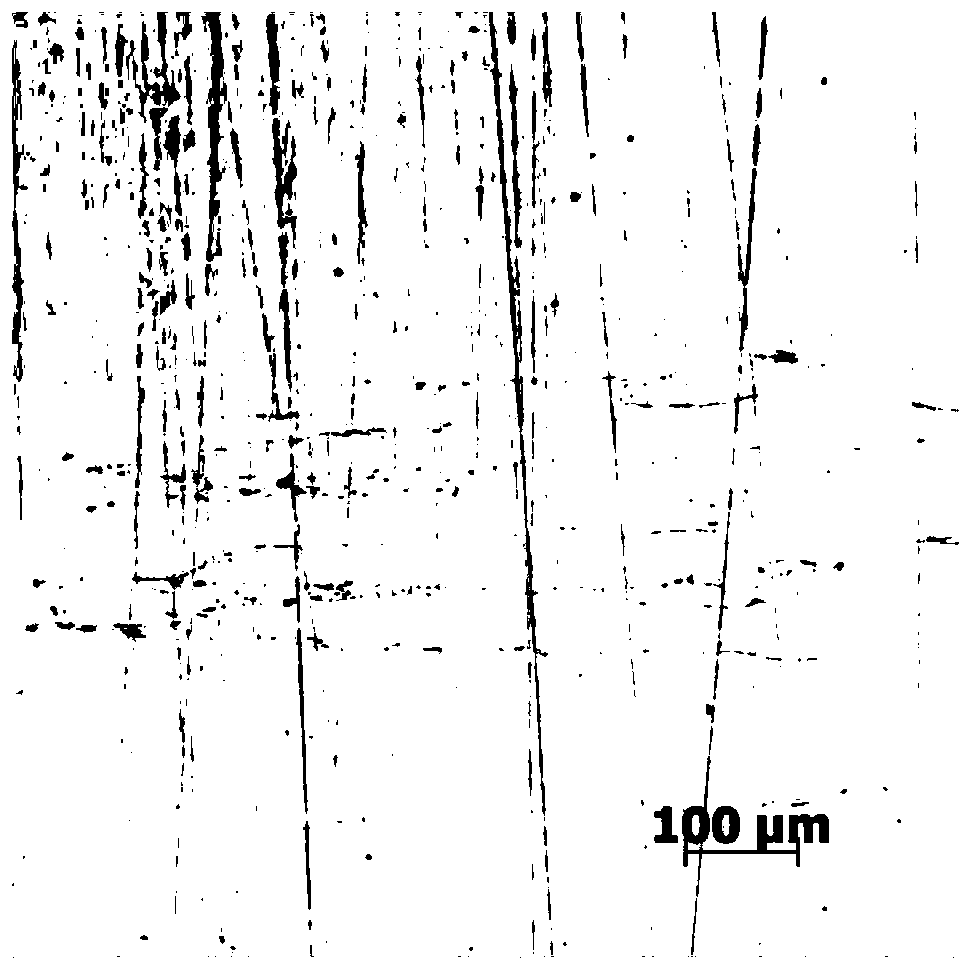

Alloy plate for automobile body and preparation method thereof

The invention provides an alloy plate for an automobile body and a preparation method of the alloy plate. An alloy comprises, by mass percentage, not larger than 0.4% of Si, not larger than 0.4% of Fe, 0.2-0.5% of Mn, 3.0-6.0% of Mg, not larger than 0.03% of Cr, not larger than 0.15% of Cu and the balance Al and impurities. According to the alloy plate and the preparation method, by controlling the content of the trace element Cr and the final annealing process and the straightening amount, on one hand, the YPE of the plate is reduced, and on the other hand, the plate still has excellent mechanical and forming properties of the material. The preparation method comprises the following steps that final annealing is carried out on a continuous annealing line, wherein the temperature rise speed is larger than 20 DEG C / s, and after heat preservation at 480-520 DEG C is carried out for 15 s and 5 min, water quenching is carried out, and the cooling speed is larger than 10 DEG C / s; the finalgrain size should be controlled at 20-40 micrometers, and the YPE is smaller than or equal to 0.2%; and the final annealing plate is subjected to straightening treatment, and the straightening amountis 0.5-1%. The plate prepared by the method is suitable for an automobile body structural member and an automobile body covering panel inner plate.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Round steel for gear and preparation method thereof

ActiveCN110777303AImprove segregationReduce the degree of inclusion aggregationSteelmakingGear wheel

The invention provides round steel for a gear and a preparation method thereof, and belongs to the technical field of steelmaking. The round steel for the gear mainly comprises the following chemicalcomponents in percentage by mass: 0.18-0.22% of C, 0.80-1.00% of Mn, 1.05-1.15% of Cr, 0.035--0.045% of Ti, 0.0050-0.0070% of N, and the balance Fe. The diameter Di of the round steel for the gear is1.34-2.12 inches; the mass percentages of C, Mn, Cr and Ti are X1%, X2%, X3% and X4% in sequence; and Di is equal to -2.8.8 + 9.3X1 + 1.5X2 + 1.2X3-0.0043.0043X 4. The preparation method of the roundsteel for the gear performs smelting according to the components and the sizes. The round steel for the gear precisely controls the components of Ti and N, and effectively and stably controls the hardenability bandwidth to be not more than 4HRC through Di formula correction.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

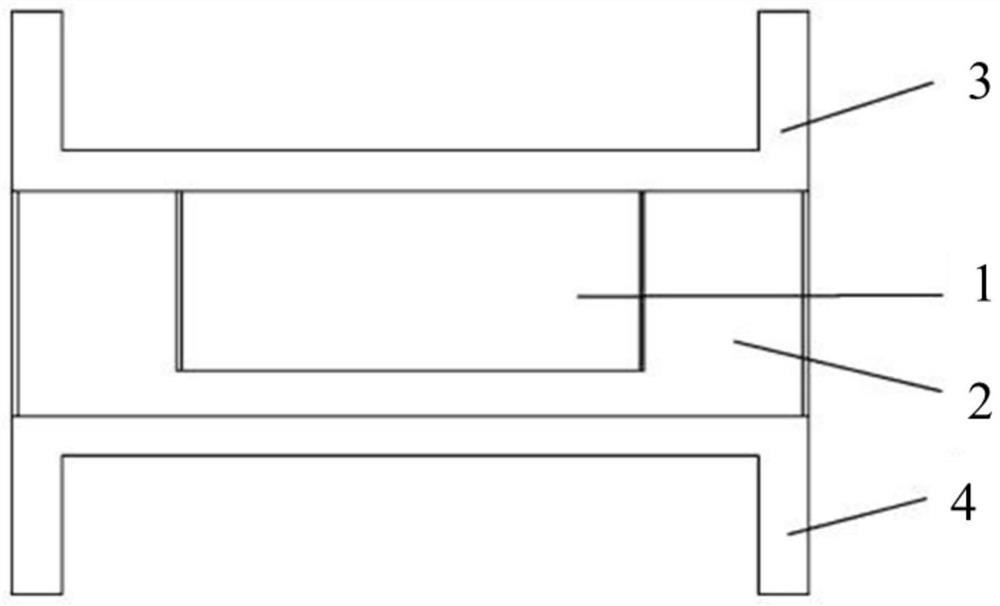

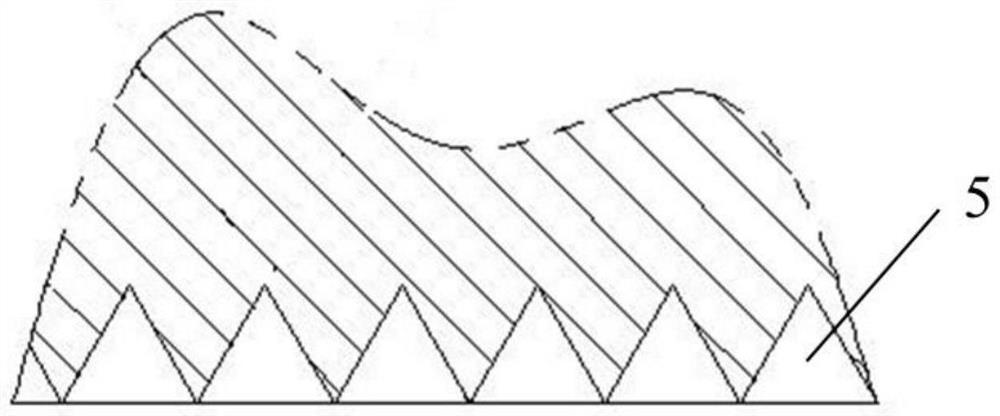

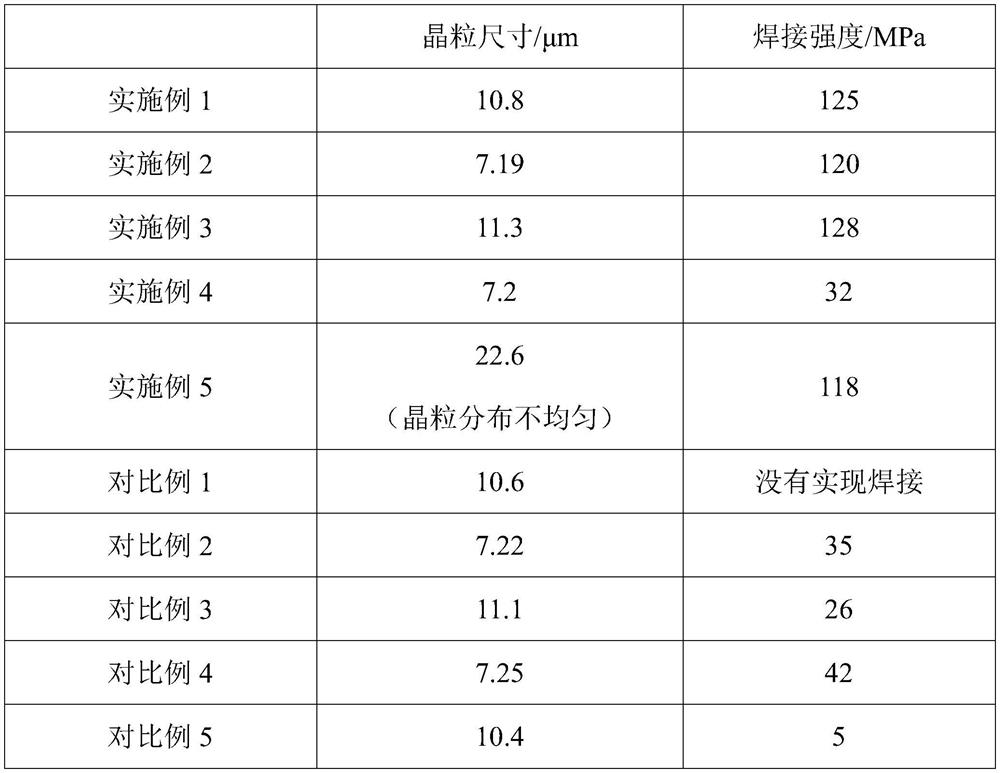

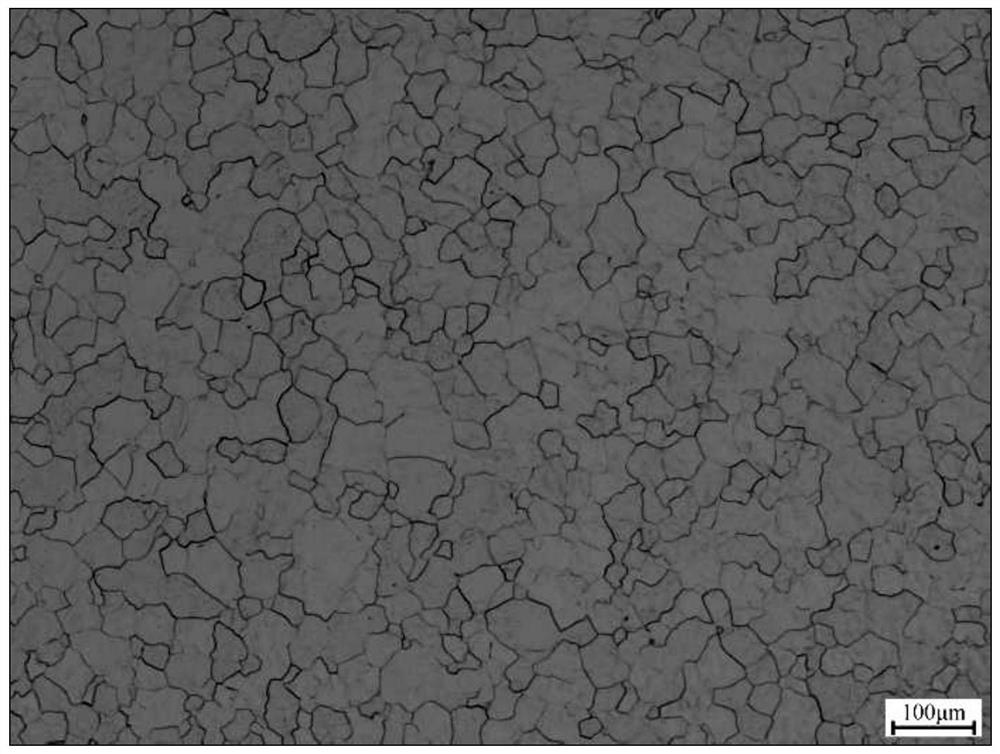

Low-temperature diffusion welding method for ultra-high-purity copper target material component

PendingCN113894401AGuaranteed Grain SizeGuaranteed electrical conductivityWelding/soldering/cutting articlesMetal working apparatusElectrically conductiveWeld strength

The invention provides a low-temperature diffusion welding method for an ultra-high-purity copper target material component. The low-temperature diffusion welding method for the ultra-high-purity copper target material component comprises the following steps that the welding face of an ultra-high-purity copper target material is pretreated; threads are turned on the welding surface of a copper alloy back plate; the distance between the threads ranges from 0.2 mm to 0.45 mm, and the depth of the threads ranges from 0.1 mm to 0.15 mm; the treated ultra-high-purity copper target material and the copper alloy back plate are assembled, and then the ultra-high-purity copper target material and the copper alloy back plate which are assembled are put into a sheath for degassing treatment after being subjected to vacuum packaging; and after degassing treatment, diffusion welding is carried out, then cooling is carried out, and the ultra-high-purity copper target material component is obtained. By turning the threads on the welding face of the back plate and further controlling the size of the threads, the ultra-high-purity copper target material and the copper alloy back plate are welded together at the low temperature, and the grain size, the electric conduction performance, the heat conduction performance and the welding strength of the ultrahigh-purity copper target material are guaranteed.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Cold drawing preparation method for TB9 titanium alloy disc round wire with lubricating coating

ActiveCN113210448AUniform adhesionInhibit sheddingFurnace typesMetallic material coating processesWire rodSand blasting

The invention discloses a cold drawing preparation method for a TB9 titanium alloy disc round wire with a lubricating coating. The method comprises the steps that firstly, the TB9 titanium alloy disc round wire is subjected to solid solution heat treatment and then scalped; secondly, sand blasting treatment is conducted; thirdly, surface pretreatment is conducted; fourthly, lubricating coating coating and drying are conducted; and fifthly, the TB9 titanium alloy disc round wire with the lubricating coating is obtained through multi-pass cold drawing. According to the method, the TB9 titanium alloy disc round wire subjected to solid solution heat treatment is sequentially subjected to sand blasting treatment and surface pretreatment, so that a uniform crystal protection layer is attached to the surface of the TB9 titanium alloy disc round wire, the lubricating coating is promoted to be more uniformly and stably attached to the surface of the TB9 titanium alloy disc round wire, the attaching uniformity and stability of the lubricating coating are further improved in combination with a cold drawing process, the TB9 titanium alloy wire rod with the lubricating coating in the wire rod state is prepared, the phenomena of oxygen increasing and hydrogen increasing in the TB9 titanium alloy wire rod are avoided, and the grain size and the structure uniformity both meet the use requirements.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

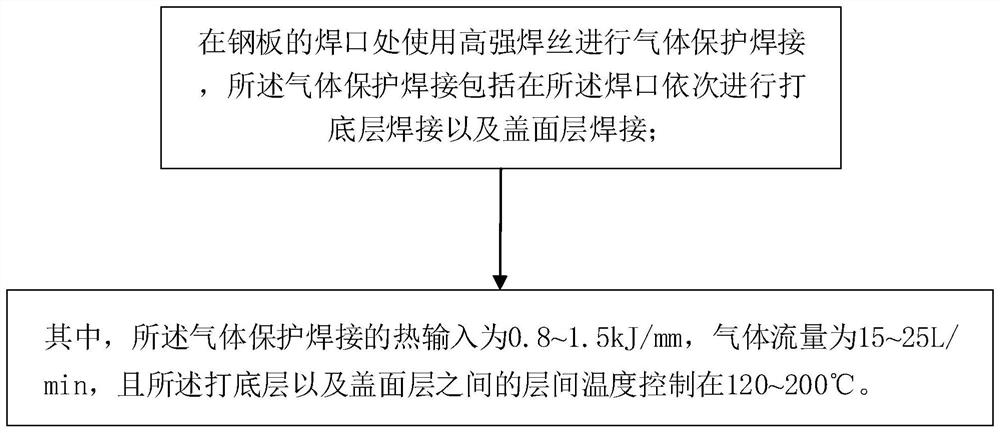

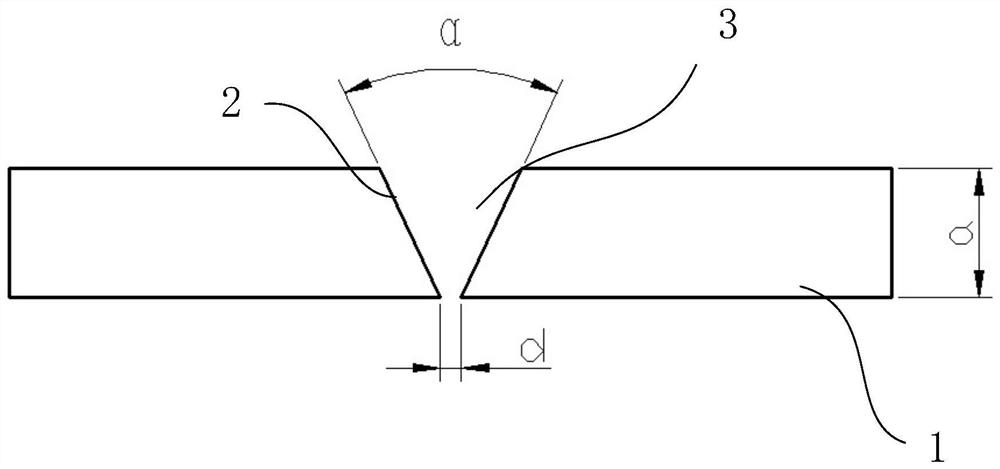

Welding method of high-strength steel

InactiveCN113118597AGuarantee organizationGuaranteed Grain SizeWelding accessoriesTemperature controlWeld seam

The invention provides a welding method for high-strength steel. The welding method comprises the following steps that a high-strength welding wire is used at a welded junction of a steel plate to carry out gas shielded welding, and the gas shielded welding comprises the step of sequentially carrying out priming layer welding and capping layer welding at the welded junction, wherein the heat input of the gas shielded welding is 0.8-1.5 kJ / mm, the gas flow is 15-25 L / min, and the interlayer temperature between the priming layer welding and the capping layer welding is controlled to be 120-200 DEG C. According to the welding method of the high-strength steel, the heat input and the interlayer temperature are strictly controlled to be within a proper range, the structure and grain size are guaranteed, and therefore it is guaranteed that a weld joint obtains good obdurability matching; the certain toughness is achieved while the strength of the welding wire is ensured; and a welding joint with high strength and good toughness and plasticity is obtained. Moreover, the welding method for the high-strength steel produced by the method adopts the same high-strength steel welding wire in the whole process, so that the welding wire is prevented from being switched back and forth, operation is simple, the implementation is easy in production, the method can be popularized to automatic robot welding, and efficient production is realized.

Owner:湖南华菱涟钢特种新材料有限公司 +1

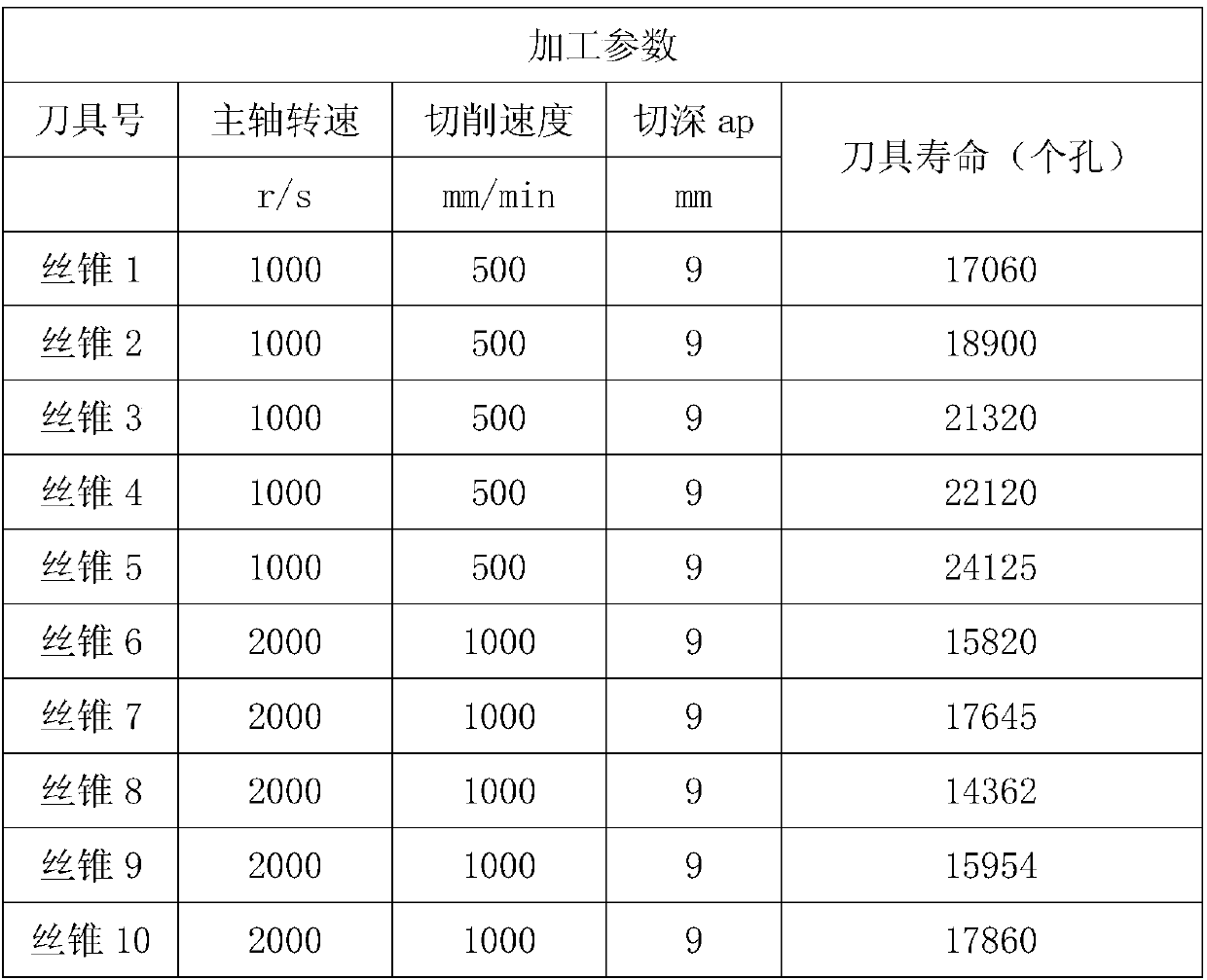

Special high-speed steel manufacturing technology for screw tap and screw tap

ActiveCN107604252ASolve segregation defectsGuaranteed uniformityThread cutting toolsIncreasing energy efficiencyManufacturing technologyCarbide

The invention discloses a special high-speed steel manufacturing technology for a screw tap. The special high-speed steel manufacturing technology comprises the following steps that preparation is conducted on the raw materials of, by weight, 1.27-1.35% of C, 0.5-0.6% of Mn, 7.3-8% of Mo, 3.5-4% of Cr, 3-3.5% of W, 2.8-3.1% of V and the balance Fe; the vacuum degree in a vacuum induction furnace is maintained to be less than or equal to 2Pa, the raw materials are heated and molten to be a melt, and then the melt is cast into a steel ingot in protective atmosphere; the steel ingot is subjectedto a treatment method of atmosphere protection electroslag remelting, so that the effect of directional solidification is achieved, and a remelted ingot is obtained; the remelted ingot is subjected tosix-side forging at the temperature of 900-1100 DEG C, so that the integral deformation ratio of the remelted ingot is higher than 10, the final forging temperature is controlled to be 850-900 DEG C,and a semi-finished product is obtained; and the forged semi-finished product is subjected to quenching and tempering treatment, and special steel for the screw tap is obtained. The invention furtherdiscloses the screw tap. The screw tap is made of the high-speed steel manufactured by utilizing the technology. By utilizing the technology, the high-speed steel with the carbide particle sizes being even and the grain sizes being small can be manufactured, and the life of the screw tap manufactured by utilizing the high-speed steel is obviously prolonged.

Owner:江苏合一金属新材料科技有限公司

Production method of cylindrical titanium sputtering target material

InactiveCN105154834AImprove qualityHigh purityVacuum evaporation coatingSputtering coatingSputteringIodide

The invention discloses a production method of a cylindrical titanium sputtering target material. Sponge titanium produced by an iodide process and having a purity above 99.9% is used as a raw material, and is smelted by an electron beam cold bed furnace to obtain a high-purity titanium blank (purity above 99.95%); after the titanium blank is milled the surface and finely polished, the head of a titanium billet is cut to form the requested size of the forged blank; the flaw detection is performed for the forged blank; the qualified forged blank is heated to 980-1020 DEG C; the forged blank is forged through three-upsetting and three-pulling; the forging mold is forged to a rod with needed specification in final pulling; after the forging is annealed, the surface scale of the rod is turned off; after forging caps at two ends are removed, the rod is sawed to a small cylinder block with needed specification; two sawed end surfaces of the small cylinder block are polished; the bottom is internally turned and milled to reserve an edge; the reserved edge is chamfered; the other end is threaded; and the cylindrical titanium sputtering target material is obtained through further cleaning. The purity of the target material produced by the method is not lower than 99.95%, and the grain size is controlled below 100 microns, so that the technical requirements of the sputtering target material can be satisfied.

Owner:YUNNAN TITANIUM IND

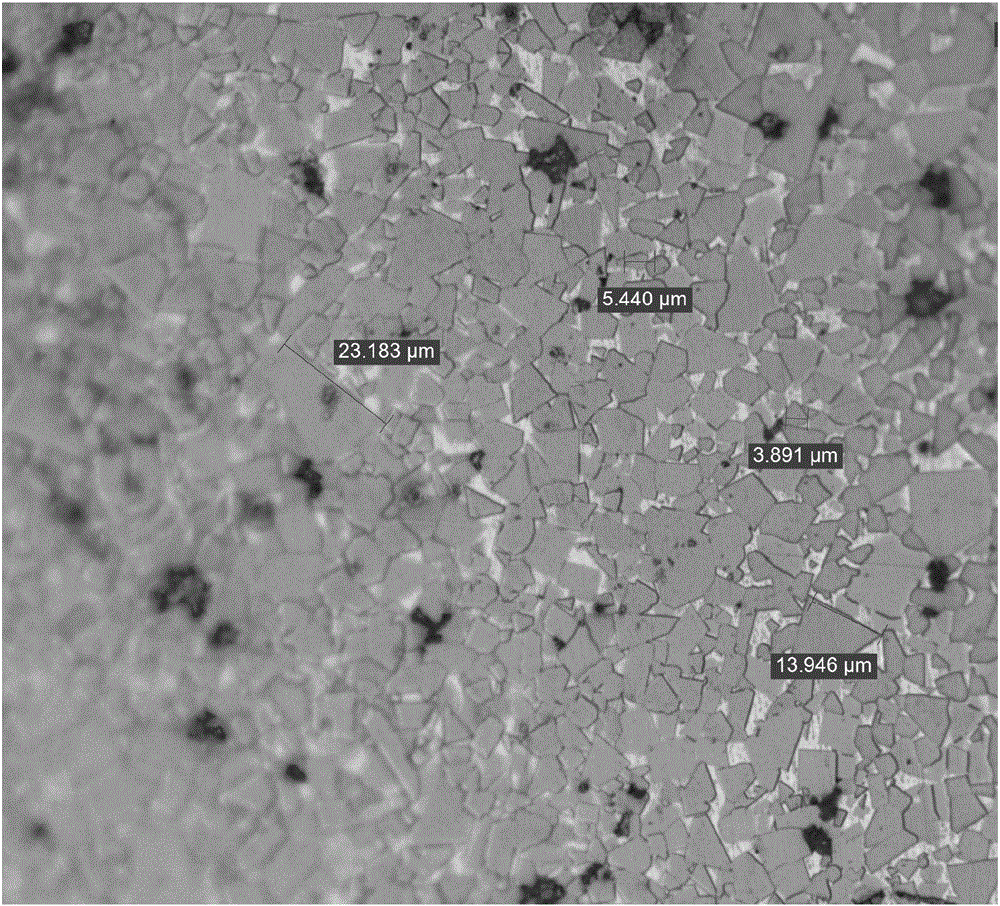

Preparation method of mining hard alloy of ultra-thick mixcrystal structure

The invention discloses a preparation method of a mining hard alloy of an ultra-thick mixcrystal structure. The preparation method comprises the following steps that cobalt oxalate is dissolved in absolute ethyl alcohol; a solution is heated till the temperature ranges from 40 DEG C to 60 DEG C, hydrazine is added, then ammonium hydroxide is added to keep the pH value of the solution between 8.5 and 12, and then activator cetyl trimethyl ammonium bromide is added; WC is added into the solution in the second step, the weight ratio of the WC to cobalt in the second step is (85-94):(6-15), and the WC is composed of 60%-80% of WC of 20-26 micrometers and 20%-40% of WC of 3-4 micrometers; an obtained mixed solution is subjected to sonic oscillation, the temperature of the mixed solution is kept between 60 DEG C and 70 DEG C, and the mixed solution is placed in an inert gas environment to react; a reaction solution is poured into a beaker while waste heat exists, sedimentation powder is collected, washing and vacuum airing are carried out, and composite powder is obtained; and paraffin and gasoline are added into the obtained composite powder, blow-drying is carried out at the normal temperature, and then sieving, granulating and press sintering are carried out to obtain a product. The thermal fatigue resistance of the alloy is improved.

Owner:重庆莱斯五金制造有限公司 +1

Heat treatment method for 10Cr11Co3W3NiMoVNbNB blade steel bar

InactiveCN110699535AImprove high temperature durabilitySimple stepsFurnace typesHeat treatment furnacesHeat conservationEngineering

The invention discloses a heat treatment method for a 10Cr11Co3W3NiMoVNbNB blade steel bar, relates to the technical field of heat treatment, and provides a heat treatment method which is relatively low in cost and can improve high-temperature durability of 10Cr11Co3W3NiMoVNbNB blade steel. The heat treatment method for the 10Cr11Co3W3NiMoVNbNB blade steel bar sequentially comprises the followingsteps: A, annealing treatment: after forging of the blade steel bar is completed, feeding the blade steel bar into a heat treatment furnace for heat preservation, and then performing air cooling untilthe temperature is lower than 500 DEG C, wherein the heat preservation temperature is 700-750 DEG C, the heat preservation time is 8-10 h * a / 100, a is the diameter of the blade steel bar, and the unit of a is mm; B, austenitizing treatment: heating the blade steel bar to 1080-1120 DEG C at a heating rate of less than 120 DEG C / h, and then performing heat preservation, wherein the heat preservation time is 3h * a / 100; C, oil quenching treatment of the blade steel bar; and D, tempering treatment: putting the blade steel bar into a heat treatment furnace at 700-750 DEG C for heat preservation,wherein the heat preservation time is 5-6 h * a / 100, and then discharging the blade steel bar out of the furnace and performing air cooling to room temperature.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

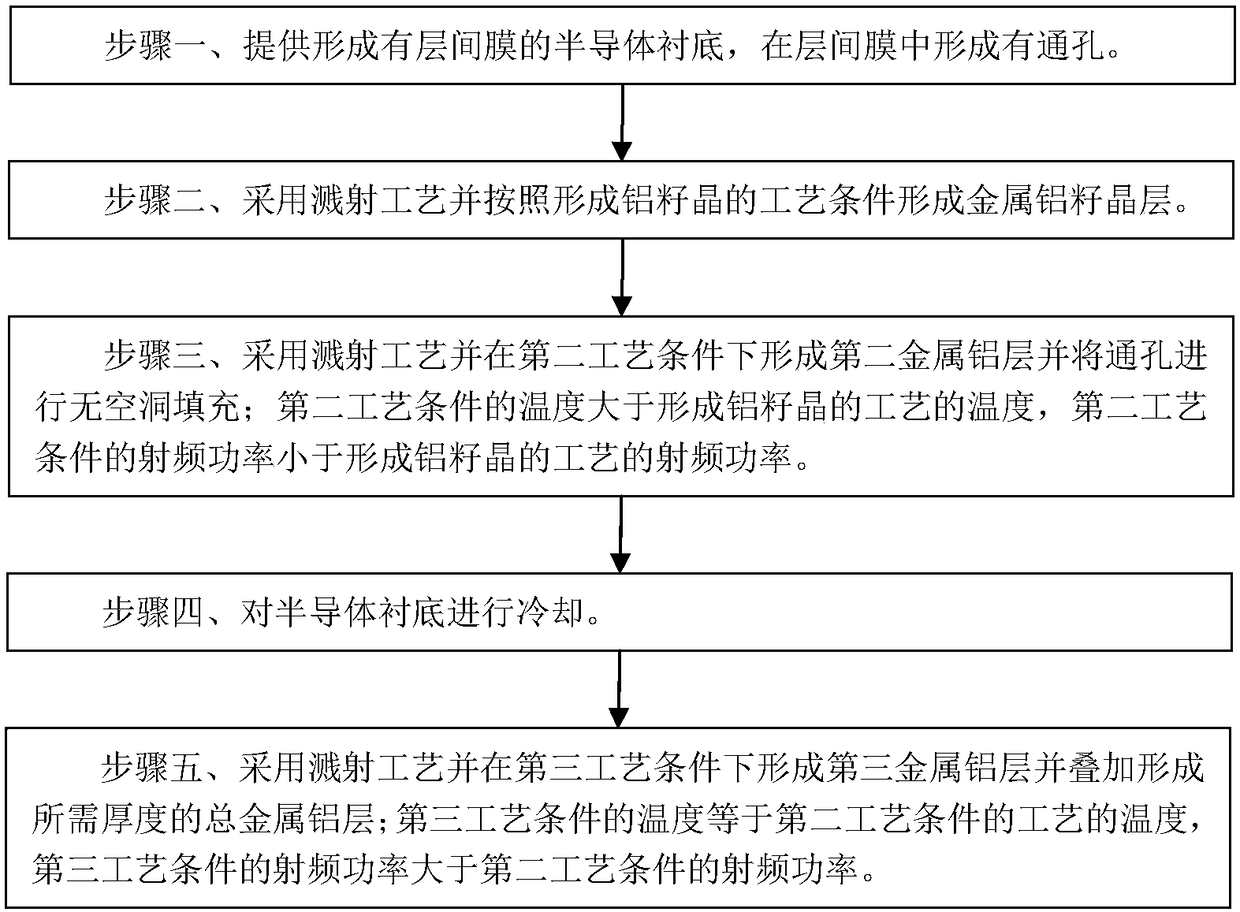

Metal aluminum pore filling method

ActiveCN108389832ASmall grainThe grains are small and continuousSemiconductor/solid-state device manufacturingElectrical performanceRadio frequency

The invention discloses a metal aluminum pore filling method. The metal aluminum pore filling method comprises the steps of providing a semiconductor substrate formed with an interlayer film and forming through holes in the interlayer film; adopting a sputtering technology to form a first metal aluminum seed crystal layer according to an aluminum seed crystal process condition; forming a second metal aluminum layer by adopting the sputtering technology in a second process condition, and performing no-void filling in the through holes, wherein the temperature in the second process condition ishigher than that in the aluminum seed crystal formation process, and the radio frequency power in the second process condition is lower than that in the aluminum seed crystal formation process; performing cooling on the semiconductor substrate; and forming a third metal aluminum layer by adopting the sputtering technology in a third process condition, and performing overlaying to form a total metal aluminum layer with the needed thickness, wherein the temperature in the third process condition is equal to that in the second process condition, and the radio frequency power in the third processcondition is higher than that in the second process condition. By virtue of the metal aluminum pore filling method, metal aluminum stage coverage rate is improved and the electrical performance and reliability of metal aluminum are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Preparation method of high-purity molybdenum plate for target material

InactiveCN109811317AProduction quality is reliableSimple production processVacuum evaporation coatingSputtering coatingCrystalliteOxide

The invention discloses a preparation method of a high-purity molybdenum plate for a target material. A molybdenum alloy with the purity of 99.9% or above is produced by using a sputtering method as araw material, a high-purity molybdenum workblank is obtained by smelting by adopting an electron beam cooling bed furnace, wherein the purity of the high-purity molybdenum workblank is 99.9% or above, the surface of the molybdenum workblank is milled, after finely grinding is performed, cropping is performed on a molybdenum square billet, then the forging workblank is cut into the required size,and flaw detection is performed on the forged workblank, the qualified forged workblank is heated to 980-1020 DEG C, forging is performed on the forged workblank by adopting a three-upsetting and three-drawing method, and the forge piece is made into a required specification bar in a die forging mode during final drawing, after annealing is performed on the forge piece, the oxide skin on the surface of the bar is removed, and then sawing is performed to form small column blocks with the required specifications after forged caps of the two heads are removed; and two sawing end surfaces of the small column blocks are polished by lathe machining, turn milling is performed on the inner bottom, an edge is reserved, and the reserved edge is chamfered, and thread machining is further performed onthe other end part to obtain the cylindrical molybdenum sputtering target material after further clearing. According to the preparation method, the purity of the produced target material is not lessthan 99.8%, the grain size is controlled to be 100 micron or below, and the technical requirements of the sputtering target materials can be met.

Owner:王鹏

Corrosion-resistant air cooler and reinforcing process thereof

InactiveCN107988559AImprove atomic activityHigh strengthAnti-corrosive paintsPolyurea/polyurethane coatingsRare-earth elementEngineering

The invention discloses a corrosion-resistant air cooler. The corrosion-resistant air cooler is characterized in that the corrosion-resistant air cooler comprises an air cooler shell, a draught fan, arefrigerant circulation system and a control module. The draught fan and the refrigerant circulation system are arranged in the air cooler shell. The control module is used for controlling the draught fan and the refrigerant circulation system. The air cooler shell comprises, by mass percentage, 8-10% of Al, 1-3% of Mn, 0.18-0.3% of C, 0.05-0.1% of Cr, 0.01-0.05% of Nb, 0.01-0.03% of Cu, 2-5% ofSr, 0.0002-0.005% of Nb, 0.005-0.008% of N, 0.0002-0.005% of S, 0.5-0.8% of Zn, 1.5-1.8% of Si, 3-5% of Ca, 0.5-0.8% of Ti, 0.3-0.5% of Ni, 0.002-0.004% of B, 0.1-0.4% of V, 0.5-0.8% of a rare earth element and the balance Fe. The invention further designs a reinforcing process of the corrosion-resistant air cooler. The air cooler is simple and compact in structure and good in corrosion resistingeffect; the service life of the air cooler is prolonged; and the cost is lowered.

Owner:博维恩冷冻科技(苏州)有限公司

A steel bar for high-strength prestressed concrete and its production process

ActiveCN104404380BImproved resistance to hydrogen-induced delayed fractureAvoid inhalationChemical compositionRare earth

The invention discloses a steel bar for high-strength prestressed concrete, the chemical composition of which is: C: 0.20-0.25%, Si: 1.50-1.85%, Mn: 0.20-0.50%, Cr: 0.07-0.09%, Mo: 0.30‑0.35%, V: 0.25‑0.35%, Nb: 0.05‑0.08%, Ti: 0.42‑0.61%, Ni: 0.15‑0.25%, Ca: 0.25‑0.40%, S≤0.025%, P≤0.025 %, Cu≤0.20%, compound rare earth: 0.15-0.30%, and the balance is Fe; the present invention also designs a production process of steel rods for high-strength prestressed concrete as follows: smelting to obtain steel billet-rolling-cooling treatment-the first Secondary rolling - heat treatment and stabilization treatment - gas nitriding treatment - spinning and coiling - bundling and storage.

Owner:溧阳市万兴特种建材有限公司

A method for manufacturing nitrogen-controlled austenitic stainless steel large forgings

ActiveCN105088094BImprove performanceSolve the mixed crystal problemHeating/cooling devicesSlagDie casting

A manufacturing method of a nitrogen-controlled austenitic stainless steel large forging piece comprises the following steps of electric furnace primary melting, AOD refining, LF refining, die casting pouring, electroslag remelting and forging. In LF refining, double deoxidizer with the mass ratio of Al to Si being 7:3 is adopted. In electroslag remelting, a quaternary slag system with the ratio of CaF2:Al2O3:CaO:MgO equal to 72:18:5:5 is selected as electroslag protection slag. In forging, a multi-time heading pulling manner is adopted, the first fire temperature, the second fire temperature, the third fire temperature and the deformation are all controlled to be larger than 30%, it is ensured that a large amount of recrystallization is generated in the post-forging cooling process, the grain sizes are all not thicker by 4 levels after products are in solid solution, and the problem of mixed crystals of the large forging piece is effectively solved; and the nitrogen-controlled austenitic stainless steel large forging piece has good comprehensive performance and can be kept with good performance under the condition of the temperature of 350 DEG C, and the using requirement of engineering structural pieces is met.

Owner:宝武特种冶金有限公司

Method for preparing high-purity titanium sputtering target material through sputtering method

InactiveCN109778123AImprove qualityHigh purityVacuum evaporation coatingSputtering coatingSputteringMicrometer

The invention discloses a method for preparing a high-purity titanium sputtering target material through a sputtering method. The method comprises the steps that a titanium alloy which has the purityof 99.9% or above and is produced through the sputtering method is taken as a raw material, and a high-purity titanium blank (with the purity of 99.98% or above) is obtained by conducting smelting through an electron beam cold bed furnace; face milling is conducted on the titanium blank, ends of the titanium square blank are cut after fine grinding is finished, the titanium blank is cut to have the size required by a forging blank, flaw detection is conducted on the forging blank, the qualified forging blank is heated to 980-1,020 DEG C, the forging blank is forged through three times of upsetting and three times of drawing, a forging piece is made into a bar with the needed specification in a die forging mode, oxide skin on the surface of the bar is turned after the forging piece is annealed, and after forging caps at the two ends are removed, the bar is sawn into a small columnar block with the needed specification; the two sawn end faces of the small columnar block are turned to besmooth, turn milling is conducted on the interior of the bottom, the edge is reserved, the reserved edge is chamfered, and wire opening is conducted on the other end; and after further cleaning is conducted, the cylindrical titanium sputtering target material is obtained. According to the target material produced through the method, the purity is no less than 99.98%, the grain size is controlled to be 100 micrometers or below, and the technological requirement of the sputtering target material can be met.

Owner:雷雨婷

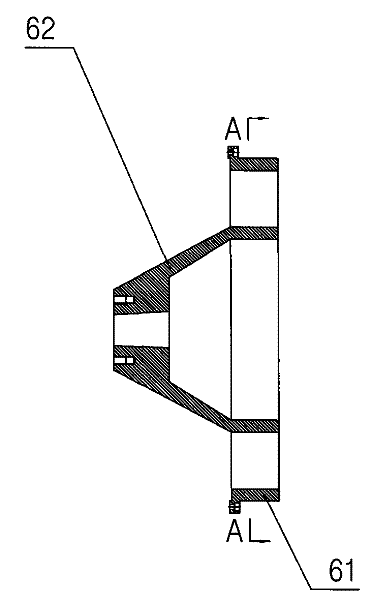

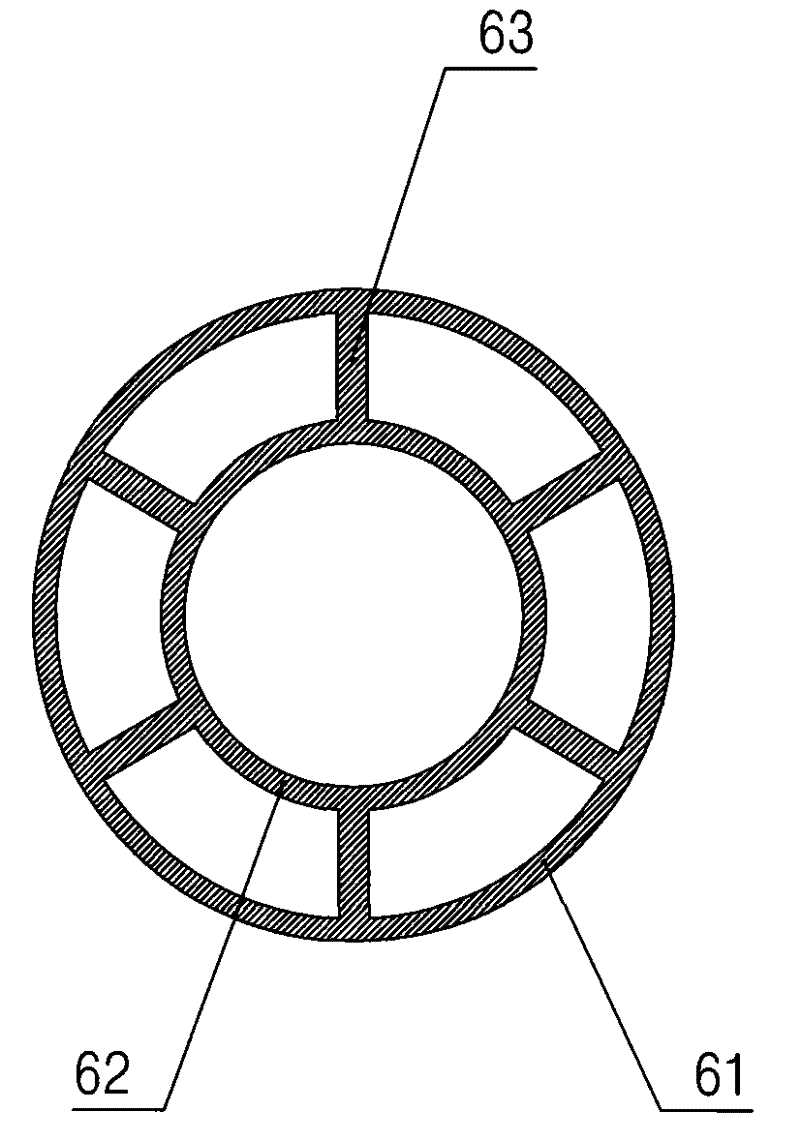

Vertical gravity discharging centrifuge

The invention discloses a vertical gravity discharging centrifuge which is capable of charging under the condition of static or low speed rotation and is capable of discharging relying on self gravity, comprising an engine base; the engine base is provided with a bearing block which is provided with a spindle, the spindle is sheathed with a rotary drum body, the lower part of the rotary drum bodyis provided with a discharge hole, the rotary drum body is provided with a conical rotary drum which is provided with a cylindrical rotary drum, the engine base is further provided with a case, the top of the case is provided with a cover which is internally provided with a feeding pipe communicated with a rotary drum cavity in a penetrating way, the cover is further provided with a lifting cylinder, a piston rod of the lifting cylinder is connected with a horn-shaped seal cover arranged on the spindle in flexible way through a connecting rod, and the lower end of the seal cover is provided with a seal flange which is sealed with the rotary drum body via a seal ring arranged on the outer wall thereof in an embedding way. The centrifuge of the invention can be applied to industries of saccharin and the like with higher requirements for grain size and smooth finish, thus the application range is wider.

Owner:张家港市华祥离心机制造有限公司

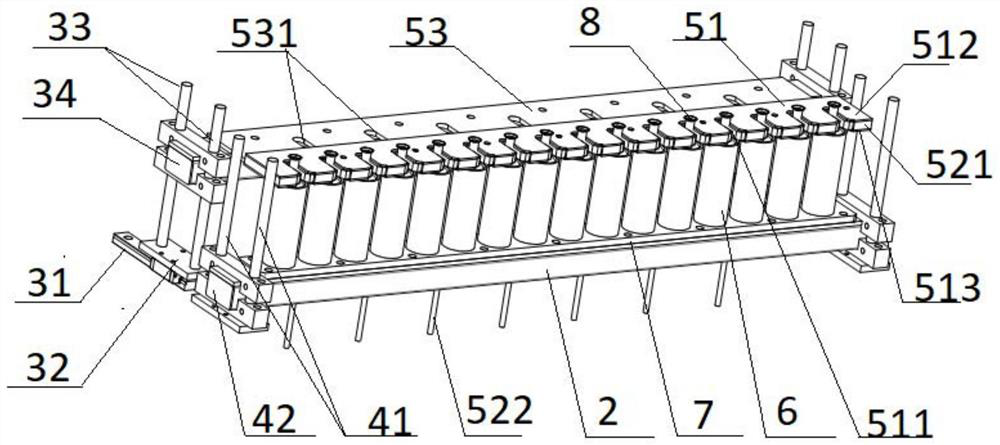

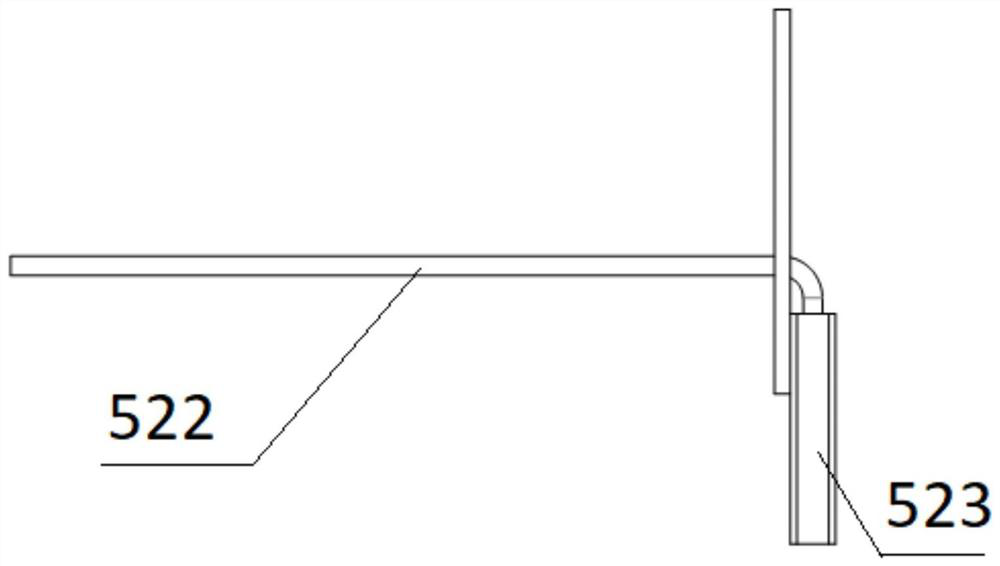

Protective welding tool

PendingCN114226902AGuaranteed Grain SizeQuality assuranceHeating appliancesMetal working apparatusStructural engineeringWelding

The invention provides a protective welding tool. The protective welding tool comprises a bearing platform; the first supporting piece is arranged on the bearing platform, a plurality of first limiting pieces are arranged on the first supporting piece, and the first supporting piece is suitable for correspondingly bearing and limiting a plurality of parts to be welded; the first lifting assembly is arranged on the bearing platform; the clamp assembly is connected with the first lifting assembly and comprises a first clamping piece provided with a plurality of clamping openings, and the clamping openings are provided with humidifying structures; and the first clamping piece has a first clamping state in which the first clamping piece moves to one side of the to-be-welded part and each clamping opening on the first clamping piece correspondingly clamps the peripheral side of the welding spot of each to-be-welded part and is wetted under the driving of the first lifting assembly, and a second standby state in which the first clamping piece is far away from the to-be-welded part and each clamping opening on the first clamping piece is separated from each to-be-welded part. By means of the humidifying structure, the peripheral sides of the welding spots are wetted, the temperature of the peripheral sides of the welding spots is reduced, the quality of the whole to-be-welded parts is guaranteed, in addition, the multiple first limiting pieces and the multiple clamping openings are arranged, and the processing number and welding efficiency of the to-be-welded parts are improved.

Owner:GREE ELECTRIC APPLIANCES ZHENGZHOU +1

A small size led copper strip production process

ActiveCN108155281BGuaranteed roughnessEliminate work hardeningSemiconductor devicesIngot castingIndustrial engineering

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com