Preparation method of metal nano plate or metal/high polymer composite nano plate

A metal nanometer and polymer technology, applied in electrolysis process, electroforming and other directions, can solve the problem of difficult control of nanosheet thickness, and achieve the effect of good industrial application prospect, uniform structure and mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Electrode preparation: Polish the pure copper sheet (or pure nickel sheet), and wash it with acetone, ethanol and deionized water in sequence, and obtain a substrate with a clean and smooth surface after drying.

[0022] 2. Preparation of lamellar liquid crystal: the concentration is respectively 0.005mol / L, 0.05mol / L, 0.1mol / L, 0.3mol / L copper sulfate (or nickel sulfate) solution, and sodium lauryl sulfate and benzyl alcohol Mixed, the prepared mass fractions were SDS / BA / H 2 Two lamellar liquid crystal systems of O=60 / 40 / 31.0 and 60 / 40 / 25.3.

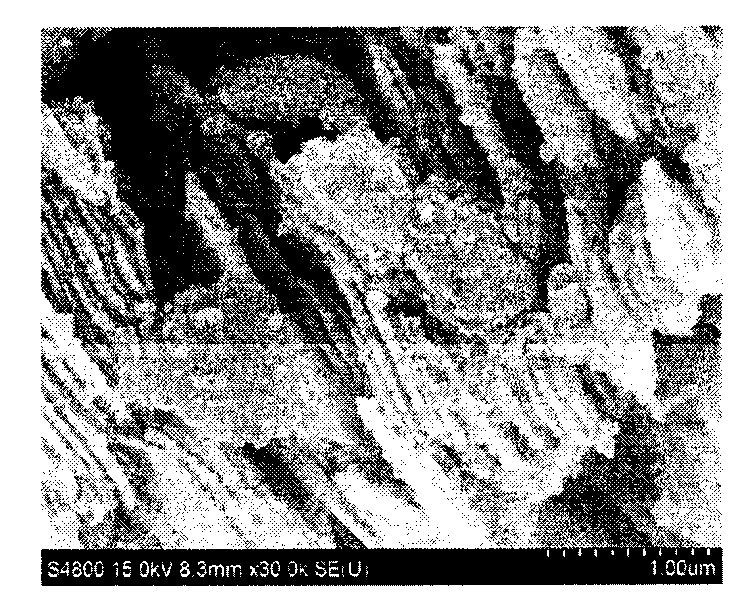

[0023] 3. Conduct constant voltage electrodeposition in two layered liquid crystal systems respectively, and control the current density at 1.0-5.0A / dm 3 , deposition time 24h, the product is characterized as copper (or nickel) nanosheets, such as figure 1 So not.

[0024] The thickness of the copper (or nickel) nanosheet is 10-20nm, and the thickness is uniform.

Embodiment 2

[0026] 1. Preparation of conductive substrate: Polish pure platinum sheet (purity ≥ 99.95%) with diamond sandpaper, and wash with acetone, ethanol and deionized water successively, and obtain a substrate with a clean and smooth surface after drying.

[0027] 2. Preparation of lamellar liquid crystals: replace water with acidic aniline solutions with concentrations of 0.05mol / l, 0.1mol / l, and 0.3mol / l respectively, and prepare SDS / BA with sodium lauryl sulfate and benzyl alcohol respectively. / H 2 Two lamellar liquid crystal systems of O=60 / 40 / 31.0 and 60 / 40 / 25.3.

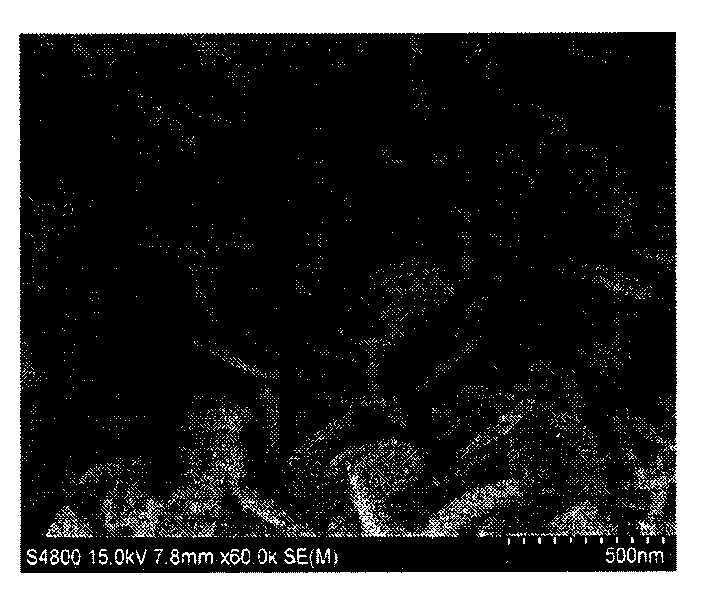

[0028] 3. Conduct constant voltage electrodeposition in two layered liquid crystal systems respectively, and control the current density at 1.0-5.0A / dm 3 , deposition time 24h, the product is characterized as polyaniline nanosheets, such as figure 2 shown.

[0029] The thickness of the platinum / polyaniline nanosheet is 15nm-35nm, and the thickness is uniform.

Embodiment 3

[0031] 1. Preparation of conductive substrate: Polish pure platinum sheet (purity ≥ 99.95%) with diamond sandpaper, and wash with acetone, ethanol and deionized water successively, and obtain a substrate with a clean and smooth surface after drying.

[0032] 2. Preparation of lamellar liquid crystals: replace water with a mixed solution containing 0.05-0.3mol / l aniline and 0.005-0.3mol / l copper sulfate (or nickel), and prepare the quality with sodium lauryl sulfate and benzyl alcohol respectively for SDS / BA / H 2 O=60 / 40 / 31.0 and 60 / 40 / 25.3 lamellar liquid crystal system.

[0033] 3. Conduct constant voltage electrodeposition in two layered liquid crystal systems respectively, and control the current density at 1.0-5.0A / dm 3 , deposition time 24h, the product is characterized as polyaniline / nickel composite nanosheets, such as image 3 shown.

[0034] The thickness of the polyaniline / nickel composite nanosheet is 10-30nm, and the thickness is uniform.

[0035] In addition, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com