Simple conveying mechanism

A transmission mechanism and simple technology, applied in the directions of transportation, packaging, chute, etc., can solve the problems of low work efficiency and high labor intensity, and achieve the effect of avoiding large swing and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

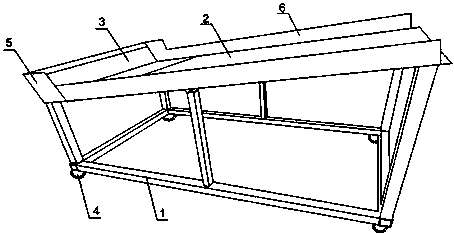

[0020] like figure 1 As shown, this embodiment includes a support frame 1, a transmission plate 2, a baffle plate 5 and a plurality of universal wheels 4, the transmission plate 2 is connected to the baffle plate 5, and the transmission plate 2 and the baffle plate 5 are all arranged on the support frame 1 Above, the universal wheels 4 are evenly distributed on the bottom of the support frame 1, and the connection between the transmission plate 2 and the support frame 1 is also provided with a spring, and also includes a rubber pad 3 arranged on the bottom of the transmission plate 2 and the baffle plate 5. The transmission plate 2 set on the support frame 1 is at a certain angle to the horizontal direction, and the silencer cylinder that has completed the curling process is placed on the top of the transmission plate 2, and slides down to the bottom of the transmission plate 2 under the action of the silencer cylinder’s own gravity , and finally collected by the staff respons...

Embodiment 2

[0024] like figure 1 As shown, this embodiment is based on Embodiment 1, the inclination angle of the transmission plate 2 is 15°-45°, and the transmission plate 2 is provided with anti-slip patterns. Tilting at a certain angle allows the muffler to freely slide downwards to the detection place for detection under the action of gravity; the transmission distance may be long or short, and the anti-skid pattern set on the transmission plate 2 can control the sound of the muffler to a certain extent. Decrease speed, avoid its descending too fast and cause violent collision with baffle plate 5.

Embodiment 3

[0026] like figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes side baffles 6 arranged on both sides of the conveying plate 2 , and the side baffles 6 are vertically connected to the baffles 5 . When the muffler slides down, the rolling track is easy to change. When the transmission distance is long, the muffler will slide out of the transmission plate 2 and fall to the ground causing damage to the muffler. The side baffles 6 on both sides of the transmission plate 2 can limit the sliding track of the muffler to prevent its side Slide out the transfer plate 2.

[0027] Preferably, the rubber pad 3 is styrene-butadiene rubber. Styrene-butadiene rubber (SBR) is a copolymer of styrene and butadiene. Compared with natural rubber, it has uniform quality, less foreign matter, and excellent mechanical stability.

[0028] Preferably, the support frame 1 is made of cast iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com