Mesoporous Me/UIO-66-Zr MOF material as well as preparation method and application thereof

A technology of uio-66-zrmof and mesoporous, applied in the field of mesoporous Me/UIO-66-ZrMOF material and its preparation, can solve the problems of poor circulation and cost, and achieve improved stability, easy removal, and simple and easy method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

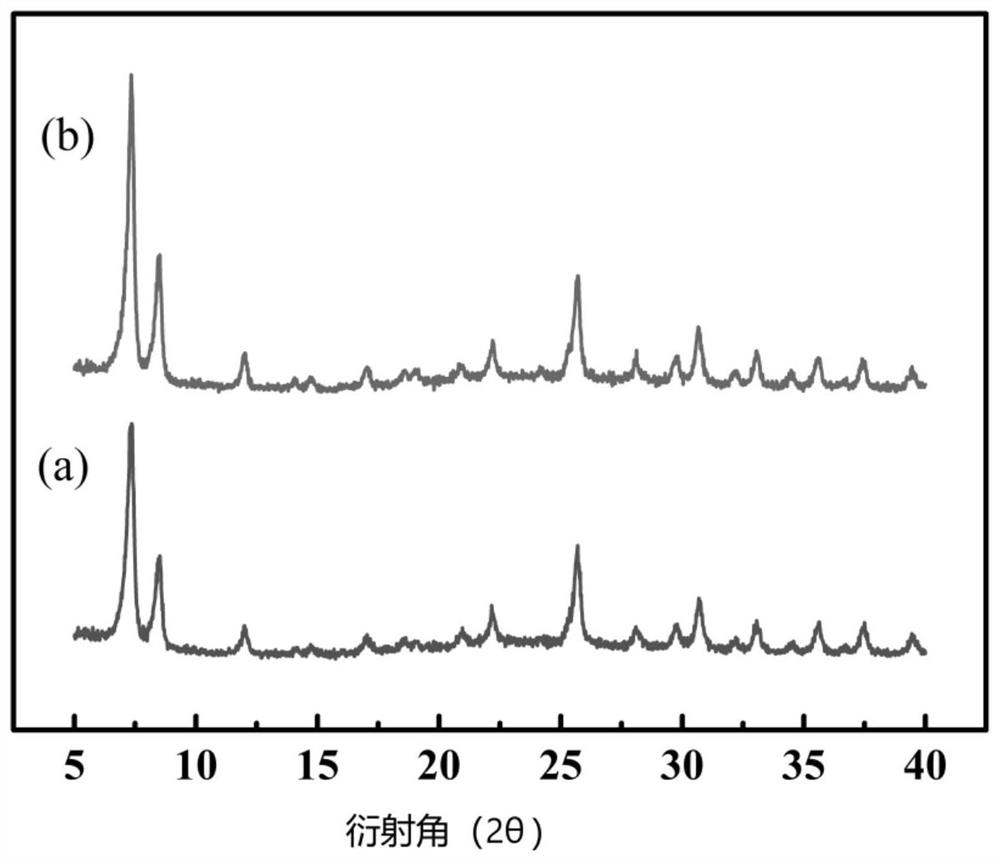

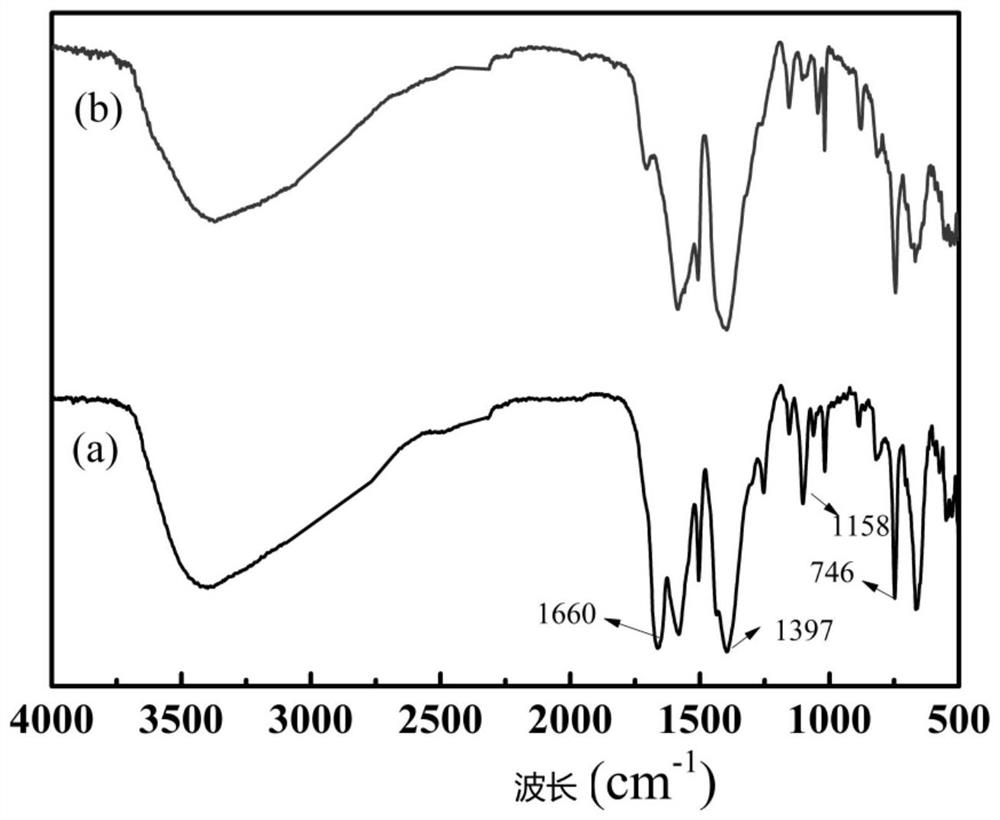

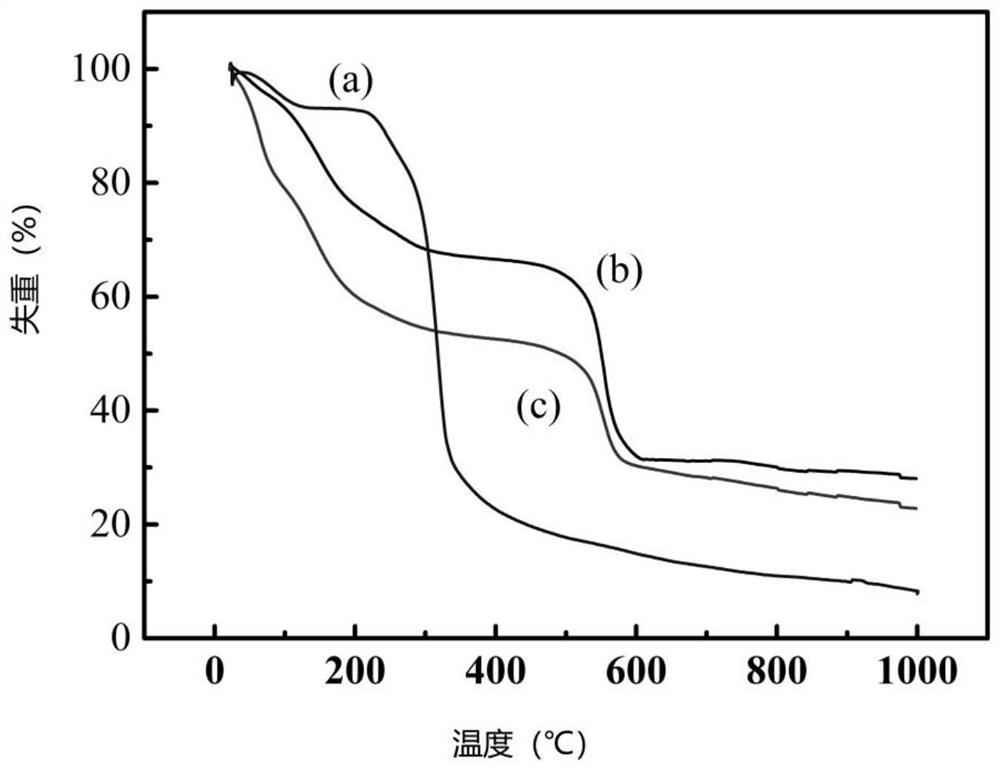

[0049] Example 1: Preparation of UIO-66-Zr, dextran 1500@UIO-66-Zr and mesoporous Me / UIO-66-Zr MOF materials

[0050] Preparation of UIO-66-Zr MOF material: Weigh 0.163 g of zirconium chloride and 0.116 g of terephthalic acid and dissolve them in 10 mL of DMF respectively, add zirconium chloride solution into the DMF solution containing terephthalic acid, and mix thoroughly by ultrasonication for 30 minutes . Then keep it in an oil bath at 80°C for 24 h, after natural cooling, wash with DMF and methanol three times, and dry at 60°C under vacuum.

[0051] Preparation of Dextran 1500@UIO-66-Zr: Weigh 0.163 g of zirconium chloride and 0.116 g of terephthalic acid and dissolve them in 10 mL of DMF respectively, and add 2 mg of dextran in turn to the DMF solution containing terephthalic acid Sugar 1500 and zirconium chloride solution were thoroughly mixed by ultrasonication for 30 minutes. Then put it in an oil bath at 80°C for 24 h, after natural cooling, wash with DMF and metha...

Embodiment 2

[0059] Embodiment 2: Preparation of mesoporous Me / UIO-66-Zr MOF material

[0060] Weigh 0.163 g of zirconium chloride and 0.116 g of terephthalic acid and dissolve them in 10 mL of DMF, respectively, add 2 mg of dextran 1500 and zirconium chloride solution to the DMF solution containing terephthalic acid, and mix thoroughly by ultrasonication for 30 minutes . Then put it in an oil bath at 70°C for 24 h, after natural cooling, wash with DMF and methanol three times respectively, and place it at 60°C for vacuum drying. After drying, the sample is ground evenly. Then it was calcined in a tube furnace at 325°C for 2h. The sample was activated in 10 mL of methanol for three days to obtain a mesoporous Me / UIO-66-Zr MOF material, which was stored for future use.

Embodiment 3

[0061] Embodiment 3: Preparation of mesoporous Me / UIO-66-Zr MOF material

[0062] Weigh 0.163 g of zirconium chloride and 0.116 g of terephthalic acid and dissolve them in 10 mL of DMF, respectively, add 2 mg of dextran 1500 and zirconium chloride solution to the DMF solution containing terephthalic acid, and mix thoroughly by ultrasonication for 30 minutes . Then put it in an oil bath at 120°C for 24 h, after natural cooling, wash with DMF and methanol three times each, and dry it in vacuum at 60°C. After drying, the sample is ground evenly. Then it was calcined in a tube furnace at 325°C for 2h. The sample was activated in 10 mL of methanol for three days to obtain a mesoporous Me / UIO-66-Zr MOF material, which was stored for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com