Low-temperature diffusion welding method for ultra-high-purity copper target material component

A diffusion welding and target material technology, which is applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of low welding joint degree and poor high temperature resistance of brazing method, so as to ensure the crystal grain Effect of size, productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

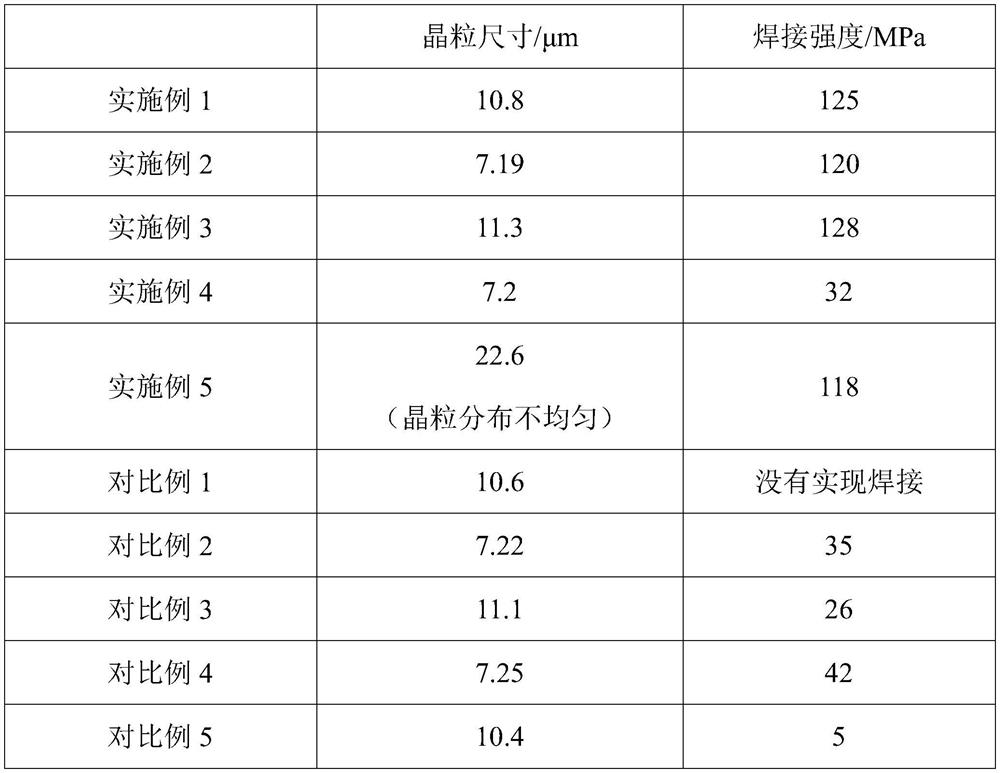

Examples

Embodiment 1

[0061] This embodiment provides a method for low-temperature diffusion welding of ultra-high-purity copper target components, and the method includes the following steps:

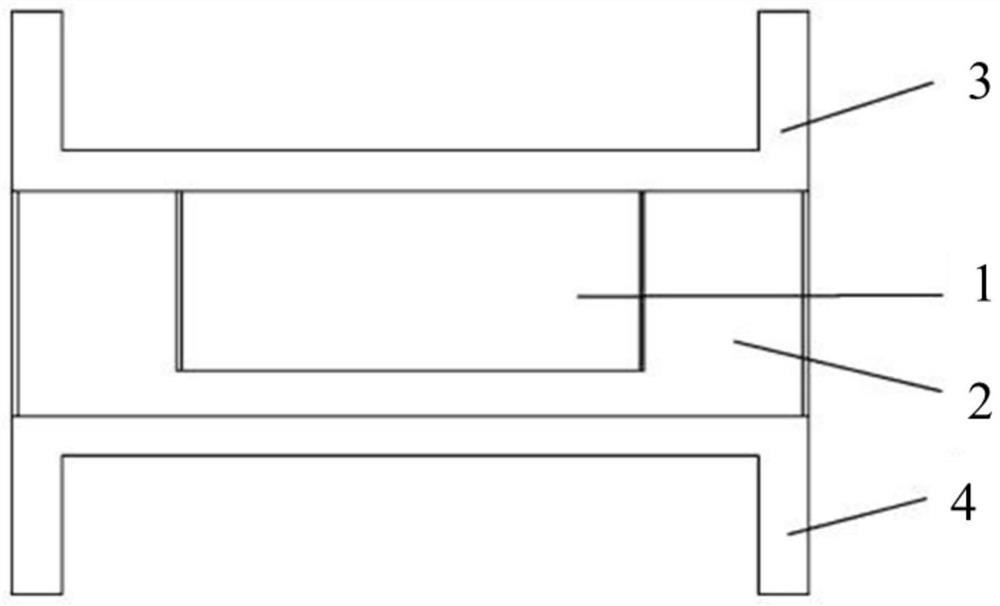

[0062] Provide an ultra-high-purity copper target 1 (purity is 6N) and a copper alloy back plate 2; the material of the copper alloy back plate 2 is a copper-zinc alloy, and the copper alloy back plate 2 is provided with grooves, and the concave The bottom surface of the groove is the welding surface;

[0063] (1) The welding surface of the ultra-high-purity copper target 1 is turned with a diamond tool, and the roughness after turning is 0.8 μm;

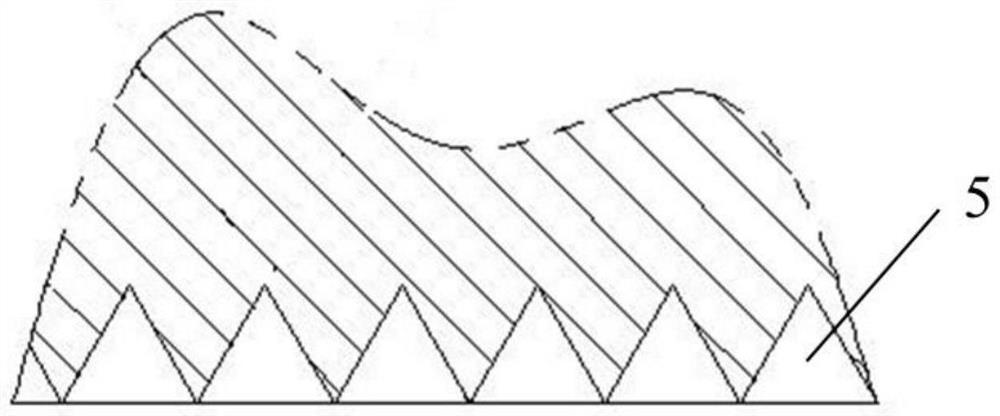

[0064] Turn the welding surface of the copper alloy back plate 2 to the thread 5 with a spacing of 0.3 mm and a depth of 0.15 mm, then use a wire brush to clean along the direction of the turning thread, and then use isopropanol to perform ultrasonic cleaning for 25 minutes. Under the condition of 70 ℃, carry out vacuum drying for 70 minutes, and control the pre...

Embodiment 2

[0069] This embodiment provides a method for low-temperature diffusion welding of ultra-high-purity copper target components, and the method includes the following steps:

[0070] Provide an ultra-high-purity copper target material 1 (purity is 6N) and a copper alloy back plate 2; the material of the copper alloy back plate 2 is copper-chromium alloy, and the copper alloy back plate 2 is provided with grooves, The bottom surface of the groove is the welding surface;

[0071] (1) The welding surface of the ultra-high-purity copper target 1 is turned with a diamond tool, and the roughness after turning is 0.7 μm;

[0072] Turn the welding surface of the copper alloy back plate 2 to the thread 5 with a spacing of 0.2 mm and a depth of 0.15 mm, then use a wire brush to clean along the direction of the turning thread, and then use isopropanol to perform ultrasonic cleaning for 20 minutes. Carry out vacuum drying at 60°C for 60 minutes, and control the pressure of vacuum drying at ...

Embodiment 3

[0076] This embodiment provides a method for low-temperature diffusion welding of ultra-high-purity copper target components, and the method includes the following steps:

[0077] Provide an ultra-high-purity copper target material 1 (purity is 6N) and a copper alloy back plate 2; the material of the copper alloy back plate 2 is copper-chromium alloy, and the copper alloy back plate 2 is provided with grooves, The bottom surface of the groove is the welding surface;

[0078] (1) The welding surface of the ultra-high-purity copper target 1 is turned with a diamond tool, and the roughness after turning is 0.7 μm;

[0079] Turn the welding surface of the copper alloy back plate 2 to the thread 5 with a spacing of 0.45 mm and a depth of 0.1 mm, then use a wire brush to clean along the direction of the turning thread, and then use isopropanol to perform ultrasonic cleaning for 30 minutes. Under the condition of 80 ℃, carry out vacuum drying for 80 minutes, and control the pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com