Lifting control method, device and system as well as lifting appliance and hoisting machine

A control algorithm and spreader technology, applied in the field of hoisting control of hoisting machinery and spreaders, can solve problems such as unsatisfactory, and achieve the effects of suppressing swing, improving anti-sway effect and improving anti-sway ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

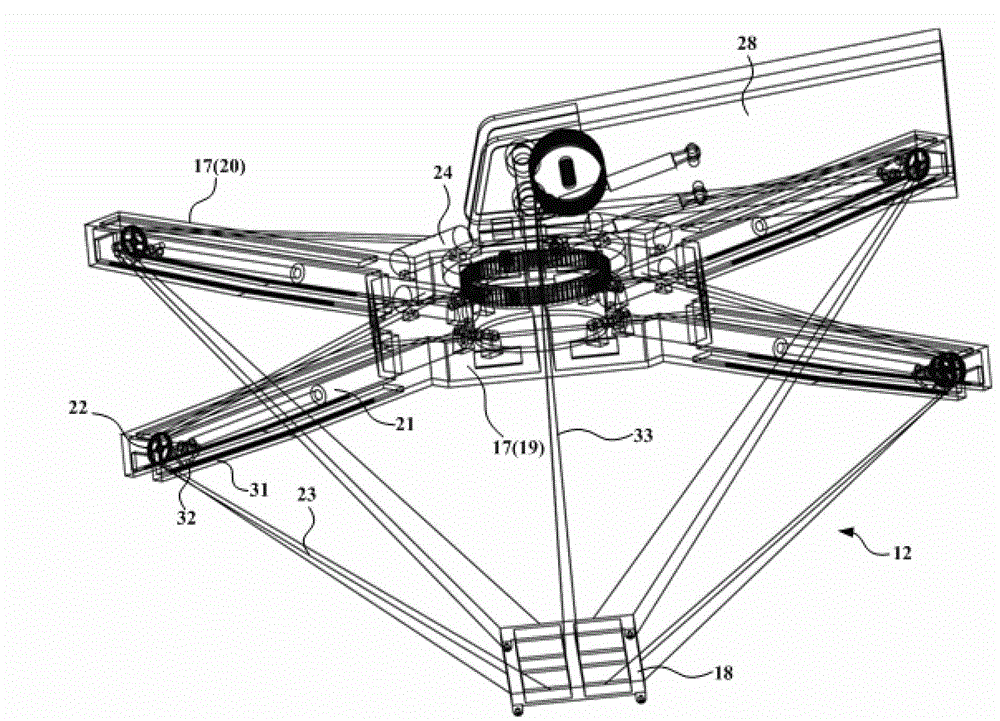

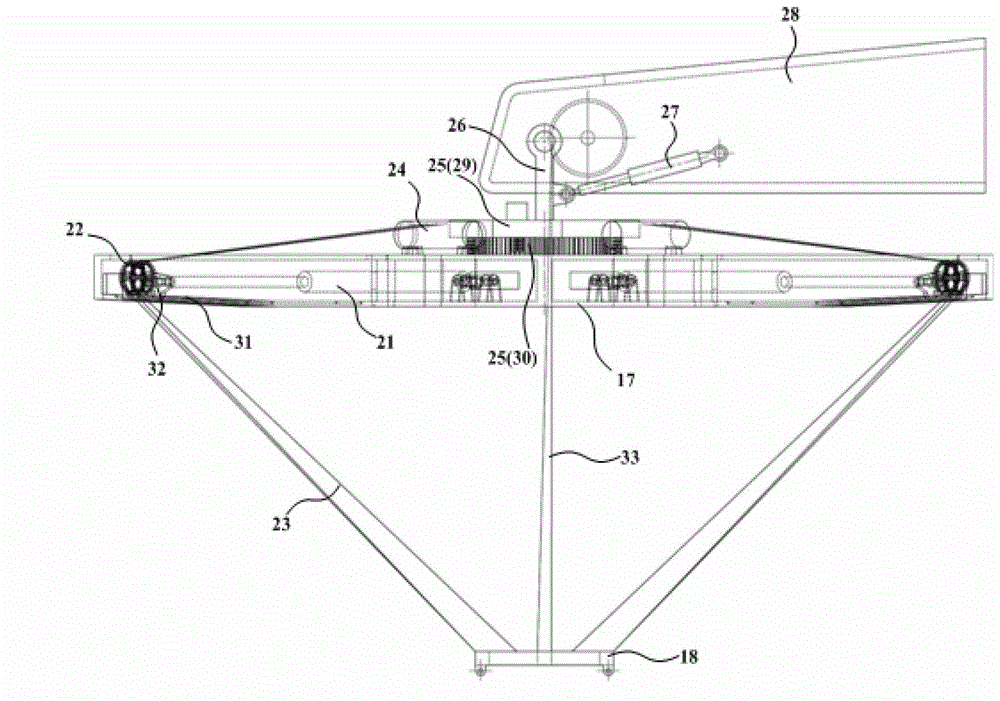

[0062] Such as Figure 6 As shown, the first embodiment of the hoisting control method of the hoisting machinery of the present invention, using the spreader described in the previous embodiment, includes the following steps:

[0063] Step 101. Obtain the swing angle information of the suspension beam detected by the first detection device relative to the spreader frame in the vertical plane, the posture displacement information of the spreader frame relative to the inertial coordinate system detected by the second detection device, and the third detection device The attitude displacement information of the delivery platform detected by the device relative to the inertial coordinate system;

[0064] Step 102: output the first swing control signal according to the swing angle information of the hanging beam, the attitude displacement information of the spreader frame, the attitude displacement information of the delivery platform and the first swing control algorithm, and contr...

no. 3 example

[0071] The third embodiment of the hoisting control method of the present invention further includes:

[0072] Obtain the rotation angle information of the gear turntable detected by the fifth detection device;

[0073] According to the rotation angle information of the gear turntable, the attitude displacement information of the spreader frame, the attitude displacement information of the delivery platform and the third swing control algorithm, the third swing control signal is output to control the rotation of the gear turntable relative to the pallet to the lifting beam and the delivery platform counterpoint.

[0074] The method in this embodiment is applicable to the situation where the hoisting weight and the loading platform are not aligned. The delivery area of the cargo platform. The third swing control signal is used to control the gear turntable of the turntable to rotate relative to the pallet until the lifting beam is aligned with the loading platform. This emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com