High-strength rare earth wrought magnesium alloy and preparation method thereof

A deformed magnesium alloy, high-strength technology, applied in the field of magnesium alloys, can solve the problems of poor elastic deformation resistance and unsatisfactory performance, and achieve the effect of improving the elastic modulus of the alloy, promoting grain recrystallization, and widening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

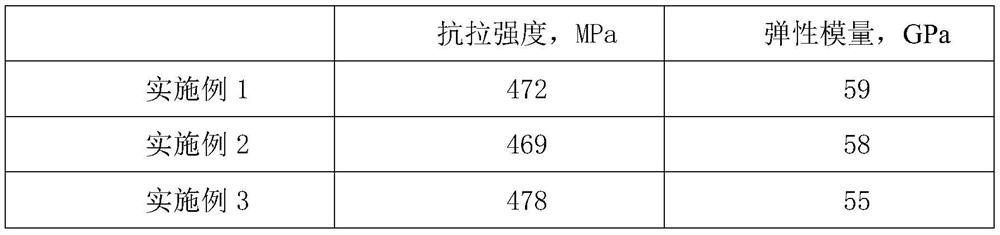

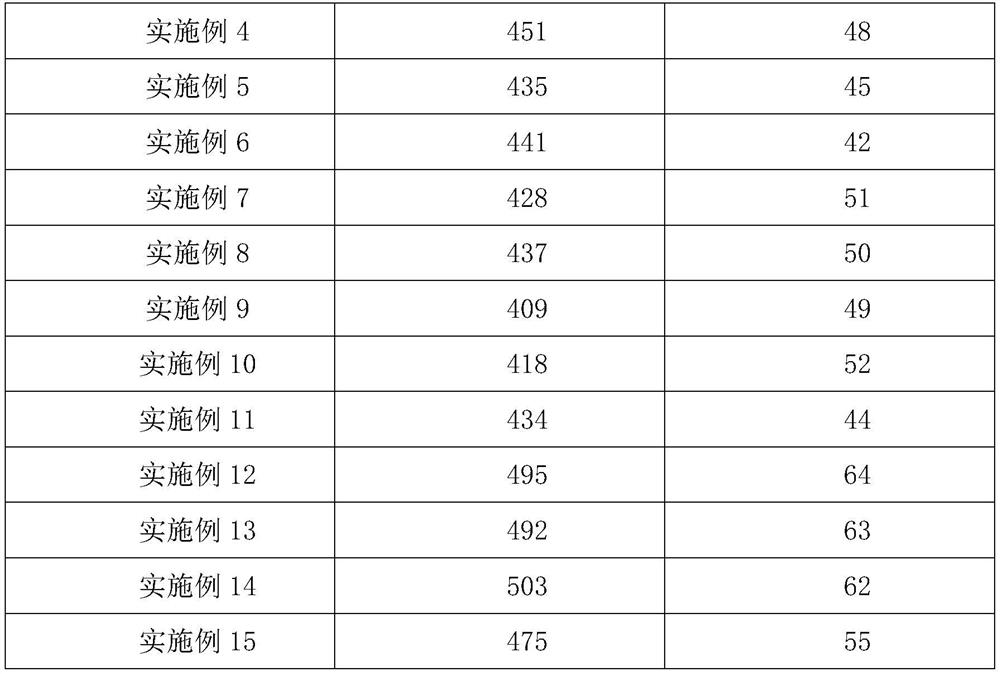

Examples

Embodiment 1

[0039] (1) According to the composition ratio: Al 9%, Nd 2.0%, Zn 1.5%, Si 1.0%, Zr 1.5%, Y 6%, Gd5%, Sm 4%, and the balance is Mg. Weigh the raw material and place it at 180 Preheat raw materials at ℃ environment.

[0040] (2) Under argon atmosphere, place magnesium and aluminum in a crucible at 720°C and heat and melt for 2 hours, then raise the temperature to 770°C, add zirconium, neodymium and silicon to melt, then cool down to 700°C, add zinc and continue to melt for 3 hours, then heat up to 820°C Add rare earth elements yttrium, gadolinium, and samarium at ℃ to stir and melt the alloy to homogenize the alloy, then skim off the scum to obtain alloy liquid. After the alloy liquid is refined at 750 °C for 20 minutes, it is poured to obtain a high-strength rare earth deformed magnesium alloy.

Embodiment 2

[0042] (1) According to the composition ratio: Al 6%, Nd 2.5%, Zn 0.8%, Si 1.2%, Zr 1.2%, Y 7%, Gd7%, Sm 5%, the balance is Mg, weigh the raw material and place it in 200 Preheat raw materials at ℃ environment.

[0043] (2) Under argon atmosphere, place magnesium and aluminum in a crucible at 700°C to heat and melt for 1 hour, then raise the temperature to 750°C, add zirconium, neodymium and silicon in turn to melt, then cool down to 680°C, add zinc and continue to melt for 5 hours, then heat up to 800°C Add rare earth elements yttrium, gadolinium, and samarium to stir and melt the alloy at ℃ to homogenize the alloy, then skim off the scum to obtain alloy liquid. After the alloy liquid is refined at 780 °C for 20 minutes, it is poured to obtain a high-strength rare earth deformed magnesium alloy.

Embodiment 3

[0045] (1) According to the composition ratio: Al 8%, Nd 1.5%, Zn 0.2%, Si 0.5%, Zr 1.2%, Y 5%, Gd5%, Sm 2%, the balance is Mg, weigh the raw material and place it at 150 Preheat raw materials at ℃ environment.

[0046] (2) Under argon atmosphere, place magnesium and aluminum in a crucible at 710°C to heat and melt for 2 hours, then raise the temperature to 760°C, add zirconium, neodymium and silicon in turn to melt, then cool down to 690°C, add zinc and continue to melt for 3 hours, then heat up to 810°C Add rare earth elements yttrium, gadolinium, and samarium at ℃, stir and melt the alloy to homogenize the alloy, and then skim off scum to obtain alloy liquid. The alloy liquid is refined at 770°C for 30 minutes and cast to obtain a high-strength rare earth deformed magnesium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com