Method and equipment for printing textile using inkjet printer

A technology of inkjet printing and printing, which is applied to printing machines, rotary printing machines, printing, etc., and can solve problems such as the impact of printing clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

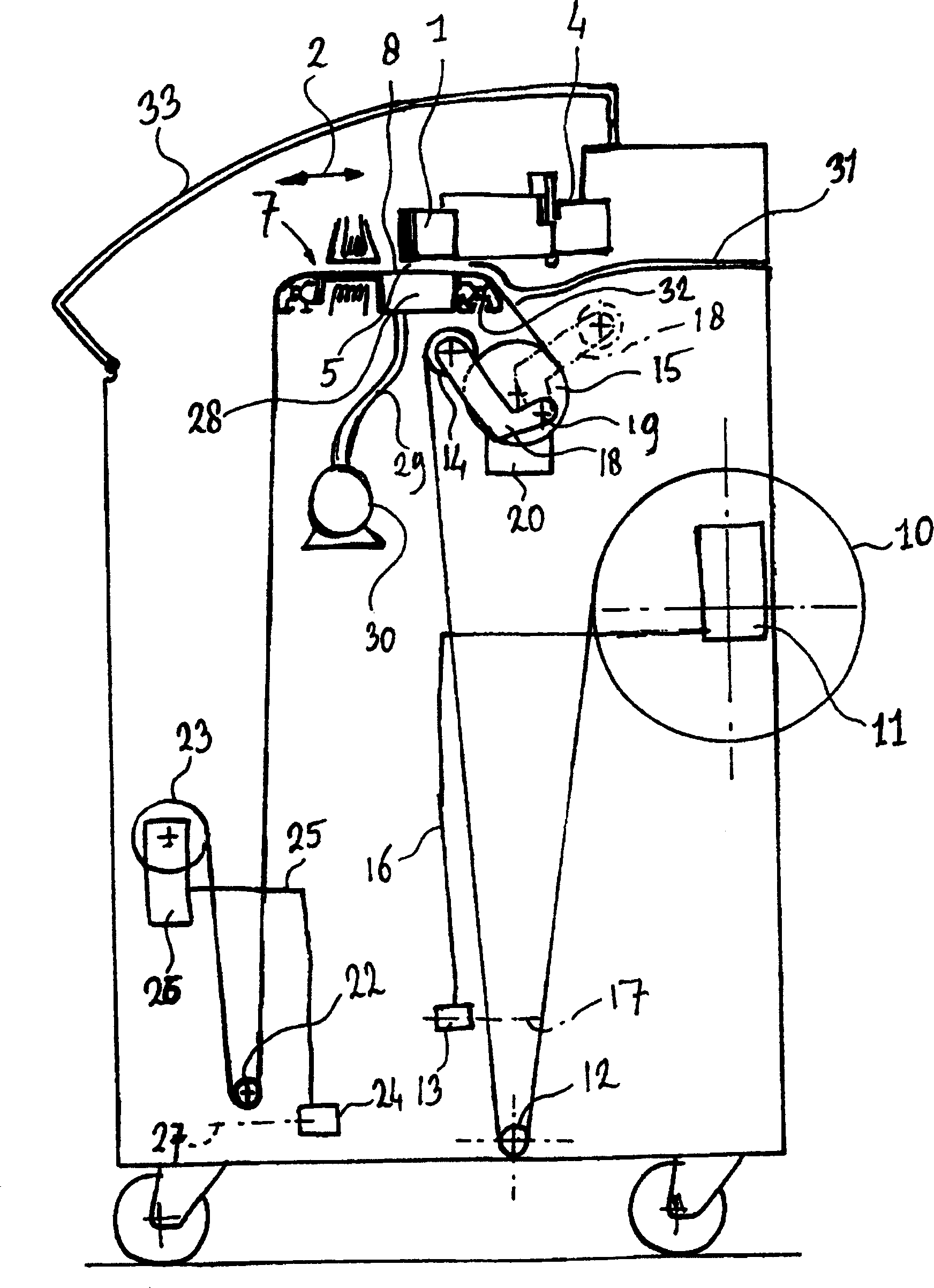

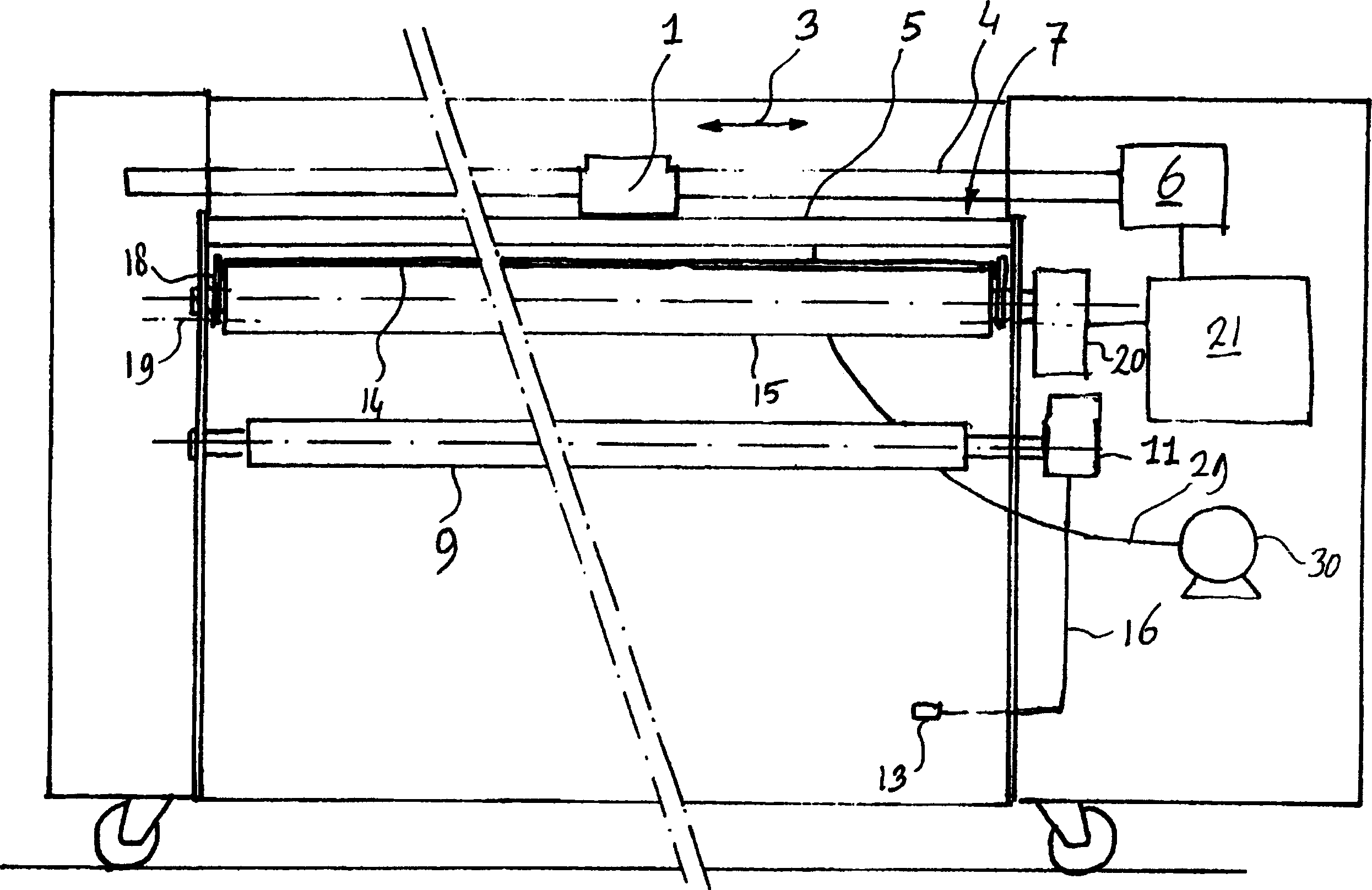

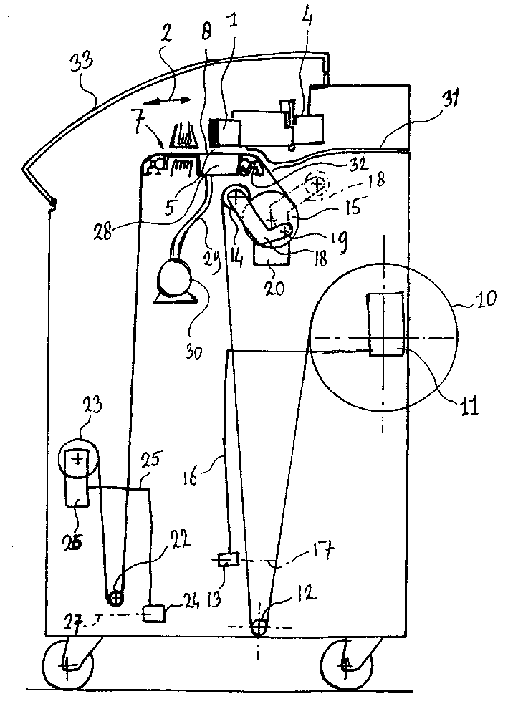

[0012] The printing machine shown in the figure has an assembly 1 of four printing heads which are interleaved in the direction of fabric feed (arrow 2) and the direction of printing head movement (arrow 3) to print yellow, magenta and Blue and green these three color inks and black ink. The print head assembly 1 can reciprocate along a track 4 to cover a specific printing area 5 .

[0013] In order to control the movement and ink supply of the printhead assembly 1, the apparatus contains a printhead controller which is figure 2 Indicated by box 6.

[0014] A guide table 7 is arranged opposite the printing head assembly, to be printed fabric material 8 (only shown in figure 1 Middle) to the area 5 covered by the print head.

[0015] In order to bring the continuous portion of the textile material 8 to the area covered by the printing head 1 in a step-by-step manner, the device has a transport structure. Upstream of the guide table 7, the conveying structure comprises a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com