Alloy plate for automobile body and preparation method thereof

A technology of alloy plate and body, applied in the field of alloy and its preparation, to achieve the effect of short-term heat preservation, rapid heating and rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

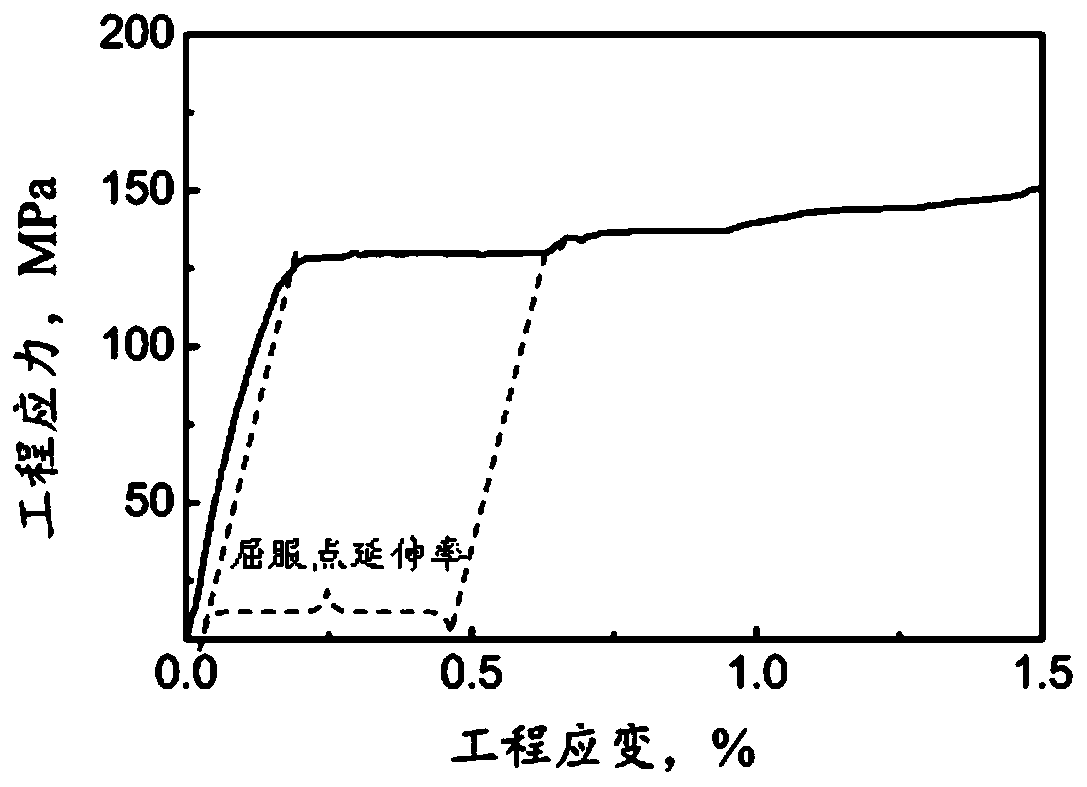

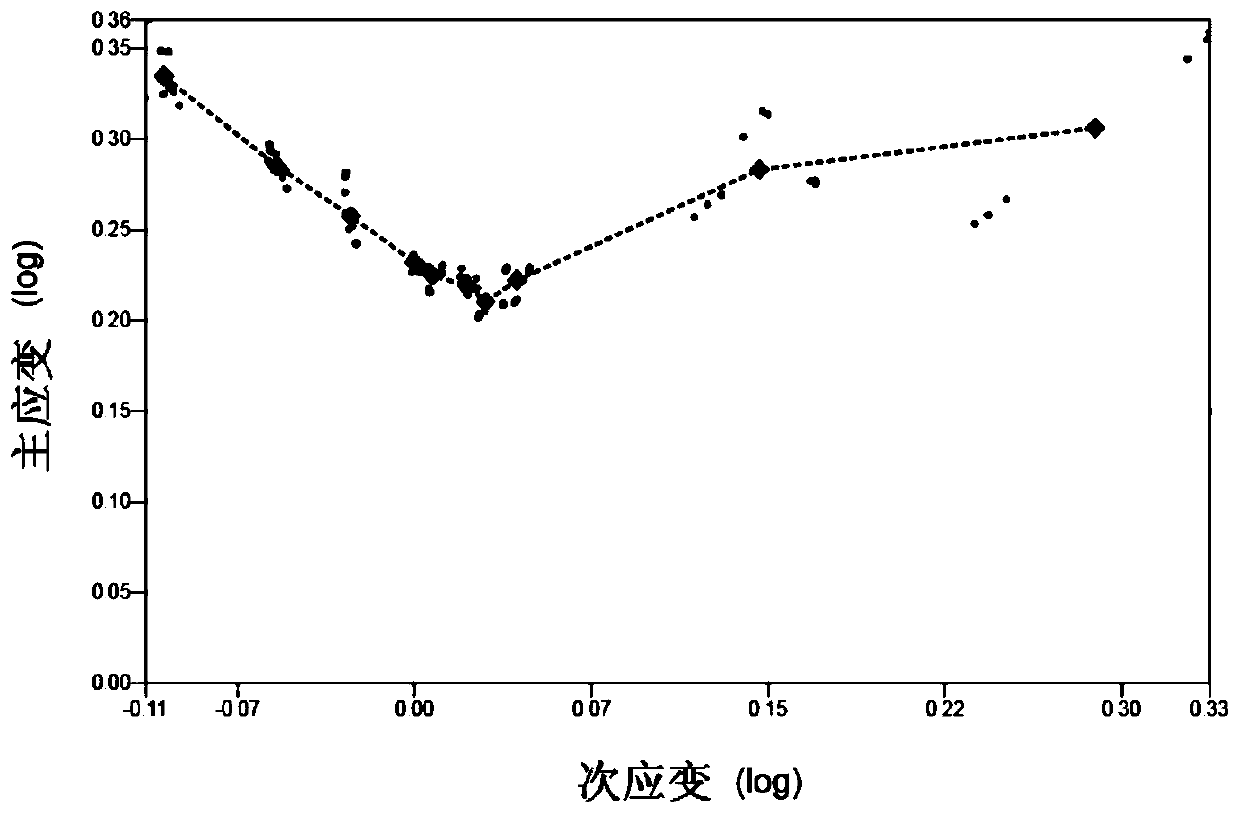

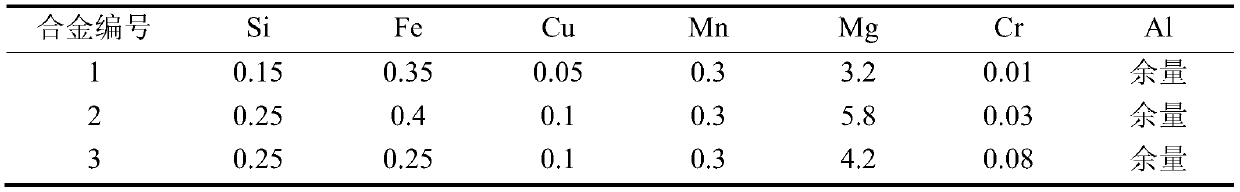

[0039] First, pure aluminum and various intermediate alloys are melted according to the composition ratio shown in Table 1. After the melt is refined, the ingot is cast by semi-continuous casting equipment, and the ingot is cut and milled and put into heat treatment. The homogenization treatment is carried out in the furnace, and the homogenized ingot is cooled to the rolling starting temperature and kept for a period of time before hot rolling. After hot rolling, the obtained hot-rolled sheet is subjected to cold rolling and intermediate annealing, and then cold-rolled to the thickness of the final finished sheet; the obtained cold-rolled sheet is finally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com