Round steel for gear and preparation method thereof

A round steel and gear technology, applied in the field of round steel for gears and its preparation, can solve the problems of difficult control, wide hardenability bandwidth of gear steel, difficult to achieve stable control, etc., and reduce the influence of hardenability uniformity , Improve round steel C segregation and ensure the effect of austenite grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A kind of round steel for gear, its chemical composition and size other than iron are as shown in table 1, and its preparation method comprises:

[0039] S1. Converter smelting.

[0040] S2. Ladle refining: Feed aluminum wire for deoxidation within 10 minutes of the beginning of refining, control the feeding amount of aluminum wire per 130t of molten steel to 100m, and then no longer feed aluminum wire.

[0041] S3. Vacuum degassing: Keep the treatment time ≥30min under a high vacuum with a pressure of ≤66.7Pa. During the degassing process, ferro-titanium alloy is added for titanium alloying treatment. After refining, blow argon softly for 20 minutes and stir to remove floating inclusions. things.

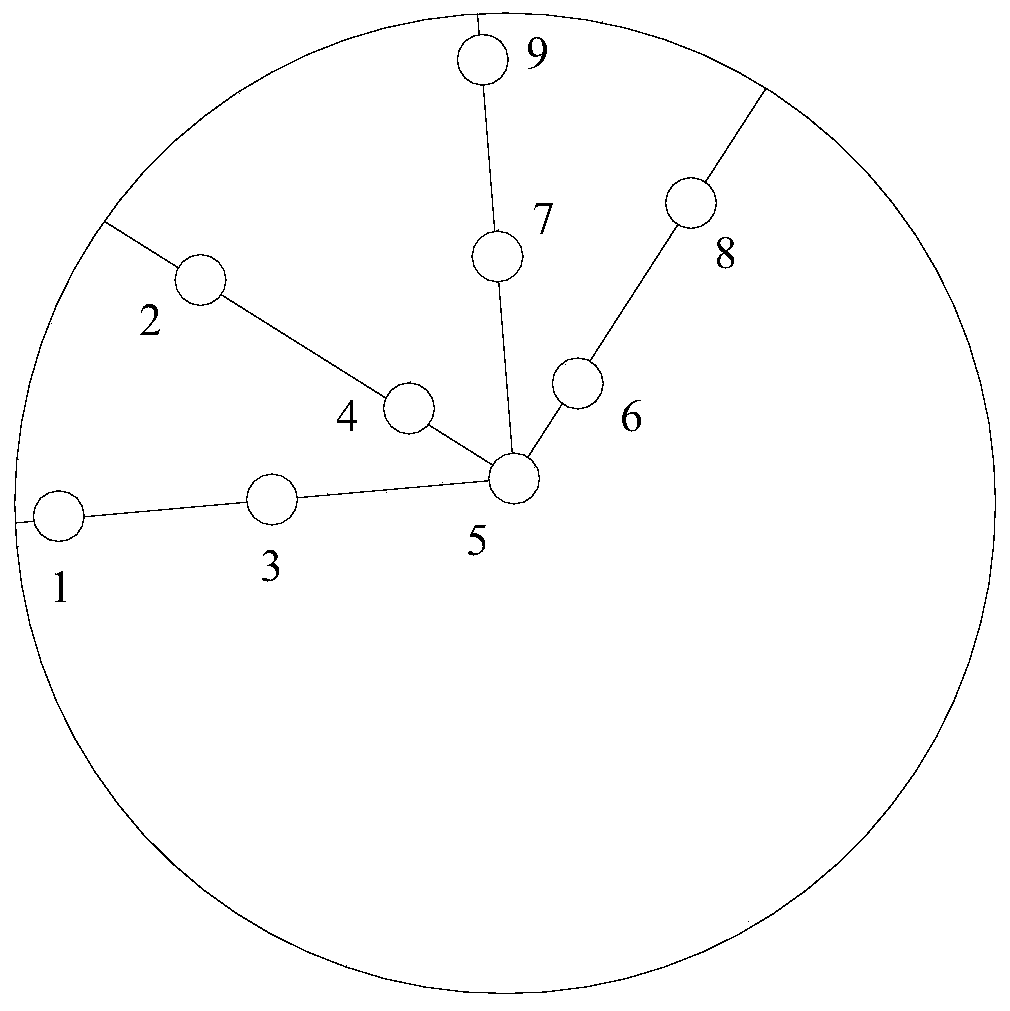

[0042] S4. Continuous casting: cast a continuous casting billet of 320*320mm, the electromagnetic stirring of the mold is combined with the electromagnetic stirring of the solidification end for stirring operation, and the specific process parameters are shown in Table 2. ...

Embodiment 2-3

[0045] A round steel for gears, which differs from Example 1 only in that: the chemical composition and size are different, see Table 1 for details; the continuous casting process parameters are different, see Table 2 for details.

Embodiment 4-5

[0047] A kind of round steel for gears, which differs from Example 1 only in that the chemical composition and size are different, please refer to Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com