Cold drawing preparation method for TB9 titanium alloy disc round wire with lubricating coating

A technology of lubricating coating and titanium alloy, which is applied in the field of cold drawing preparation of TB9 titanium alloy coiled wire with lubricating coating, can solve the problem of not being able to meet the needs of continuous production of fasteners, affecting the stability of material performance, Long processing procedures and other issues, to achieve the effect of improving the uniformity and stability of adhesion, shortening the production cycle, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

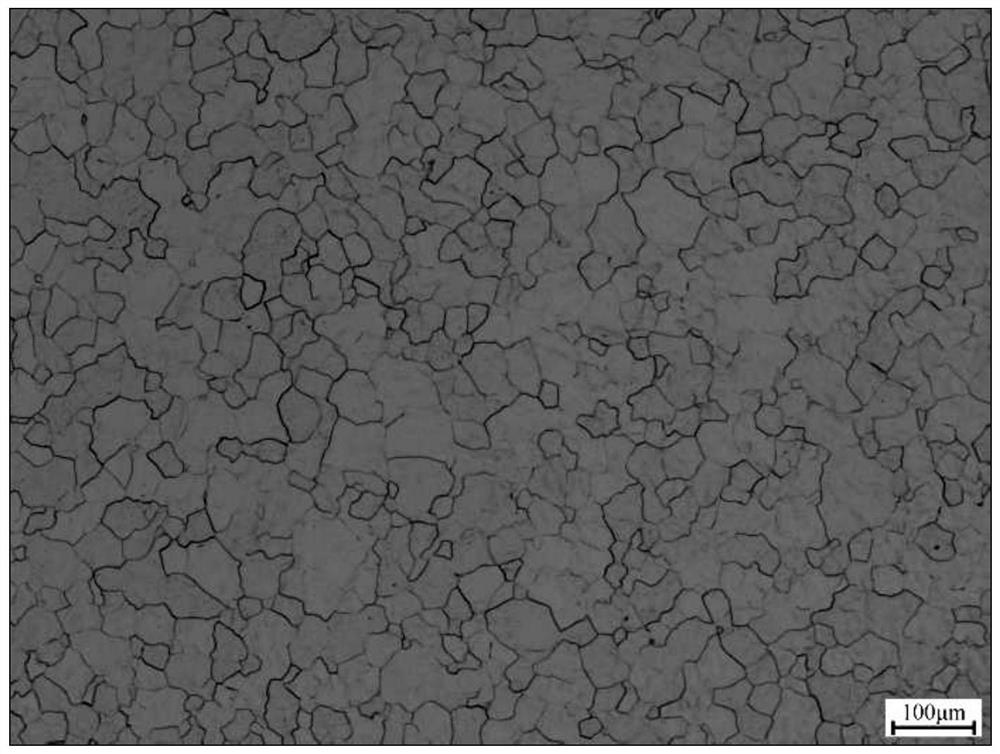

[0027] Step 1, heat treatment, peeling: the TB9 titanium alloy coiled wire with a diameter of Φ6mm is subjected to solution heat treatment, and then the peeling machine is used to remove the surface oxide until the diameter is Φ5.80mm; the system of the solution heat treatment is: 830 Keep warm for 30 minutes at ℃ and then air cool;

[0028] Step 2, sandblasting: sandblasting the TB9 titanium alloy disc round wire after peeling in step 1; the sandblasting is carried out with white corundum grit with a particle size of 80#;

[0029]Step 3, surface pretreatment: carry out surface pretreatment to the TB9 titanium alloy disc round wire after sandblasting in step 2; The coiled wire material is immersed in the pretreatment reagent, and then the pretreatment reagent is heated to 90°C and continuously stirred and adsorbed, and then dried at 130°C for 1 hour until the surface is precipitated to form a uniform and dense film; the p...

Embodiment 2

[0034] This embodiment includes the following steps:

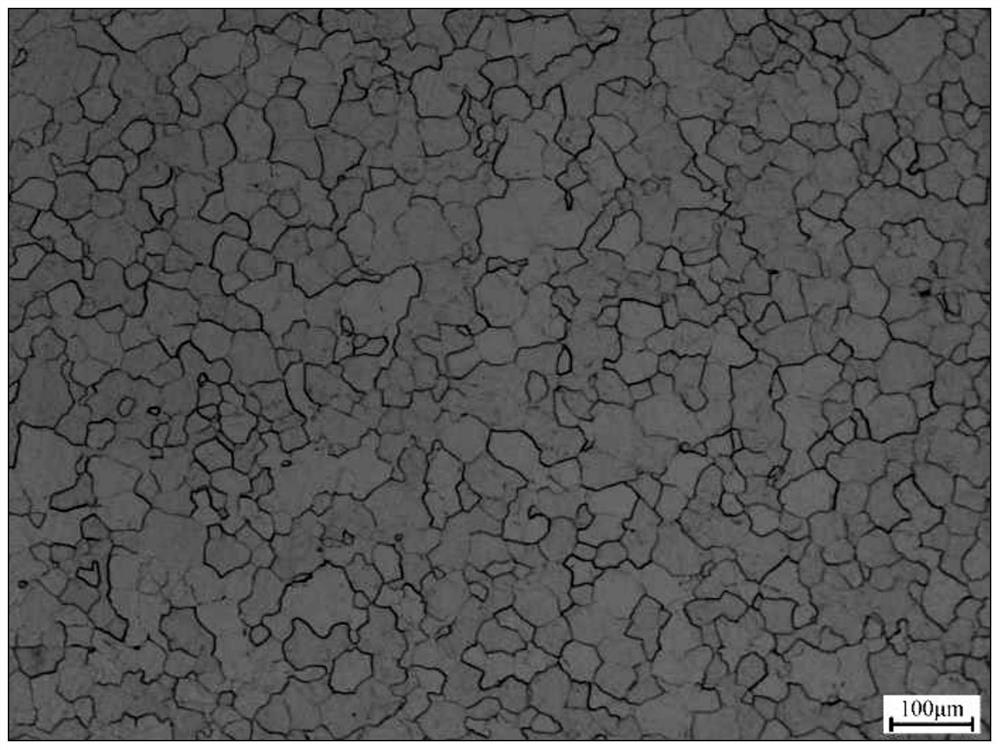

[0035] Step 1, heat treatment, peeling: the TB9 titanium alloy round wire with a diameter of Φ4.8mm is subjected to solution heat treatment, and then the peeling machine is used to remove the surface oxide scale until the diameter is Φ4.63mm; the system of the solution heat treatment is : Keep warm at 800°C for 40 minutes and then air cool;

[0036] Step 2, sandblasting: sandblasting the TB9 titanium alloy disc round wire after peeling in step 1; the sandblasting is carried out with white corundum grit with a particle size of 80#;

[0037] Step 3, surface pretreatment: carry out surface pretreatment to the TB9 titanium alloy disc round wire after sandblasting in step 2; The coiled wire material is immersed in the pretreatment reagent, and then the pretreatment reagent is heated to 85°C and continuously stirred and adsorbed, and then dried at 140°C for 1 hour until the surface is precipitated to form a uniform and dense fi...

Embodiment 3

[0042] This embodiment includes the following steps:

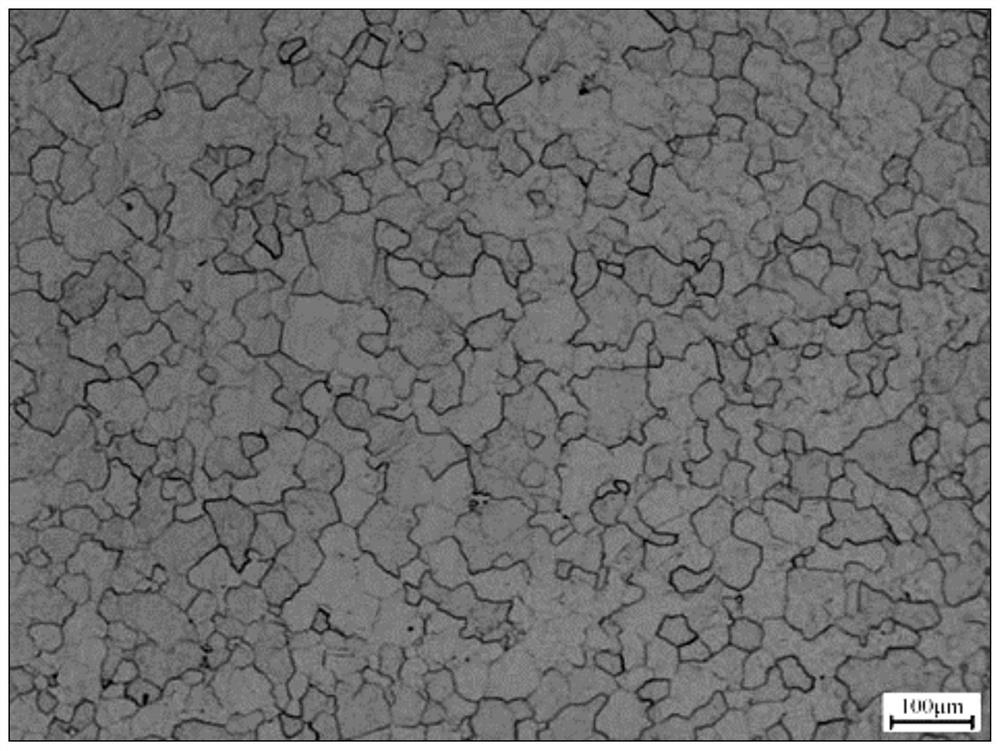

[0043] Step 1, heat treatment, peeling: the TB9 titanium alloy round wire with a diameter of Φ4.3mm is subjected to solution heat treatment, and then the peeling machine is used to remove the surface oxide scale until the diameter is Φ4.20mm; the system of the solution heat treatment is : Keep warm at 850°C for 10 minutes and then air cool;

[0044] Step 2, sandblasting: sandblasting the TB9 titanium alloy disc round wire after peeling in step 1; the sandblasting is carried out with white corundum grit with a particle size of 80#;

[0045] Step 3, surface pretreatment: carry out surface pretreatment to the TB9 titanium alloy disc round wire after sandblasting in step 2; The coiled wire material is immersed in the pretreatment reagent, and then the pretreatment reagent is heated to 95°C and continuously stirred and adsorbed, and then dried at 130°C for 1 hour until the surface is precipitated to form a uniform and dense fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com