Vertical gravity discharging centrifuge

A centrifuge and gravity technology, applied in the field of centrifuges, can solve the problems of restricting the application range of centrifuges, shortening the service life of filter screens, and low production efficiency, and achieve the effects of reliable finish, improved service life, and guaranteed finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

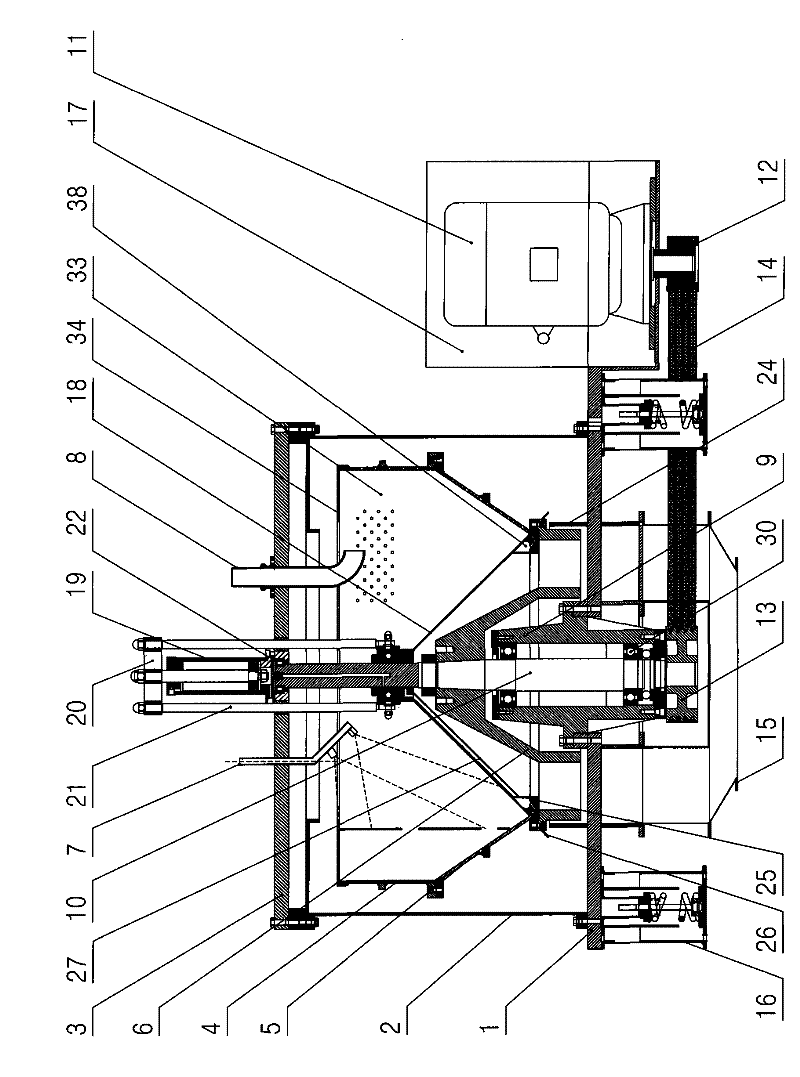

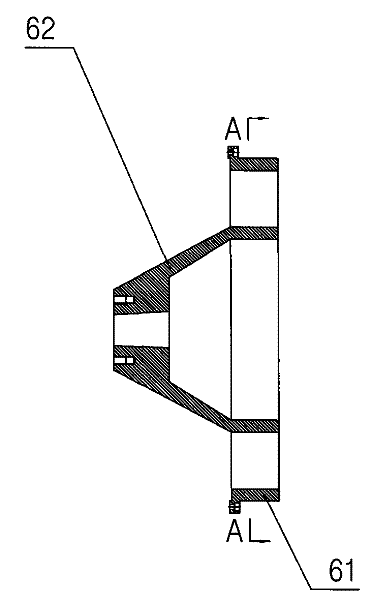

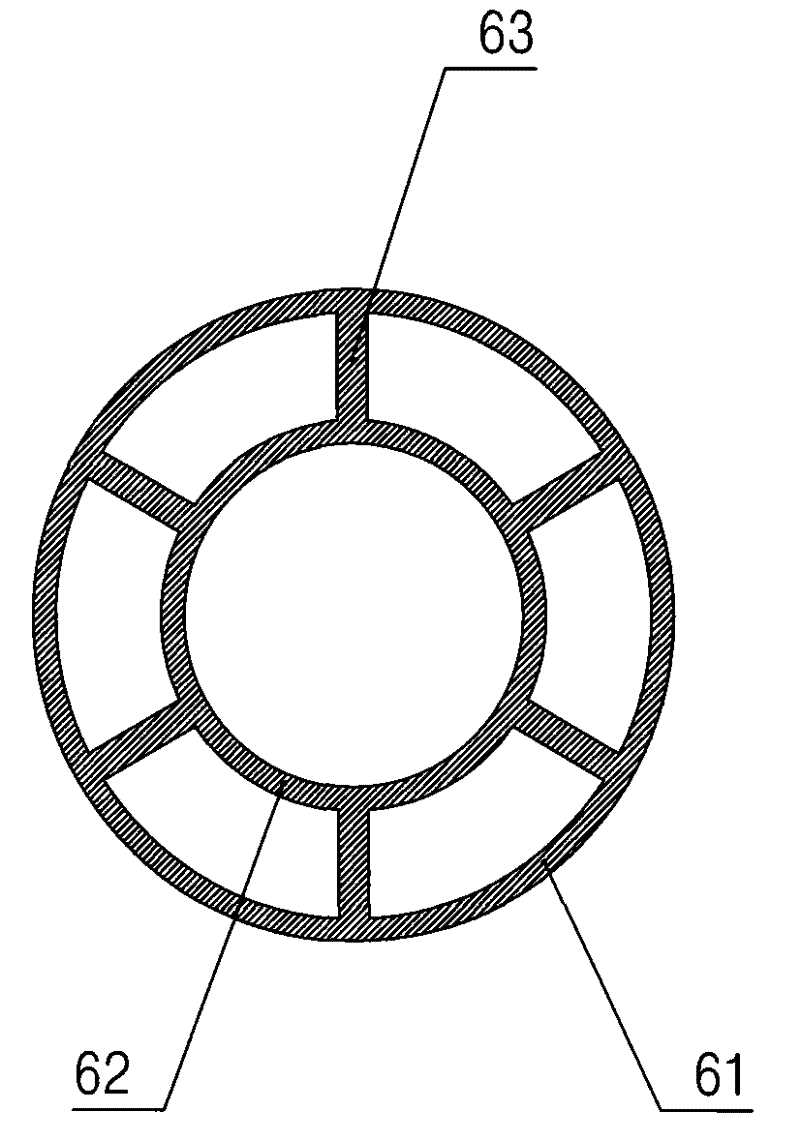

[0020] Such as figure 1 As shown, the vertical gravity unloading centrifuge of the present invention includes: a machine base 1, a bearing seat 9 is arranged in the machine base 1, a main shaft 10 is arranged in the bearing seat 9 through a bearing 30, and a rotating shaft 10 is set on the main shaft 10. Drum body 6, such as figure 2 , image 3 , Figure 4 As shown, the specific structure of the drum body 6 includes: an outer ring 61 and a drum seat 62 arranged on the main shaft 10. The drum seat 62 is connected to the outer ring 61 through six connecting ribs 63. In order to reduce the accumulation of filter residues, the connecting ribs The upper end surface (face facing the object) of 63 is provided with "eight"-shaped chamfer, and its angle is usually between 45-65 degrees; a discharge port is formed between the lower part of the drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com