Anti-shake travelling mechanism for monorail conveyor

A technology of monorail conveyor and running mechanism, applied in monorail system, transportation and packaging, locomotive and other directions, can solve the problems of reducing the safety, stability and durability of monorail conveyor, affecting storage and sales, and shaking of cargo boxes, etc. Great significance for storage and sale, the effect of reducing bumps and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

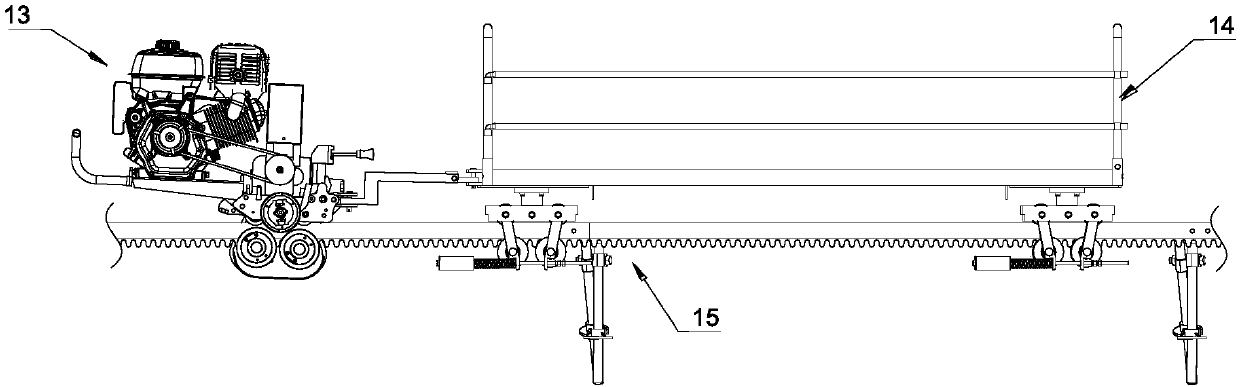

[0030] see figure 1 , the monorail transporter includes a traction section 13 , a cargo body section 14 and a rail support section 15 .

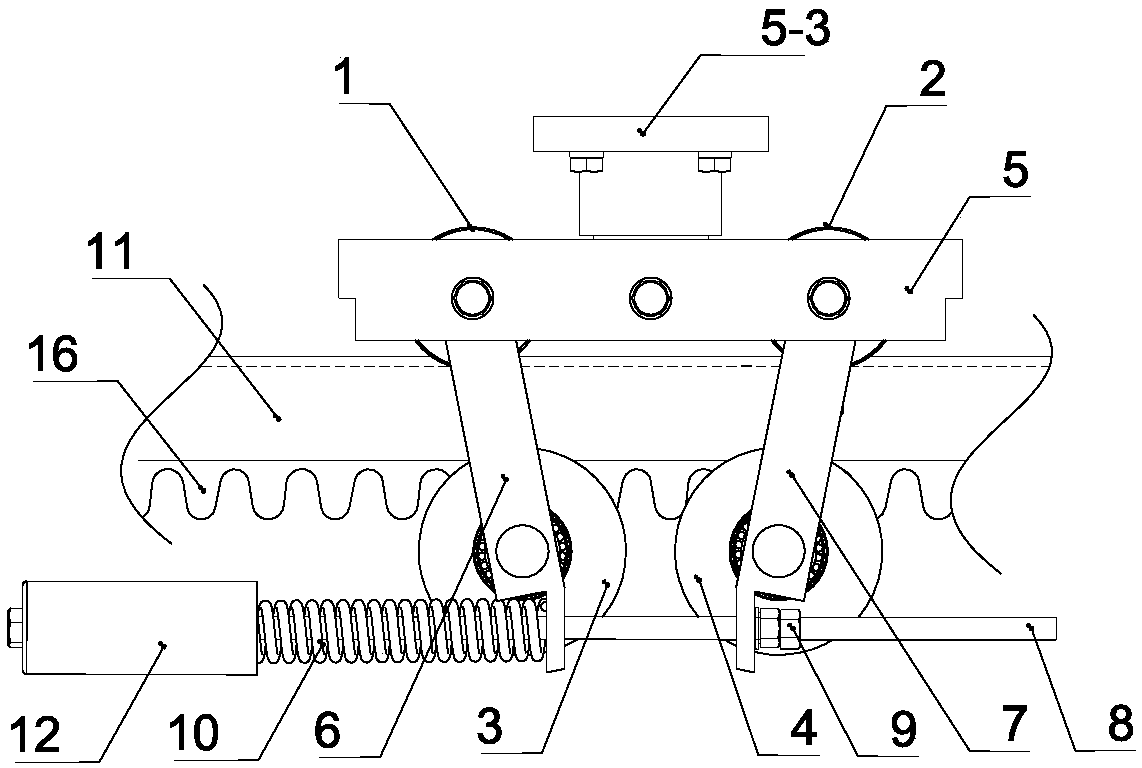

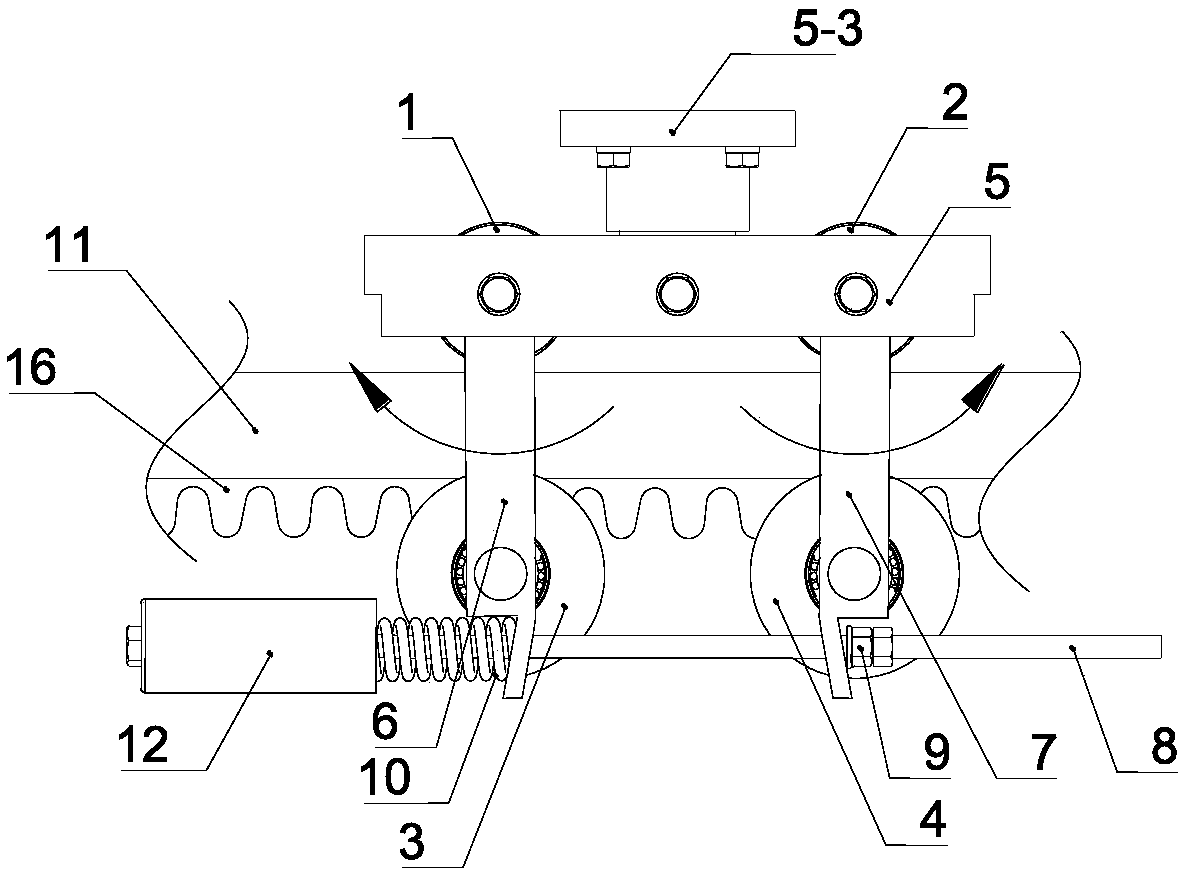

[0031] see figure 1 with figure 2 , the anti-sway running mechanism of a monorail conveyor of the present invention includes a first load-bearing wheel 1 and a second load-bearing wheel 2 arranged above the monorail 11, a first anti-rollover wheel 3 and a second anti-rollover wheel arranged under the monorail 11 4. The fixed frame 5 for installing the first bearing wheel 1 and the second bearing wheel 2, the first rotating arm 6 for installing the first anti-rolling wheel 3 and the second anti-rolling wheel 4 for installing The second rotating arm 7 and the elastic buffer mechanism arranged between the first rotating arm 6 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com