Spheroidizing annealing method for Cr and Mo steel with sheet type microstructure

A microstructure and spheroidizing annealing technology, which is applied in the field of metallurgy, can solve problems such as control technology that has not been reported in research, and achieve good application prospects, shortened holding time, and good cold heading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

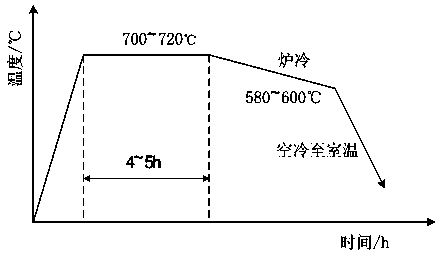

[0037] The Φ10mm wire rod for high-strength bolts is produced by using a 325mm×280mm bloom continuous casting-blanket-wire rolling process in a steel plant. The steel grades and compositions are shown in Table 1.

[0038] Table 1 Grades and compositions of steel grades

[0039] grade C Si mn P S Cr Mo SCM435 0.35 0.2 0.65 0.013 0.007 0.95 0.2

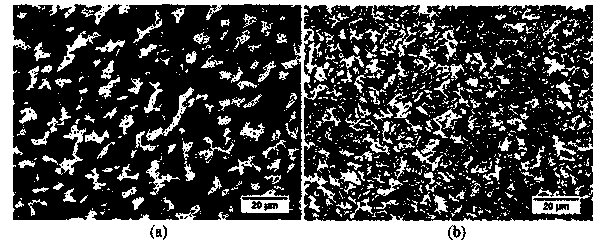

[0040] Place the rolled material sample with a height of 10mm and Φ13mm in a heating furnace, raise the temperature to 720°C and keep it for 5 hours, then cool it to 580°C, and then take the rolled material of Cr and Mo steel out of the furnace and air cool it to room temperature. The steel rolled material is wire-cut, then its cross-section is ground and polished, and it is corroded with 4% nitric acid alcohol and then observed under a metallographic microscope. The metallographic structure is as follows: Figure 5 As shown in (b), the SEM organization chart is as follows Figure 6 as shown in (b);...

Embodiment 2

[0044] The Φ13mm wire rod for high-strength bolts is produced by a 325mm×280mm bloom continuous casting-blanket-wire rolling process in a steel plant. The steel grades and compositions are shown in Table 1.

[0045] Place the rolled material sample with a height of 10mm and Φ13mm in a heating furnace, raise the temperature to 720°C and keep it for 4 hours, then cool it to 600°C, and then take the rolled material of Cr and Mo steel out of the furnace and air cool it to room temperature. The steel rolled material is wire-cut, then its cross-section is ground and polished, and it is corroded with 4% nitric acid alcohol and then observed under a metallographic microscope. The metallographic structure is as follows: Figure 7 As shown in (a), it can be seen from the figure that the spheroidal carbides are evenly distributed on the matrix, the spheroidized structure is rated as grade 5, and its microhardness is measured to be 175.35HV.

Embodiment 3

[0047] The Φ15mm wire rod for high-strength bolts is produced by using a 325mm×280mm bloom continuous casting-blanket-wire rolling process in a steel plant. The steel grades and compositions are shown in Table 1.

[0048] Place the rolled material sample with a height of 10mm and Φ15mm in a heating furnace, raise the temperature to 700°C and keep it for 4h, then cool it to 600°C, then take the rolled Cr and Mo steel out of the furnace and air cool to room temperature, and the Cr and Mo steels that have been spheroidized and annealed The steel rolled material is wire-cut, then its cross-section is ground and polished, and it is corroded with 4% nitric acid alcohol and then observed under a metallographic microscope. The metallographic structure is as follows: Figure 8 As shown in (a), the spheroidal carbides in the obtained annealed structure are more uniformly distributed on the matrix, the spheroidized structure is rated as grade 5, and its microhardness is measured to be 167...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com