Titanium flux-cored wire for additive manufacturing of titanium-aluminum intermetallic compound and preparation method of titanium flux-cored wire

A technology of intermetallic compounds and flux-cored wire, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problem of poor plasticity at room temperature and it is difficult to realize wire drawing into forming welding wire, etc., achieve excellent filling effect, refine grain, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

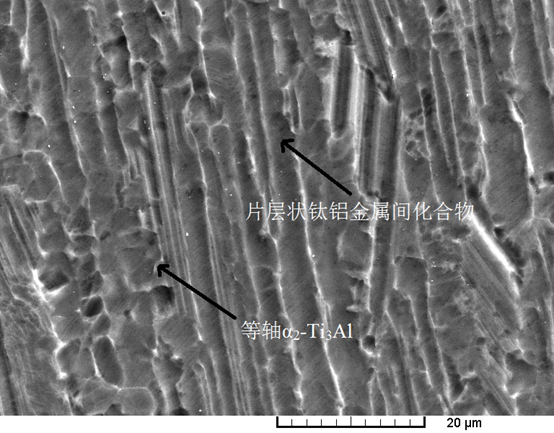

[0028] The titanium flux-cored welding wire used in the arc additive manufacturing of titanium-aluminum intermetallic compounds in this embodiment consists of a flux core wrapped with a titanium shell, the flux core is in powder state, and the titanium flux-cored welding wire consists of the following molar percentages: The composition of the composition: 44% of Al, 4% of Nb, 1.5% of Mo, 0.15% of B and the balance of Ti and unavoidable impurities.

[0029] The preparation method of the titanium flux-cored welding wire of the present embodiment comprises the following steps:

[0030] Step 1. Pickling and ultrasonic cleaning the titanium tube in sequence to obtain a clean titanium tube; the ratio of the outer diameter to the inner diameter of the titanium tube is 1.4:1;

[0031] Step 2, placing Al powder, Nb powder, Mo powder and B powder in a ball mill, and then ball milling under an inert gas atmosphere to obtain a composite powder;

[0032] Step 3, filling the clean titanium...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is that the sealing in step 3 is performed by laser welding, the stress annealing treatment in step 4 takes 60 minutes and the temperature is 630°C.

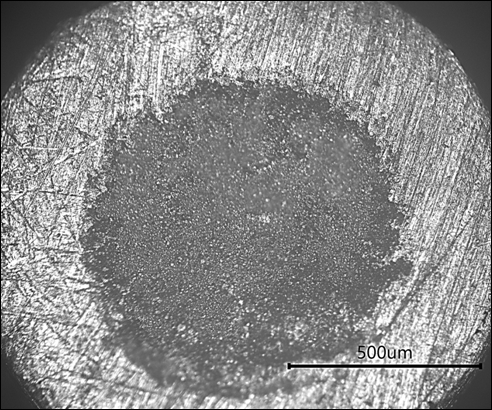

[0040] The titanium flux-cored welding wire prepared in this example is prepared by arc additive manufacturing method to prepare titanium-aluminum intermetallic compounds. The obtained titanium-aluminum intermetallic compounds have good molding quality, smooth surface, and no defects such as cracks, pores, welding spots, and oxidation. .

Embodiment 3

[0042] The difference between this embodiment and embodiment 1 is that the sealing in step 3 is carried out by electron beam welding, the time of stress annealing in step 4 is 50 min, and the temperature is 640°C.

[0043] The titanium flux-cored welding wire prepared in this example is prepared by arc additive manufacturing method to prepare titanium-aluminum intermetallic compounds. The obtained titanium-aluminum intermetallic compounds have good molding quality, smooth surface, and no defects such as cracks, pores, welding spots, and oxidation. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com