Silicon-based molecular sieve/carbon tube sulfur-loaded composite positive electrode material, preparation method and application thereof

A composite positive electrode material and silicon-based molecular sieve technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrical components, etc., can solve problems such as volume expansion of lithium metal that is prone to shuttle effect, utilization rate of corrosion active materials, poor cycle performance, etc. , to achieve the effect of improving Coulombic efficiency and cycle stability, improving discharge capacity and cycle stability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

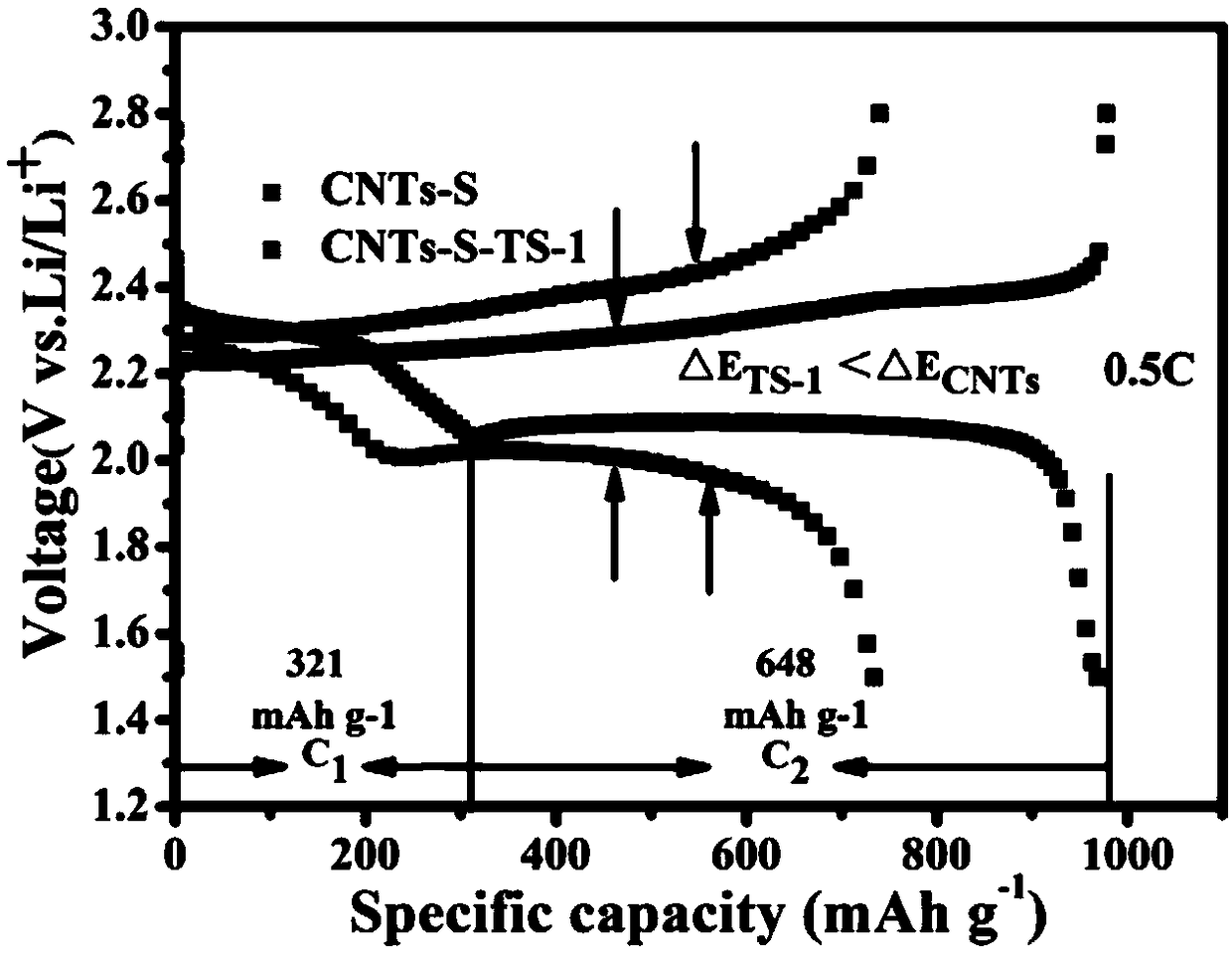

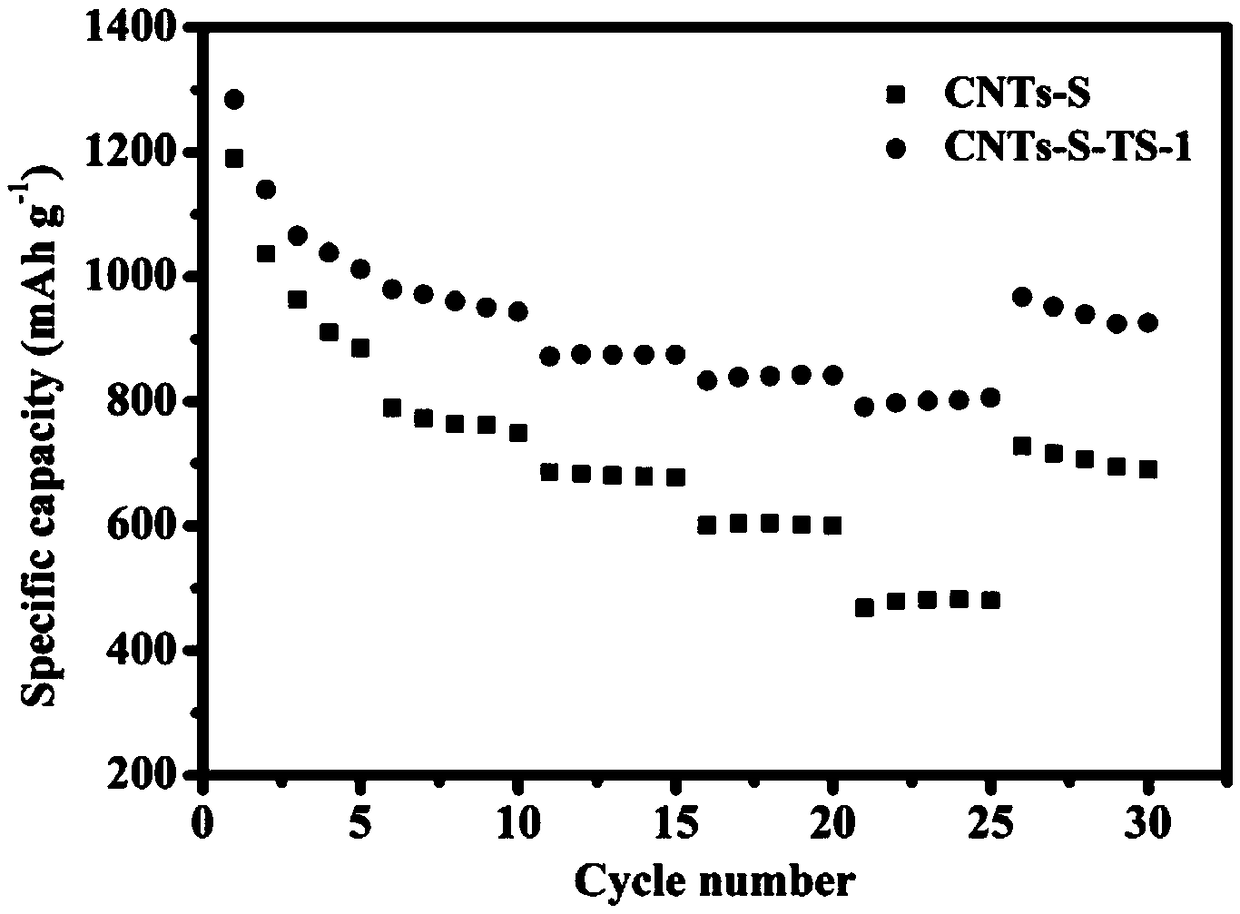

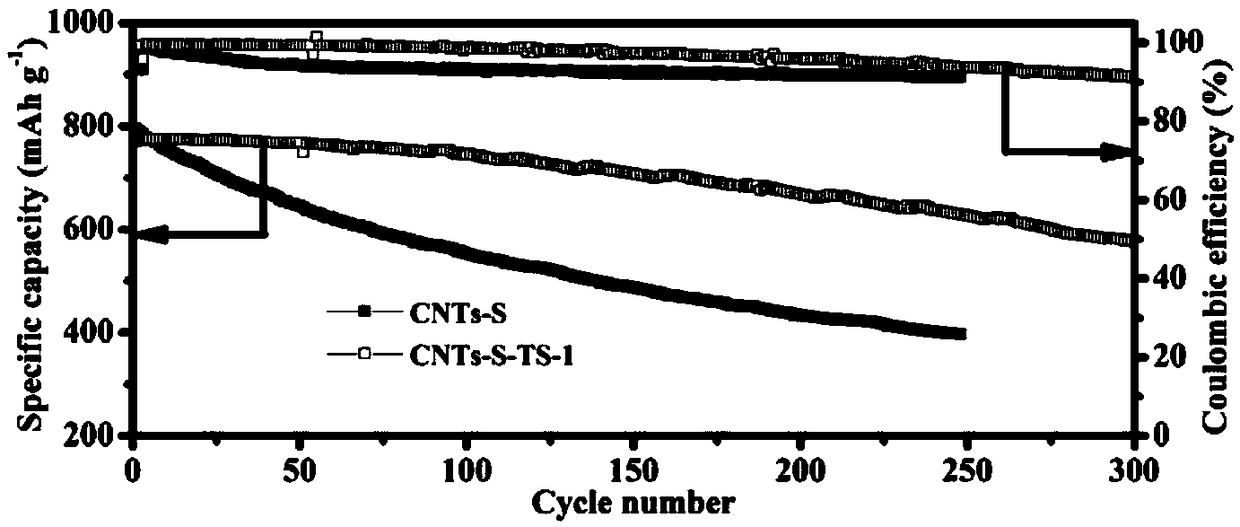

[0034] Preparation of titanium-silicon molecular sieve TS-1 and carbon tube sulfur-loaded composite cathode material and its application in lithium-sulfur batteries

[0035] (1) Preparation of carbon tube sulfur-loaded composite material: Take 200 mg of carbon tube and 200 mg of elemental sulfur in a mortar, thoroughly grind the porous carbon and sulfur evenly, transfer the resulting mixture to a 25 ml weighing bottle, and add 3.2 mL of CS 2 Stir well, wait until CS 2 After the volatilization is complete, transfer the mixture to an oven at 120°C for 12 hours, then cool to room temperature, and collect the resulting product to obtain the carbon tube sulfur-loaded composite material;

[0036] (2) Preparation of titanium-silicon molecular sieve TS-1 carbon tube sulfur-loaded composite positive electrode material: 300 mg of carbon tube-loaded sulfur composite material, 15 mg of conductive additive carbon black, 15 mg of binder polyvinylidene fluoride, and 10-20 mg of titanium-sili...

Embodiment 2

[0043] Preparation of Porous Silicon KIT‐6 Molecular Sieve and Carbon Tube Sulfur-loaded Composite Cathode Material and Its Application in Lithium-Sulfur Batteries

[0044] (1) Preparation of carbon tube sulfur-loaded composite material: take 200 mg of the above-mentioned carbon tube composite material and 400 mg of elemental sulfur in a mortar, fully grind the porous carbon and sulfur evenly, transfer the resulting mixture to a 25 ml weighing bottle, and Add 6mL CS 2 Stir well, wait until CS 2 After the volatilization is complete, transfer the mixture to an oven at 150°C for 10 hours, then cool to room temperature, and collect the resulting product to obtain the carbon tube sulfur-loaded composite material;

[0045] (2) Preparation of porous silicon KIT-6 molecular sieve carbon tube sulfur-loaded composite positive electrode material: 400 mg of carbon tube sulfur-loaded composite material, 50 mg of conductive additive carbon black, 50 mg of binder polyvinylidene fluoride, 5-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com