1,000 MPa level hot-rolled TRIP steel based on CSP process and manufacturing method

A manufacturing method and process technology, applied in 1000MPa grade hot-rolled TRIP steel and its manufacturing field, can solve the problems of precipitation of micro-alloy elements and control difficulty of phase proportion, etc., and achieve good strong plasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

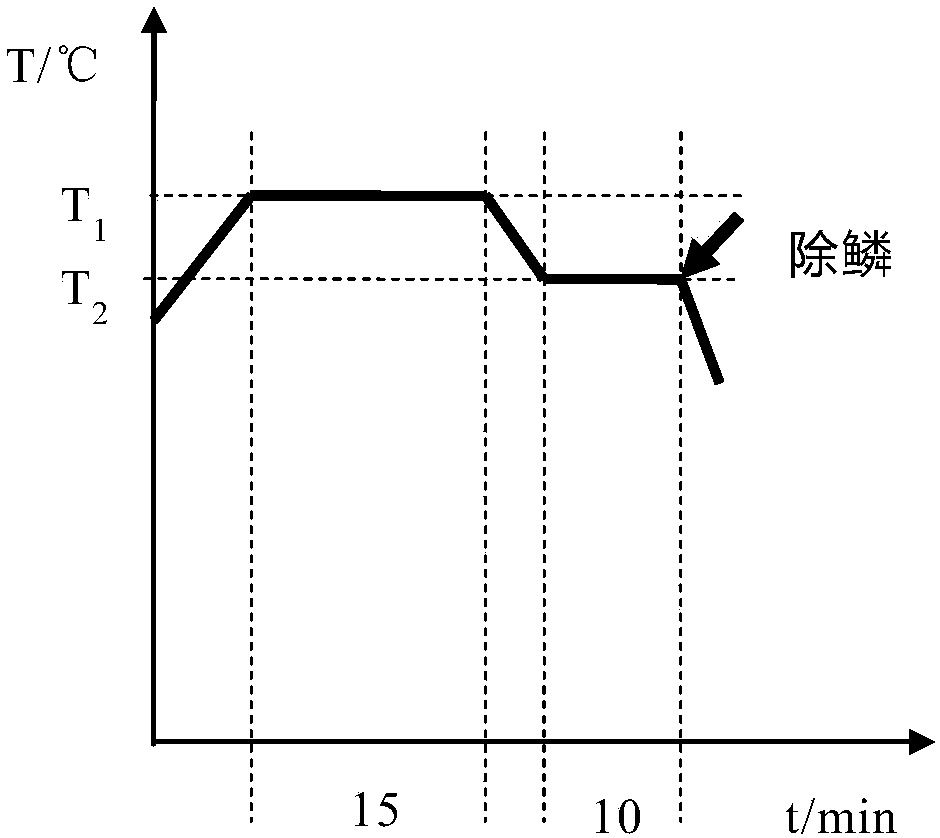

[0058] The hot-rolled TRIP steel of the present invention is produced by a converter-thin slab continuous casting and rolling CSP process, and the specific steps include converter smelting, refining, thin slab continuous casting, continuous casting slab soaking, high-pressure water descaling, controlled rolling, controlled cooling, coiled.

[0059] The steel is smelted using the converter steelmaking-LF-RH process, and the deep desulfurization pretreatment of molten steel is used in the converter steelmaking to ensure a low S content in the steel. The calcium and magnesium deoxidizer is used for deoxidation to reduce the oxygen and Aluminum, and improve the shape, size and distribution of inclusions. After the RH vacuum treatment, molten steel having chemical compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com