Stress spheroidizing method of Mg-Al system magnesium alloy

A spheroidizing treatment and magnesium alloy technology, applied in the field of material science, can solve the problems of reduced tensile strength and elongation, limited strengthening effect, high energy consumption, etc., to achieve improved performance, shortened processing time, yield strength and tensile strength The effect of strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

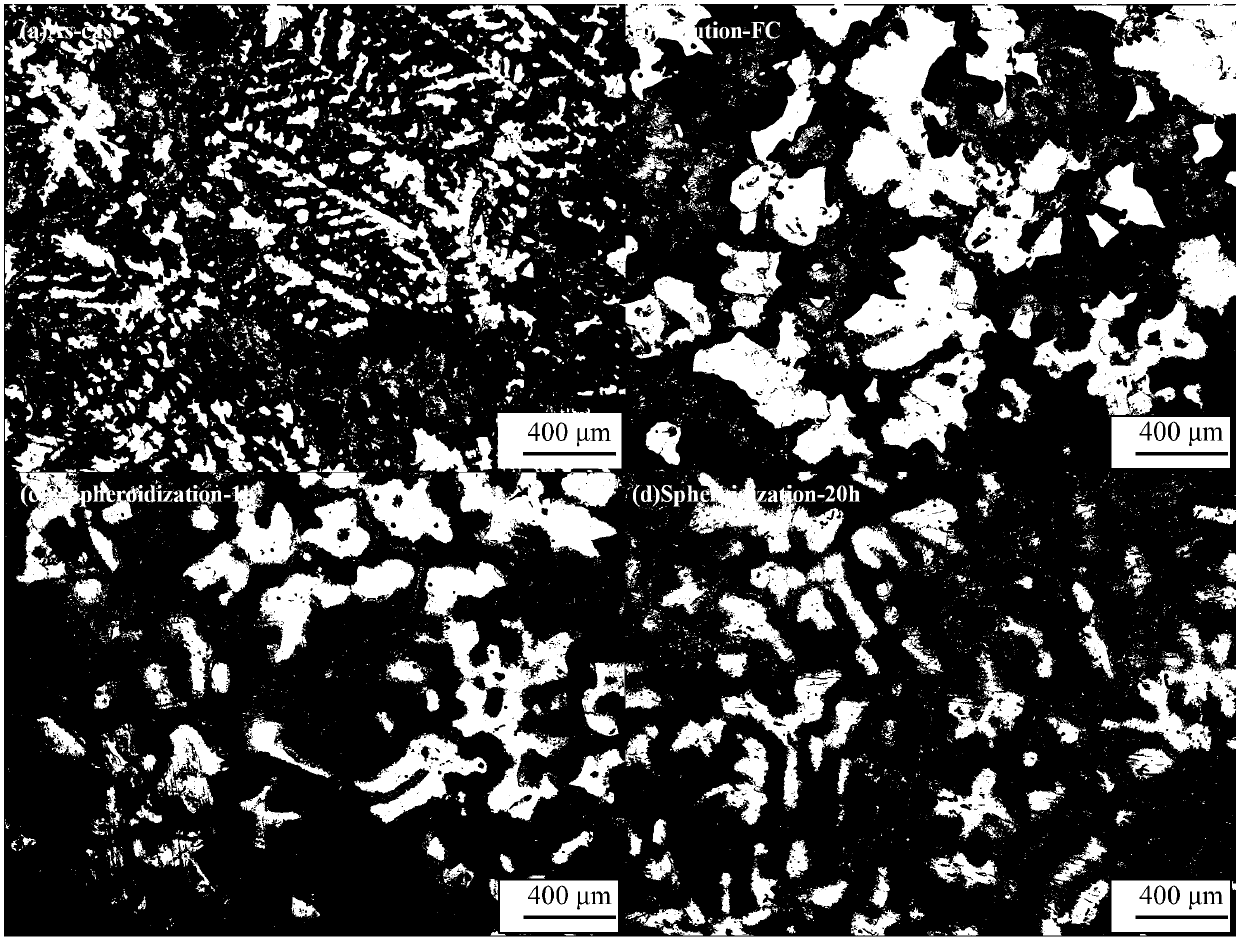

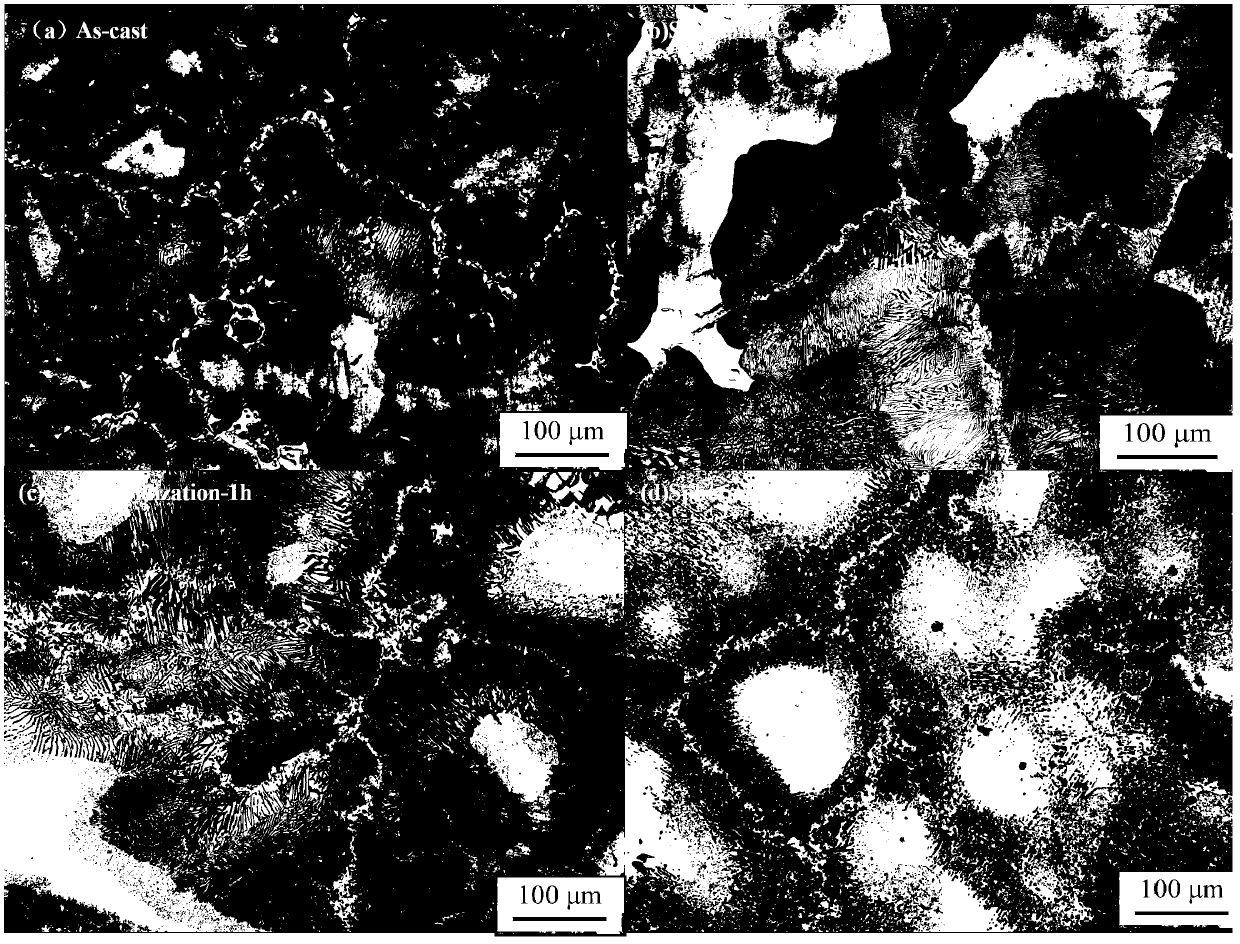

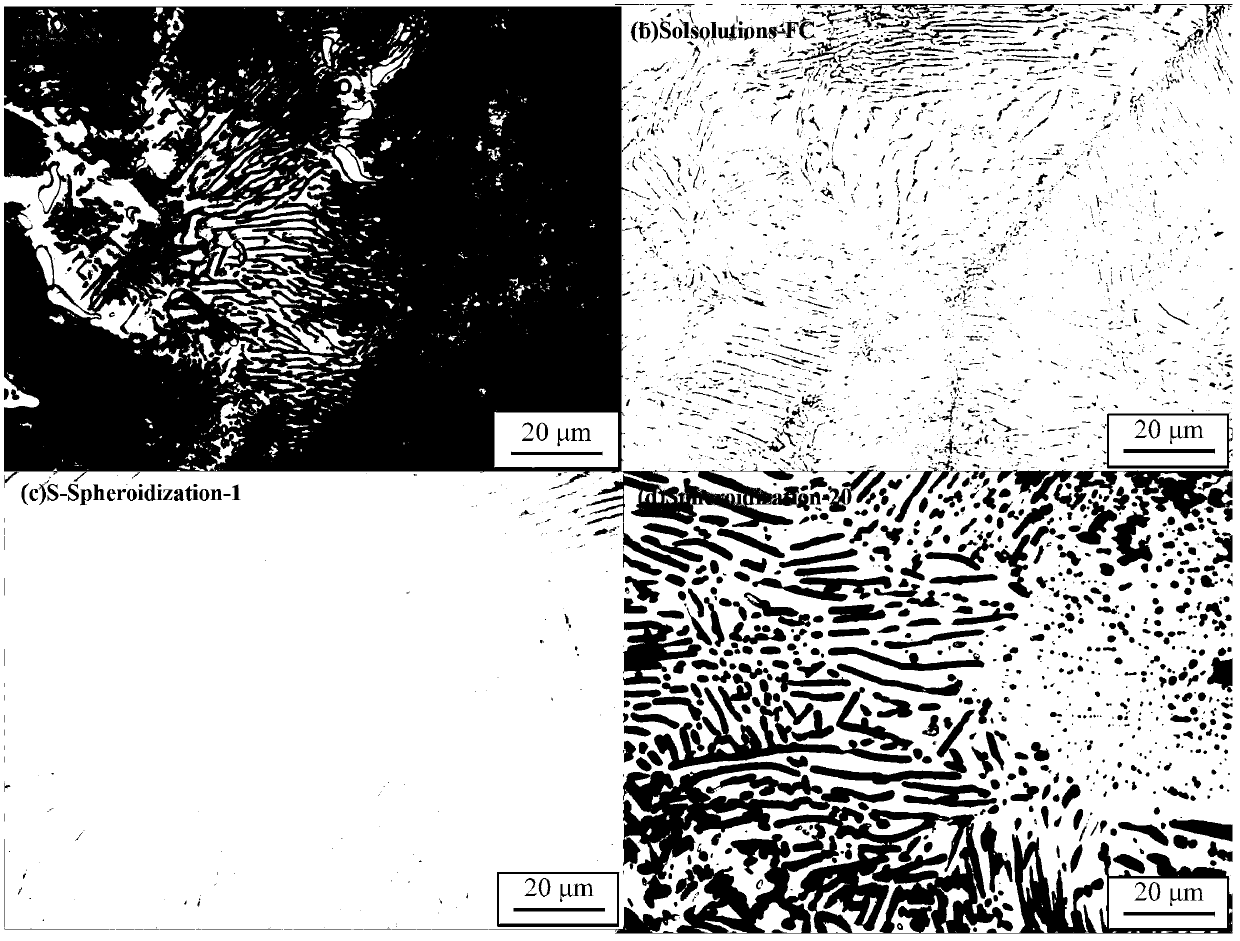

Embodiment 1

[0016] The AZ80 magnesium alloy ingot with a specification of Φ40cm×15cm was cut into tensile samples with a size of 64×12×2mm by wire cutting, and placed in a vacuum resistance furnace, heated to 380°C, kept for 24 hours, and then stopped. furnace, cooled to room temperature with the furnace, and then heated to 260°C while applying 30MPa tensile stress to the above-mentioned magnesium alloy in the RDL50 electronic creep testing machine, and then air-cooled to room temperature after holding for 0.5h. The hardness was measured on a Vickers hardness tester, the model is: FM-ARS9000 automatic microhardness measurement system, the load is 50gf, and the holding time is 30s. The mechanical properties are measured on the tensile testing machine, the tensile machine model is: INSPEKTTABLE100 electronic universal testing machine, and the performance indicators include tensile strength, yield strength and elongation. Its hardness and mechanical properties are listed in Table 1.

Embodiment 2

[0018] The AZ80 magnesium alloy ingot with a specification of Φ40cm×15cm was cut into tensile samples with a size of 64×12×2mm by wire cutting, and it was placed in a vacuum resistance furnace and heated to 400°C for 10 hours, then the furnace was stopped. Cool to room temperature with the furnace, and then heat to 300°C while applying a tensile stress of 15MPa to the above-mentioned magnesium alloy in the RDL50 electronic creep testing machine, keep it warm for 1h, and then air-cool to room temperature. The hardness was measured on a Vickers hardness tester, the model is: FM-ARS9000 automatic microhardness measurement system, the load is 50gf, and the holding time is 30s. The mechanical properties were measured on a tensile testing machine. The model of the tensile machine is: INSPEKT TABLE100 electronic universal testing machine. The performance indicators include tensile strength, yield strength, and elongation. The hardness and mechanical properties are shown in Table 1.

...

Embodiment 3

[0024] The AZ80 magnesium alloy ingot with a specification of Φ40cm×15cm was cut into tensile samples with a size of 64×12×2mm by wire cutting, and it was placed in a vacuum resistance furnace and heated to 410°C for 16 hours, then the furnace was stopped. Cool to room temperature with the furnace, and then apply a tensile stress of 5 MPa to the above-mentioned magnesium alloy in an RDL50 electronic creep testing machine while heating to 320°C, keep warm for 2 hours, and then air-cool to room temperature. The hardness was measured on a Vickers hardness tester, the model is: FM-ARS9000 automatic microhardness measurement system, the load is 50gf, and the holding time is 30s. The mechanical properties were measured on a tensile testing machine. The model of the tensile machine was: INSPEKT TABLE100 electronic universal testing machine. The performance indicators included tensile strength, yield strength, and elongation. Its hardness and mechanical properties are listed in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com