High-toughness silicon carbide ceramic and preparation method thereof

A silicon carbide ceramic and high toughness technology, applied in the field of high toughness silicon carbide ceramic and its preparation, can solve the problems of high brittleness, low fracture toughness, difficulty in meeting high toughness and high strength, etc. Excellent mechanical properties, the effect of improving bulk density and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

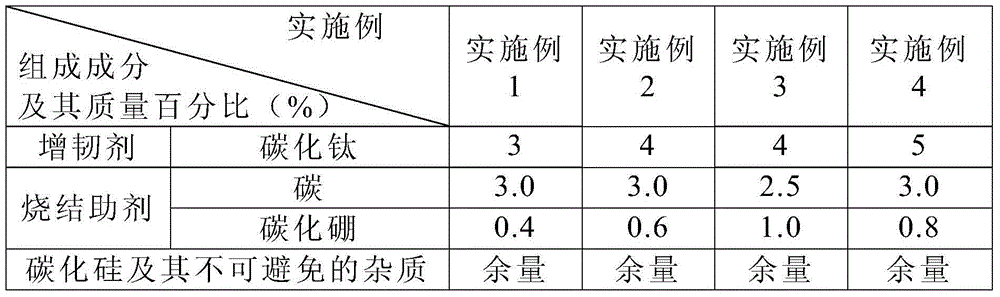

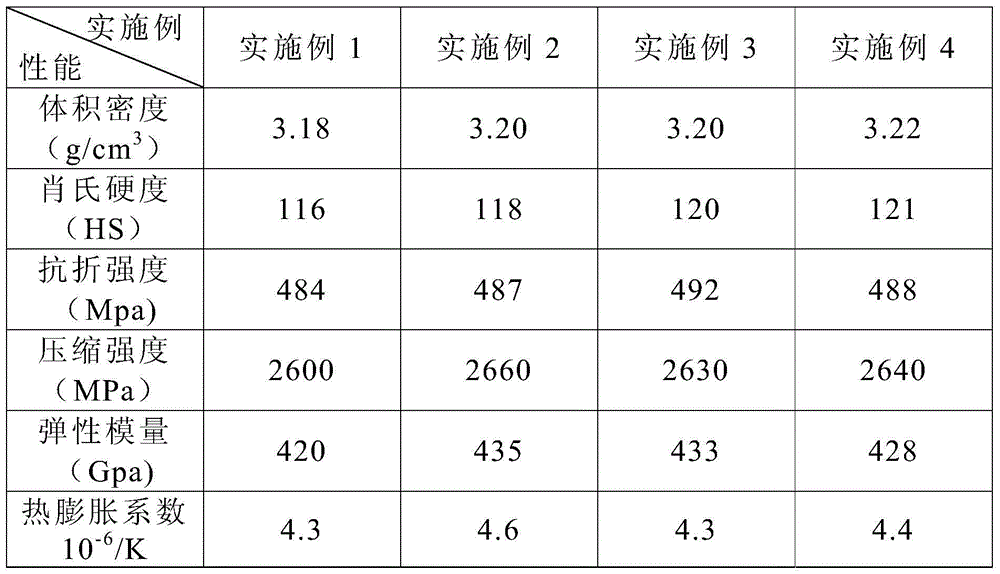

[0030] According to the composition and mass percentage of high-toughness silicon carbide in Example 1 in Table 1, weigh silicon carbide with a particle size of 0.3-0.6 μm, titanium carbide with 1-1.5 μm, sintering aid carbon and boron carbide with 1-2 μm and mix well. After mixing evenly, put it into a ball mill, control the ratio of ball to material to 3:1, and add 3% water-soluble resin and 80% distilled water for ball milling for 2 hours. After ball milling, dry the powder in a steam drying oven, then add it to the steel mold and pressurize it to 150MPa / cm 2 Press molding, the pressing time is controlled to 4s. Then put the pressed blank into a vacuum furnace for sintering, the sintering temperature is controlled at 2130° C., and the holding time is 3 hours. Finally, the sintered green body is subjected to surface grinding to obtain a final product of high-toughness silicon carbide ceramics.

Embodiment 2

[0032] According to the composition and mass percentage of high-toughness silicon carbide in Example 2 in Table 1, weigh silicon carbide with a particle size of 0.6-1.0 μm, titanium carbide with a particle size of 1.3-1.6 μm, and sintering aid carbon and carbide with a particle size of 1.5-2.5 μm. Boron and mix well. After mixing evenly, put it into a ball mill, control the ratio of ball to material to 3:1, and add 4% water-soluble resin and 100% distilled water for ball milling for 2 hours. After ball milling, dry the powder in a steam drying oven, then add it to the steel mold and pressurize it to 180MPa / cm 2 Press molding, the pressing time is controlled to 2s. Then put the pressed blank into a vacuum furnace for sintering, the sintering temperature is controlled at 2150° C., and the holding time is 2 hours. Finally, the sintered green body is subjected to surface grinding to obtain a final product of high-toughness silicon carbide ceramics.

Embodiment 3

[0034] According to the composition and mass percentage of high-toughness silicon carbide in Example 3 in Table 1, weigh silicon carbide with a particle size of 0.8-1.3 μm, titanium carbide with a particle size of 1.5-2 μm, sintering aid carbon and boron carbide with a particle size of 2-2.5 μm and mix well. After mixing evenly, put it into a ball mill, control the ratio of ball to material to 3:1, and add 5% water-soluble resin and 120% distilled water for ball milling for 2 hours. After ball milling, dry the powder in a steam drying oven, then add it to the steel mold and pressurize it to 160MPa / cm 2 Press molding, the pressing time is controlled to 3s. Then put the pressed compact into a vacuum furnace for sintering, the sintering temperature is controlled at 2160° C., and the holding time is 2 hours. Finally, the sintered green body is subjected to surface grinding to obtain a final product of high-toughness silicon carbide ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com