Nozzle for floor vacuum cleaner

A technology of vacuum cleaners and straws, applied in the directions of vacuum cleaners, nozzles, applications, etc., can solve problems such as loss of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

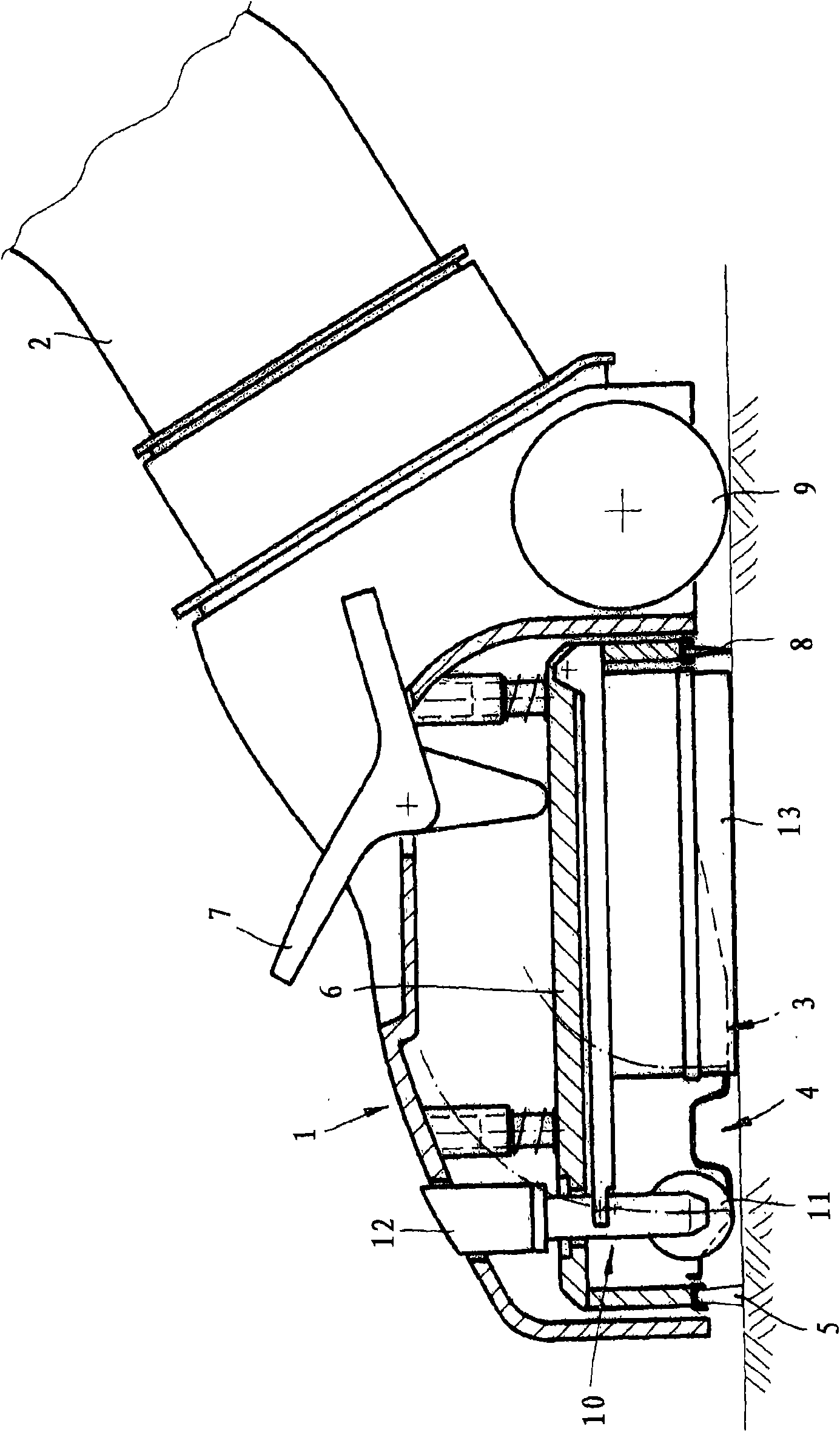

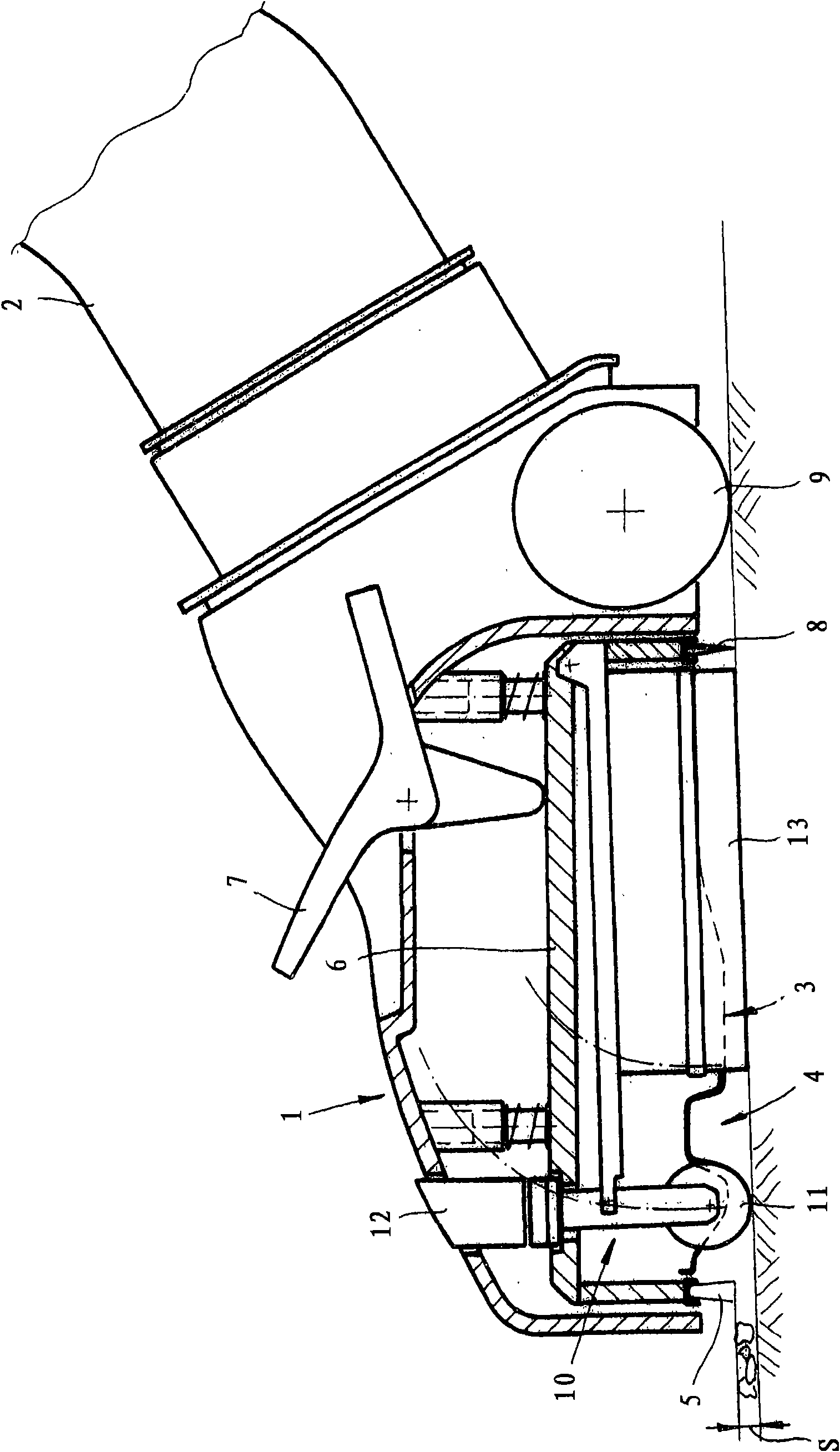

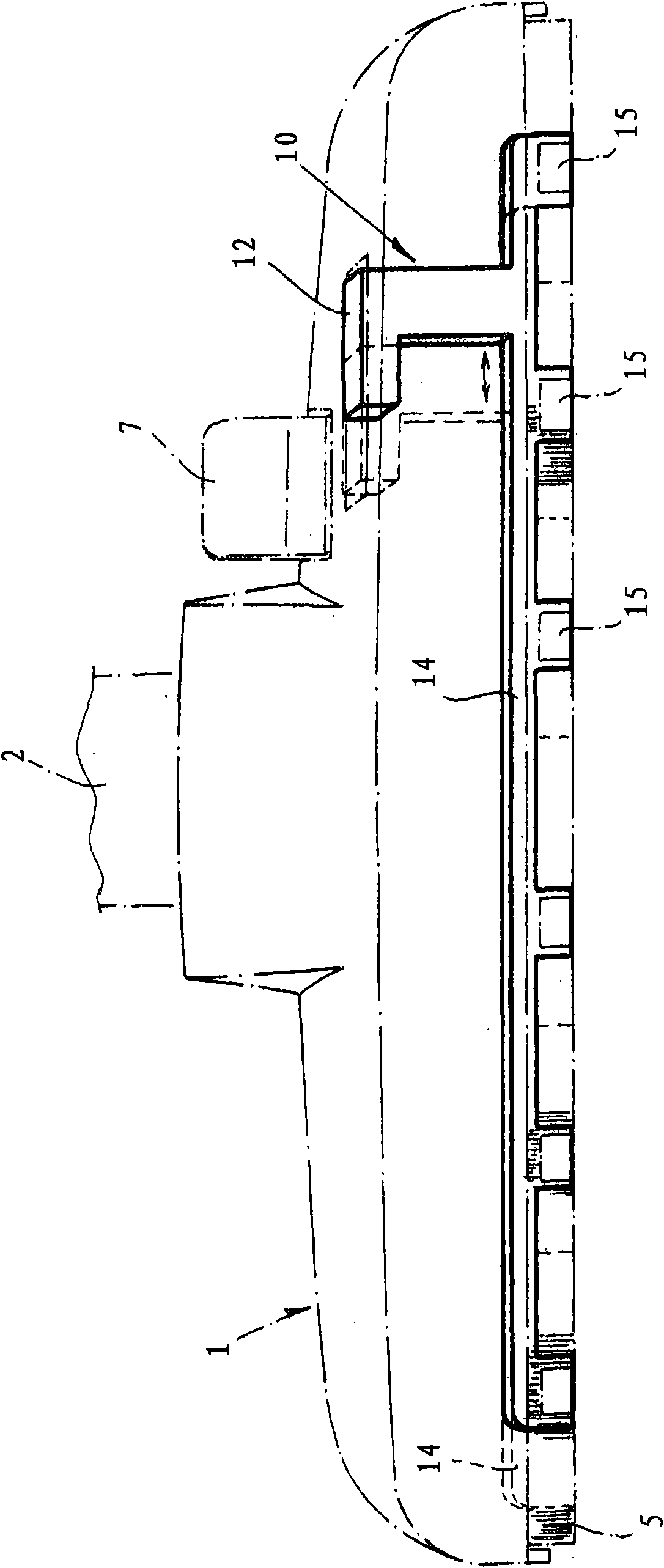

[0020] The nozzle shown in the picture can be attached to the vacuum cleaner via the suction tube and suction hose and is optimal for vacuuming on fabric surfaces and smooth floors. The basic structure of this suction nozzle consists of a suction head 1, a suction tube adapter 2, a sliding base 3, and a telescoping support and sealing element, wherein said suction tube adapter 2 is attached to the suction head in a movable manner about an axis of rotation Or a suction channel, which is rotatably connected to the suction head; the sliding base 3 has at least one lower side suction groove 4 defined by the edge of the suction port; the telescopic support and sealing The element for vacuuming smooth floors on the underside of the suction head comprises a front strip 5 which is breathable and / or has openings and is arranged upstream of the suction slot 4 in the suction direction. The front strip 5 is fixed to a vertically adjustable or rotatably arranged support 6 in the suction he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com