Welding method of high-strength steel

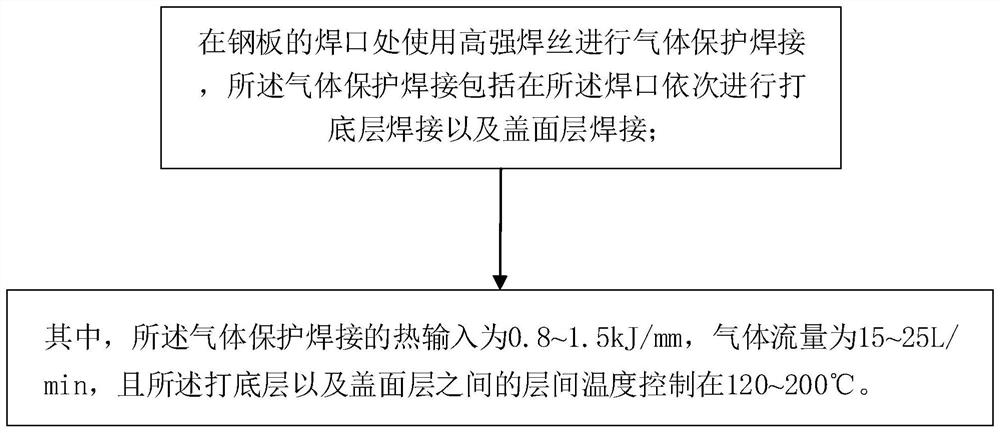

A welding method and technology of high-strength steel, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of low welding joint strength, and achieve the effect of easy execution, avoiding switching welding wires back and forth, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

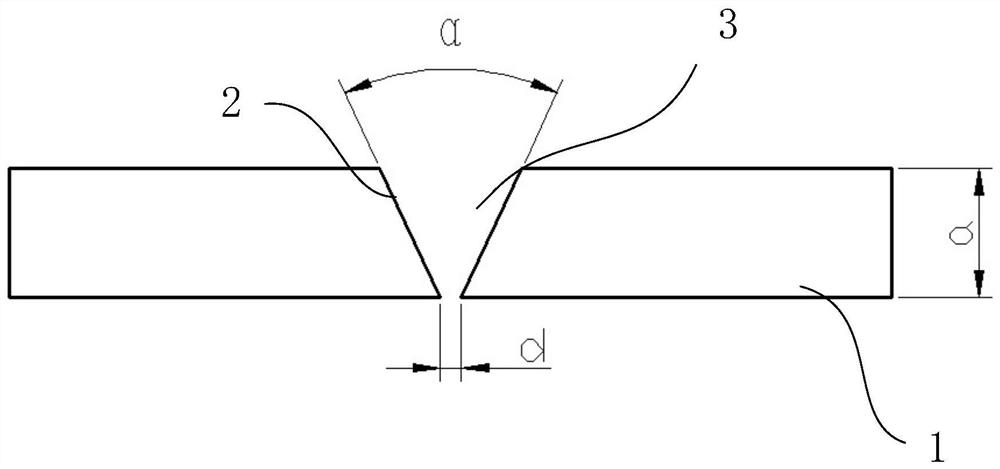

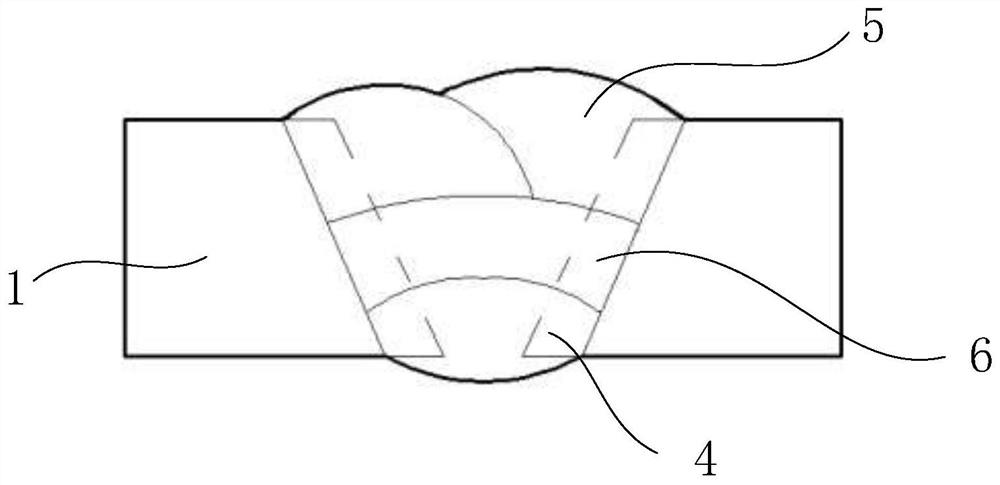

[0049] Use a 6mm thick steel plate with a yield strength of 1300MPa, open a 50°V-shaped groove, preheat at 100°C before welding, and use Bole GM120 welding wire to complete the welding of the bottom layer and the welding of the cover layer. The welding parameters are as follows: (1) Boring: welding Current 130A, welding voltage 20V, welding speed 160mm / min; (2) Overlay welding: welding current 260A, welding voltage 27.5V, welding speed 450mm / min. The interlayer temperature is controlled at 120-200°C. It can swing properly to ensure good fusion between the weld seam and both sides of the groove.

[0050] Through the above method, smooth welded joints can be obtained without defects such as cracks and pores, and the mechanical properties are good; the tensile strength of the weld metal at room temperature is greater than 1217MPa, and the impact energy of the V-notch impact test of the weld metal at the test temperature of -40°C Greater than 47J, the 6a cold bending test is qual...

Embodiment 2

[0052] Use 8mm thick steel plate with yield strength of 1300MPa, open 60°V-shaped groove, preheat 100°C before welding, and use Bole GM120 welding wire to complete the welding of the bottom layer and the welding of the cover layer. The welding parameters are as follows: (1) bottom layer welding: Welding current 140A, welding voltage 20.5V, welding speed 170mm / min; (2) Overlay welding: welding current 270A, welding voltage 29V, welding speed 430mm / min. The interlayer temperature is controlled at 120-200°C. It can swing properly to ensure good fusion between the weld seam and both sides of the groove.

[0053] Through the above method, smooth welded joints can be obtained without defects such as cracks and pores, and the mechanical properties are good; the tensile strength of the weld metal at room temperature is greater than 1240MPa, and the impact energy of the V-notch impact test of the weld metal at the test temperature of -40°C Greater than 47J, the 6a cold bending test is...

Embodiment 3

[0055] A 12mm thick steel plate with a yield strength of 1300MPa is used, a 60°V-shaped groove is opened, and the preheating is 130°C before welding. Bole GM120 welding wire is used to complete the welding of the bottom layer, filling layer and cover layer. The welding parameters are as follows: (1) Underlayer welding: welding current 140A, welding voltage 20.5V, welding speed 170mm / min; (2) Filling layer welding and cover layer welding: welding current 260A, welding voltage 27.5V, welding speed 450mm / min. The interlayer temperature is controlled at 120-200°C. It can swing properly to ensure good fusion between the weld seam and both sides of the groove.

[0056] Through the above method, smooth welded joints can be obtained without defects such as cracks and pores, and the mechanical properties are good; the tensile strength of the weld metal at room temperature is greater than 1220MPa, and the impact energy of the V-notch impact test of the weld metal at the test temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com