Spoke air hole machining die

A technology for processing molds and spokes, which is applied in the field of stamping processing, can solve problems such as the inability of the stamping machine to work continuously, scratches on the inner wall of the spokes, and affect the processing efficiency, and achieve the effects of avoiding deformation, accelerating heat dissipation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

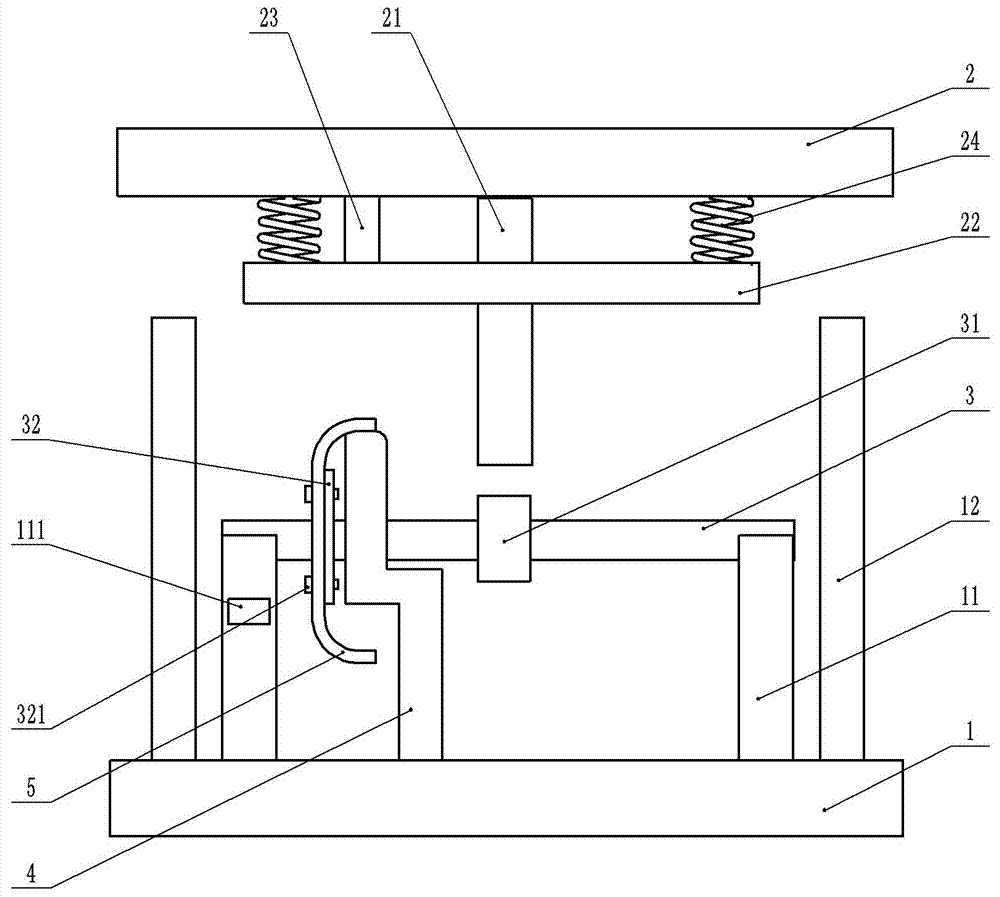

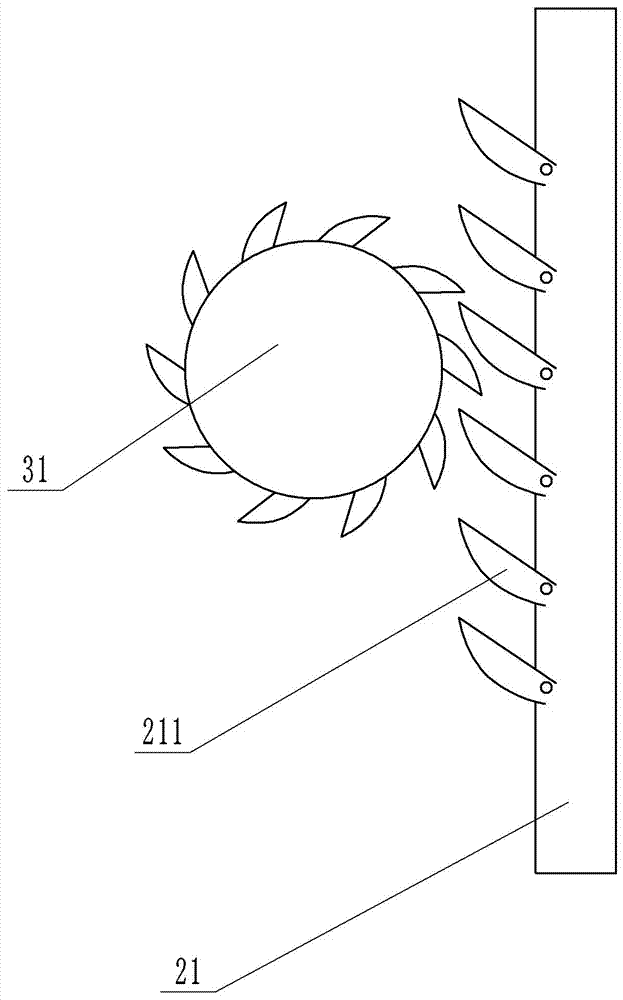

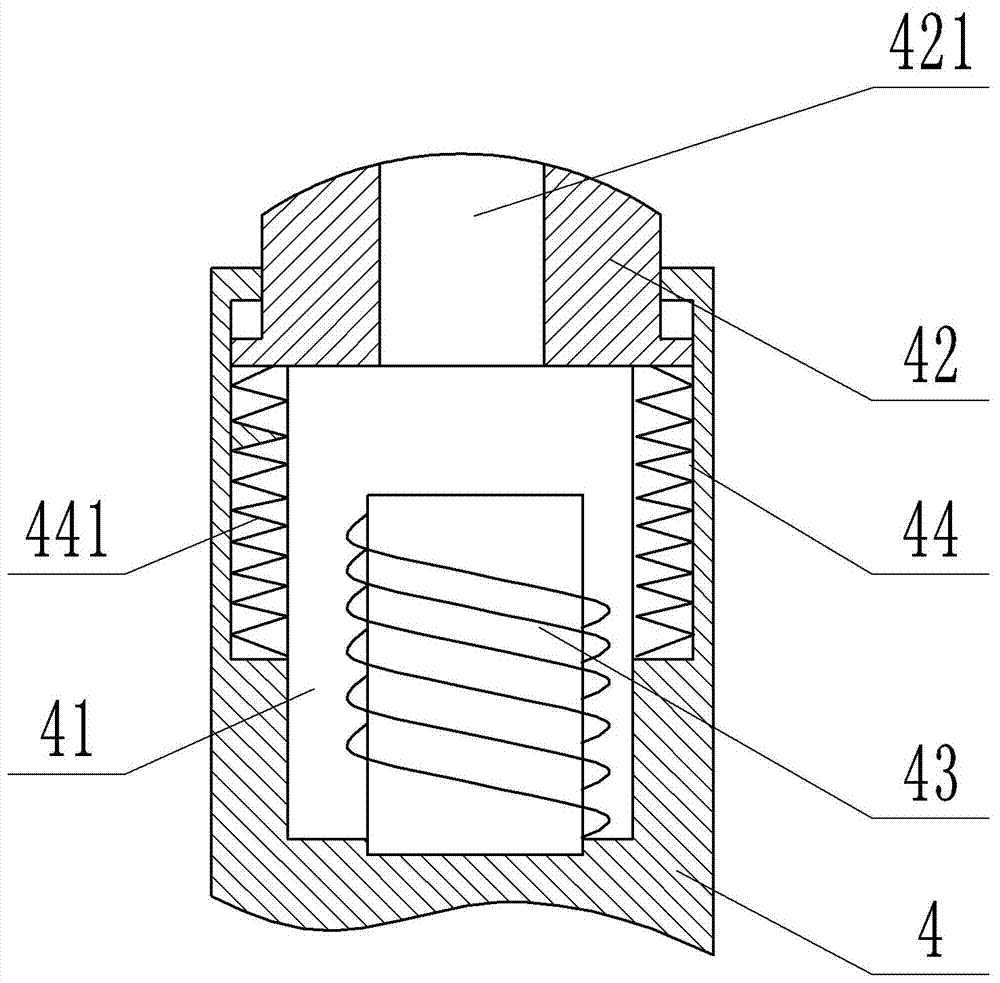

[0023] The reference signs in the accompanying drawings include: lower template 1, frame 11, guide post 12, upper template 2, transmission rod 21, pawl 211, elastic plate 22, punch 23, spring 24, rotating shaft 3, ratchet 31 , positioning plate 32, positioning pin 321, punching block 4, cavity 41, magnet bump 42, punching hole 421, coil 43, chute 44, extension spring 441, wheel spoke 5.

[0024] Such as figure 1 , figure 2 As shown, the spoke air hole processing mold includes an upper mold and a lower mold for installing the spoke 5, the upper mold is installed on the punching machine, and moves up and down as the punching machine works. The upper mold includes an upper template 2, a punch 23 and a transmission rod 21, and the side wall of the punch 23 is provided with an electromagnet; Lower movable stopper, so this ratchet 211 can only swing upwards. Both the punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com