High-speed carding machine

A carding machine, high-speed technology, used in fiber processing, deburring devices, textiles and papermaking, etc., can solve problems affecting the smoothness and speed of carding device operation, uneven thickness of textile raw materials, affecting product quality, etc. Simple, prevent tipping, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

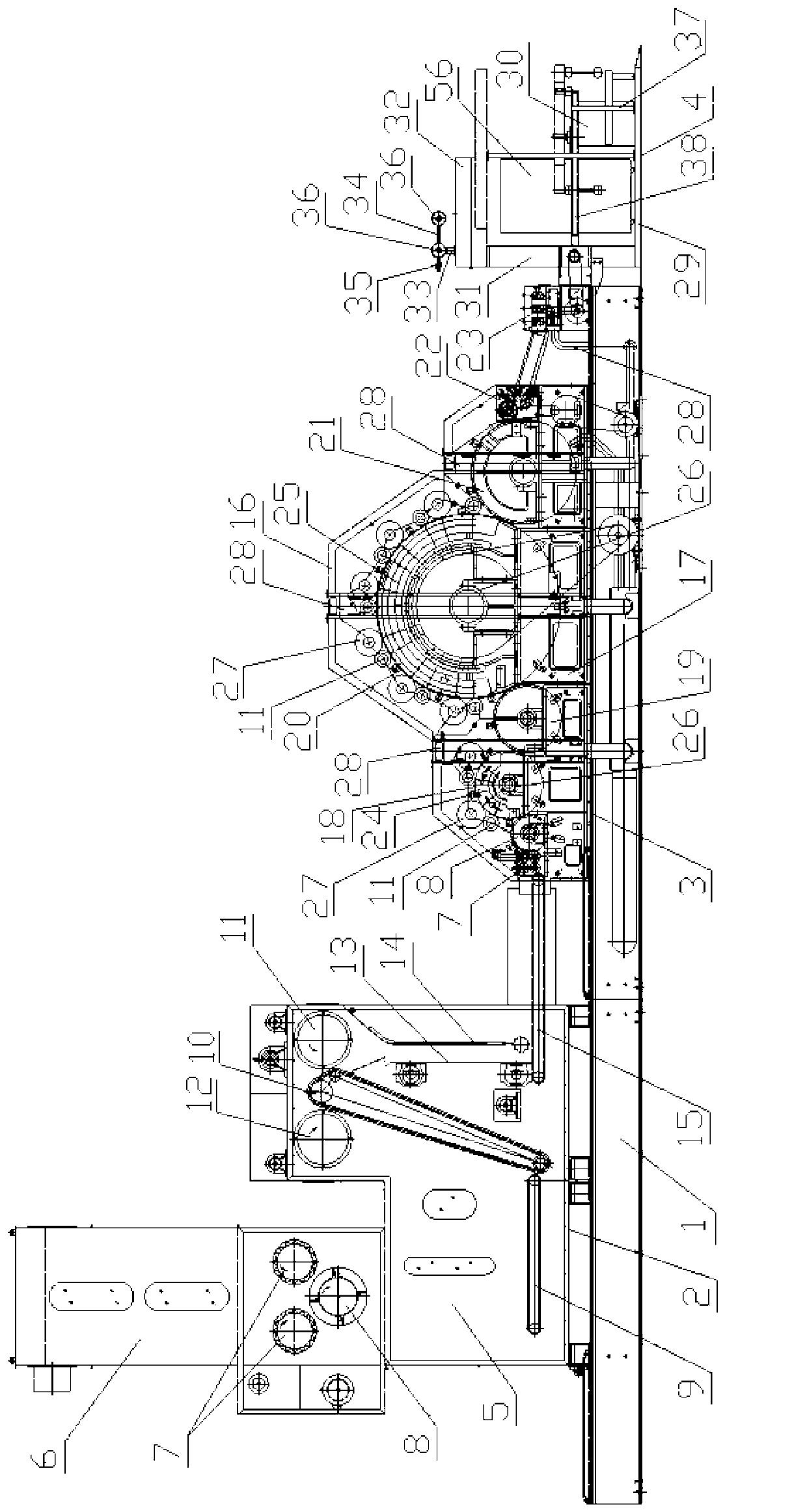

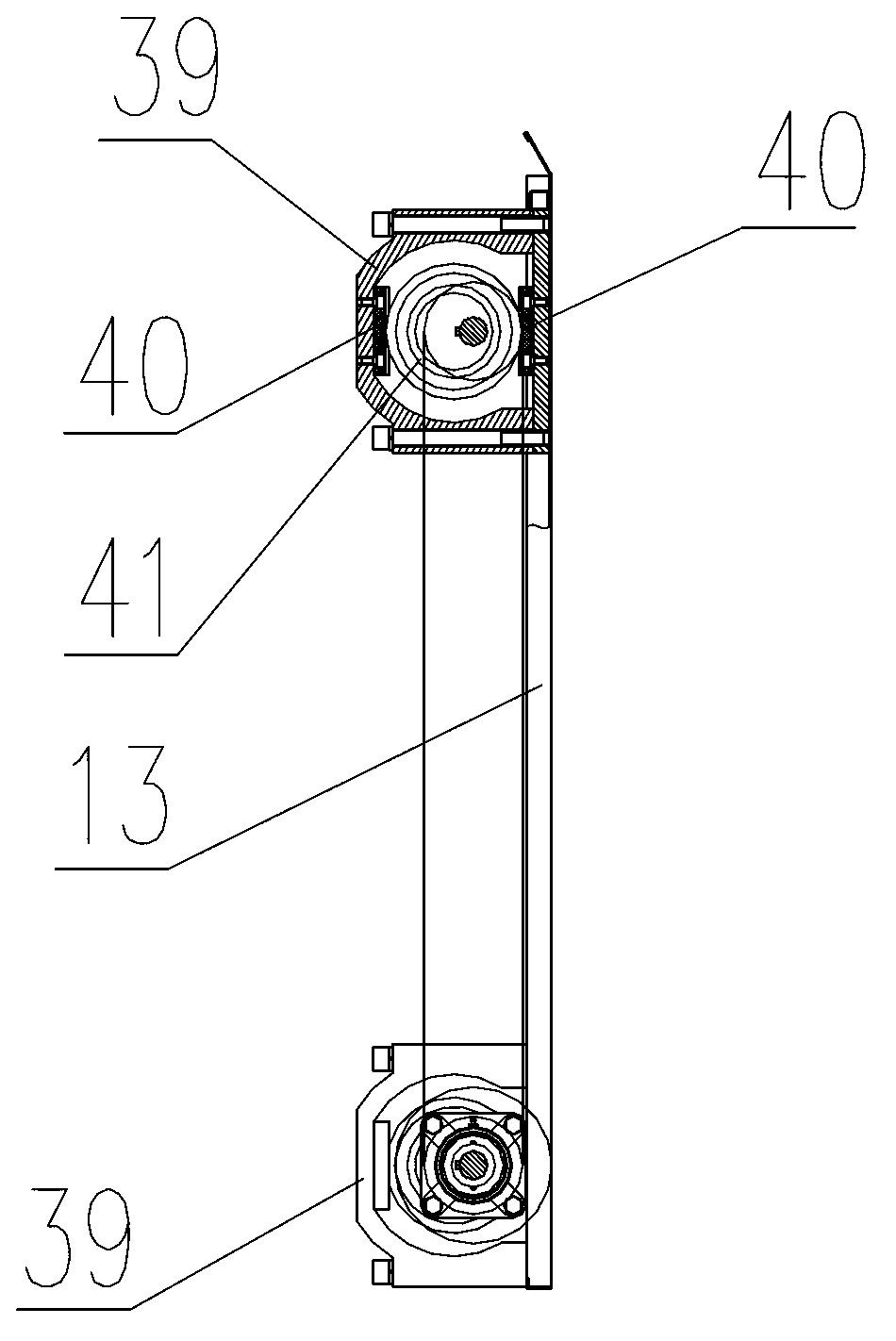

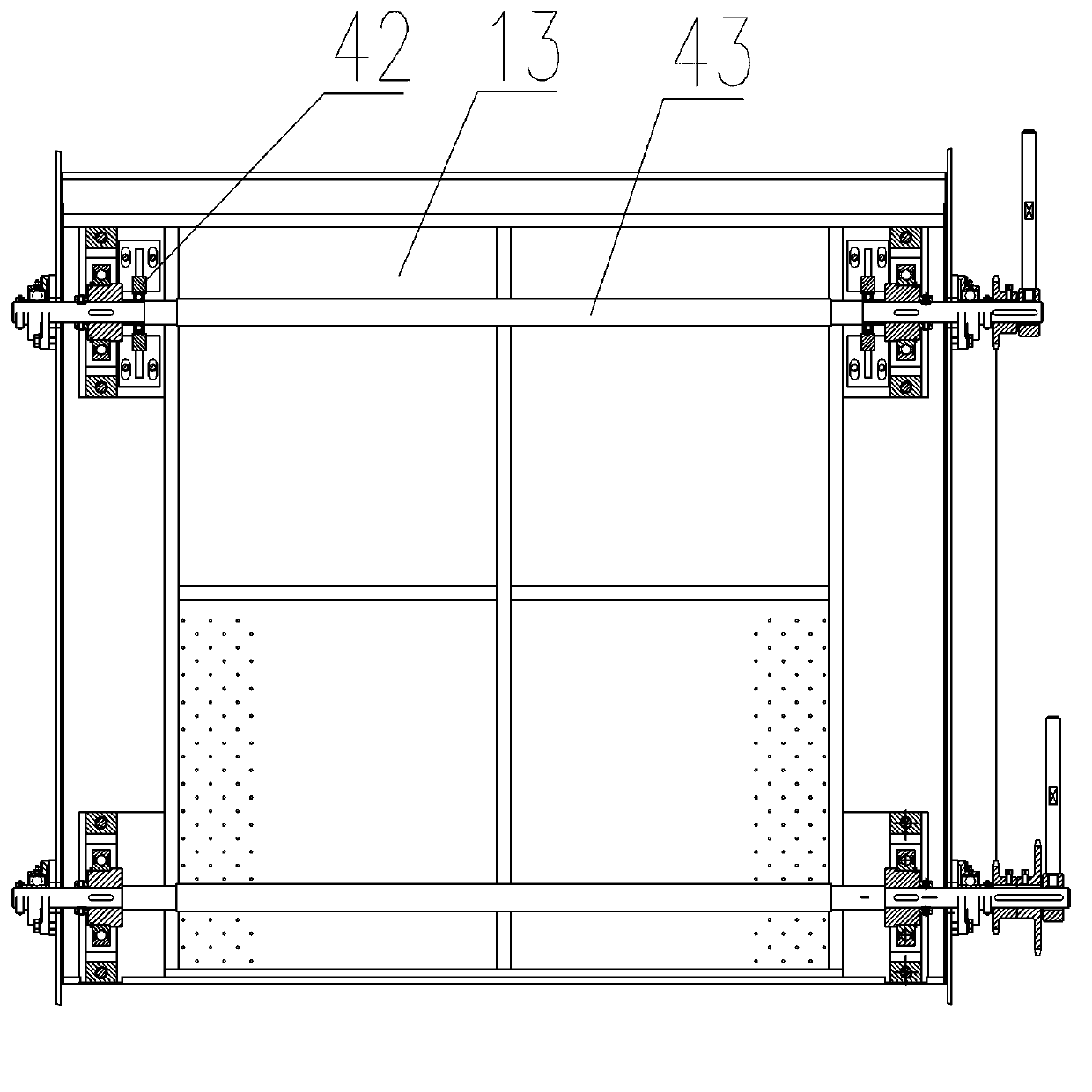

[0015] High-speed carding machine of the present invention, as figure 1 As shown, it includes a base 1 and a vibrating wool feeding machine 2 connected in sequence, a high-speed carding device 3, and a three-station automatic barrel changing device 4; the vibrating wool feeding machine 2 includes a shell 5, and the shell 5 is installed on the base 1 Above, the top surface of the front part of the casing 5 is provided with an opening, and the rear end of the casing 5 is also provided with an opening. The opening on the front part of the casing 5 is connected with an upper material storage box 6, and the upper material storage box 6 is provided with a feeding roller 7 and an opening roller. Loosening roller 8, bottom flat curtain 9, oblique nail curtain 10 are arranged successively in the shell 5, the stripping roller 11 is arranged behind the upper part of the oblique nail curtain 10, the hair equalizing roller 12 is arranged in front of the upper part of the oblique nail curtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com