Patents

Literature

98results about How to "Good strength and plasticity matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

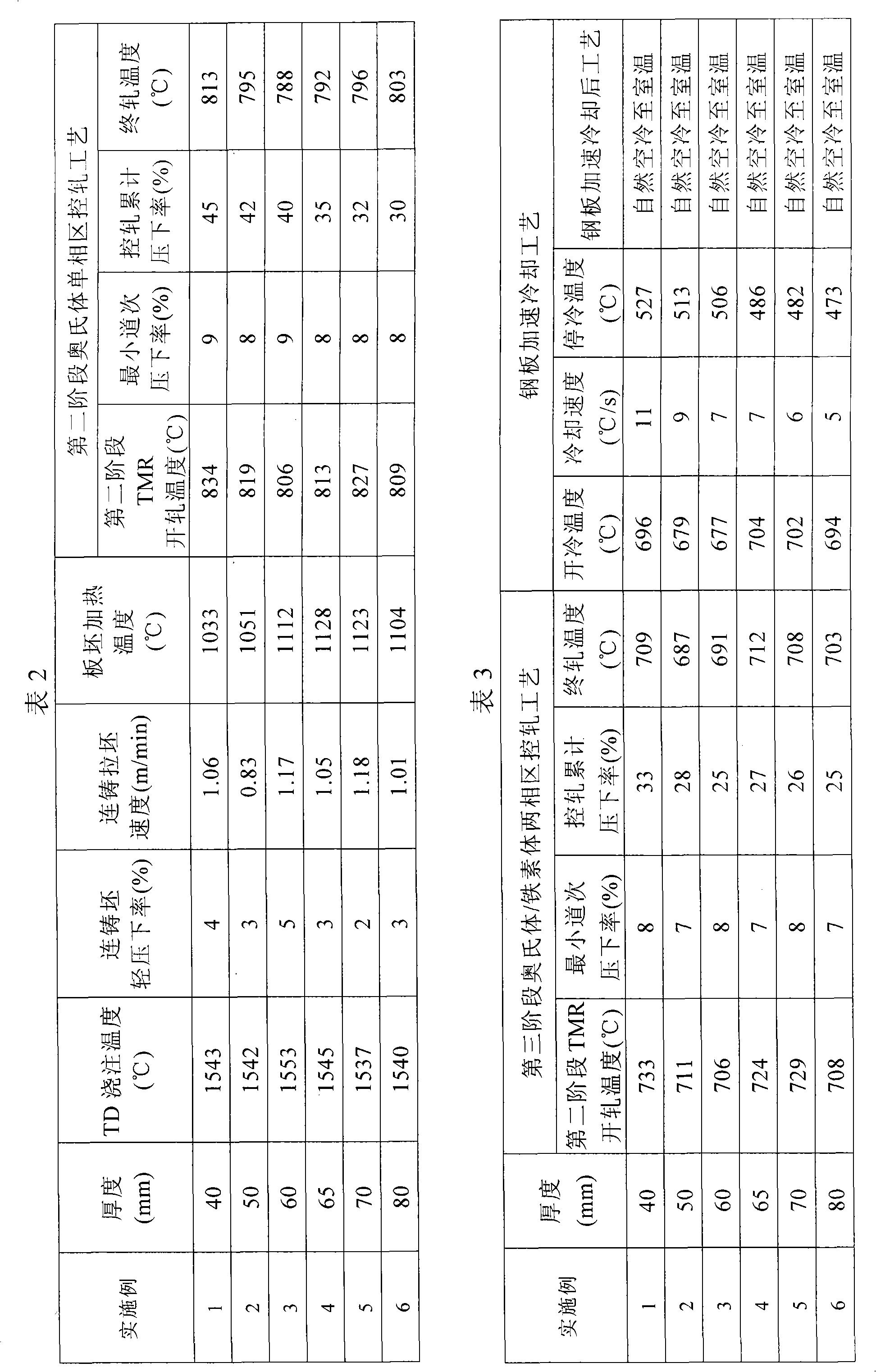

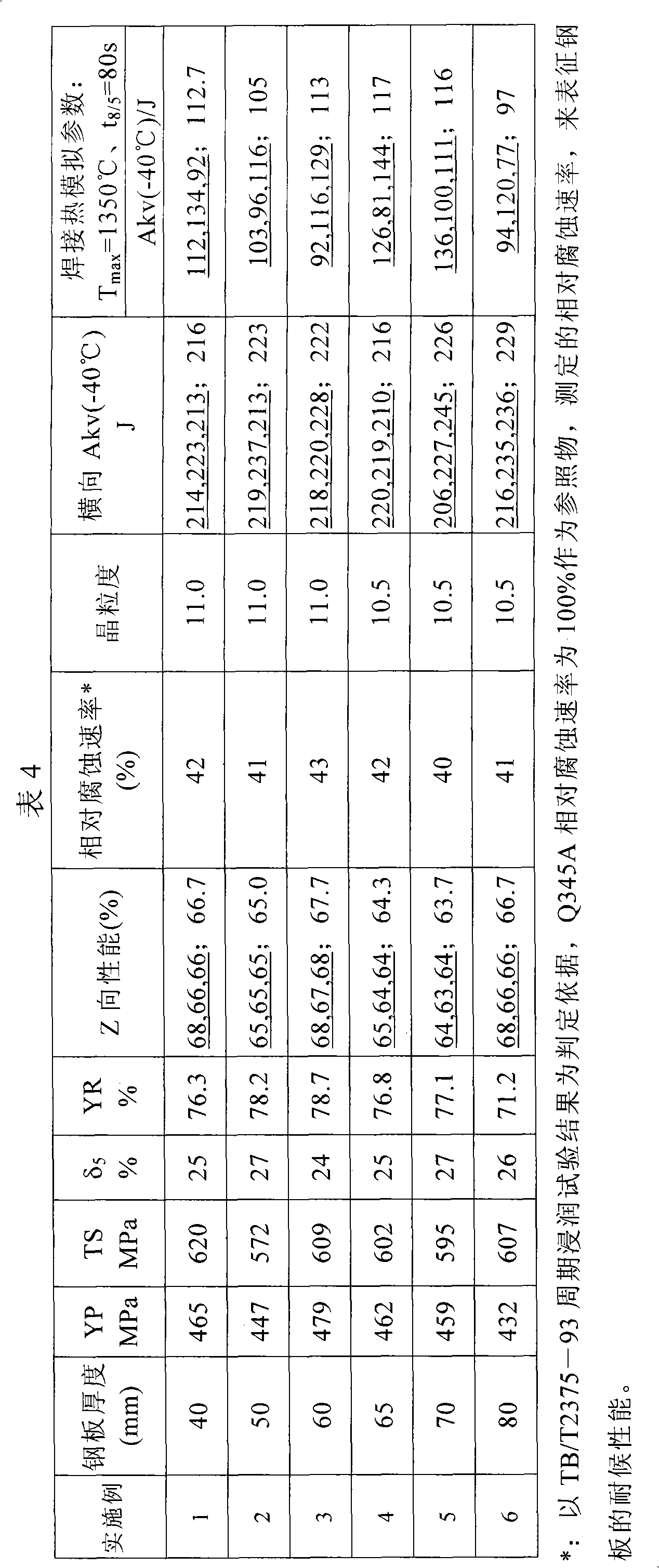

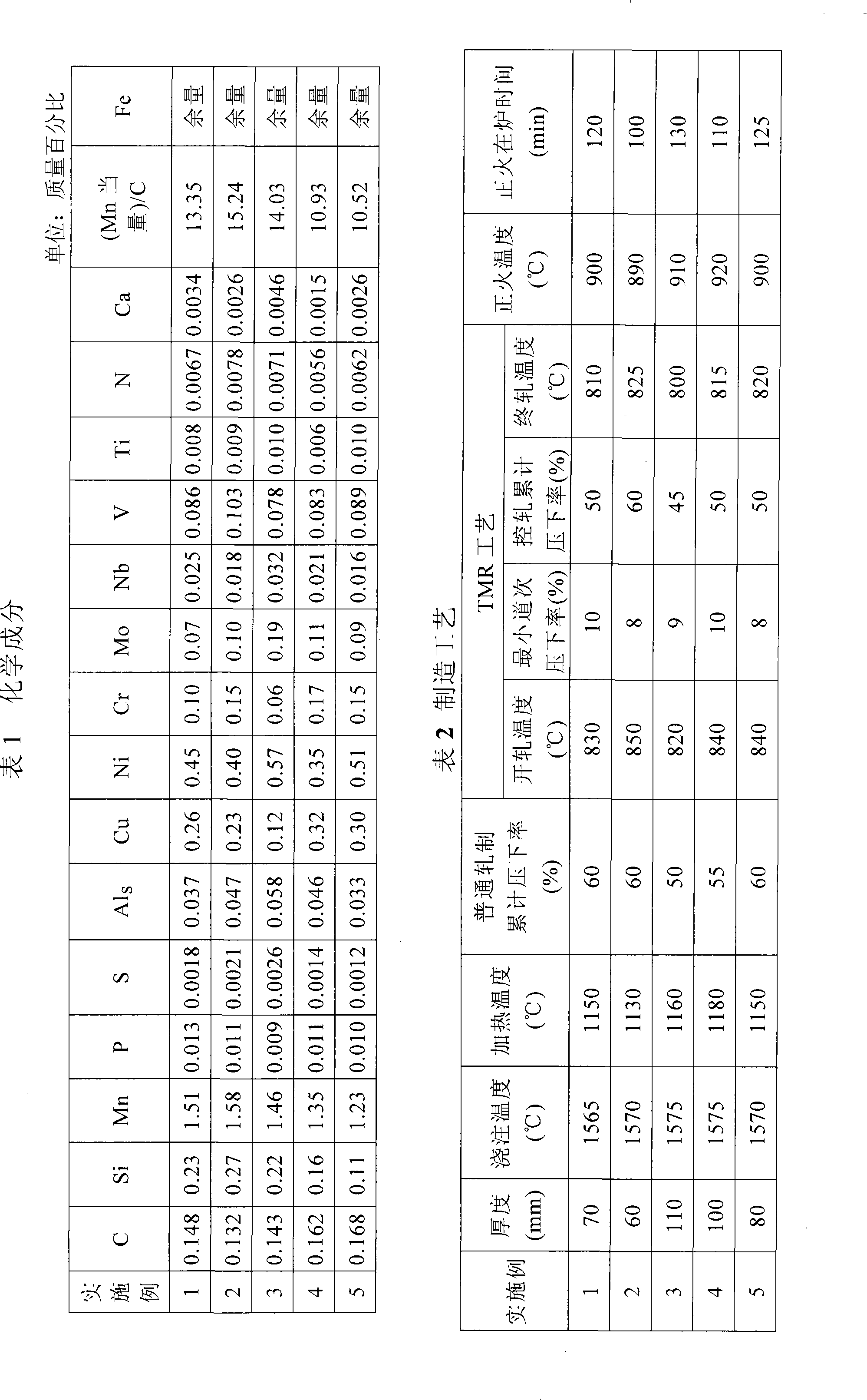

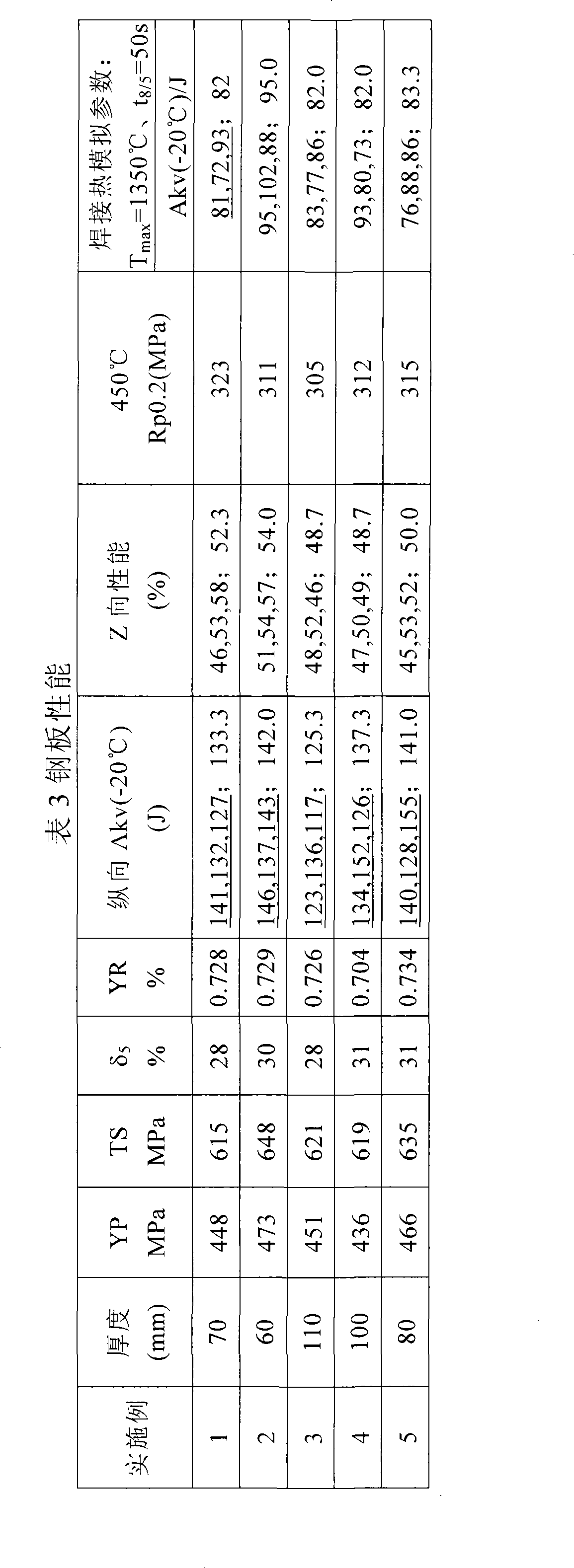

Weather resistant thick steel plate and manufacturing method thereof

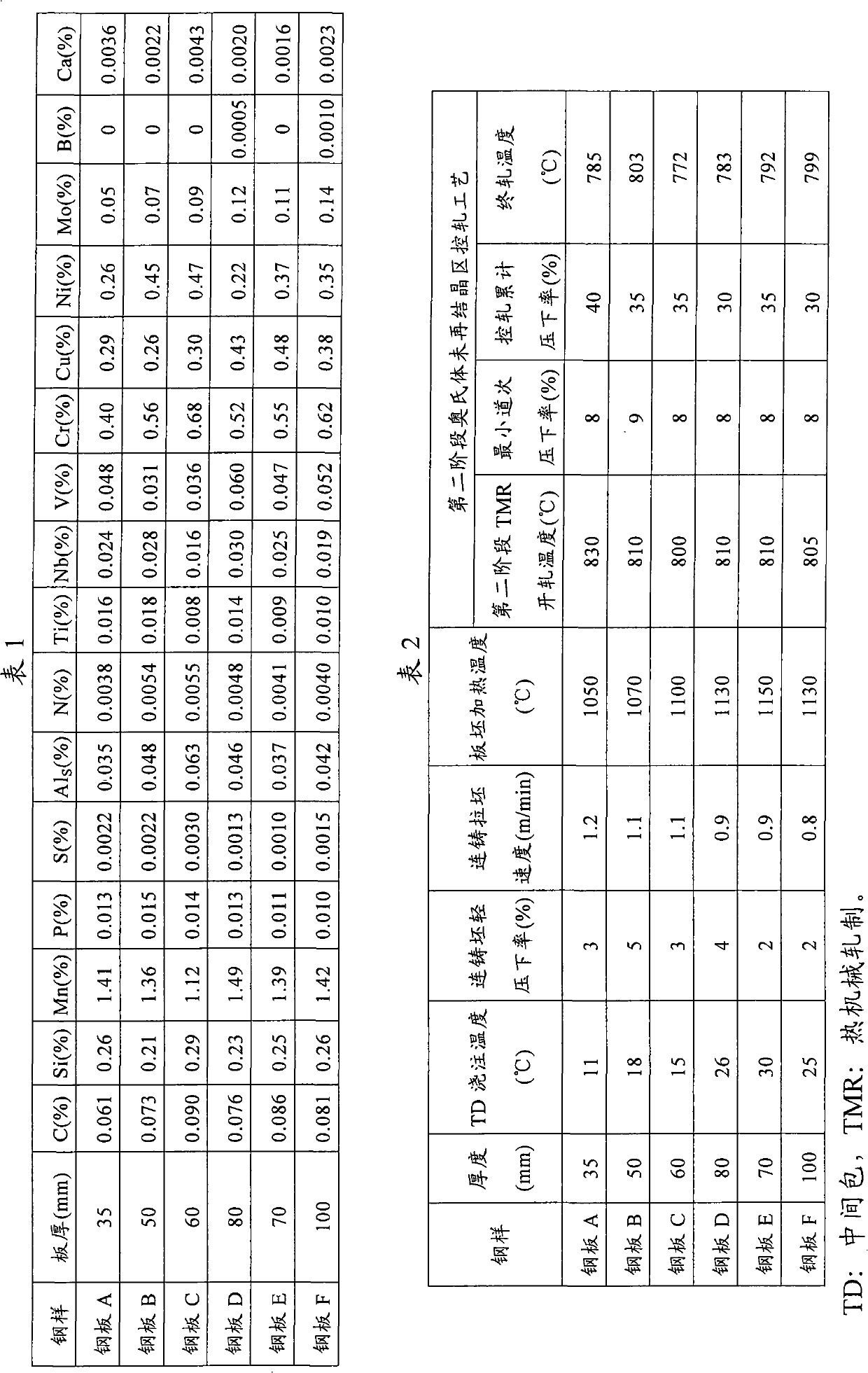

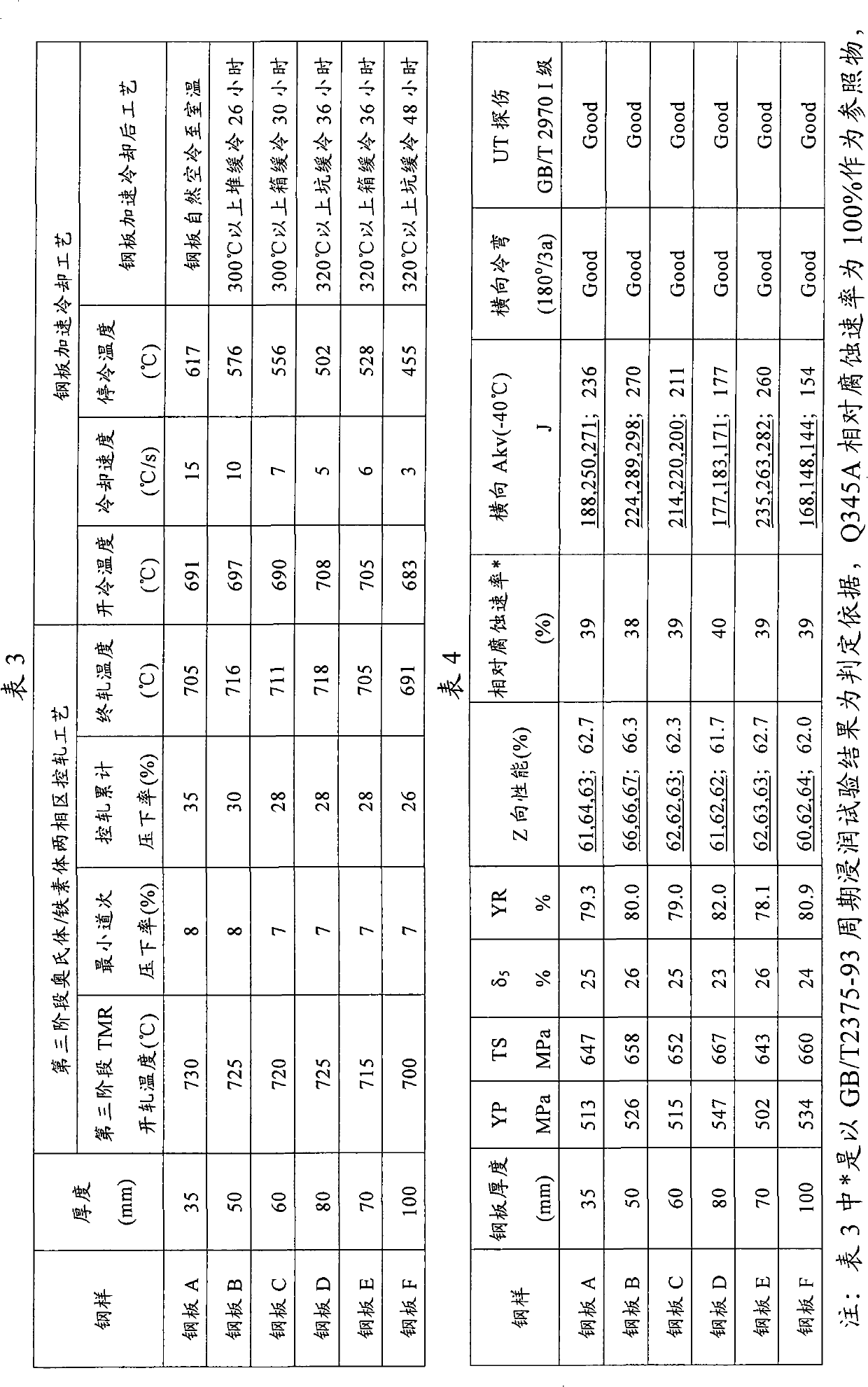

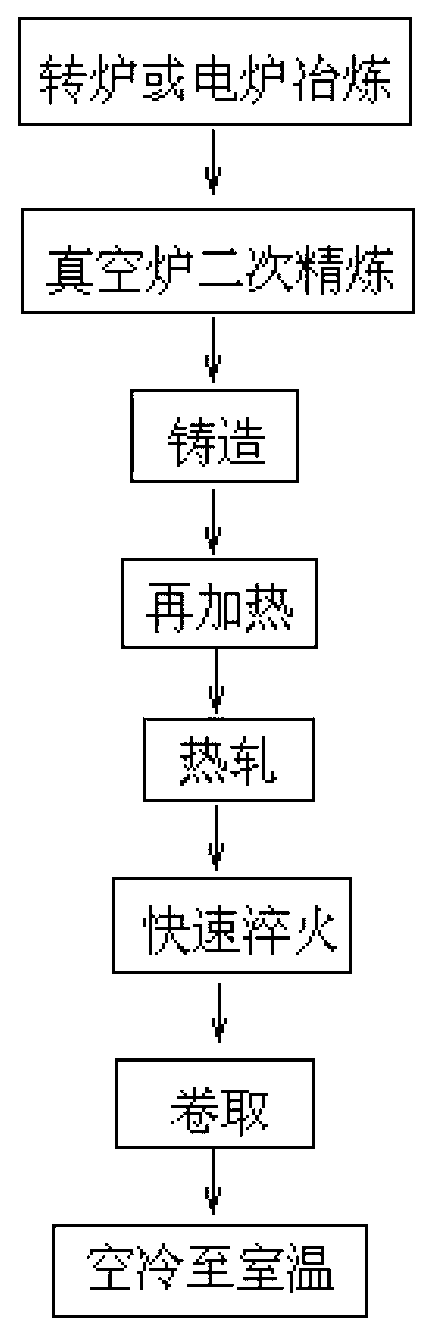

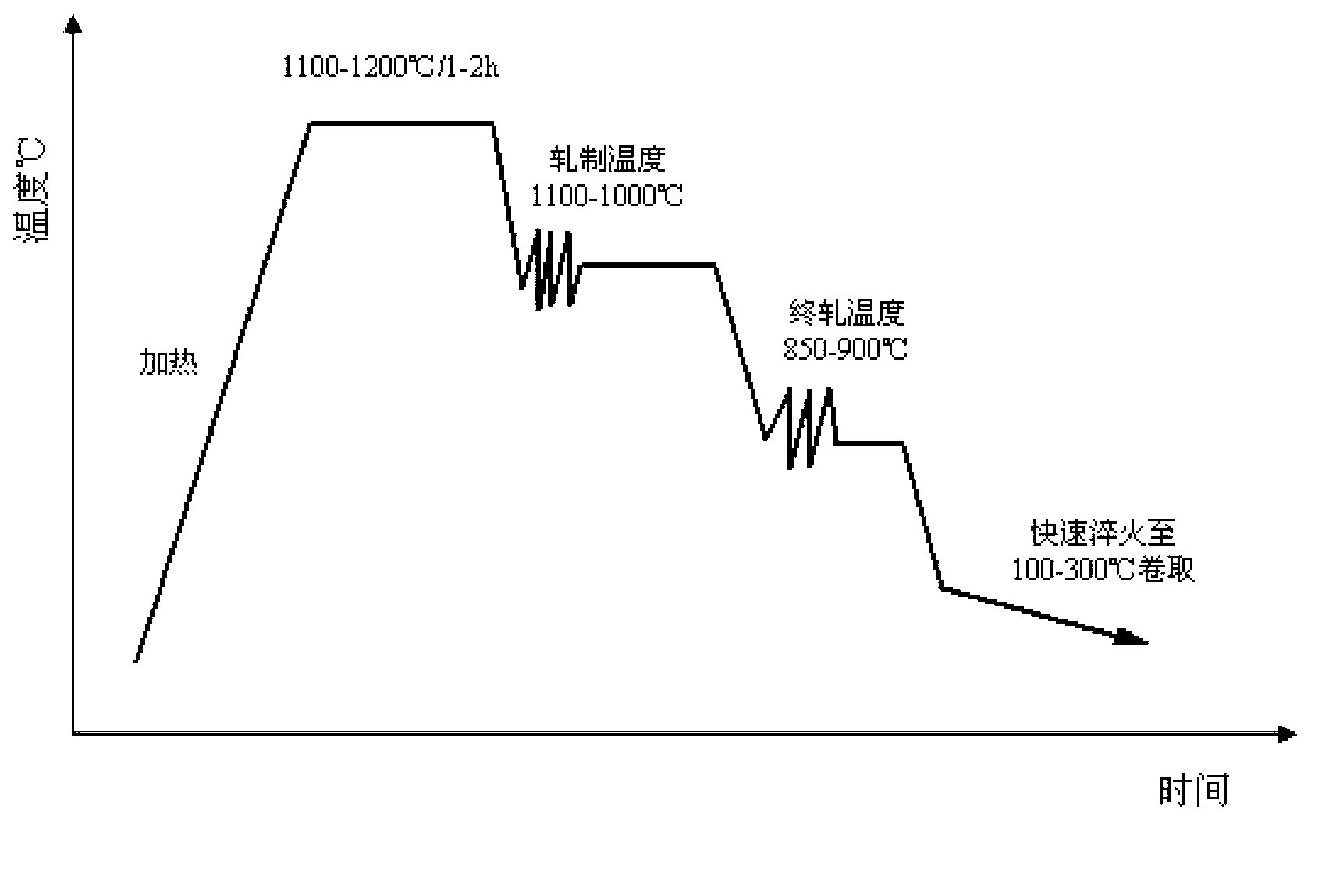

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

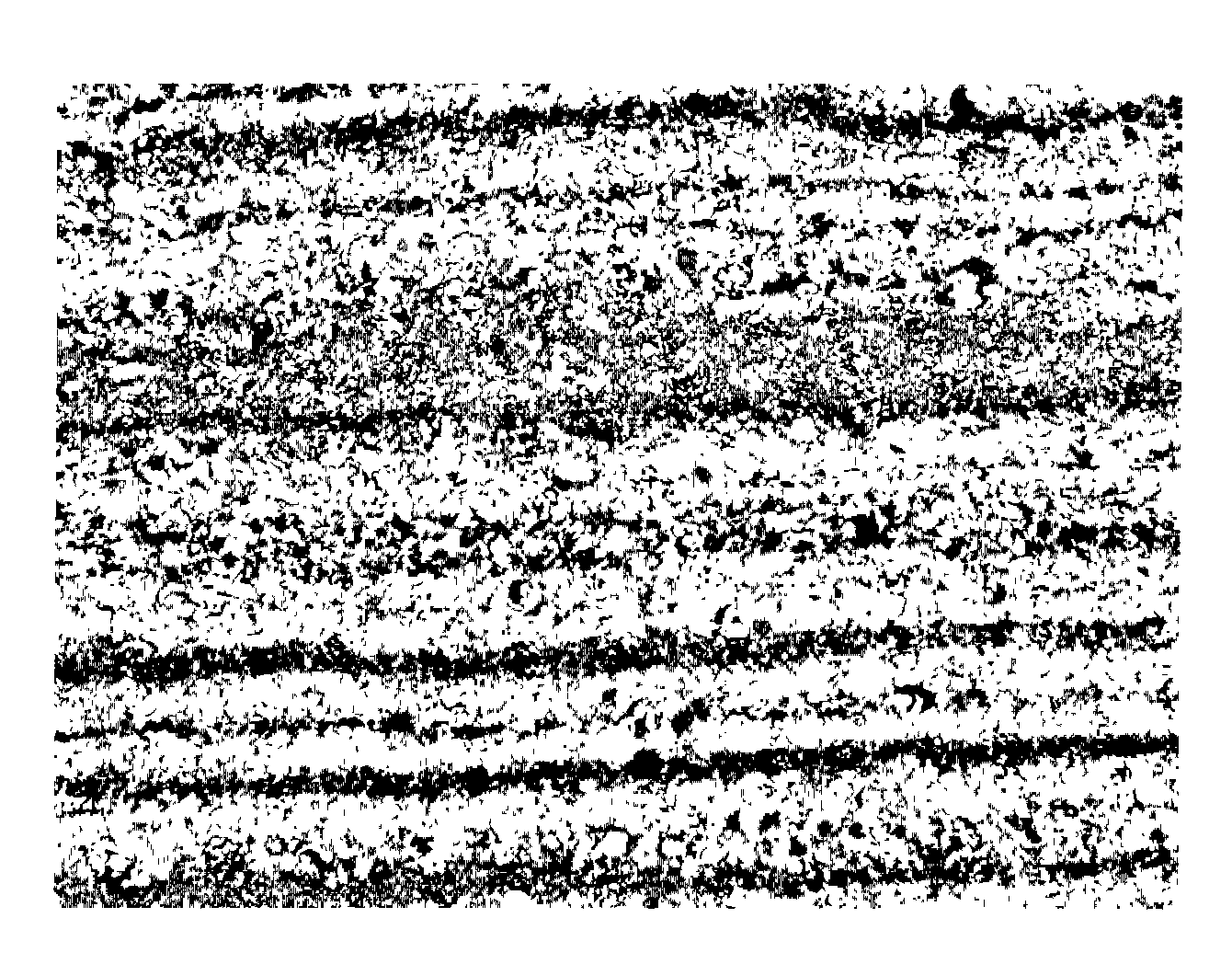

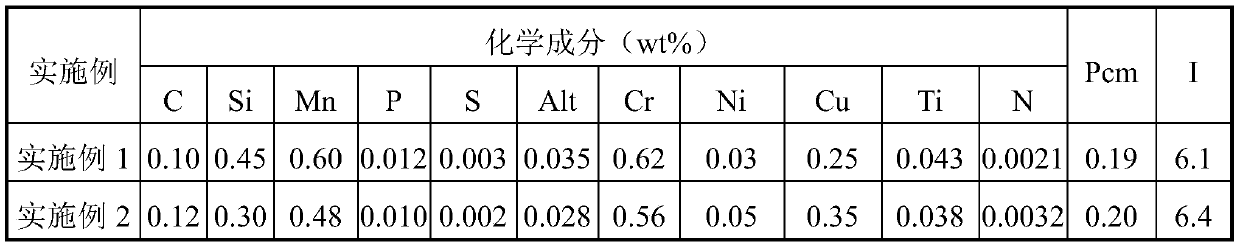

High-performance weather-proof building structural steel and manufacturing method thereof

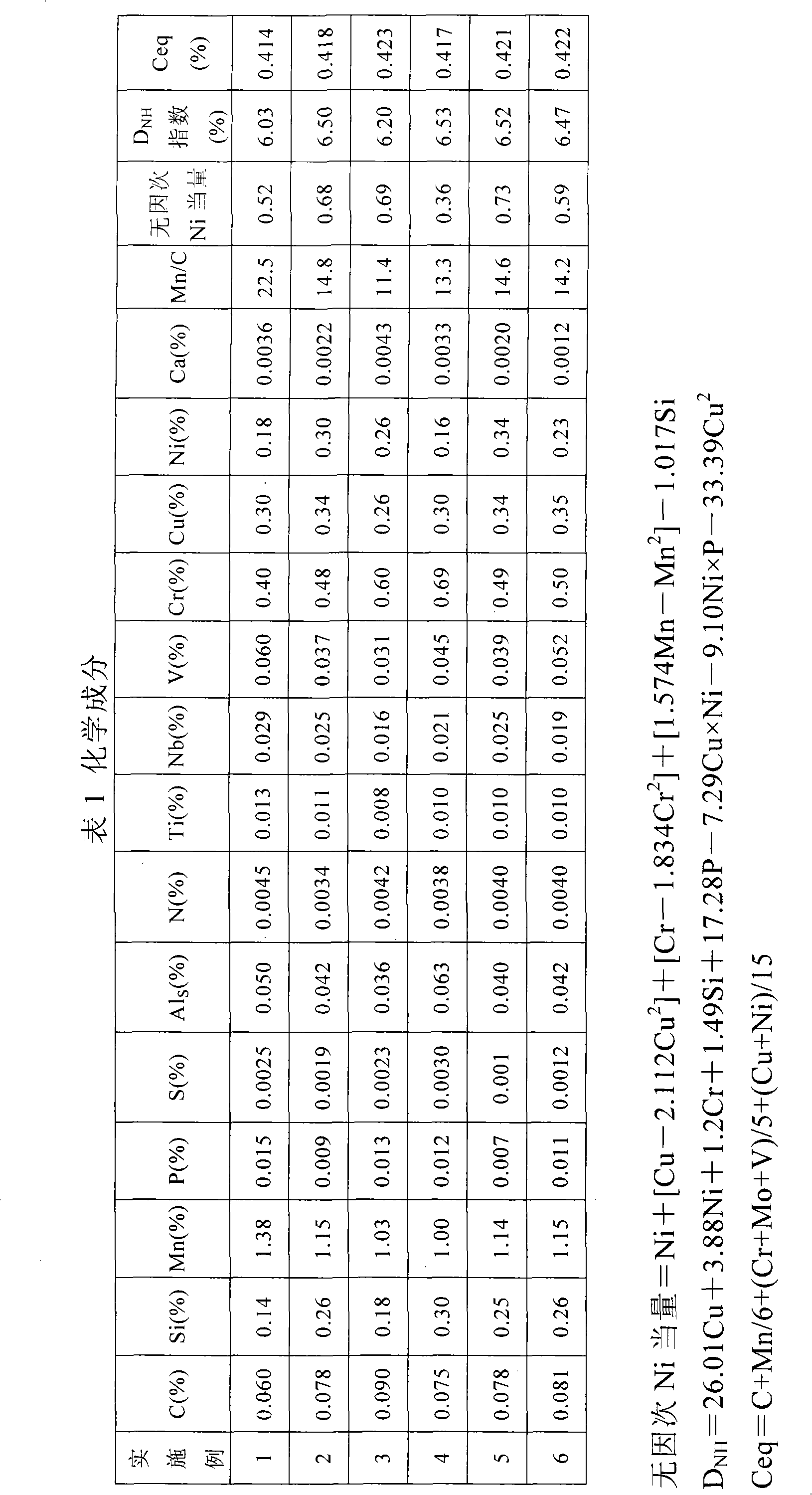

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

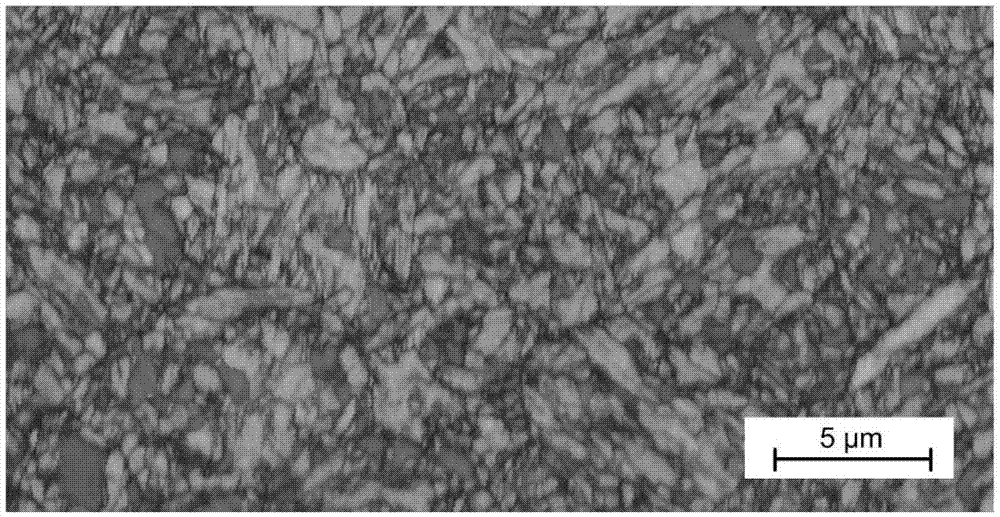

High-strength and high-toughness hot-rolled wear-resistant steel and preparation method thereof

The invention discloses high-strength and high-toughness hot-rolled wear-resistant steel and a preparation method thereof. The high-strength and high-toughness hot-rolled wear-resistant steel comprises the following chemical ingredients in percentage by weight: 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, not greater than 0.015% of P, not greater than 0.005% of S, 0.02-0.08% of Al, not greater than 0.006% of N, not greater than 30 ppm of O, 0.005-0.015% of Ti, 0.5-2.0% of Ni, and the balance of Fe and inevitable impurities, wherein the sum of Mn and Ni is 3.2-3.6%; the microscopic structure is composed of lath martensites and retained austenites, and the volume percentage content of the retained austenites is 5.0-15.0%; and the high-strength and high-toughness wear-resistant steel obtained by the processes of hot continuous rolling and rapid quenching has a tensile strength of greater than 1500 MPa, a yield strength of 1150-1400 MPa, a thickness of 3-12 mm, a good ductility (of greater than 10%), and a good low-temperature impact toughness (impact energy of 38-48 J at minus 20 DEG C), and shows excellent strong-plastic matching.

Owner:BAOSHAN IRON & STEEL CO LTD

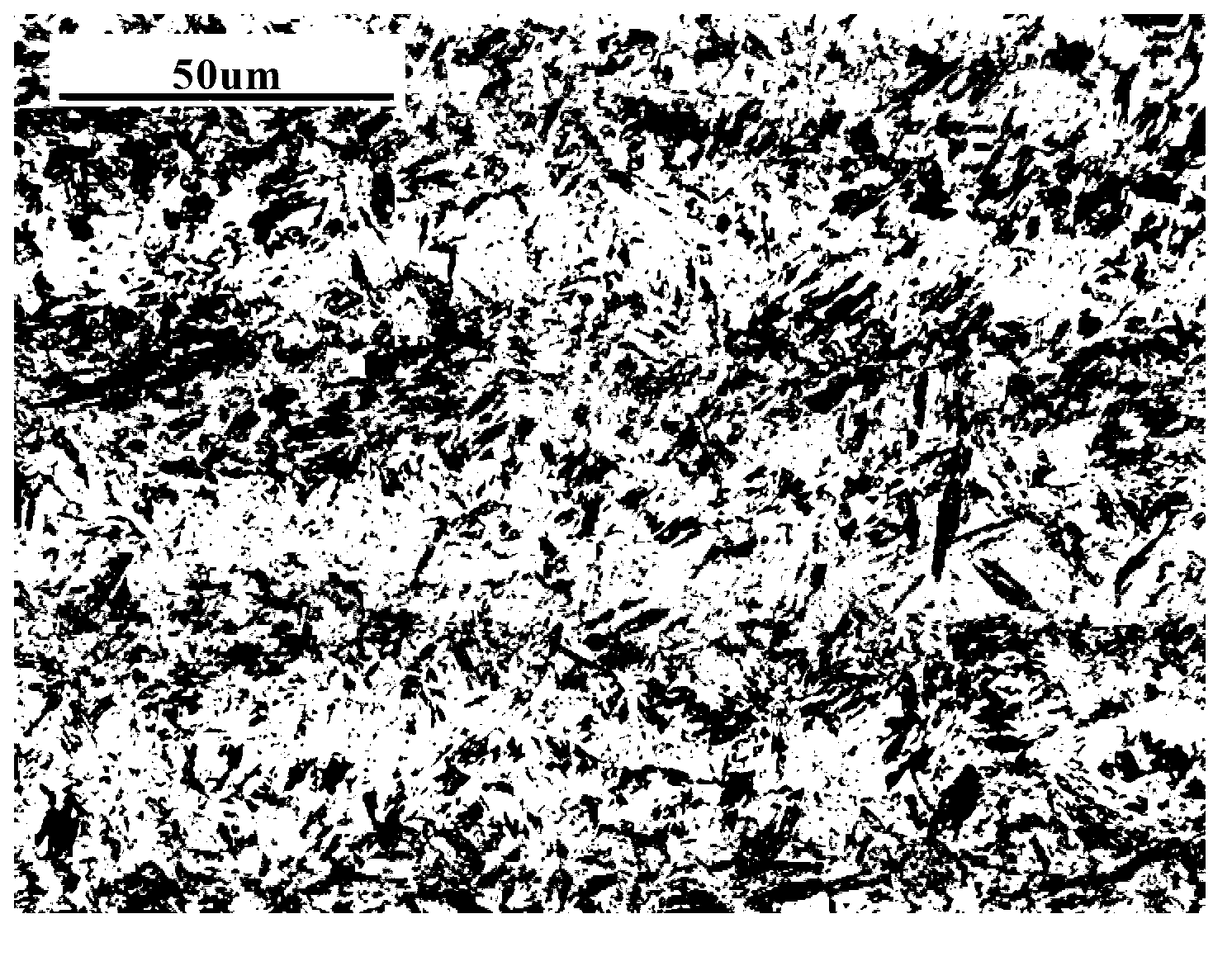

Super-thick steel plate with obdurability matching and excellent high-temperature performance and manufacturing method thereof

ActiveCN101613840AExcellent fatigue and creep resistanceExcellent resistance to temper embrittlementFurnace typesMetal rolling arrangementsEquivalent weightHeat treated

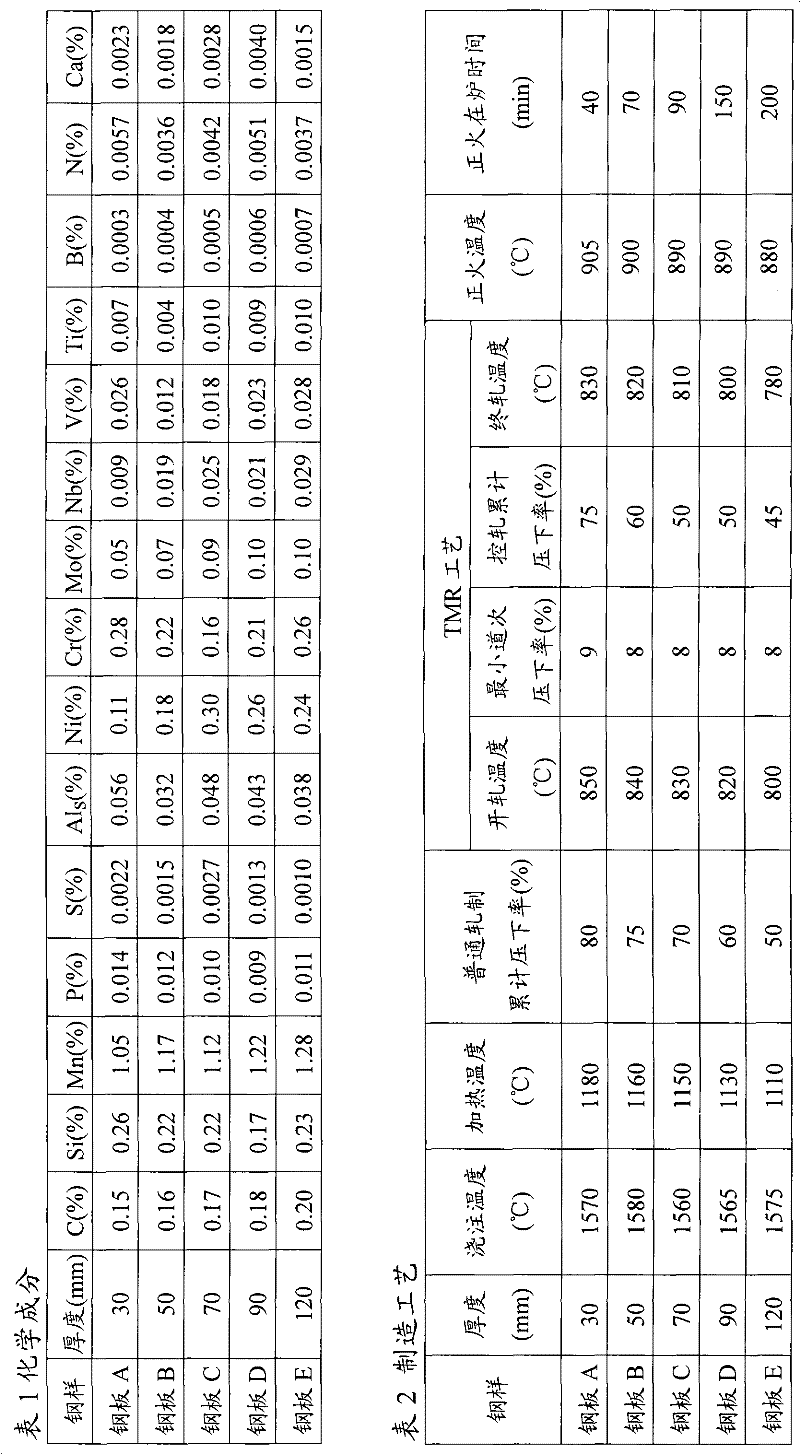

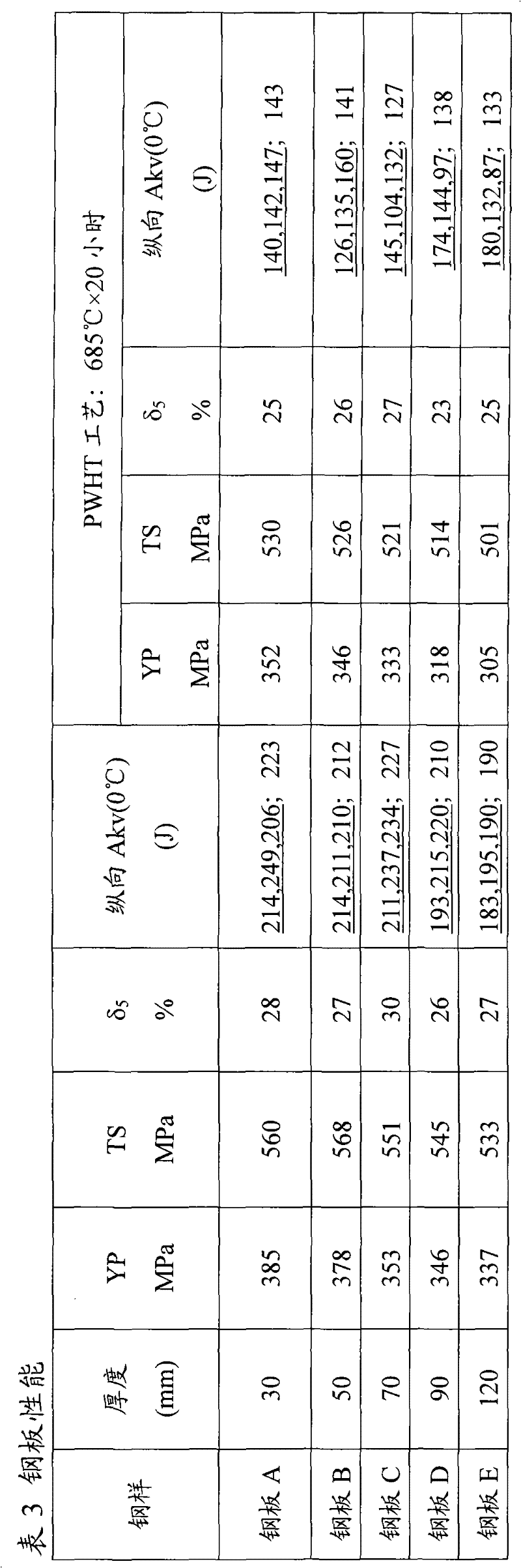

The invention relates to a super-thick steel plate with obdurability matching and excellent high-temperature performance and a manufacturing method thereof. The method comprises the following steps: adopting a component system of low alloy steel with medium C, high Mn and medium N as a basis; properly improving the acid soluble Als content in the steel and controlling the range of the content; controlling the ratio of Mn equivalent weight to C to between 10 and 20; alloying Cu, Ni, Cr, Mo and V; performing Nb and ultromicro Ti treatment, wherein the ratio of Nb to Ti is more than or equal to 1.50; performing Ca treatment, wherein the ratio of Ca to S is between 1.00 and 3.00; and optimizing the process of controlled rolling and subsequent heat treatment, thus the super-thick steel plate obtains excellent obdurability matching, exhaustion creep resistance, temper embrittlement resistance and welding manufacturability, in particular to excellent exhaustion creep resistance for a welding joint, and is particularly suitable to serve as a heat resistant pressure vessel body.

Owner:BAOSHAN IRON & STEEL CO LTD

Normalized steel plate resistant to high temperature pwht softening and manufacturing method thereof

ActiveCN102277540AImprove performanceIncrease the content of acid-soluble AlsTemperature control deviceSheet steelToughness

The invention relates to a normalized steel plate having excellent matching of toughness and strength and plasticity, good anti-fatigue and creeping resistance, resistance to high temperature PWHT softening, welding properties, and uniformity of tissue and property along with the direction of thickness of plating. The normalized steel plate can be used for preparing housings of pressure vessels, particularly carcass structures of steam evaporators voltage-stablizers. The resistance to high temperature PWHT softening specially comprises that after the steel plate being processed by the high temperature PWHT (postweld heat treatment) for more than 15 hours at the temperature of no less than 675 DEG C, the parent metal steel plate has the yield strength of no less than 300 MPa, and the tensile strength of no less than 490 MPa. The invention also discloses a preparation method of the steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

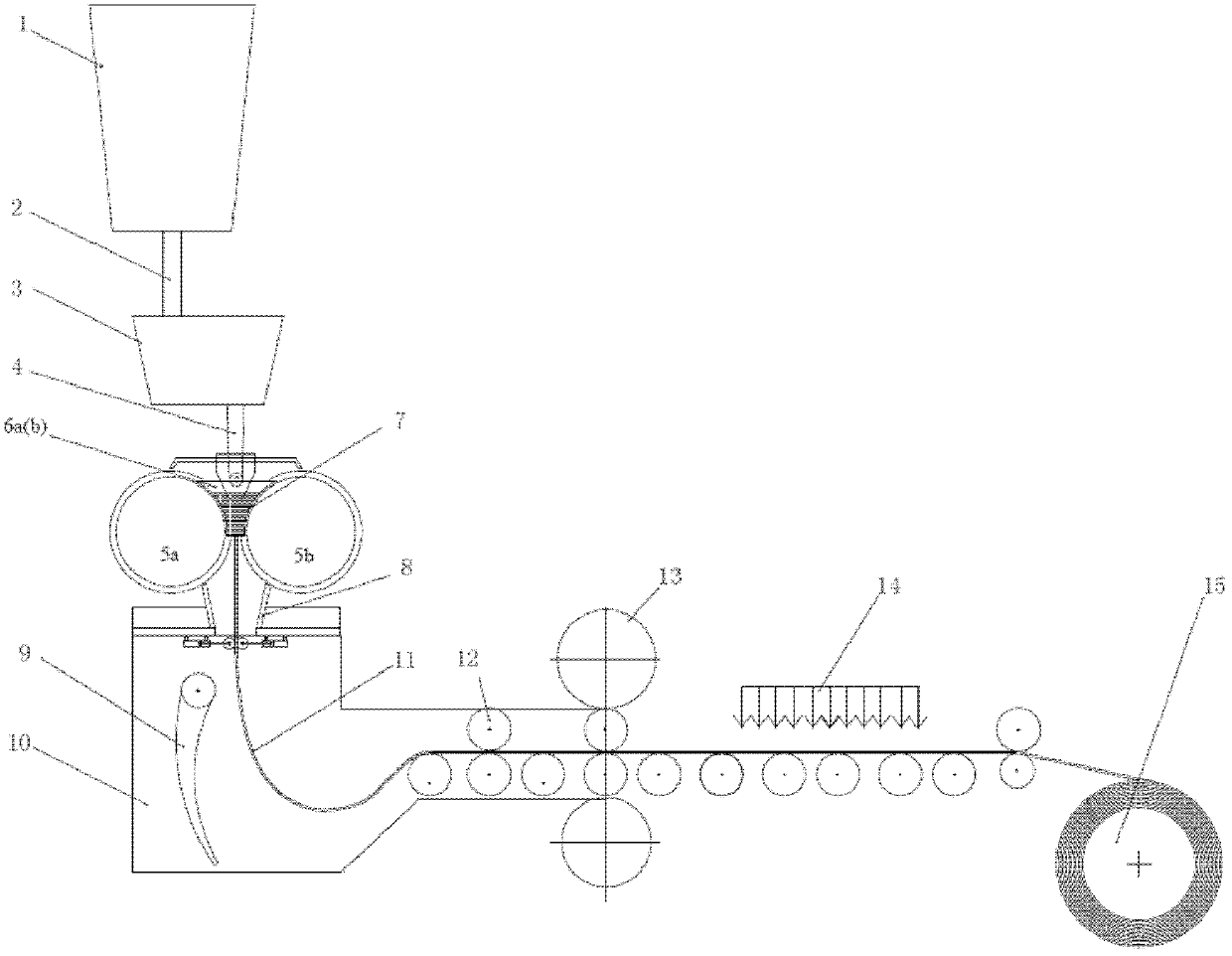

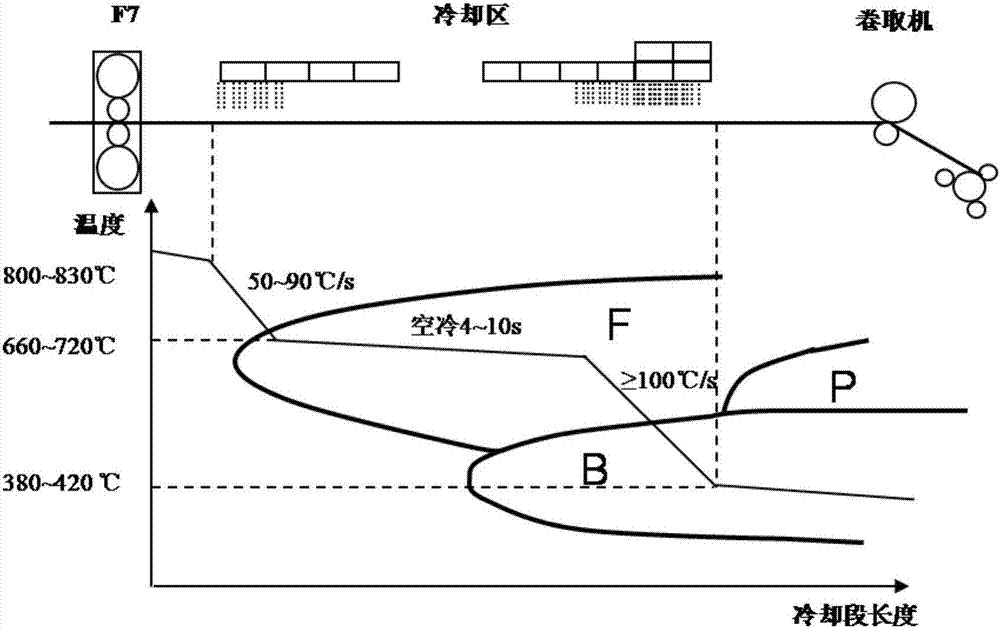

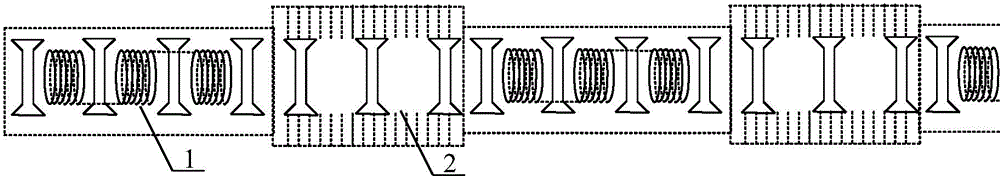

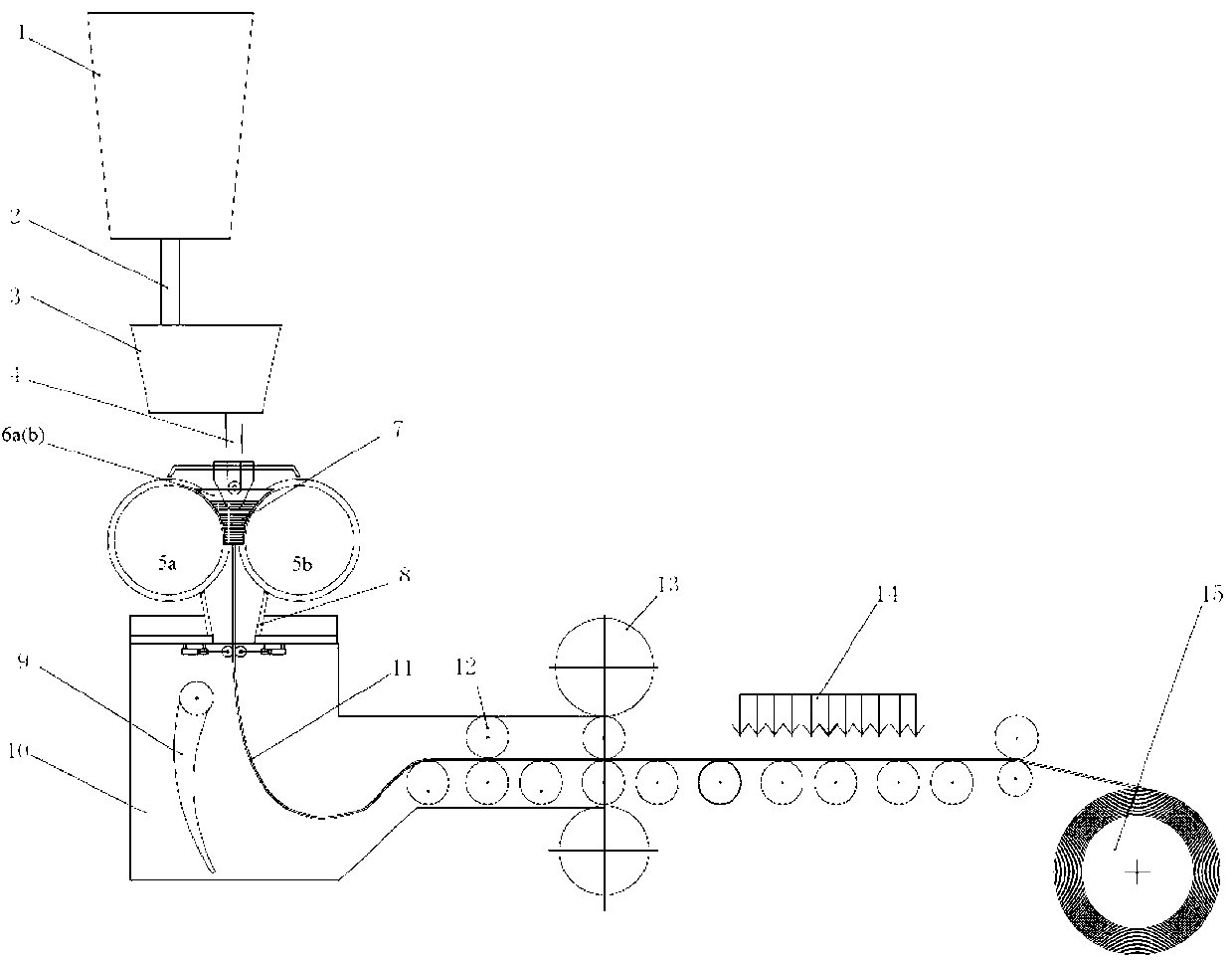

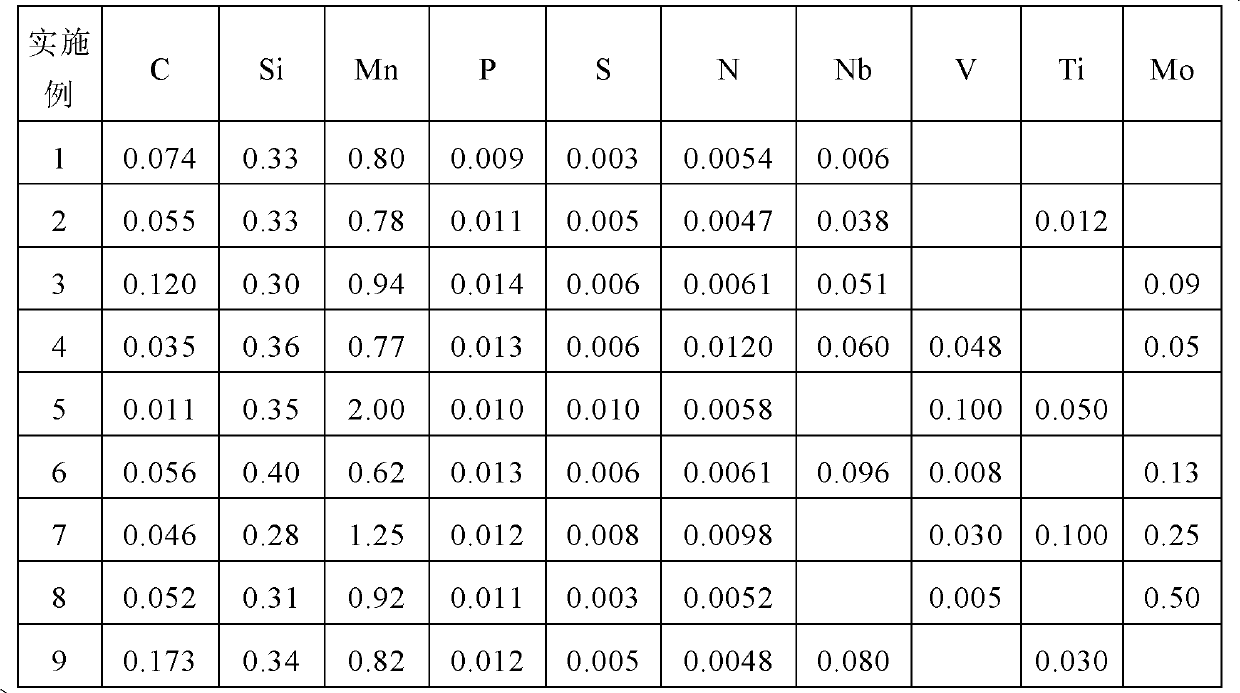

Manufacturing method of thin-strip continuous casting low-carbon micro-alloy steel strip

The invention discloses a manufacturing method of a thin-strip continuous casting low-carbon micro-alloy steel strip. The manufacturing method comprises the following steps of: (1) casting a cast strip with the thickness of 1-5mm in a double-roll continuous casting machine, wherein the steel strip comprises the following chemical components in percentage by weight: 0.01-0.25 percent of C, less than or equal to 0.4 percent of Si, 0.6-2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.012 percent of N and further comprises at least one of 0.005-0.1 percent of Nb, 0.005-0.1 percent of V, 0.005-0.1 percent of Ti, 0.05-0.5 percent of Mo, and the balance of Fe and inevitable impurities; (2) cooling the cast strip, wherein the cooling rate is greater than 20 DEG C / s; (3) performing hot rolling, wherein the hot rolling temperature is 1,050-1,250 DEG C, the reduction rate is 20-50 percent, and the deformation rate is greater than 20 s<-1>; and (4) cooling, wherein the cooling rate is 10-80 DGE C / s; and (5) coiling, wherein the cooling temperature is 550-700 DEG C. According to the manufacturing method, austenite is re-crystallized on line after the hot rolling of the cast strip is realized, so that a product obtains a small size of ferrite and pearlite structure which is more uniformly distributed, and meanwhile the product simultaneously has high strength and extensibility.

Owner:BAOSHAN IRON & STEEL CO LTD

Al-Co-Cr-Ni quaternary high-entropy alloy system and preparation method thereof

ActiveCN110438385ARich high entropy alloy systemGood mechanical propertiesHigh entropy alloysChemical composition

Owner:QINGHAI UNIVERSITY

Weather-resistant bridge steel with yield strength not less than 345 MPa and preparation method thereof

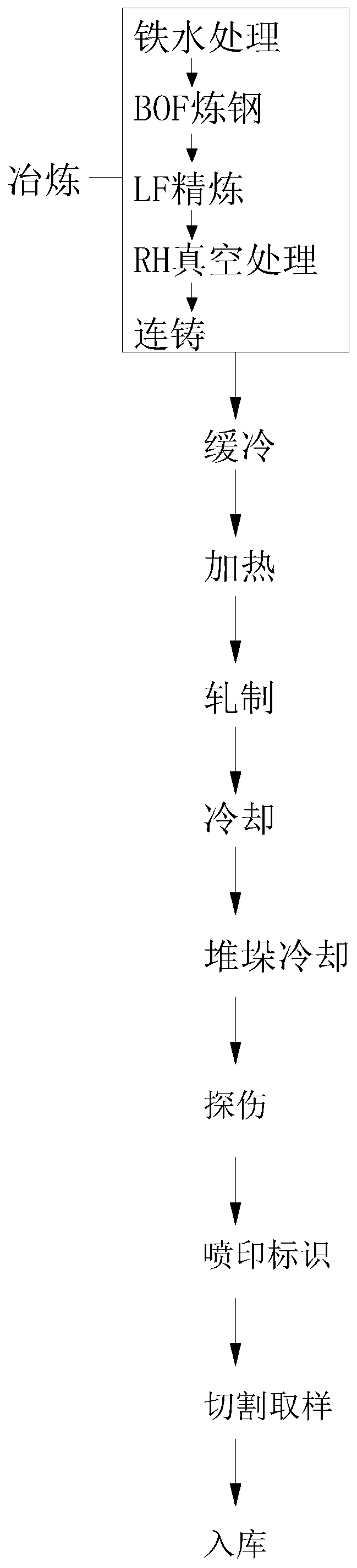

The invention relates to weather-resistant bridge steel with yield strength not less than 345 MPa and a preparation method thereof. The weather-resistant bridge steel with the yield strength not lessthan 345 MPa comprises the following components of, in percentage by weight, 0.07%-0.11% of C, 0.15%-0.30% of Si, 0.80-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.01-0.04% of Al, 0.20-0.40% of Cr, 0.20-0.40% of Cu, 0.20-0.50% of Ni, 0.020-0.050% of Nb, 0.010-0.040% of Ti and the balance Fe and inevitable impurities; and the preparation method comprises thefollowing steps of smelting, slow cooling, heating, rolling, cooling and stacking and cooling. According to the weather-resistant bridge steel with the yield strength not less than 345 MPa and the preparation method thereof, the low-cost micro-alloying design is adopted, the production period is short, the cost is low, popularization and application are facilitated, the weather-resistant bridge steel has excellent welding performance, strong toughness and strong plasticity matching performance, low yield ratio, corrosion resistance, weather resistance, welding performance and anti-fatigue performance, compared with traditional weather-resistant steel, the weather resistance is improved by one time or above, the weather-resistant bridge steel can replace the traditional high-strength weathering steel, and can be applied to the fields of bridges, outdoor tower frames and the like without coating, so that the use cost and the maintenance cost are reduced.

Owner:SD STEEL RIZHAO CO LTD

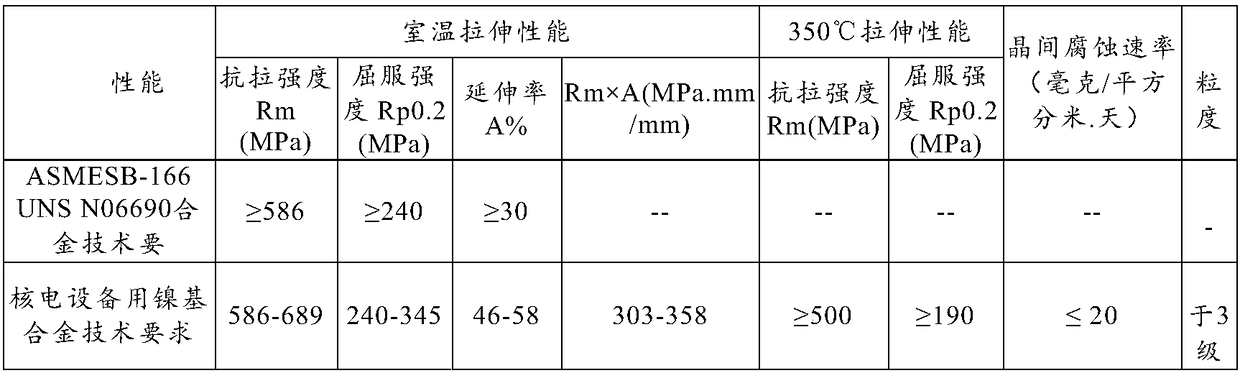

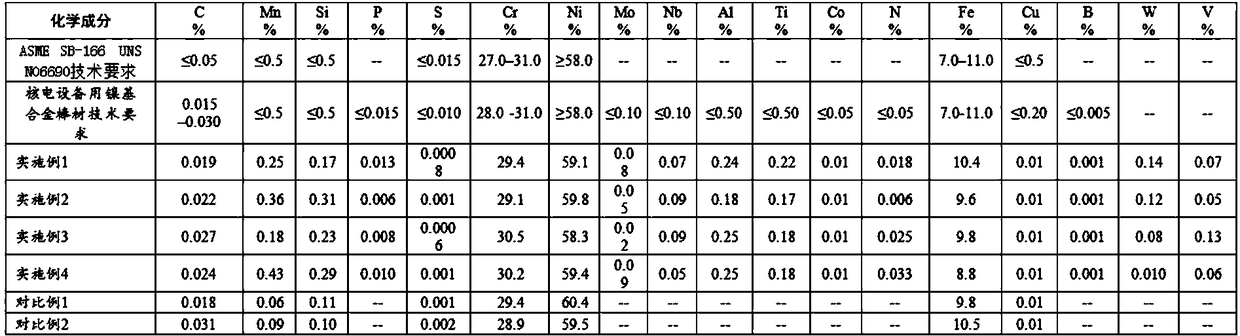

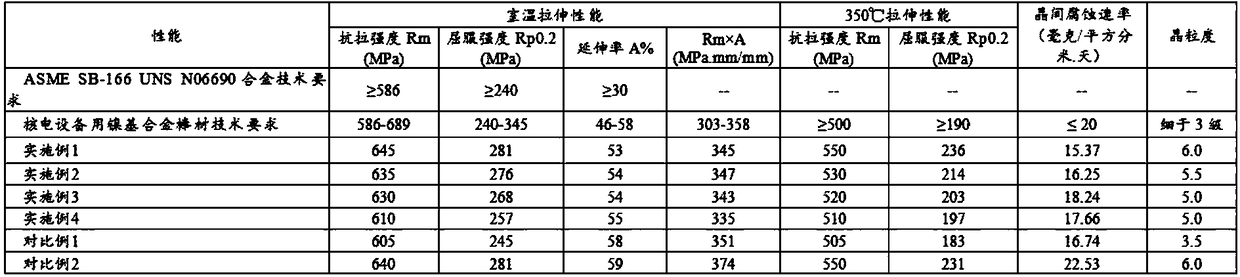

Nickel-based alloy large-section bar used for nuclear power critical equipment and manufacturing method of large-section bar

The invention provides a nickel-based alloy used for nuclear power critical equipment and a manufacturing method of a nickel-based alloy bar. The alloy comprises the following elements: C, Cr, Fe, W and the balance Ni and unavoidable impurities, wherein the content of Ni is not less than 58%. The preparation method of the bar includes the following steps of nickel-based alloy preparation, hot rolling and forming of the bar and heat treatment of the bar. Compared with the prior art, the nickel-based alloy and the manufacturing method has the following advantages that the manufacture process isespecially suitable for manufacturing large-section nickel-based alloy bar of Phi 300 mm to Phi660 mm, and the nickel-based alloy bar is completely applicable to key components of nuclear island equipment in nuclear power plants and of great significance for effectively promoting the independent construction of large nuclear power plants in China.

Owner:宝武特种冶金有限公司

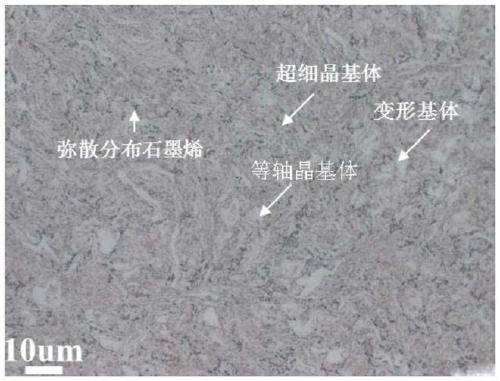

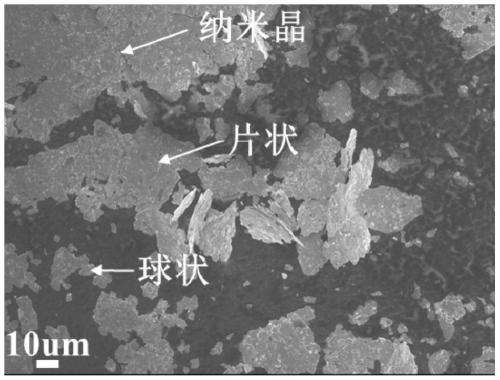

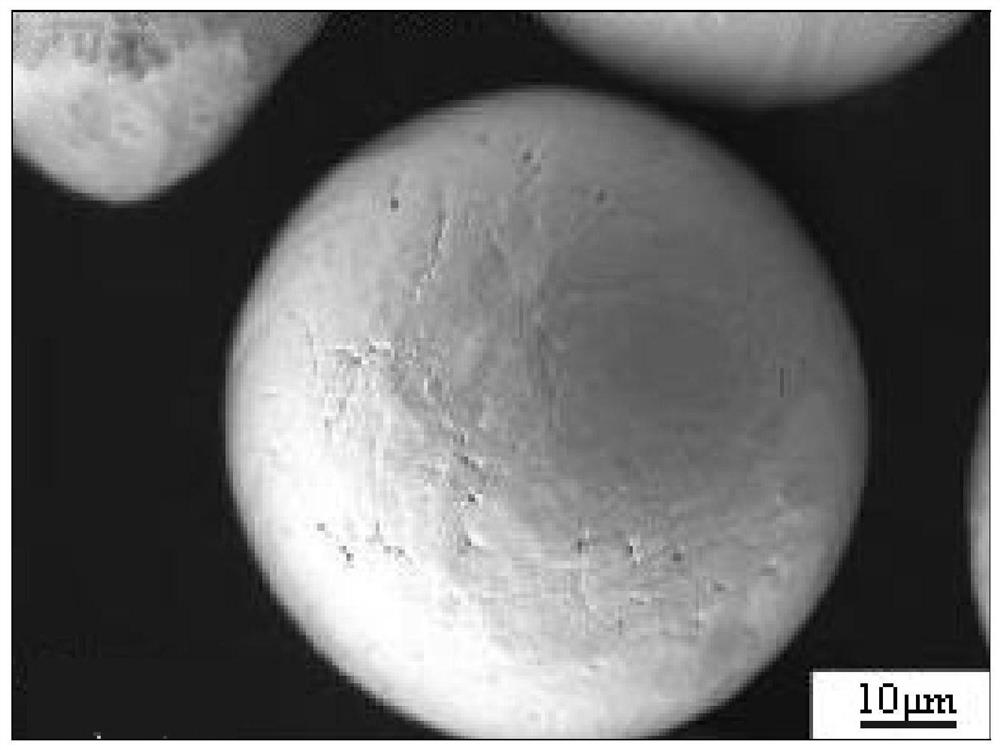

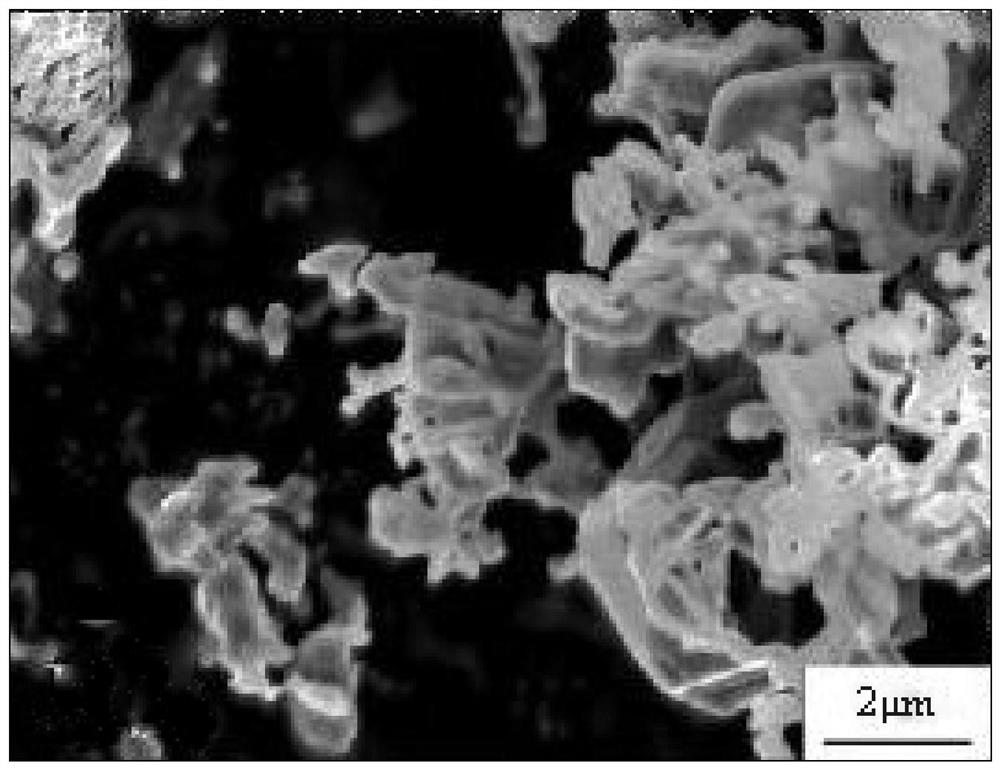

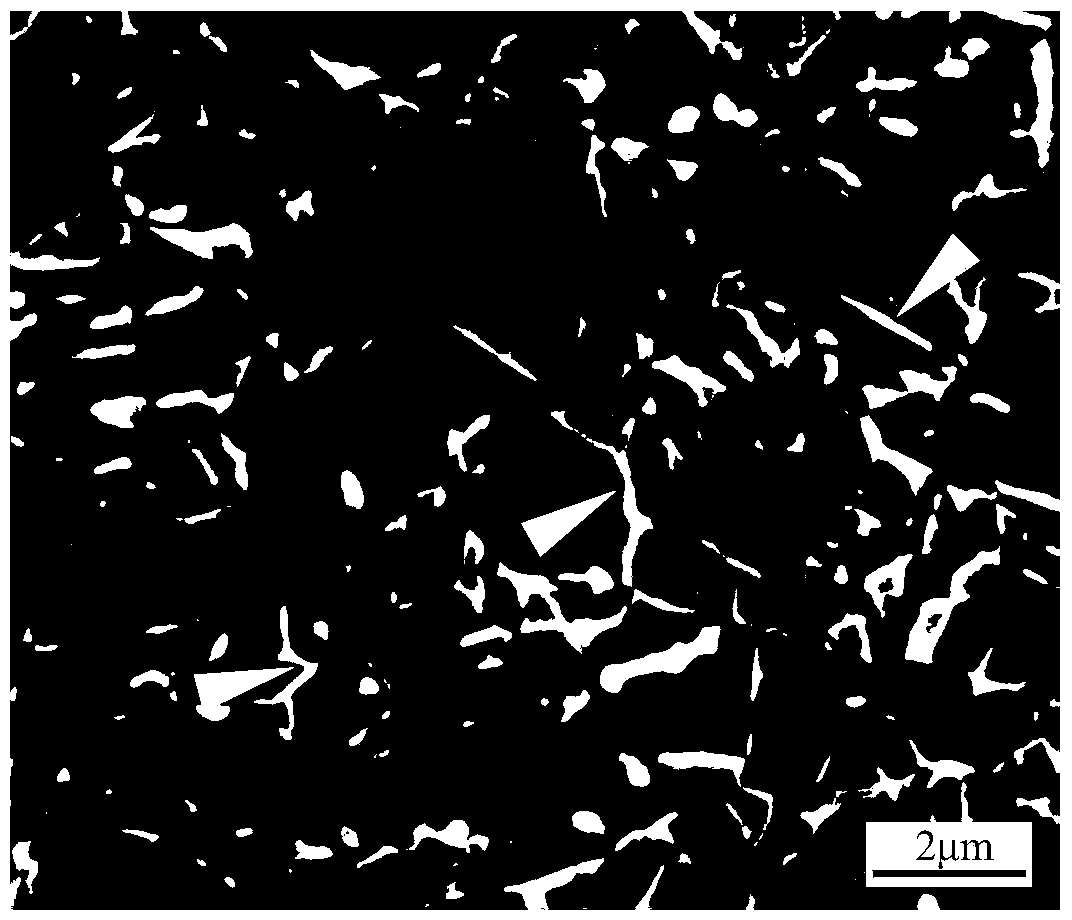

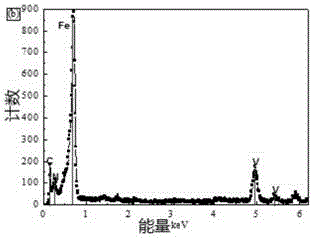

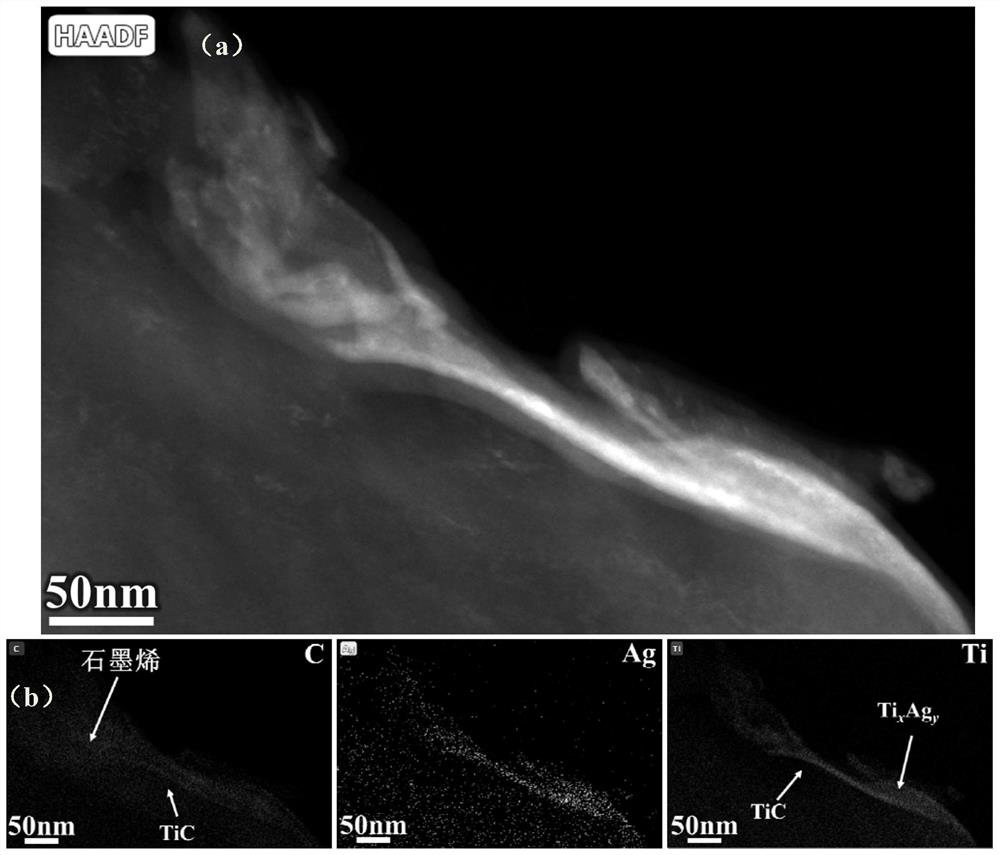

Preparation method of graphene enhanced FCC-type high-entropy alloy

ActiveCN111534712AImprove strong plasticityGood strength and plasticity matchingHigh entropy alloysGraphite

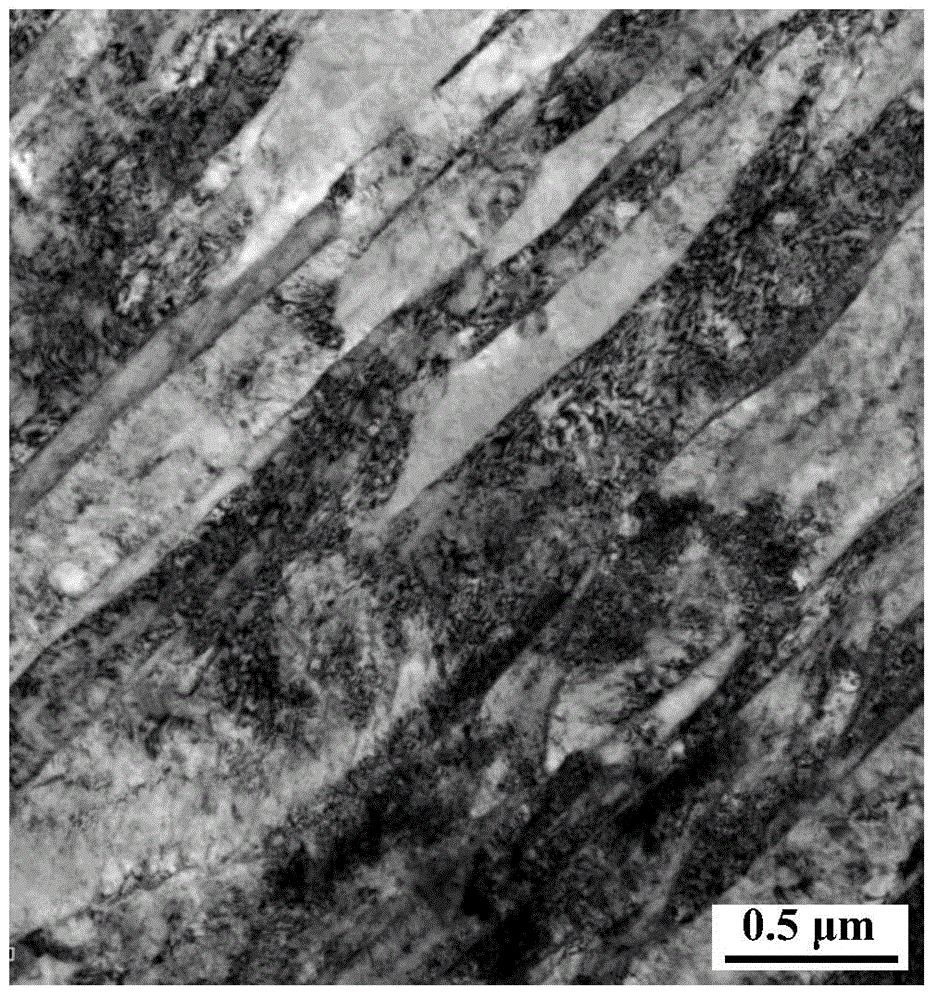

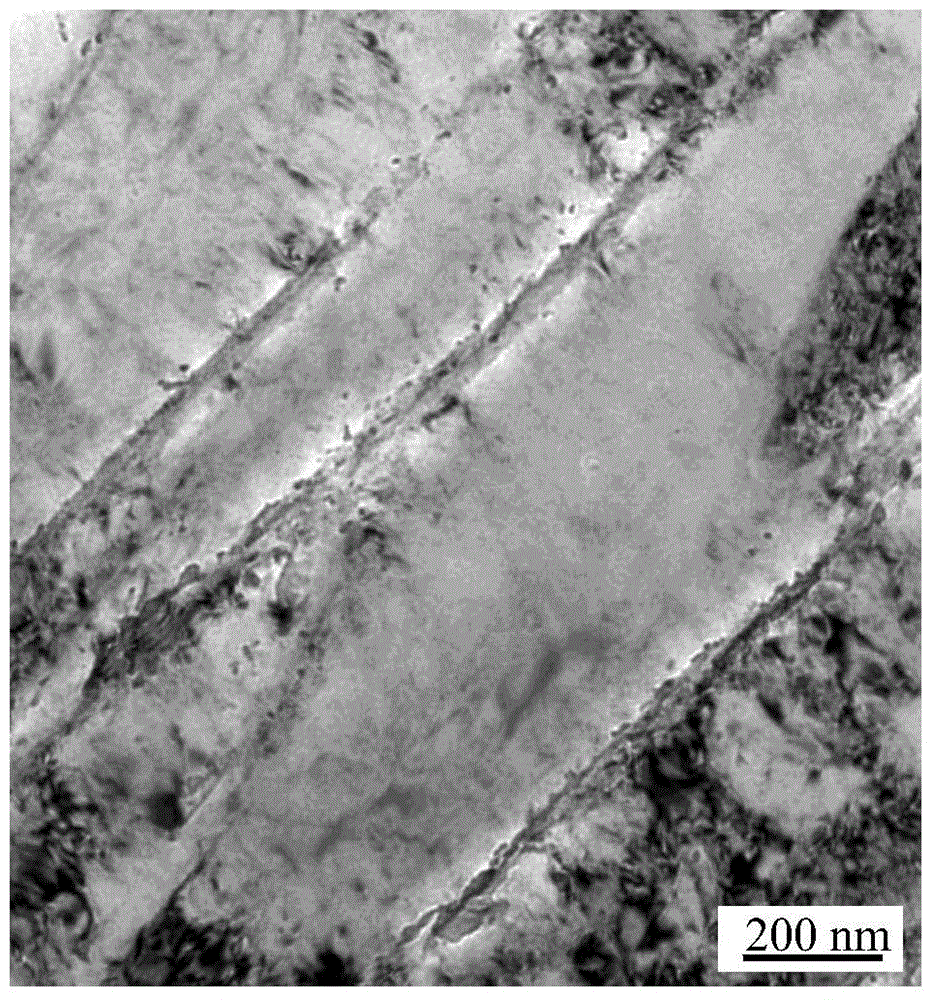

The invention discloses a preparation method of a graphene enhanced FCC-type high-entropy alloy. The method comprises the steps that 1, FCC-type high-entropy alloy powder is prepared by a gas atomization method; 2, the FCC-type high-entropy alloy powder is subjected to ball milling and then dried; 3, the dried FCC-type high-entropy alloy powder is mixed with graphene nanoflakes, then composite powder is obtained by ball milling; and 4, the composite powder is subjected to spark plasma sintering, and the graphene enhanced FCC-type high-entropy alloy is obtained after cooled in a furnace. According to the preparation method, short-time high-energy ball milling is adopted, so that the FCC-type high-entropy alloy powder forms multi-scale lamellar structures and produces fine nanocrystals, combined with low-energy ball milling, the graphene nanoflakes are completely and evenly dispersed between the lamellar structures, the graphene enhanced FCC-type high-entropy alloy with multi-scale crystals is prepared, the strengthening effect is effectively enhanced, and the good matching of strength and plasticity is achieved.

Owner:西安稀有金属材料研究院有限公司 +1

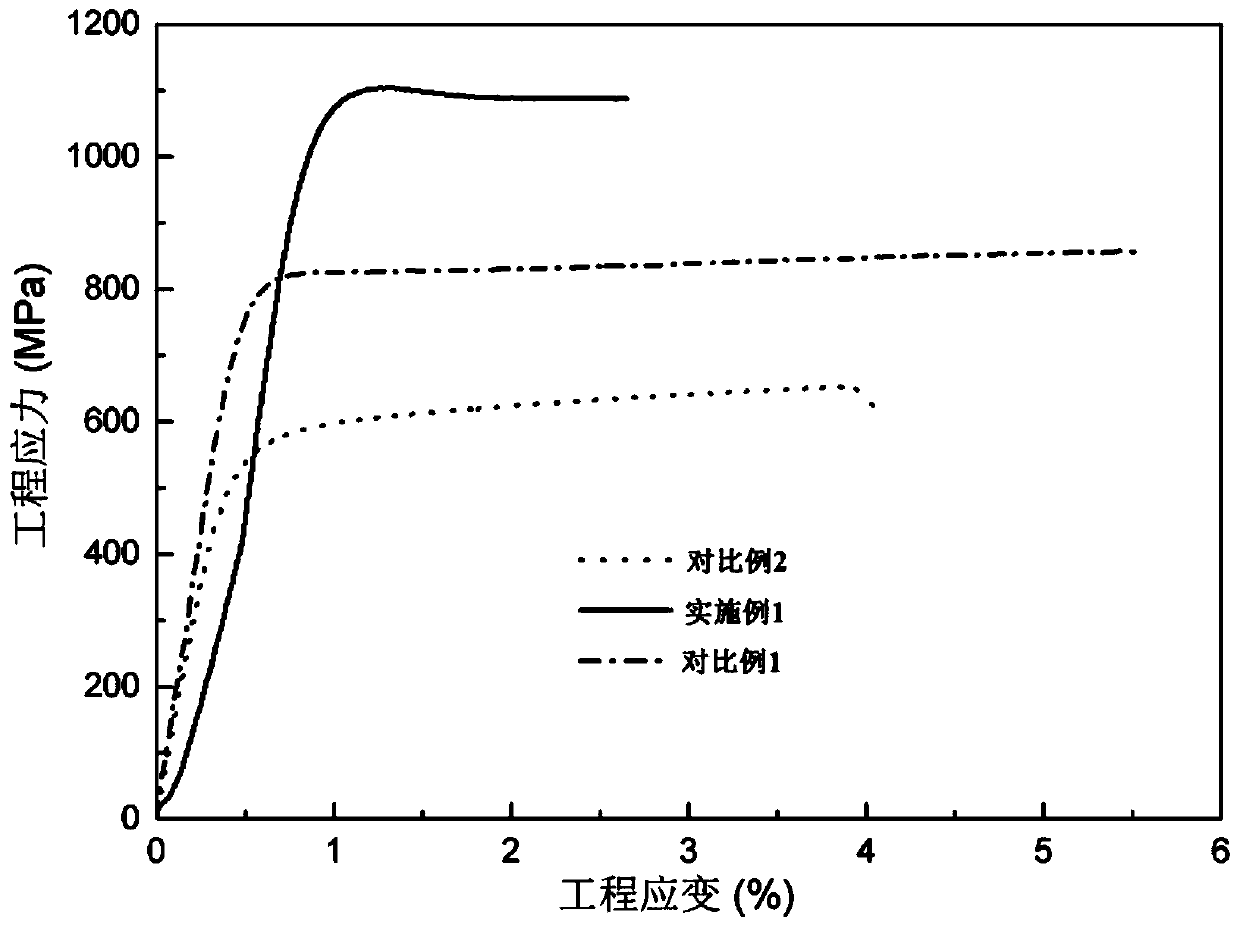

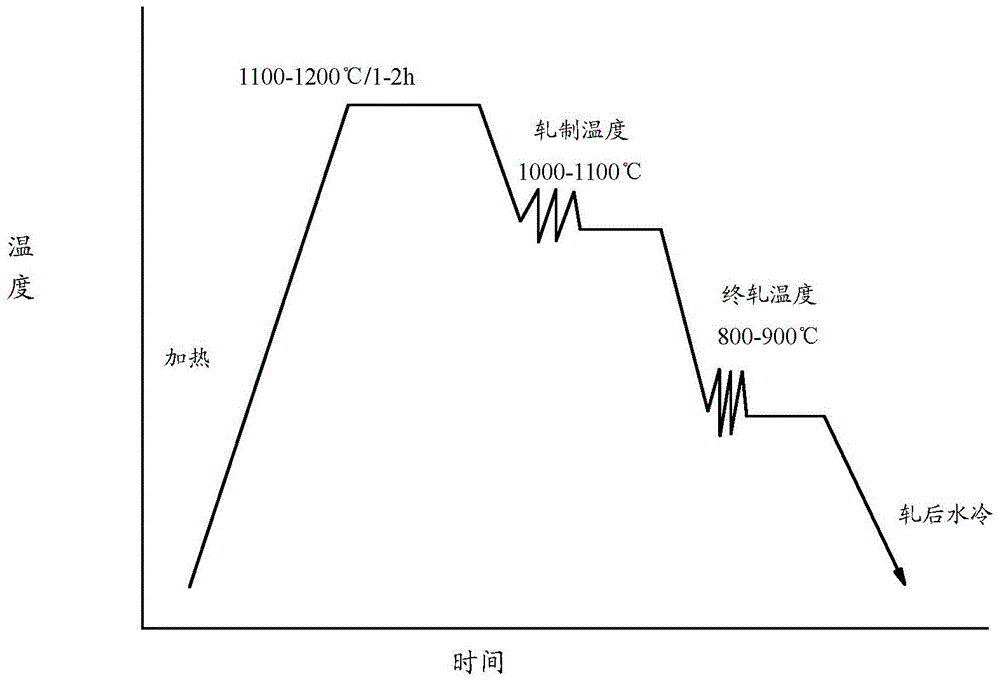

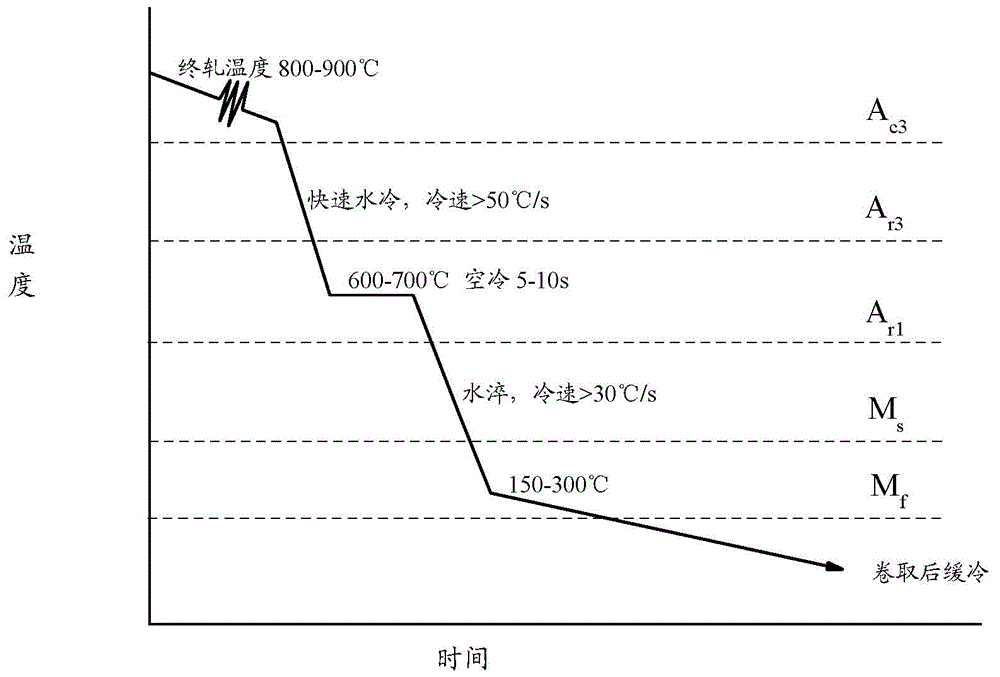

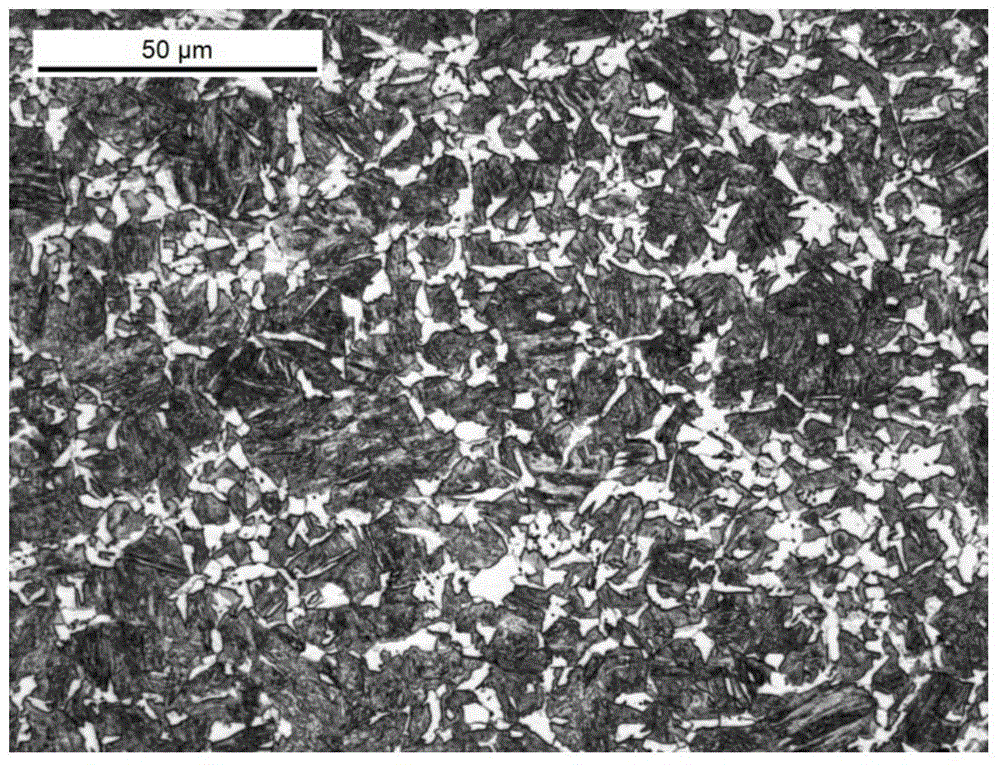

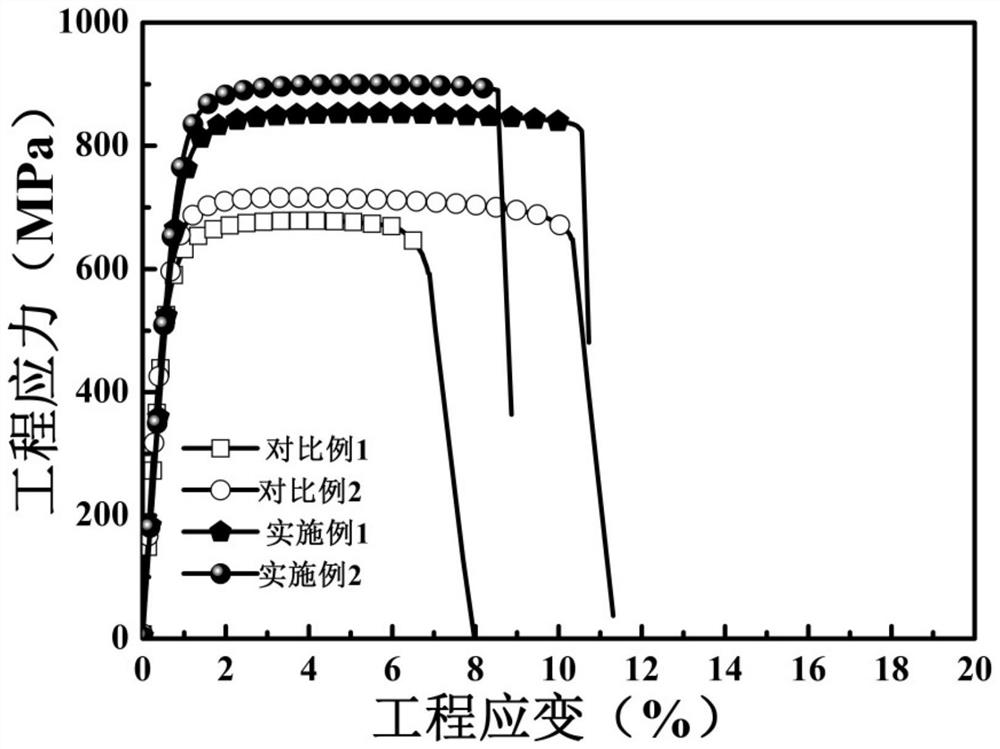

Hot rolled Q&P steel with 700MPa grade yield strength and ultralow yield ratio and manufacturing method thereof

The invention relates to a hot rolled Q&P steel with 700MPa grade yield strength and ultralow yield ratio and a manufacturing method thereof. The hot rolled Q&P steel comprises the following components by weight: 0.2-0.3% of C, 1.0-2.0% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.5-1.0% of Al, or less than or equal to 0.006% of N, 0.05-0.5% of Cr, less than or equal to 0.05% of Ti, and the balance Fe and inevitable impurities. The ultrahigh strength hot rolled Q&P steel provided by the invention has yield strength of greater than or equal to 700MPa and tensile strength of greater than or equal to 1300MPa.

Owner:BAOSHAN IRON & STEEL CO LTD

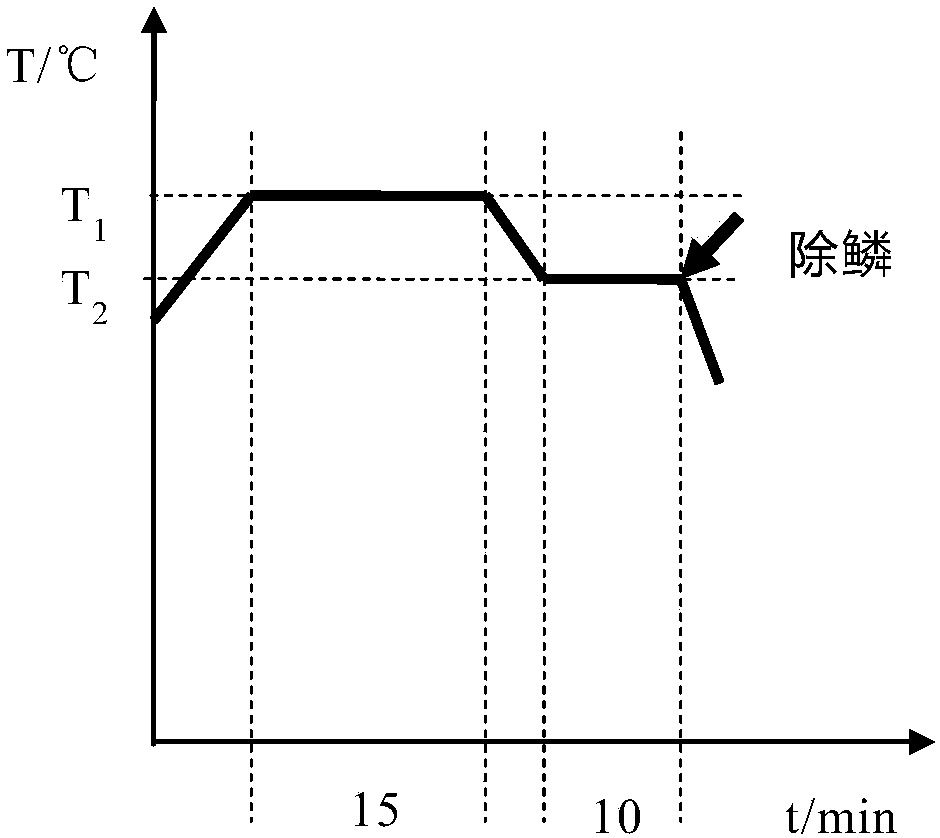

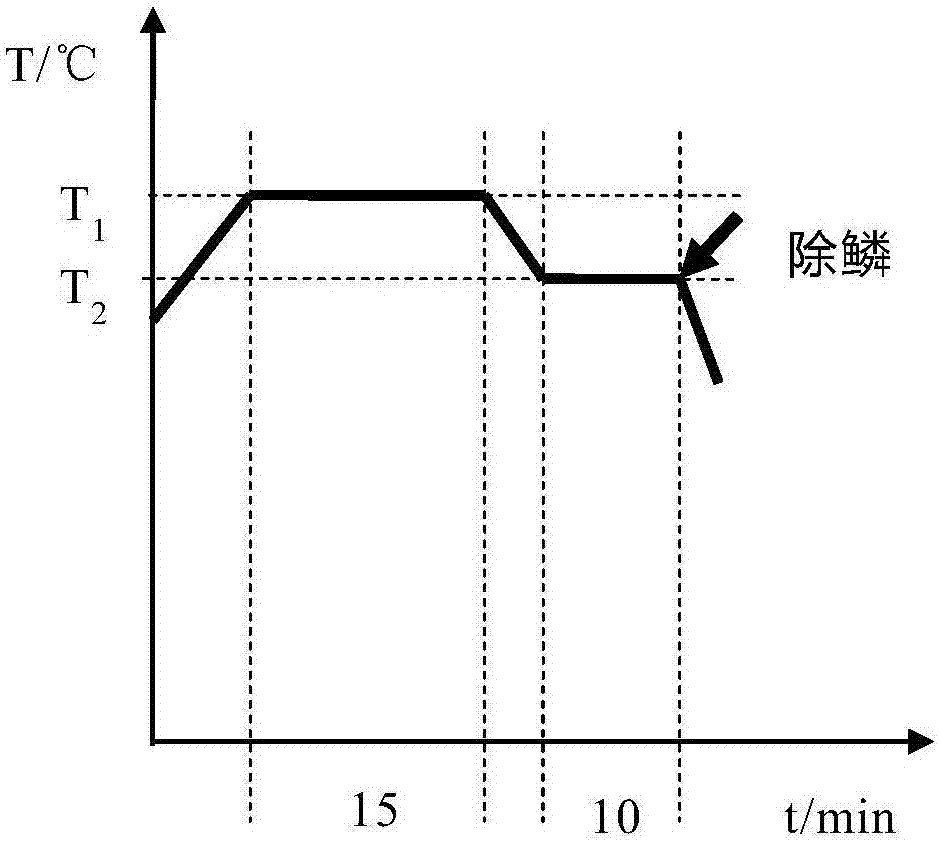

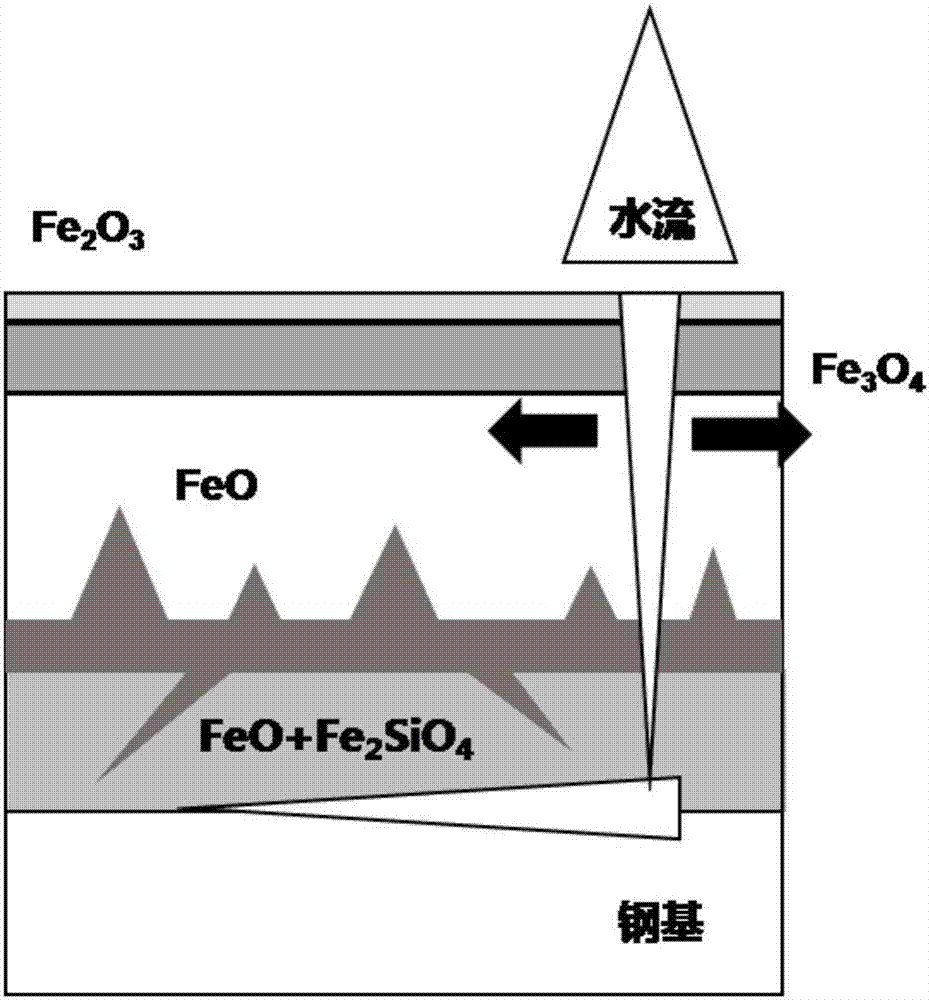

1,000 MPa level hot-rolled TRIP steel based on CSP process and manufacturing method

ActiveCN107557692AGood strong plasticityGuaranteed stabilityHeat treatment process controlAluminiumTRIP steel

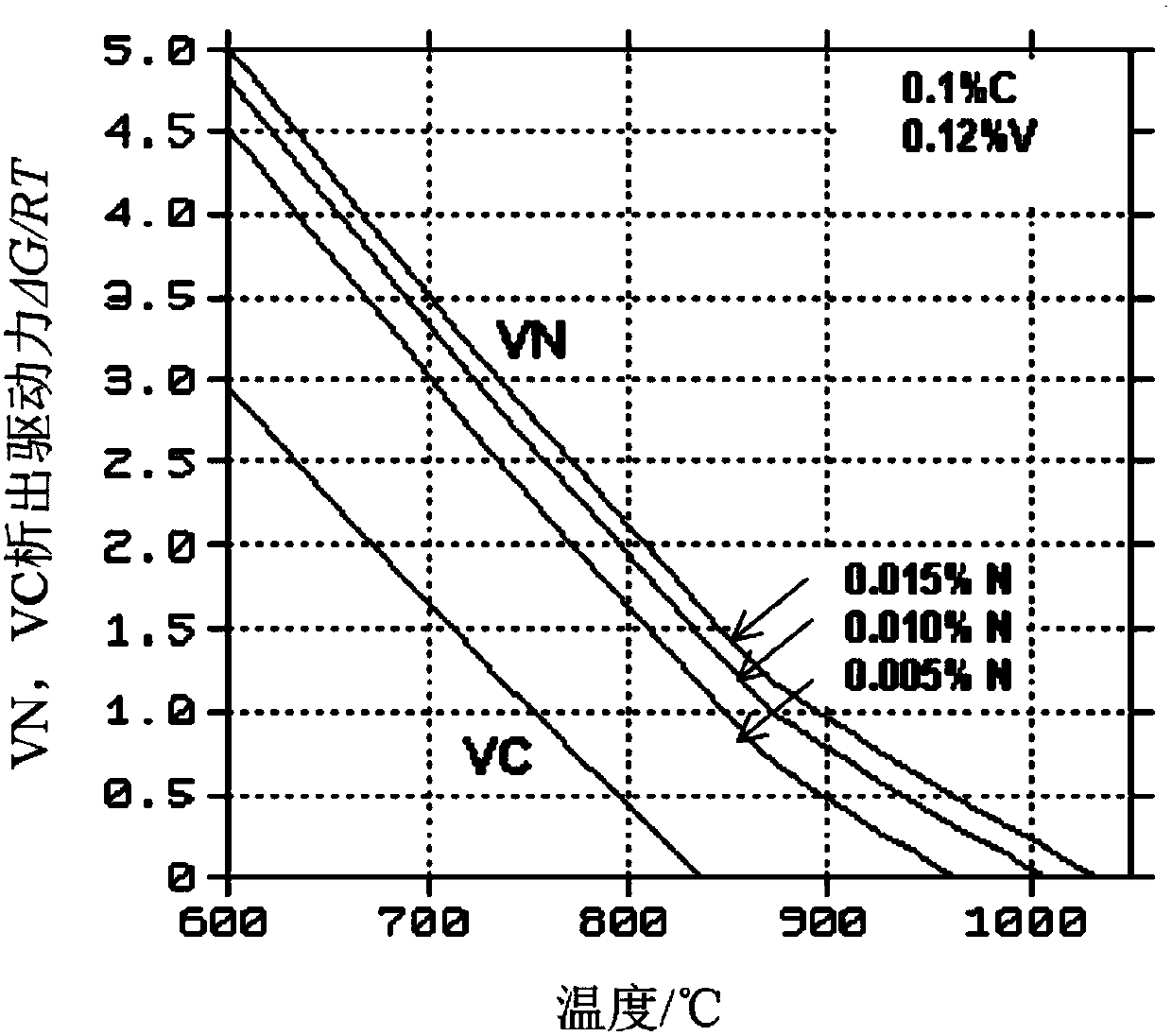

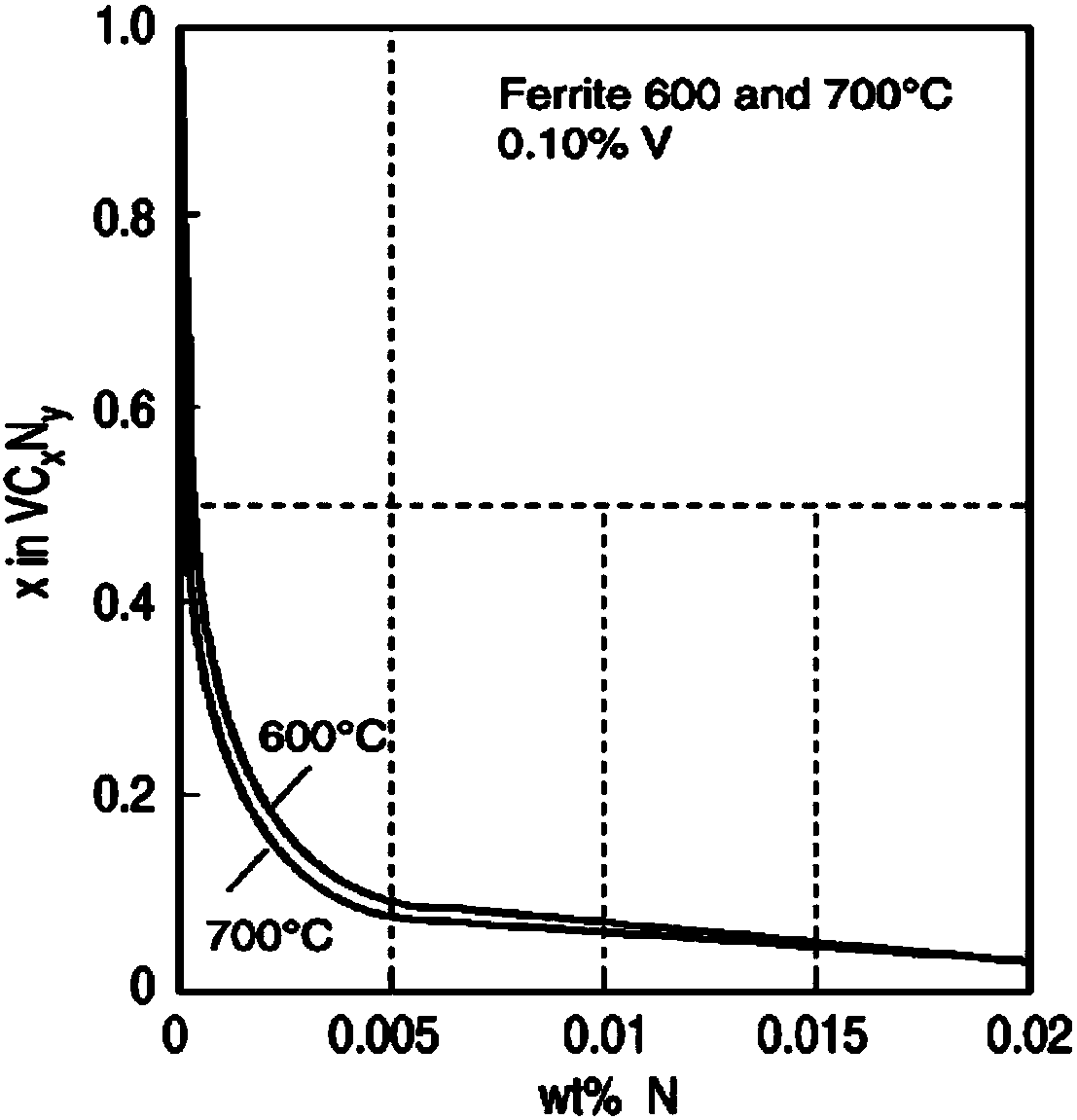

The invention discloses 1,000 MPa level hot-rolled TRIP steel based on the CSP process. The 1,000 MPa level hot-rolled TRIP steel comprises chemical elements and components including, by weight percent, 0.16%-0.20% of carbon, 1.60%-1.80% of silicon, 1.50%-1.60% of manganese, 0.20%-0.24% of vanadium, smaller than or equal to 0.008% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.015%-0.060% of acid soluble aluminum, 0.015%-0.025% of nitrogen and the balance iron and inevitable impurities. The steel manufacturing method comprises converter smelting, refining, sheet billet continuouscasting, continuous casting blank uniform heating, high-pressure water descaling, controlled rolling, controlled cooling and coiling. Through the V-N adding microalloying component design, a ferrite phase and a bainite phase are strengthened, meanwhile, carbon concentration is not reduced, stability of retained austenite is maintained, and good strength and plasticity matching is achieved.

Owner:武汉钢铁有限公司

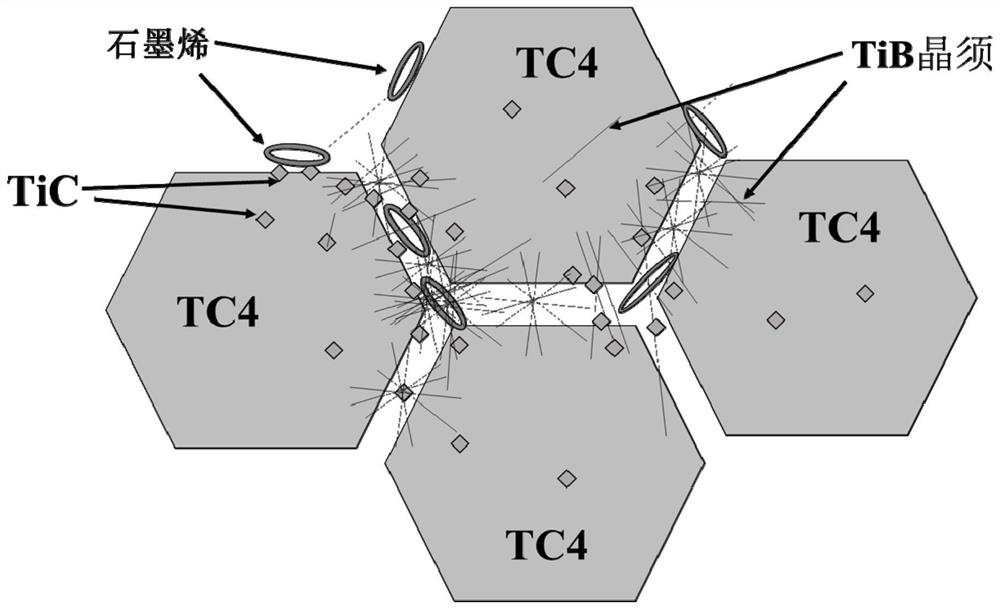

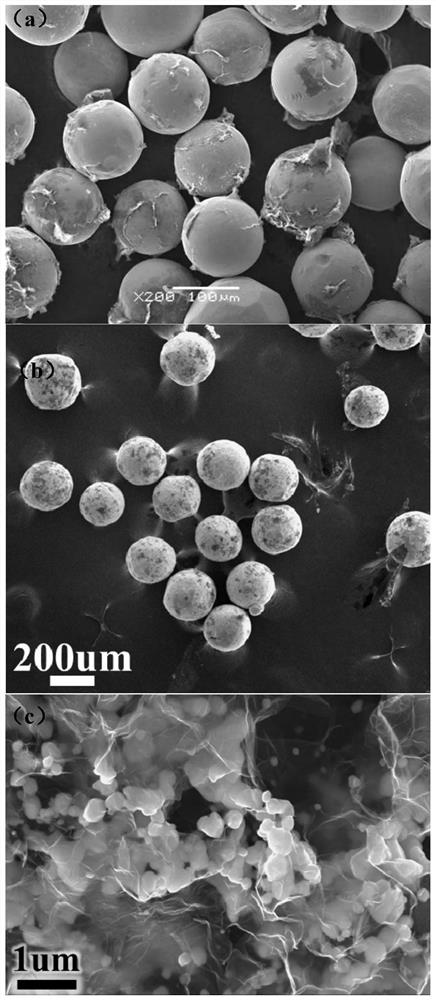

Preparing method capable of achieving TC4 titanium alloy high toughness through co-reinforcement method

ActiveCN111644615AImprove load transfer performancePayloadTransportation and packagingMetal-working apparatusNanoparticleGraphite

The invention discloses a preparing method capable of achieving TC4 titanium alloy high toughness through a co-reinforcement method. The method comprises the steps that firstly, boron powder and TC4 titanium alloy spherical powder are subjected to ball milling to obtain boron coated TC4 titanium alloy spherical powder; secondly, the boron coated TC4 titanium alloy spherical powder is added into agraphene material solution to be evenly stirred, and graphene material coated boron coated TC4 titanium alloy powder is obtained; and thirdly, the graphene material coated boron coated TC4 titanium alloy powder is sequentially subjected to plasma sintering and rolling to obtain a graphene-boron co-reinforced TC4 titanium alloy composite. The TC4 titanium alloy spherical powder is sequentially coated with boron and the graphene material, through sintering in-situ synthesis, TiB crystal whiskers in non continuous hook net structure distribution are present, in combination with dispersion strengthening and fixing effects of in-situ synthesis nano TiC particles and residual graphene materials, the action effects of TiB, graphene and TiC co-reinforcing is achieved, and the composite has the good strength and plastic matching.

Owner:西安稀有金属材料研究院有限公司 +1

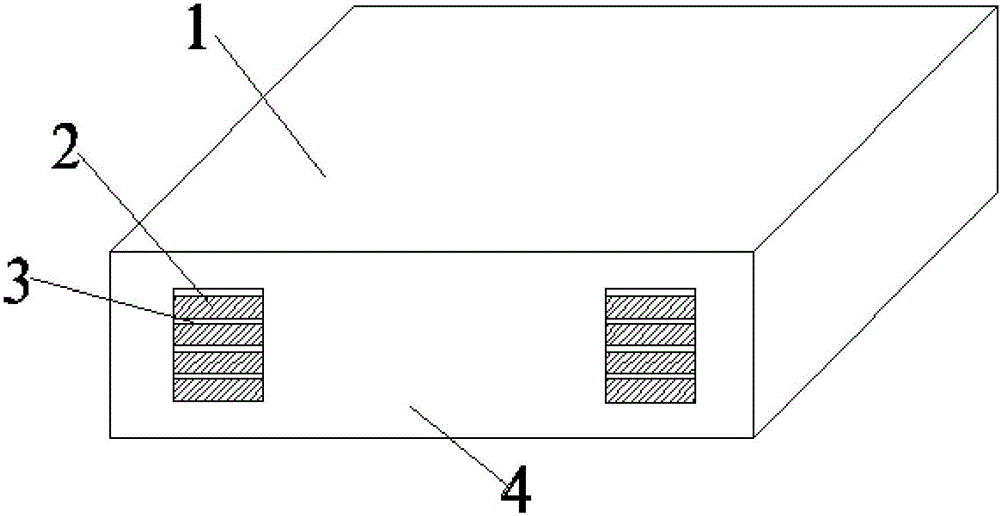

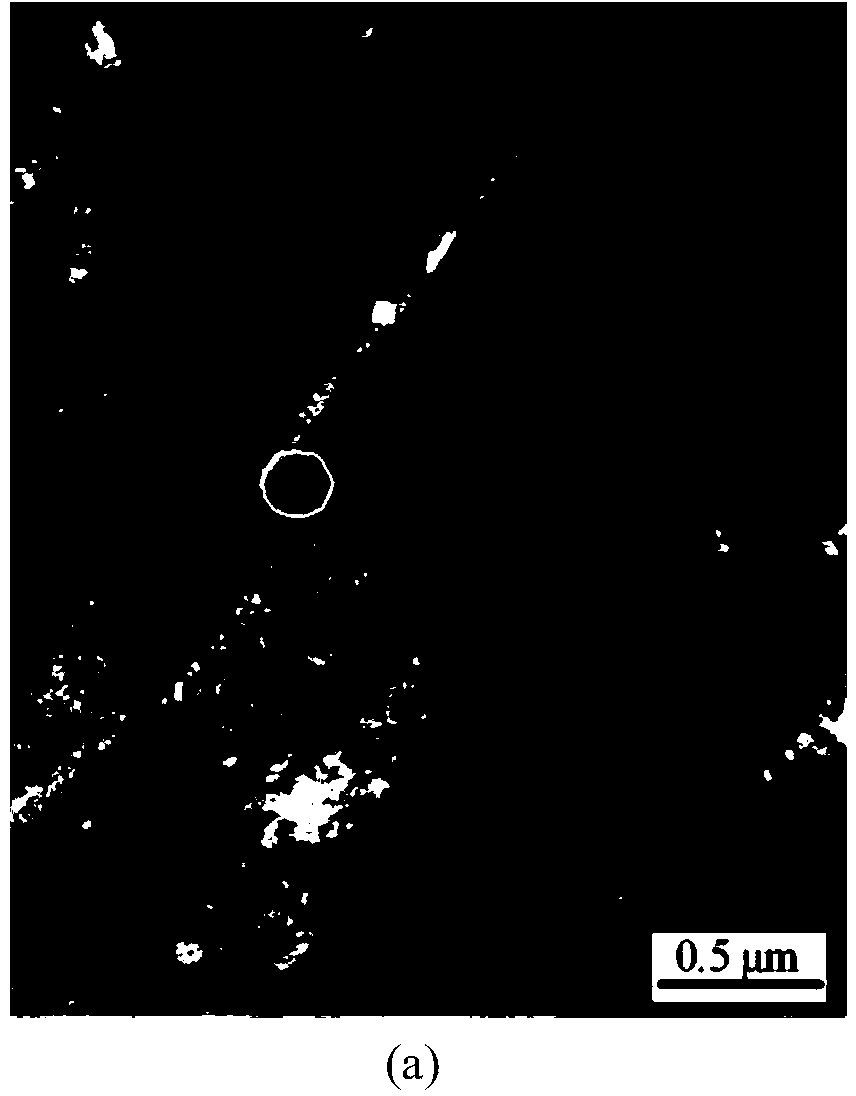

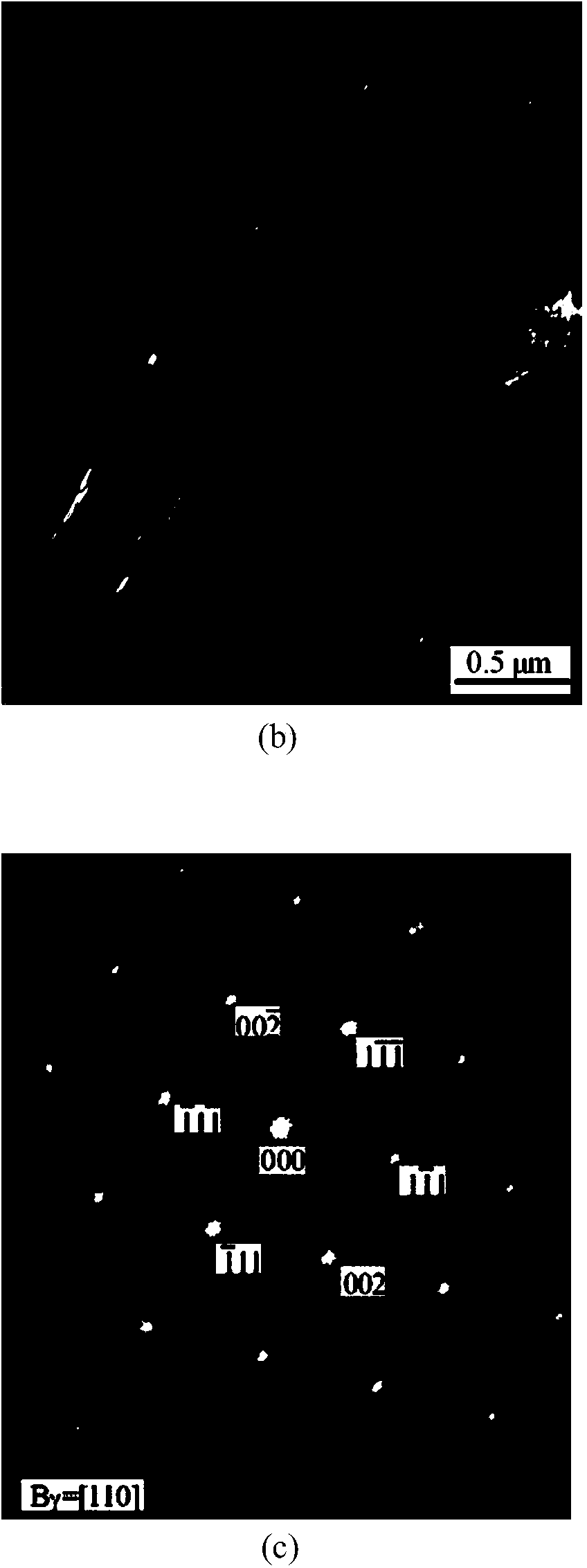

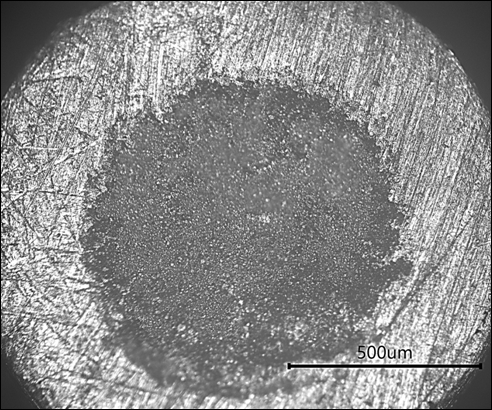

Processing method for Ti2AlNb alloy wide thin plate

ActiveCN106734318AReduce crackingGood strength and plasticity matchingTemperature control deviceMetal rolling arrangementsAlloyHeating furnace

The invention discloses a processing method for a Ti2AlNb alloy wide thin plate. The processing method comprises the steps that 1, a Ti2AlNb alloy plate blank is placed into a heating furnace to be subjected to heat preservation and then is fed into a hot rolling mill to be subjected to primary rolling, and a first semi-finished plate blank is obtained; 2, the first semi-finished plate blank is cut into two to four pieces of Ti2AlNb alloy semi-finished plate blank bodies, and then the Ti2AlNb alloy semi-finished plate blank bodies are stacked together to be made into a stacked rolled bag; 3, the stacked rolled bag is placed into the heating furnace to be subjected to heat preservation and then is fed into the hot rolling mill to be subjected to secondary rolling; and 4, finished product annealing treatment is conducted on the stacked rolled bag subjected to secondary rolling, then the stacked rolled bag subjected to finished product annealing treatment is sheared and unpacked, and the Ti2AlNb alloy thin plate of which the thickness is 1 mm-4 mm and the width is 800 mm-1500 mm is obtained after leveling, sanding and cutting. According to the processing method for the Ti2AlNb alloy wide thin plate, the processing route is simple; the preparation cost is low; the efficiency is high; the thin plate excellent in mechanical performance can be prepared; and mass production is achieved.

Owner:WESTERN TITANIUM TECH +1

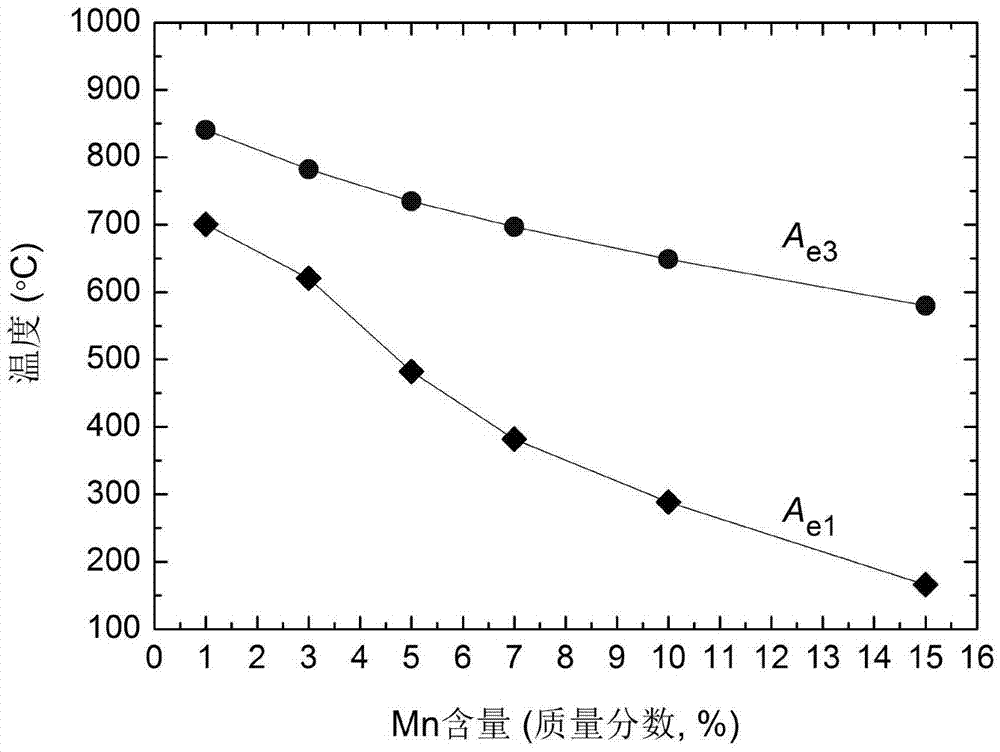

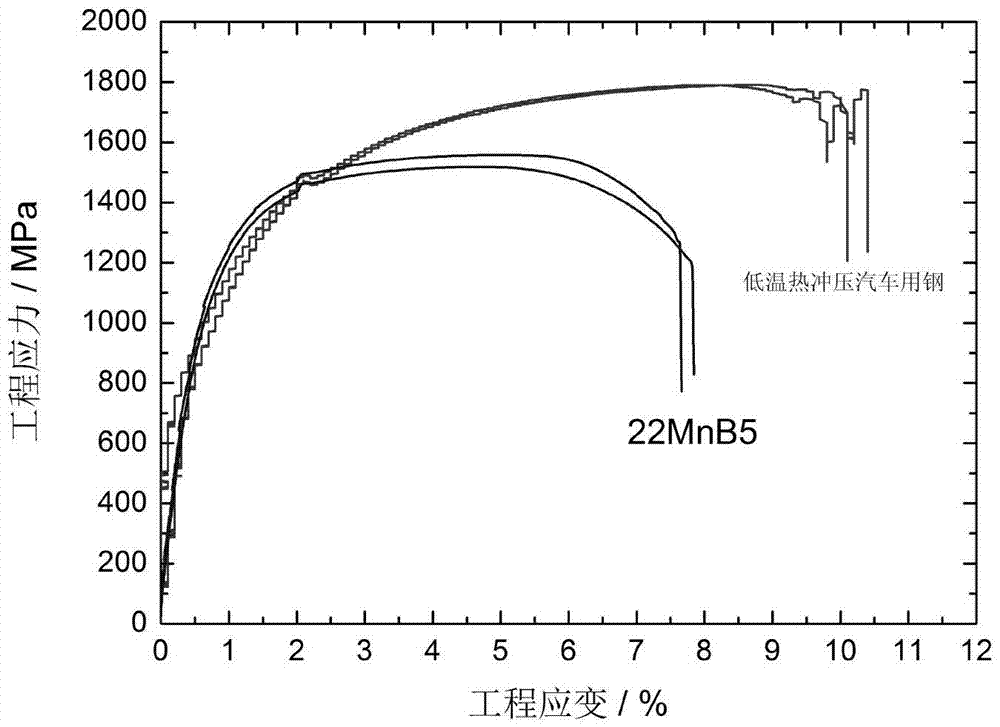

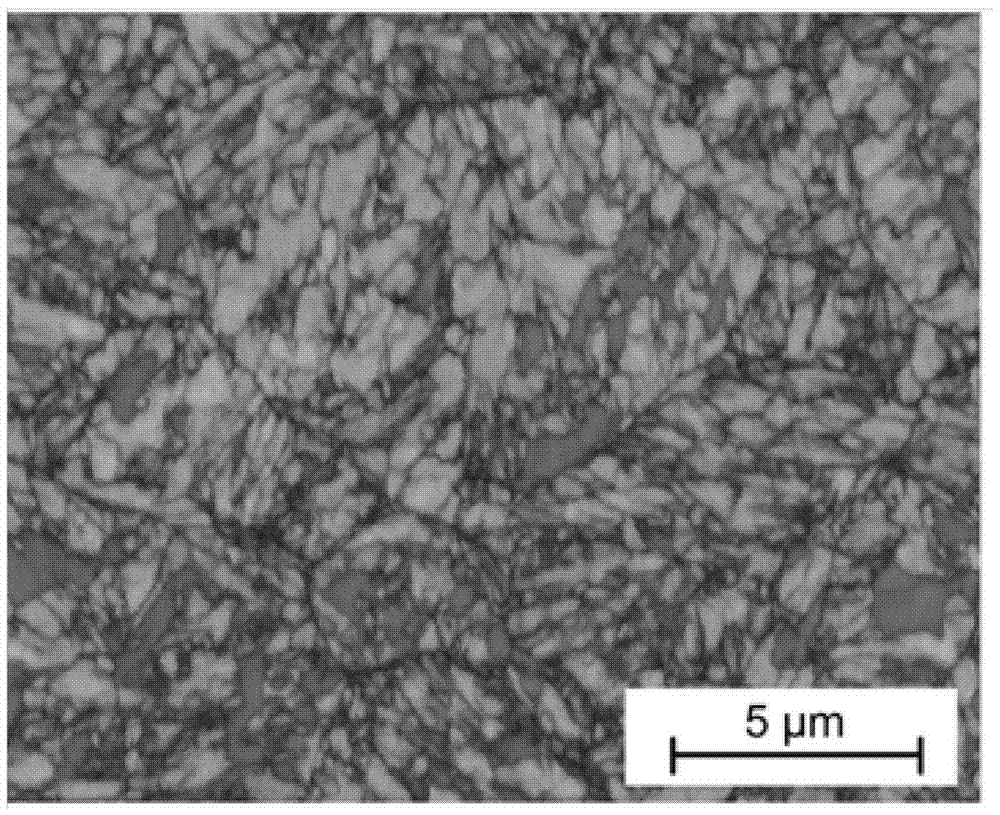

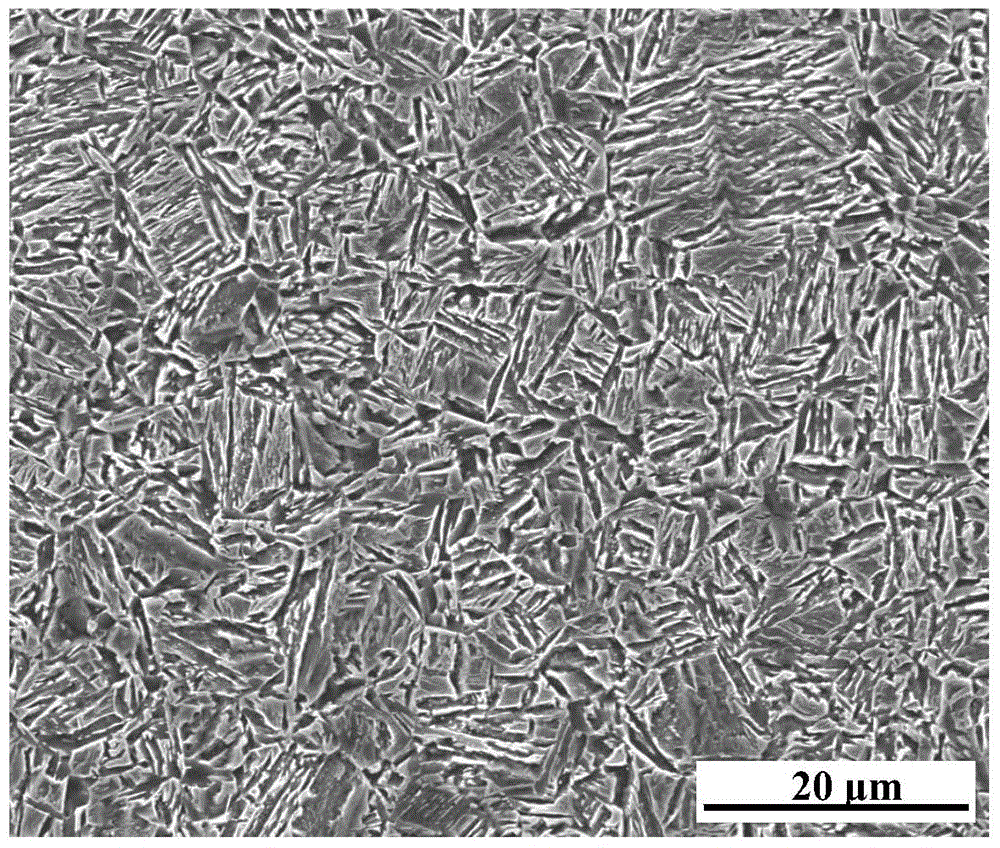

Steel plate used for producing low-temperature hot-stamped automobile part as well as manufacturing method of steel plate and use of steel plate

InactiveCN106929755AReduce intensityAdditional annealing stepsShaping toolsRoll force/gap control deviceSheet steelImpurity

The invention discloses a steel plate used for producing a low-temperature hot-stamped automobile part. The steel plate consists of the following chemical elements in percentage by mass: 0.1%-0.3% of C, 0.1%-1.5% of Si, 7%-12% of Mn, 0.01%-3.0% of Al, 0.005%-0.010% of N, less than or equal to 0.02% of P, less than or equal to 0.02% of S, and the balance Fe and other inevitable impurities; besides, the content of the chemical elements further meets the following formula: 24.2C-2.8Si+Mn-10.1Al greater than or equal to (-)15, wherein C, Si, Mn and Al in the formula separately represent mass percentage of the corresponding elements. The invention further discloses a manufacturing method for the steel plate and a use of the steel plate. Besides, the invention further discloses the low-temperature hot-stamped automobile part manufactured by the steel plate.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength titanium alloy used at temperating being 500-600 DEG C and processing method thereof

ActiveCN112195363AIncrease the β-phase contentImprove plasticityMetal-working apparatusThermal deformationTitanium alloy

The invention discloses a high-strength titanium alloy used at the temperature being 500-600 DEG C and a processing method thereof. Alloy components, a preparation method, thermal deformation, thermaltreatment and other elements are included. The alloy components include, by weight, 5.50%-7.00% of Al, 3.5%-5.00% of Mo, 3.00%-8.00% of Zr, 1.50%-4.00% of Sn, 0.80%-2.0% of W, 0.2%-1% of Si, 0.5%-1.3% of B, smaller than or equal to 0.3% of O and the balance Ti and inevitable impurity elements. The alloy material can be obtained through a smelting method and a powder metallurgy sintering method, then a forged piece product is obtained through combination of thermal deformation and a thermal treatment process, the forged piece prepared through the process is of a double-state structure, TiB andsilicide are evenly distributed in a base body, and the material has high strength and good plasticity within the range from the room temperature to 600 DEG C. The alloy can be used for manufacturingaerospace key parts used for a long time at the temperature being 500-600 DEG C, and can also be used for temperature-resistant structural parts, such as aerospace crafts, used for a short time at the temperature being 600-650 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High-strength titanium alloy containing eutectoid type beta stable elements

The invention provides a high-strength titanium alloy containing eutectoid type beta stable elements. The high-strength titanium alloy is composed of, by mass percent, 4.5% to 5.5% of Al, 3% to 5% of Mo, 2% to 4% of Cr, 1.5% to 3% of Co, 0.6% to 1.5% of Fe and the balance Ti and inevitable impurities. The titanium alloy contains few isomorphous beta stable elements, the eutectoid type beta stable elements of Cr, Co and Fe serve as main beta stable elements, hot workability and hardenability of the high-strength titanium alloy are excellent, the strength can be adjusted within the wide range of 900 MPa to 1600 MPa, the good strength and plasticity matching is achieved, compared with cost of a high-strength-structure titanium alloy of the same level, the cost of the high-strength titanium alloy is lower, and the requirement of multiple application fields for the performance of the high-strength titanium alloy is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

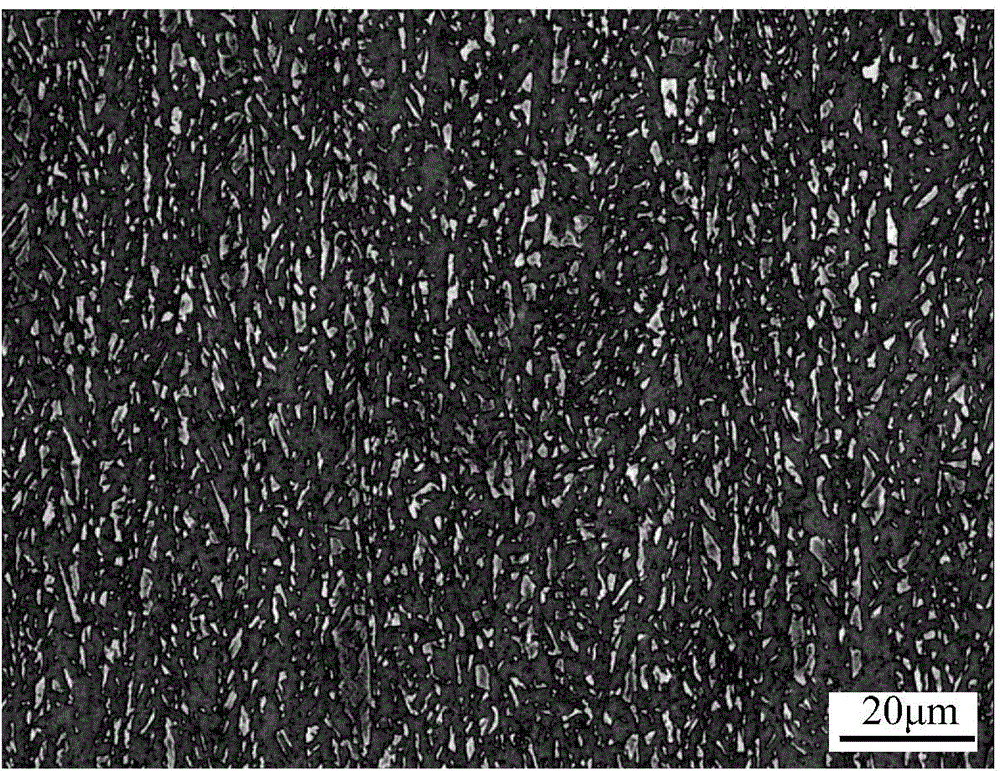

Vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe and preparation method thereof

ActiveCN104372239AStable heating rateHigh degree of automationProcess efficiency improvementSteel tubeHigh intensity

The invention belongs to the steel technical field, and specifically, relates to a vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe and a preparation method thereof. The vanadium-nitrogen microalloyed high-strength phase-transformation induced plastic steel seamless pipe comprises the chemical ingredients by the weight percentage: 0.18%-0.24% of C, 1.0%-1.6% of Si, 1.2%-1.6% of Mn, 0.17%-0.22% of V, 0.01%-0.03% of N, not more than 0.06% of P, not more than 0.005% of S, and the balance iron and unavoidable impurities. With utilization of an intermediate-frequency induction heat treatment device of a thin-wall steel pipe and with supplementary of a vanadium-nitrogen microalloyed component design, the advantage of cooperation of good strength and elongation of phase-transformation induced plastic steel is successfully applied to the steel pipe production field, a fact of replacing solid components with hollow components is effectively realized so as to achieve automobile light weighting, besides, further development of an internal high pressure forming technology is promoted, not only are the internal high pressure formed components with high strength, large deformation and complex shape produced, but also the production cost is greatly reduced, and the preparation method has wide application prospects are provided.

Owner:SHANDONG IRON & STEEL CO LTD

CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel and fabrication method

ActiveCN107475627AGood strength and plasticity matchingReduce the chance of residuesMetal rolling arrangementsManganeseHigh pressure water

The invention discloses CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel. The CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the chemical element ingredients of, in percentage by weight, 0.14-0.16% of carbon, 0.90-1.20% of silicon, 1.20-1.40% of manganese, 0.07-0.10% of phosphorus, less than or equal to 0.005% of sulphur, 0.015-0.060% of acid soluble aluminium and the balance ferrum and inevitable impurities. The fabrication method of the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the following steps of converter smelting, refined smelting, thin plate billet continuous casting, continuous-casting billet soaking, high-pressure water descaling, controlled rolling, controlled cooling and rolling up. The economic C-Si-Mn-P ingredient design is adopted, a metallographic structure is composed of 50-65% of ferrite, 25-40% of bainite and 5-20% of residual austenite; the yield strength is 390-450 MPa, the strength of extension is 600-680 MPa, and the elongation A80 is 28-35%; and the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel has good high-plasticity matching.

Owner:武汉钢铁有限公司

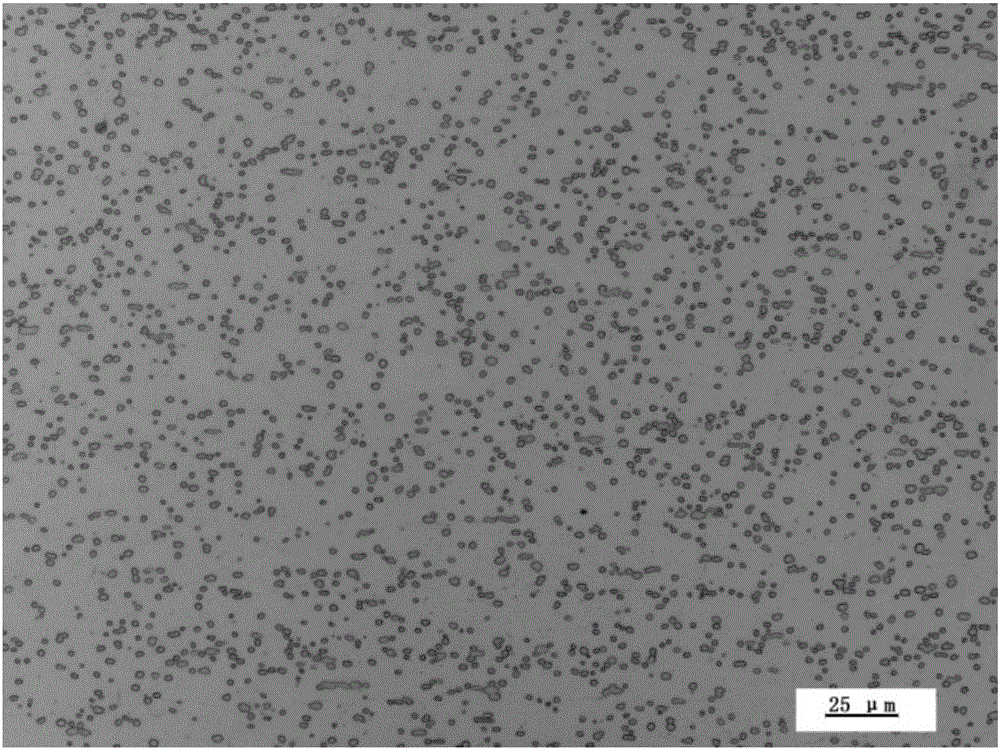

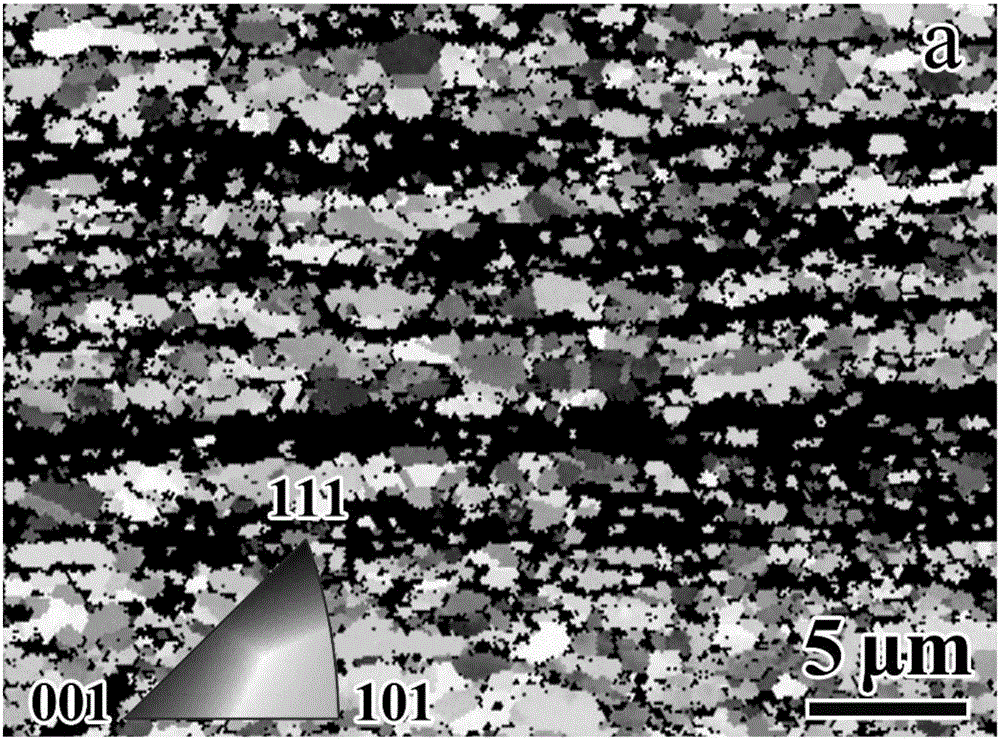

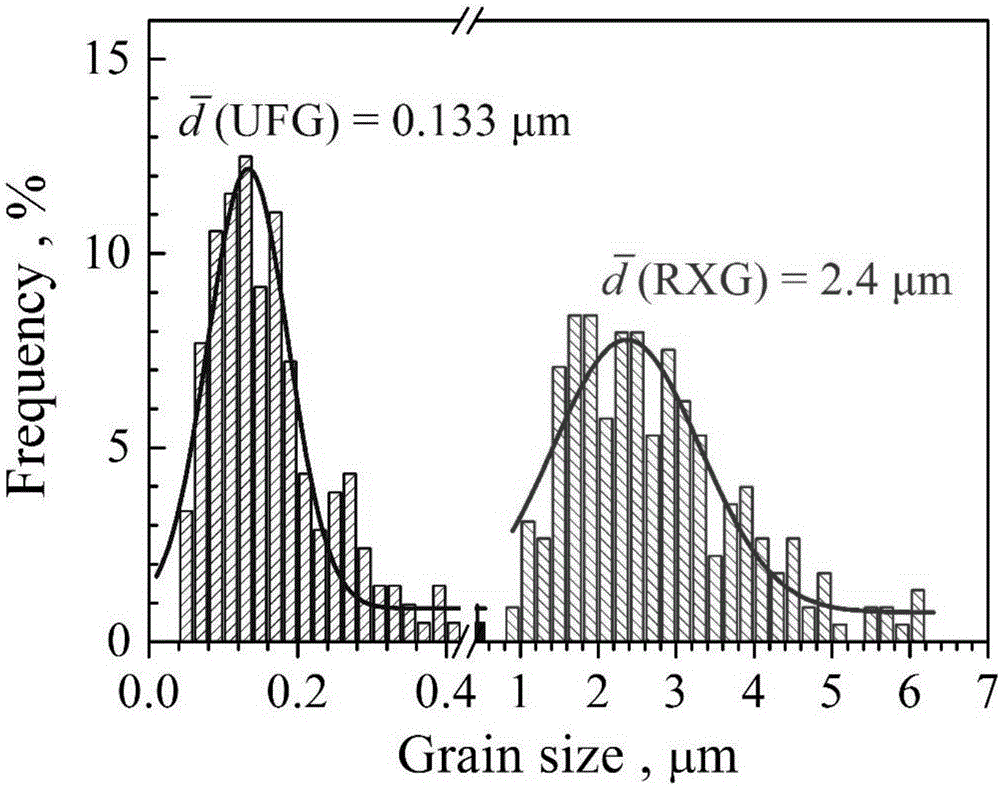

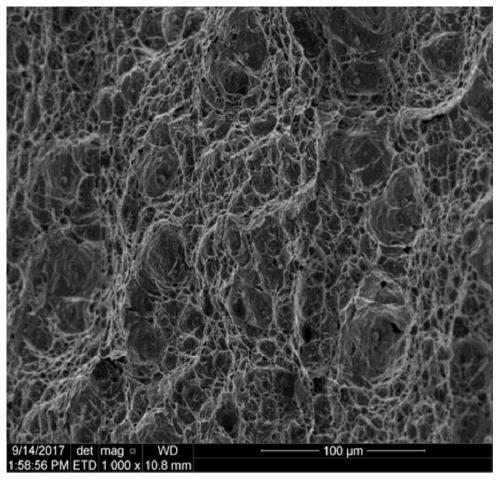

Preparation method of TWIP (Twinning Induced Plasticity) steel with high strength and high plasticity

The invention relates to an ultra-fine grain metal material, and particularly provides a preparation method of TWIP (Twinning Induced Plasticity) steel with high strength and high plasticity. The TWIP steel is formed by nearly equiaxed-shaped perfect recrystallization grains and large annealing twins in recrystallized layer sheets. The invention further discloses the preparation method. The TWIP steel with high strength and high plasticity provided by the invention has excellent performances, and the preparation method is simple.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

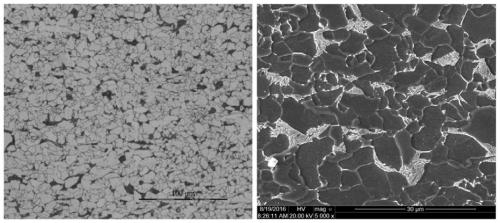

Titanium-microalloyed economical high-strength weathering steel and production method thereof

ActiveCN111235464AImprove toughnessGood strength and plasticity matchingFurnace typesHeat treatment furnacesTitaniumMechanical property

The invention provides titanium-microalloyed economical high-strength weathering steel and a production method thereof. The titanium-microalloyed economical high-strength weathering steel comprises 0.08%-0.14% of C, 0.25%-0.50% of Si, 0.40%-0.70% of Mn, no more than 0.012% of P, no more than 0.005% of S, 0.40%-0.70% of Cr, 0.02%-0.07% of Ni, 0.20%-0.40% of Cu, 0.020%-0.045% of Alt, 0.025%-0.050% of Ti, no more than 0.0040% of N, and the balance Fe and inevitable impurities. According to the titanium-microalloyed economical high-strength weathering steel and the production method thereof, the low-Mn and Ti-microalloyed design is adopted and is combined with the controlled rolling and cooling process, so that the high-strength weathering steel has excellent comprehensive mechanical properties, welding performance and forming performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Low-temperature hot-stamped automobile part, and hot stamping process and manufacturing method thereof

The invention discloses a low-temperature hot-stamped automobile part. The microstructure of the low-temperature hot-stamped automobile part is composed of martensite, austenite and ferrite. The chemical elements of the low-temperature hot-stamped automobile part comprise, by mass, 0.1-0.3% of C, 0.1-2.0% of Si, 3-7% of Mn, 0.01-0.06% of Al, 0.02% or less of P, 0.02% or less of S, 0.005% or less of N, and the balance Fe and other inevitable impurities. In addition, the invention discloses a hot stamping process of the low-temperature hot-stamped automobile part. The invention further discloses a manufacturing method of the low-temperature hot-stamped automobile part. The manufacturing method sequentially includes the steps of (1) smelting, (2) casting, (3) hot rolling, (4) annealing, (5) acid pickling, (6) cold rolling and (7) hot stamping, wherein the heating holding temperature of hot stamping is 700-850 DEG C, the holding time is 2-10 min, and thus complete austenitizing is completed. The low-temperature hot-stamped automobile part has high strength and meanwhile achieves good stretching ductility and excellent strength and plasticity matching.

Owner:BAOSHAN IRON & STEEL CO LTD

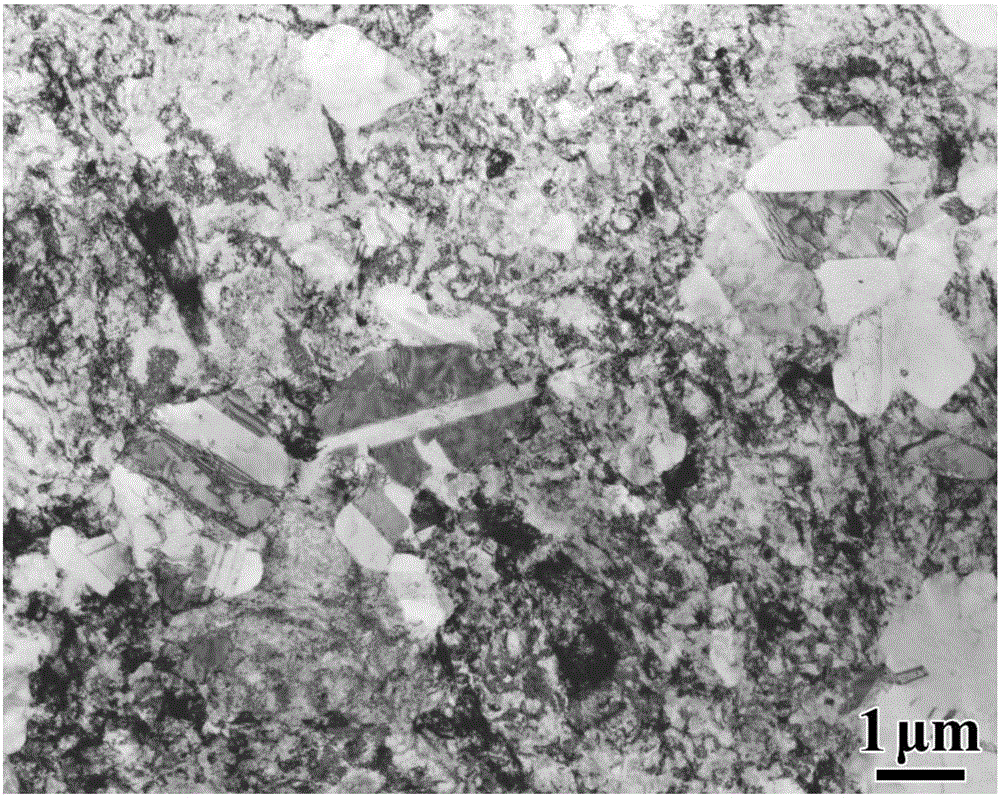

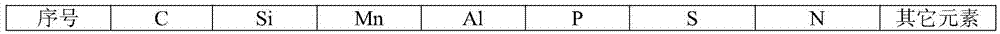

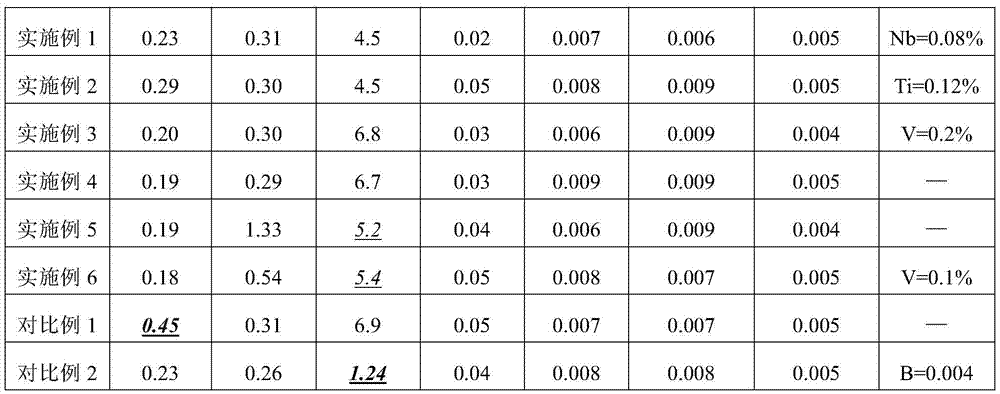

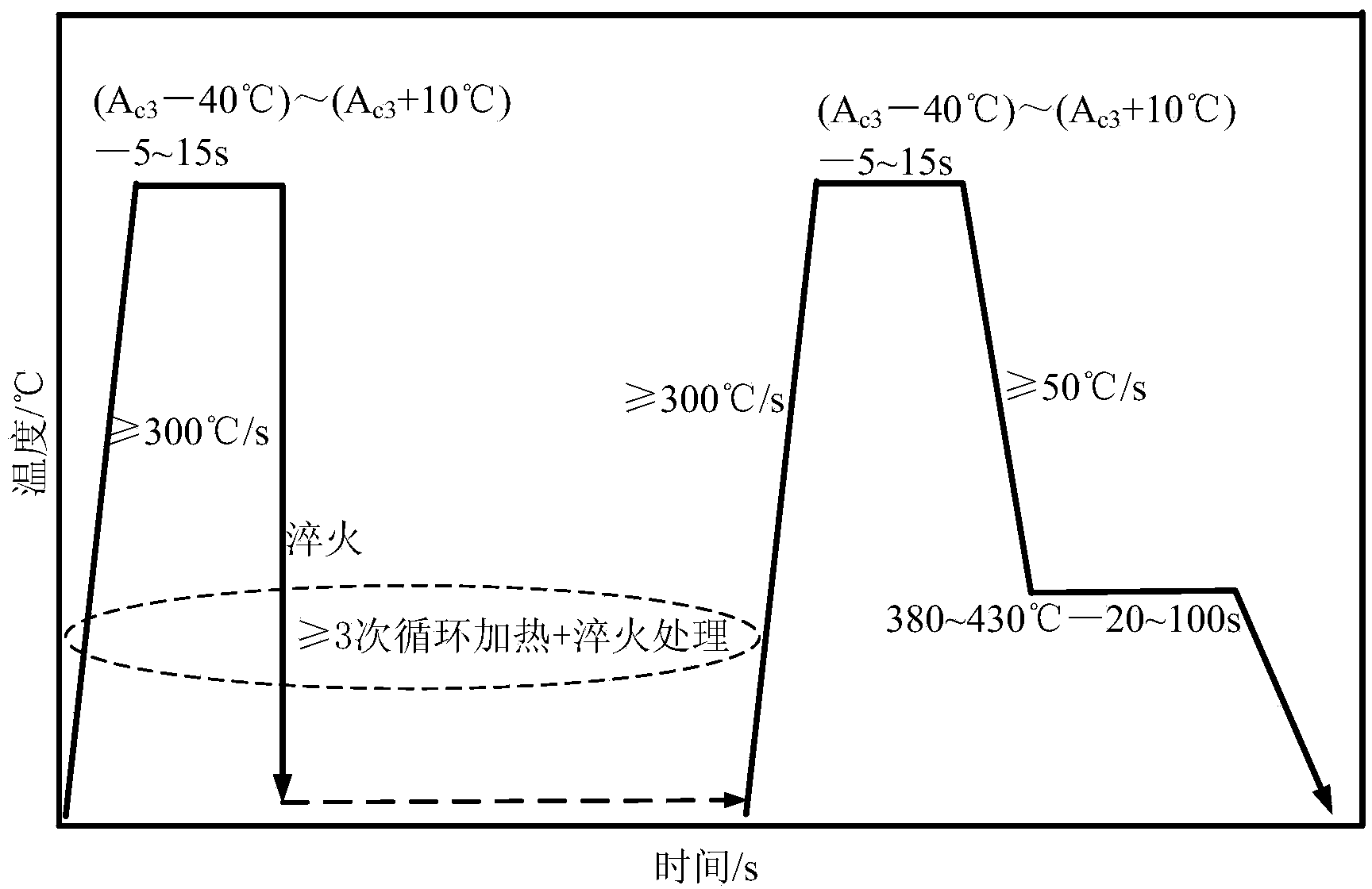

Preparation method for manufacturing low-cost ultrafine grain transformation-induced plastic steel seamless tube online

The invention relates to a preparation method for manufacturing a low-cost ultrafine grain transformation-induced plastic steel seamless tube online. The method comprises the following steps: forging, turning, heating, perforating and coldly drawing a cast ingot to obtain a seamless cold-drawn steel tube; then carrying out circulating heating and quenching treatment for over three times by adopting a medium-frequency heating induction coil; finally, air cooling, water cooling or naturally cooling to room temperature, so as to obtain the low-cost ultrafine grain transformation-induced plastic steel seamless tube. Chemical components of common low-carbon steel are utilized, so that the cost is relatively low, the tensile strength is greater than or equal to 900 MPa, the yield ratio is smaller than or equal to 0.64, the ductility is greater than or equal to 24.0%, the work hardening index is greater than or equal to 0.23, the anisotropic index is greater than or equal to 1.01, the average grain size of a microscopic structure is smaller than or equal to 3mum, and the volume fraction of the retained austenite is 11.5-19.5%.

Owner:LAIWU IRON & STEEL GRP

High-strength plastic vanadium microalloyed dual-phase steel seamless pipe and preparation method thereof

ActiveCN104018067AImprove mechanical propertiesHigh strengthFurnace typesIncreasing energy efficiencySolid componentHigh rate

The invention discloses a high-strength plastic vanadium microalloyed dual-phase steel seamless pipe and an on-line preparation method thereof. The seamless pipe is composed of the following chemical components in percentage by mass: 0.10-0.18% of C, 0.1-0.6% of Si, 1.1-1.6% of Mn, 0.16-0.20% of V, 0.01-0.03% of N, at most 0.006% of P, at most 0.005% of S, and the balance of Fe and other inevitable impurities. The intermediate-frequency induction heat treatment device of the thin-wall steel pipe is utilized and assisted by the vanadium microalloyed component design to produce the dual-phase steel seamless pipe with favorable comprehensive mechanical properties; the advantages of low yield-tensile ratio, high rate of work hardening, favorable strength and favorable elongation percentage of the dual-phase steel are matched and successfully applied to the field of production of steel pipes to efficiently substitute solid components with hollow components, thereby implementing light weight of the automobile; and meanwhile, the seamless pipe promotes further development of the internal high-pressure forming technique, and has wide application prospects.

Owner:LAIWU IRON & STEEL GRP

Preparation method of hot-working-state cobalt-based alloy rod wire

ActiveCN111575539AEliminate elemental segregationEvenly distributed ingredientsMetal-working apparatusForgingMedical device

The invention belongs to the technical field of cobalt-based high-temperature alloy material processing, and particularly relates to a preparation method of a hot-working-state cobalt-based alloy rodwire, wherein the preparation method is particularly suitable for a hot-working-state CoCrMo alloy rod wire. An alloy is prepared from the chemical components in percentage by mass: 26.0-30.0% of Cr,5.0-7.0% of Mo, smaller than or equal to 1.0% of Ni, smaller than or equal to 0.14% of C, smaller than or equal to 0.75% of Fe, smaller than or equal to 1.0% of Si, smaller than or equal to 1.0% of Mn, smaller than or equal to 0.35% of N, and the balance of Co. An alloy cast ingot is obtained through vacuum induction melting and electroslag remelting firstly and then subjected to the processes ofhomogenization heat treatment, continuous multiple-heating-number high-temperature forging, straightening, surface working and the like, the qualified CoCrMo alloy rod wire is produced, and a qualified raw material is provided for manufacturing of medical devices.

Owner:中科锐金山东钛业科技有限公司

Preparation method of titanium-graphene composite material with matched reinforced-plasticity

InactiveCN113070471AEvenly dispersedAvoid serious structural damageCarbon compoundsTransportation and packagingTitanium matrix compositesTitanium

The invention belongs to the technical field of preparation of advanced metal-based composite materials, and particularly relates to a preparation method of a titanium-graphene composite material with matched reinforced-plasticity. The preparation method comprises the following steps that firstly, proper metal nanoparticles or nanolayers on the surface of graphene are selected for modification to prepare metal modified reduced graphene oxide nanopowder; the metal modified graphene is ultrasonically dispersed in a mixed solution of alcohol and deionized water, a proper amount of titanium alloy powder is slowly added into a dispersion solution, and uniformly stirring and dispersing are carried out in a water bath at 80 DEG C to obtain composite powder; and the composite powder is sintered and subjected to subsequent hot working deformation densification, and a titanium-graphene composite plate or bar with matched high reinforced-plasticity is obtained. According to the method, eutectoid elements in titanium alloy are adopted for modifying graphene, and metal nanolayer particles are formed. The load transfer strengthening effect of the graphene is enhanced, and the plasticity of the graphene strengthened titanium-based composite material is improved.

Owner:NORTHEASTERN UNIV

Manufacturing method of age-hardened thin-strip casting low-carbon microalloyed steel strip

The invention discloses a manufacturing method of an age-hardened thin-strip casting low-carbon microalloyed steel strip. The method comprises the following steps: 1) casting a cast strip with thickness of 1-5mm in a dual-roller continuous casting machine, wherein the weight percents of the components are as follows: 0.01-0.25% of C, not more than 0.4% of Si, 0.6-2.0% of Mn, not more than 0.015% of P, not more than 0.01% of S, and not more than 0.012% of N; furthermore, the cast strip further comprises at least one of Nb, V, Ti, and Mo in the following weight percent: 0.005-0.1% of Nb, 0.005-0.1% of V, 0.005-0.1% of Ti, and 0.05-0.5% of Mo, and the balance of Fe and unavoidable impurities; 2) cooling the cast strip, wherein the cooling rate is more than 20 DEG C / s; 3) hot-rolling at 1050-1250 DEG C, wherein the reduction rate is 20-50%, and the deformation rate is more than 20s-1; 4) cooling, wherein the cooling rate is 10-80 DEG C / s; 5) reeling at 550-700 DEG C; 6) performing age-hardening treatment, wherein the age-hardening temperature is 500-800 DEG C, and the heating time is 0.1-30 minutes. The austenite online recrystallization of the cast strip after hot-rolling is realized, the microstructure of the obtained steel strip is composed of fine polygonal ferrite and a pearlite, the structure comprises nanoscale precipitation such niobium carbonitride, and the high strength and extensibility are obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Boracic deep low temperature hot rolling H-section steel and preparation method thereof

The invention discloses a boracic deep low temperature hot rolling H-section steel and a preparation method thereof. The specification range of the H-section steel is in a small specification of below H300*300*10*15, and the H-section steel has the performance requirements that the longitudinal low-temperature impact of wing plates at the temperature of -50 to -70 DEG C is greater than or equal to 80J, the transverse low-temperature impact of the wing plates at the temperature of -20 DEG C is greater than or equal to 70J, the longitudinal low-temperature impact of web plates at the temperature of -50 to -70 DEG C is greater than or equal to 100J, and the performance of the steel is higher than that of the national standard GB / T1591-2008 low-medium high-strength structure E-level steel that the low-temperature impact is greater than or equal to 34J at -40 DEG C. In order to guarantee deep low temperature impact toughness, the low temperature impact toughness is guaranteed by adopting the cooperation of low carbon, low silicon, high manganese and vanadium boron. The H-section steel comprises the following chemical components in percentage by weight: 0.06% to 0.15% of C, 0.15% to 0.25% of Si, 1.0% to 1.50% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.010% of S, 0.070% to 0.10% of V, 0.005% to 0.02% of B, greater than or equal to 0.025% of Alt, smaller than or equal to 2.0*10<-4> of [H], smaller than or equal to 20*10<-4> of [O], smaller than or equal to 60*10<-4> of [N] and the balance of Fe. The production technology comprises the steps of furnace revolving, LF refining, VD vacuum, matrix blank continuous casting, H-section steel rolling and straightening.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Bainite matrix phase-transformation induced plasticity steel seamless pipe and manufacturing method thereof

The invention discloses a bainite matrix phase-transformation induced plasticity steel seamless pipe and a manufacturing method thereof. The preparation method disclosed by the invention comprises the steps of smelting, forging a rod, turning, heating, perforating, cold drawing and thermally treating in sequence. The thermal treatment step comprises the following steps: firstly, heating a seamless cold-drawn steel pipe obtained after cold drawing to be in the austenitizing temperature range of 910-950 DEG C at the rate of 35-50 DEG C per second, and carrying out annealing treatment for 60-90 seconds; then, cooling the annealed seamless cold-drawn steel pipe to be in the bainite range of 380-430 DEG C at the ratio of 40-80 DEG C per second, and carrying out isothermal treatment for 30-100 seconds; and finally, cooling the seamless cold-drawn steel pipe subjected to isothermal treatment to room temperature. The bainite matrix phase-transformation induced plasticity steel seamless pipe having good comprehensive mechanics performance is prepared by utilizing chemical components of ordinary low-carbon steel; the cost is relatively low; the microscopic structure is composed of bainite and retained austenite, wherein the volume fraction of the retained austenite is more than or equal to 10.5%.

Owner:LAIWU IRON & STEEL GRP

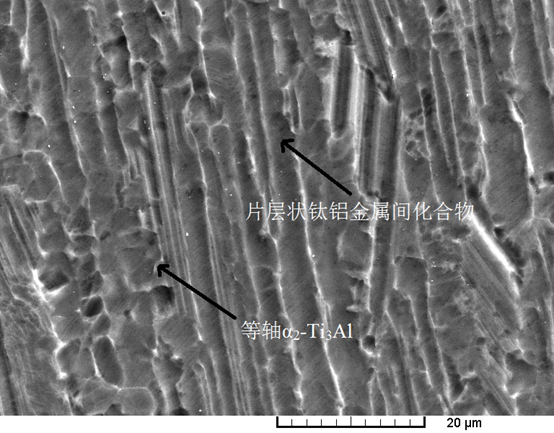

Titanium flux-cored wire for additive manufacturing of titanium-aluminum intermetallic compound and preparation method of titanium flux-cored wire

ActiveCN113245743ASolve the problem of poor plasticity at room temperature and it is difficult to realize wire drawing into forming welding wireReduce investmentWelding/cutting media/materialsSoldering mediaAl powderTitanium

The invention discloses a titanium flux-cored wire for additive manufacturing of a titanium-aluminum intermetallic compound. The titanium flux-cored wire is composed of a powder-state flux core wrapped with a titanium shell, and the titanium flux-cored wire is composed of the following components including, by molar percentage, 40%-50% of Al, 1%-8% of Nb, 1%-4% of Mo, 0.1%-0.5% of B and the balance Ti and inevitable impurities; and in addition, the invention further provides a preparation method of the titanium flux-cored wire, the Al powder, the Nb powder, the Mo powder and the B powder are put into a clean titanium tube after being subjected to ball milling, sealing is conducted, then drawing is conducted, and the titanium flux-cored wire is obtained. According to the titanium flux-cored wire, the powder-state flux core is wrapped with the titanium shell to form the titanium flux-cored wire, the problem that the titanium-aluminum intermetallic compound is poor in room-temperature plasticity and difficult to be drawn into a formed welding wire is solved, preparation of the titanium-aluminum intermetallic compound through the single welding wire is achieved, and the component formed by deposition of the titanium flux-cored wire has good strength and plasticity matching.

Owner:西安稀有金属材料研究院有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com