Patents

Literature

32results about How to "Performance deviation is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

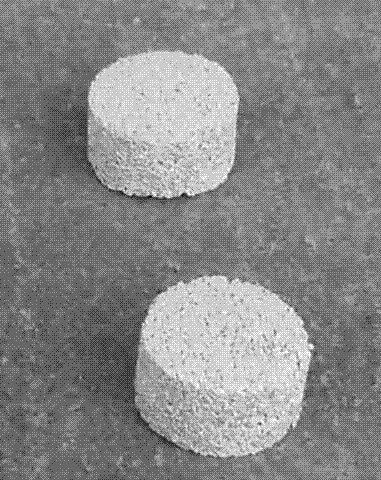

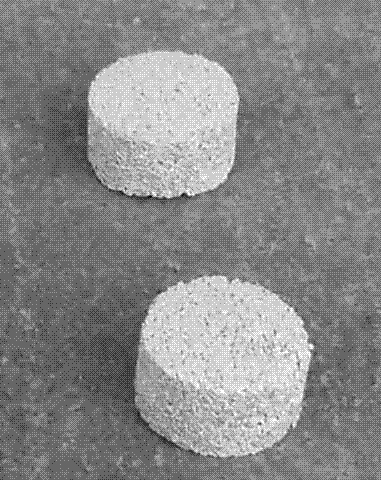

Modularized smokeless firework propellant and preparation method thereof

ActiveCN102219621ASolve residual problemsImprove securityNitrated explosive compositionsPrillFireworks

The invention discloses a modularized smokeless firework propellant which contains nitrocotton, a large quantity of tiny holes are arranged in the propellant and have block shape, and the size and shape of the holes are determined according to the caliber and shape of a firework transmitting barrel. The preparation method of the modularized smokeless firework propellant comprises the following steps: firstly mixing organic bond with granular pore firework powder, secondly preparing block-shaped solid by using the mixed materials through mould pressing, and then expelling volatilizing components in the block-shaped medicine by stoving. Compared with the granular pore firework powder, the modularized smokeless firework propellant can thoroughly solve the problem of propellant residue of granular propellant feeding, and simplifies the operation of transmitting propellant feeding, so that the stability and consistency of an end firework product are better; and in addition, the modularizedsmokeless firework propellant also avoids the mechanical friction action among granules, and improves the safety of manufacture, transmission, and storage of the firework products.

Owner:NANJING UNIV OF SCI & TECH

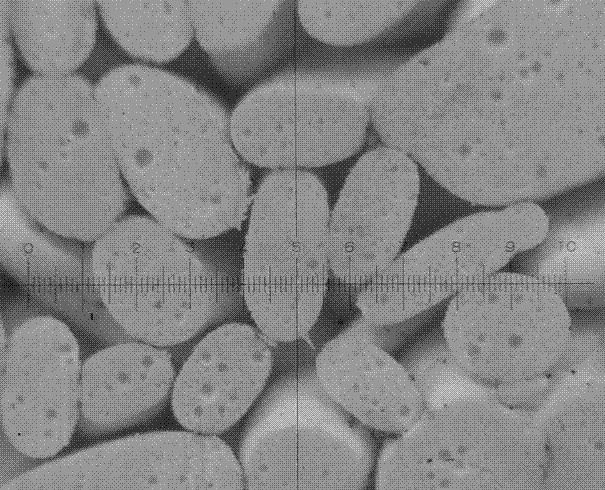

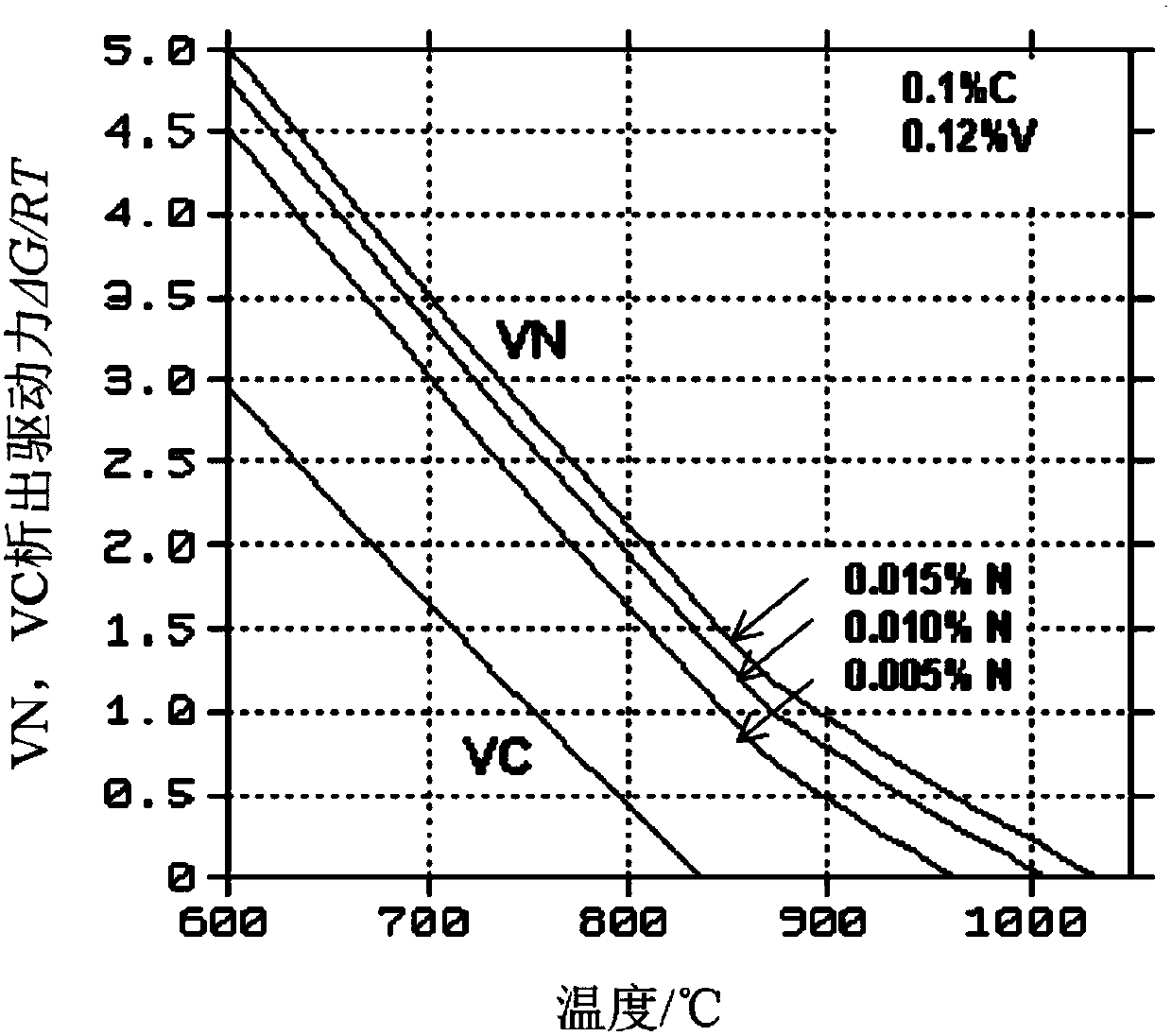

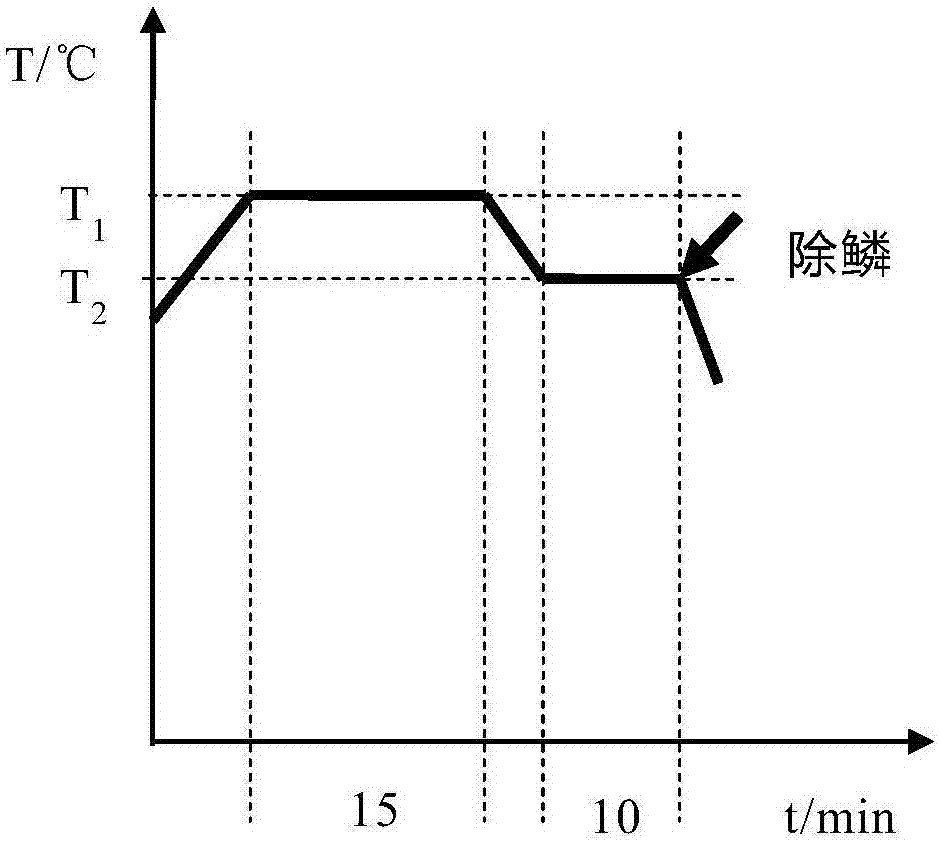

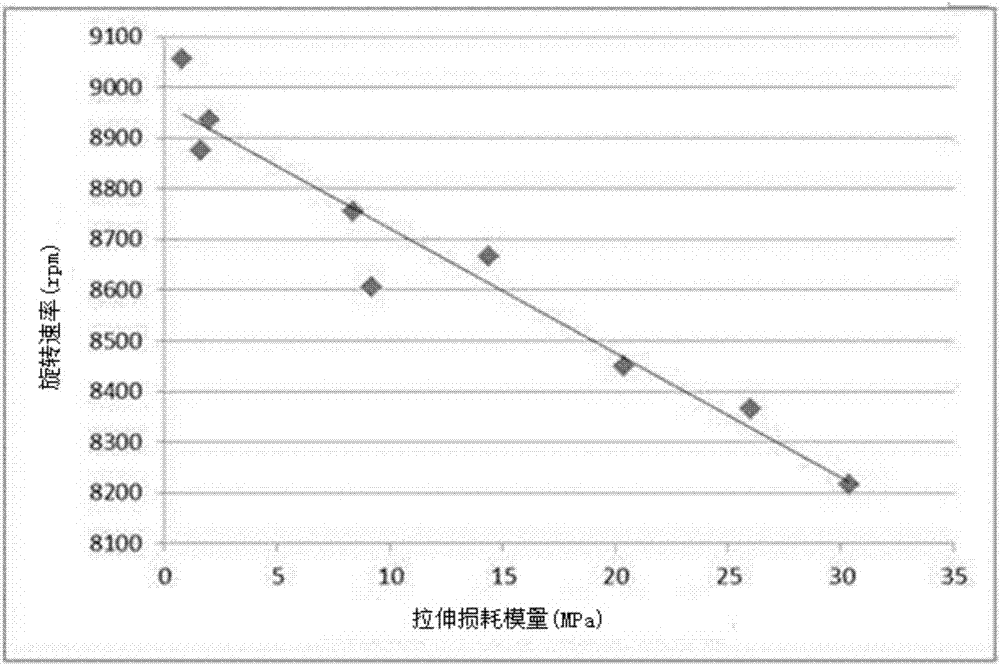

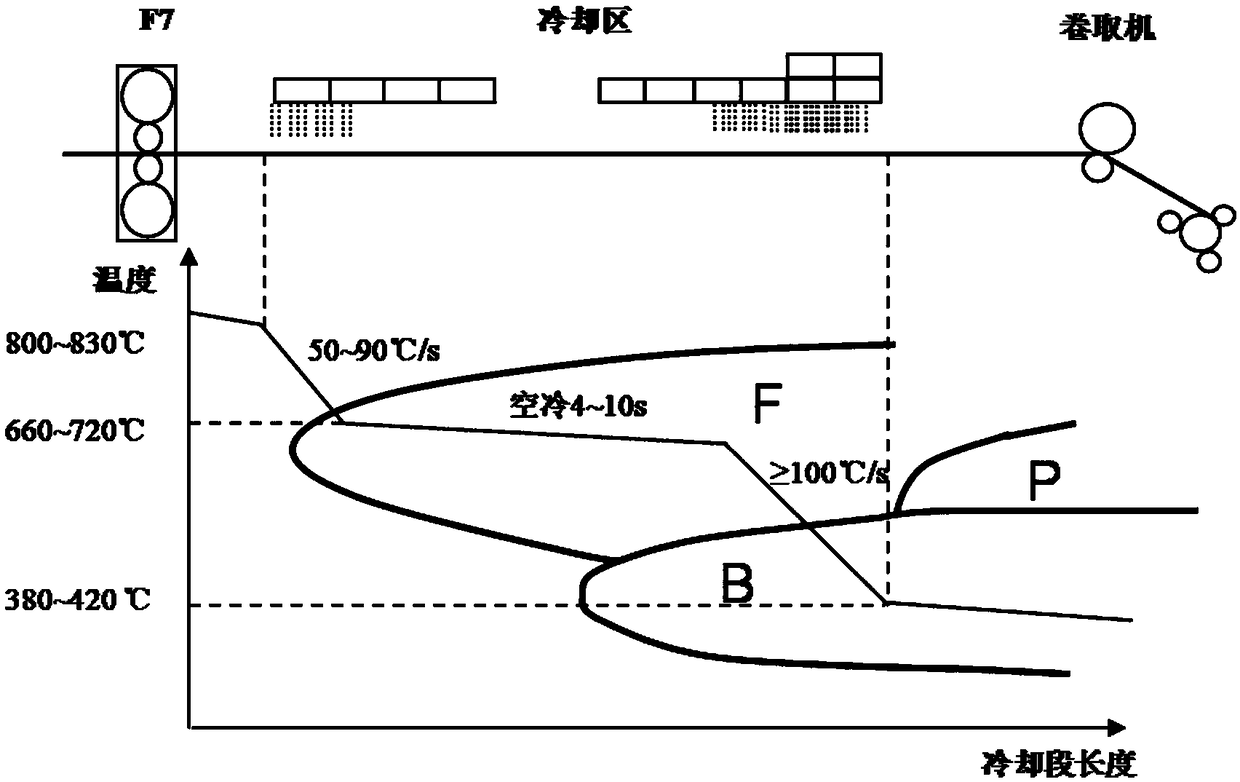

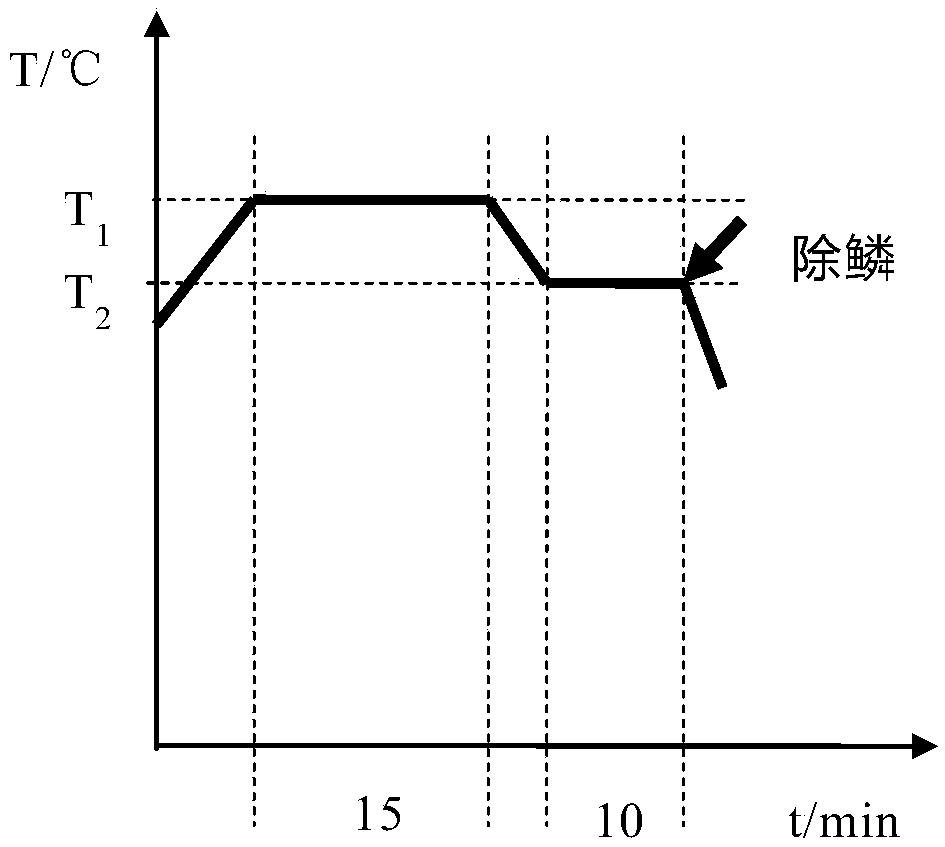

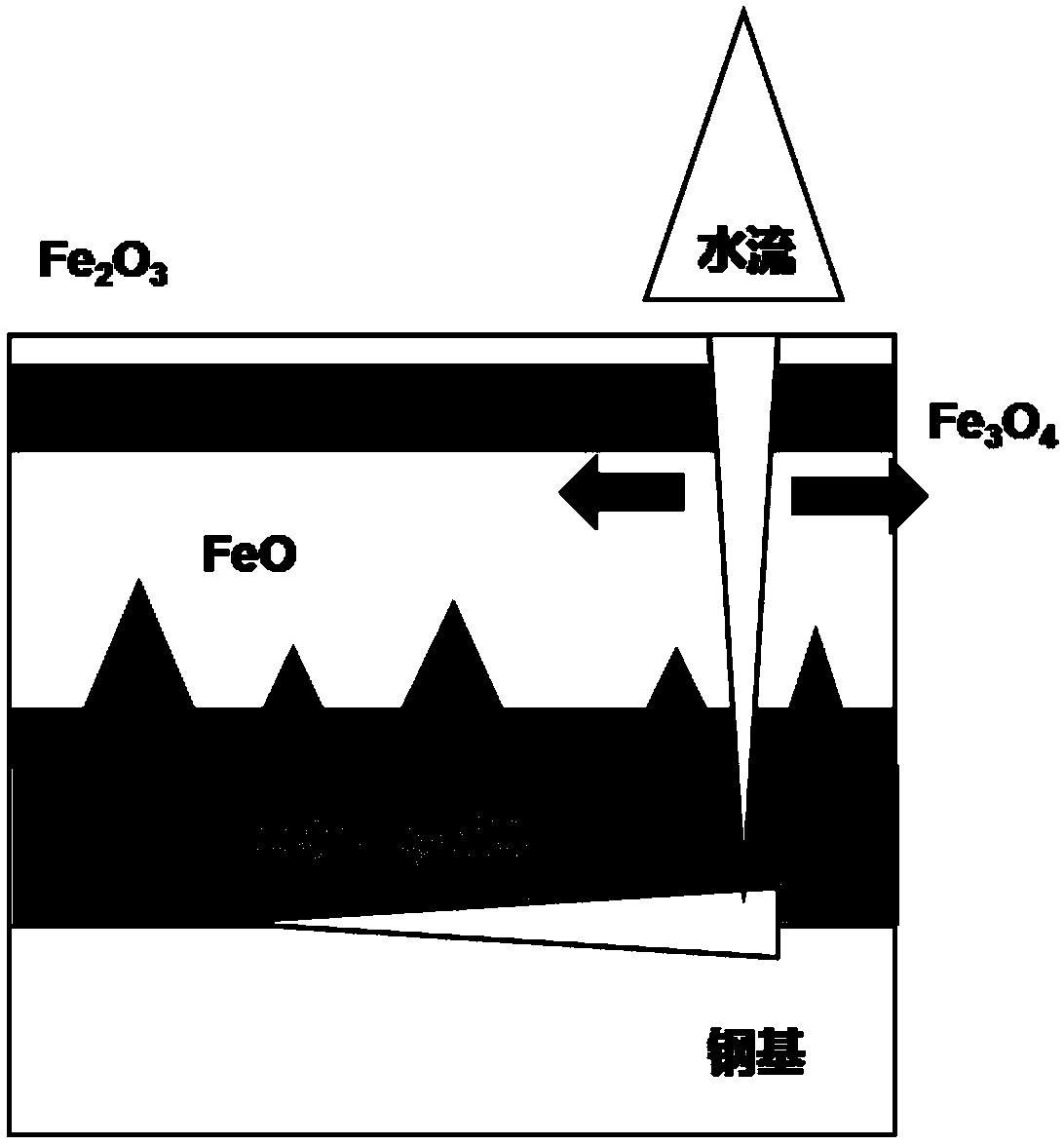

1,000 MPa level hot-rolled TRIP steel based on CSP process and manufacturing method

ActiveCN107557692AGood strong plasticityGuaranteed stabilityHeat treatment process controlAluminiumTRIP steel

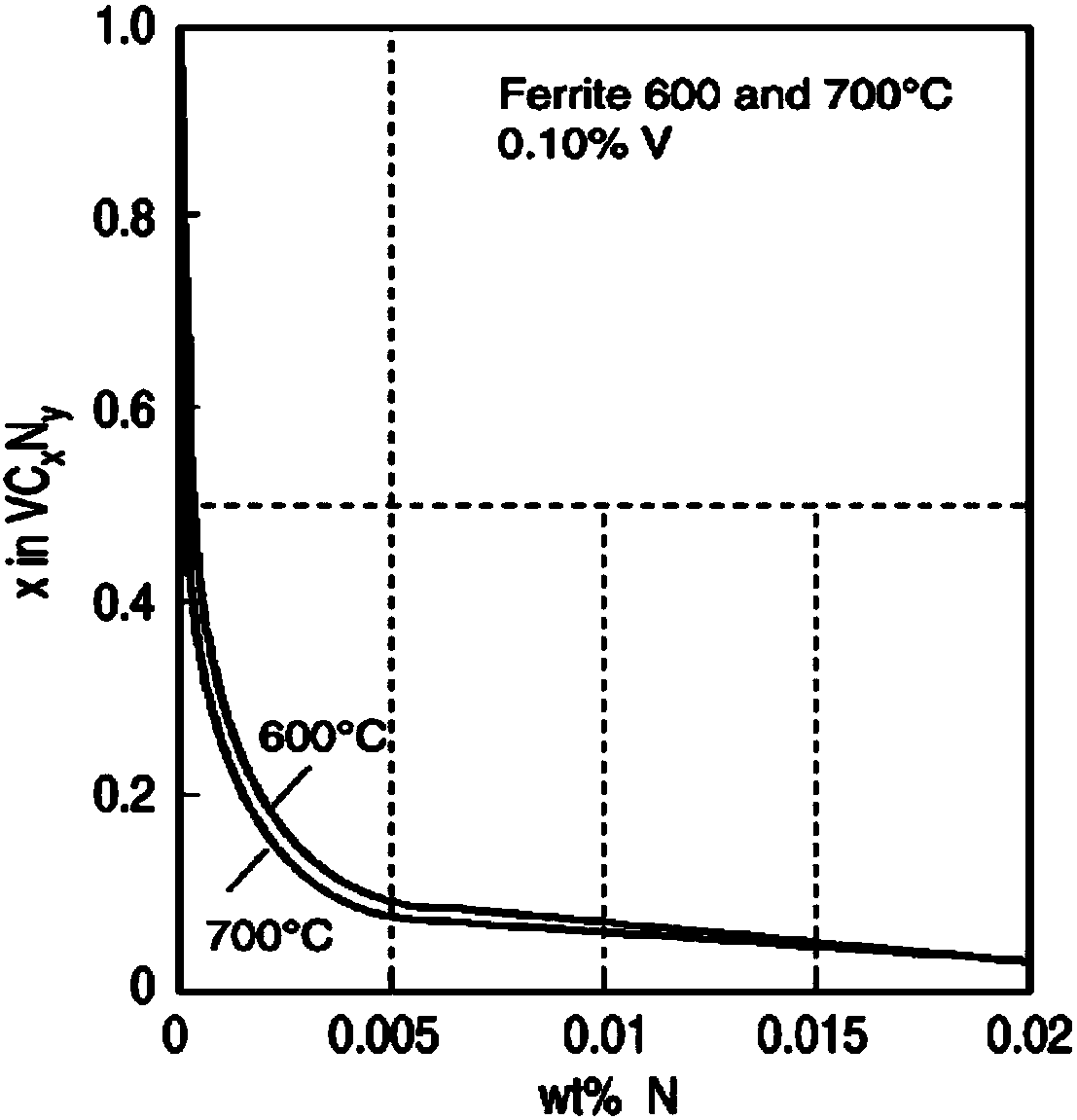

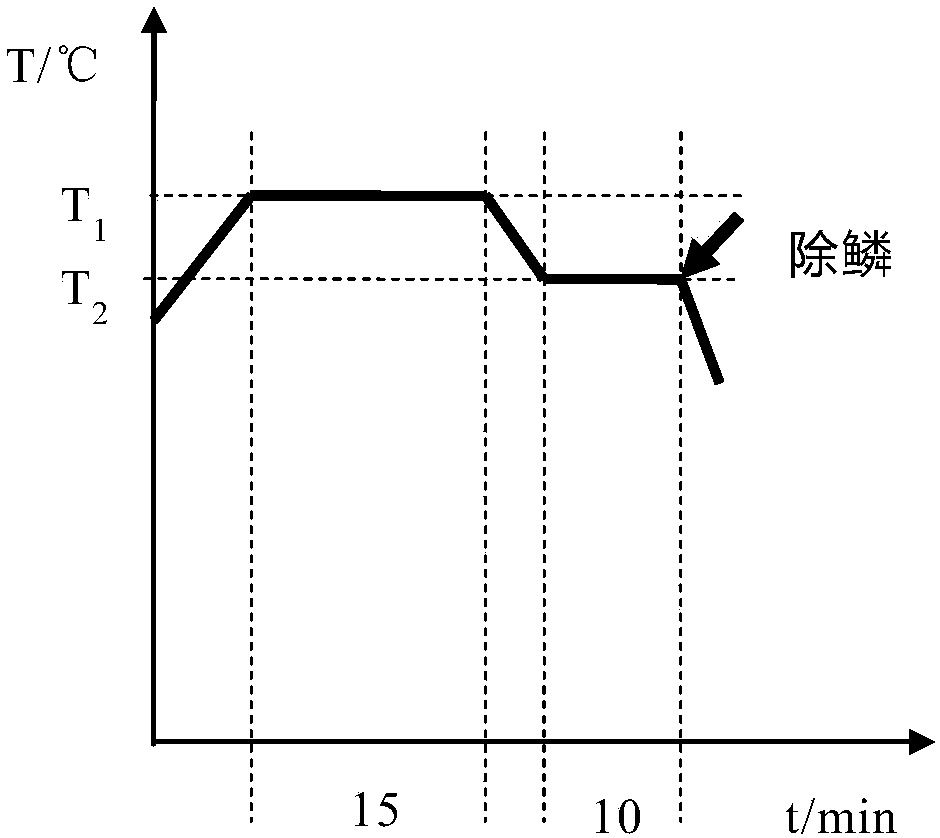

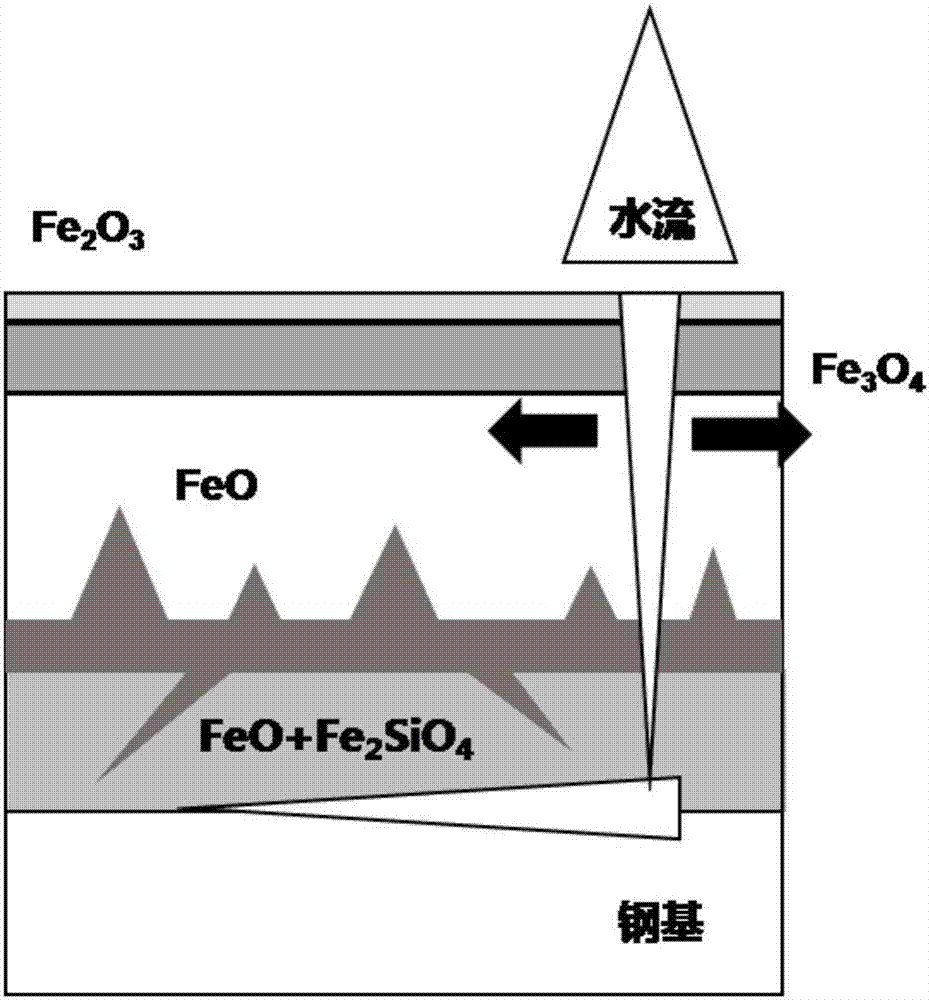

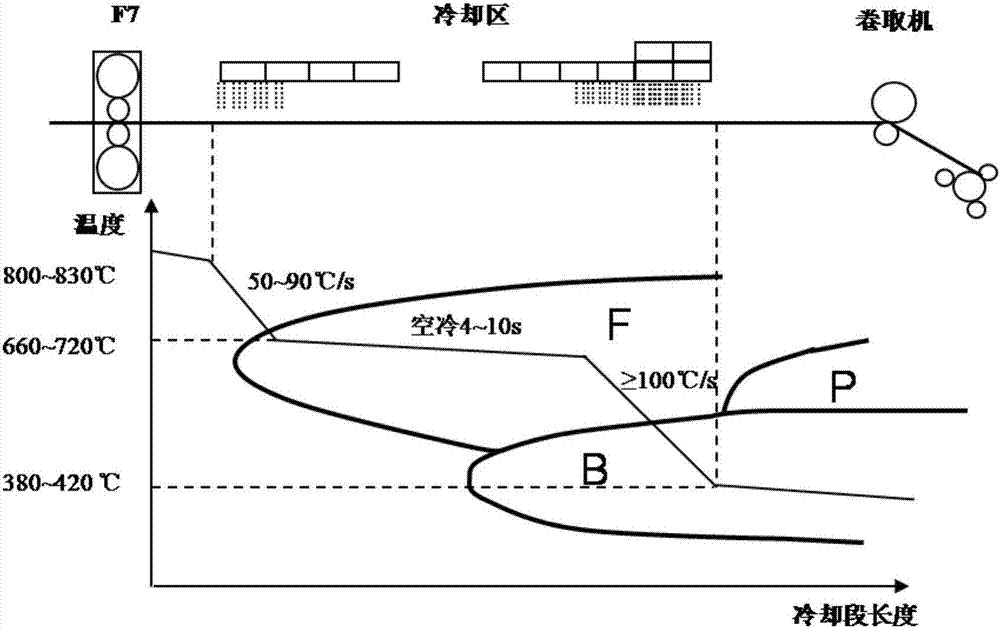

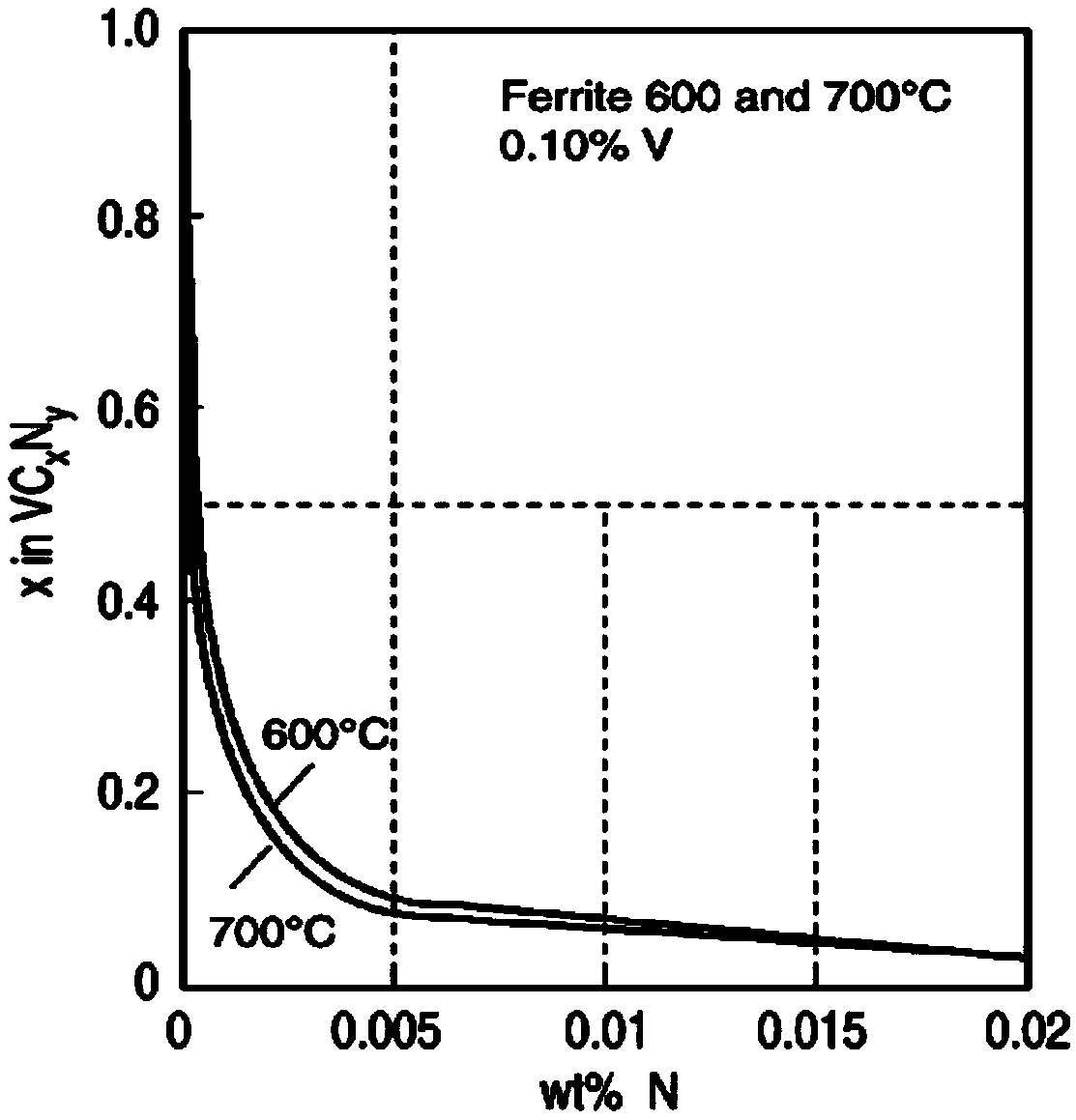

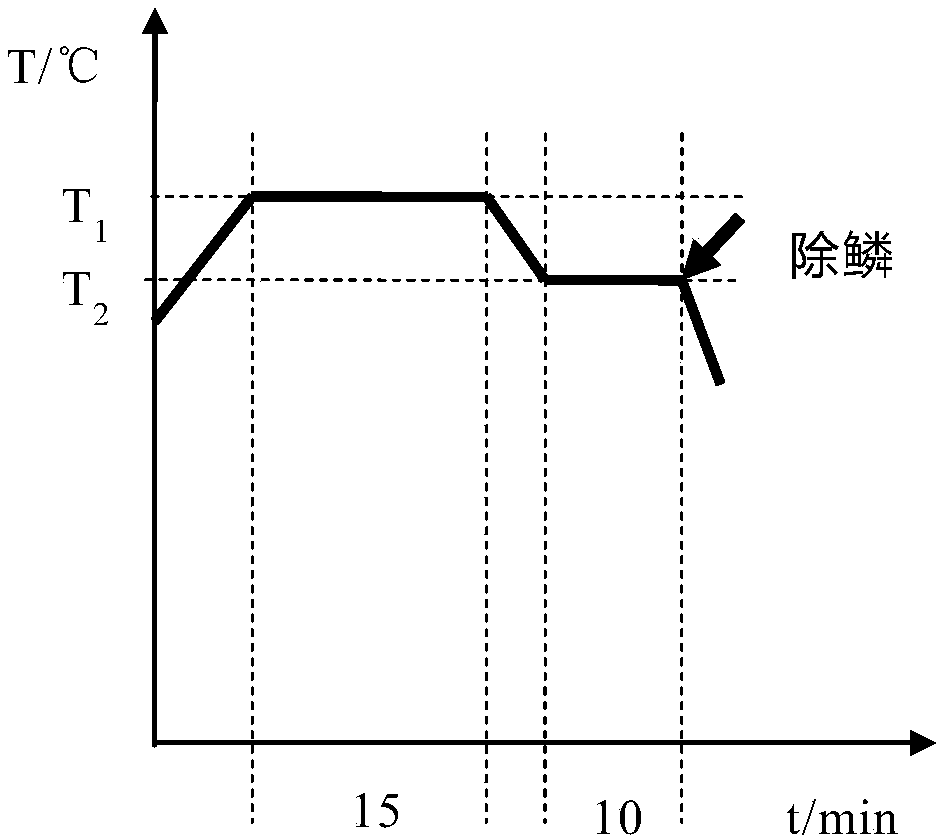

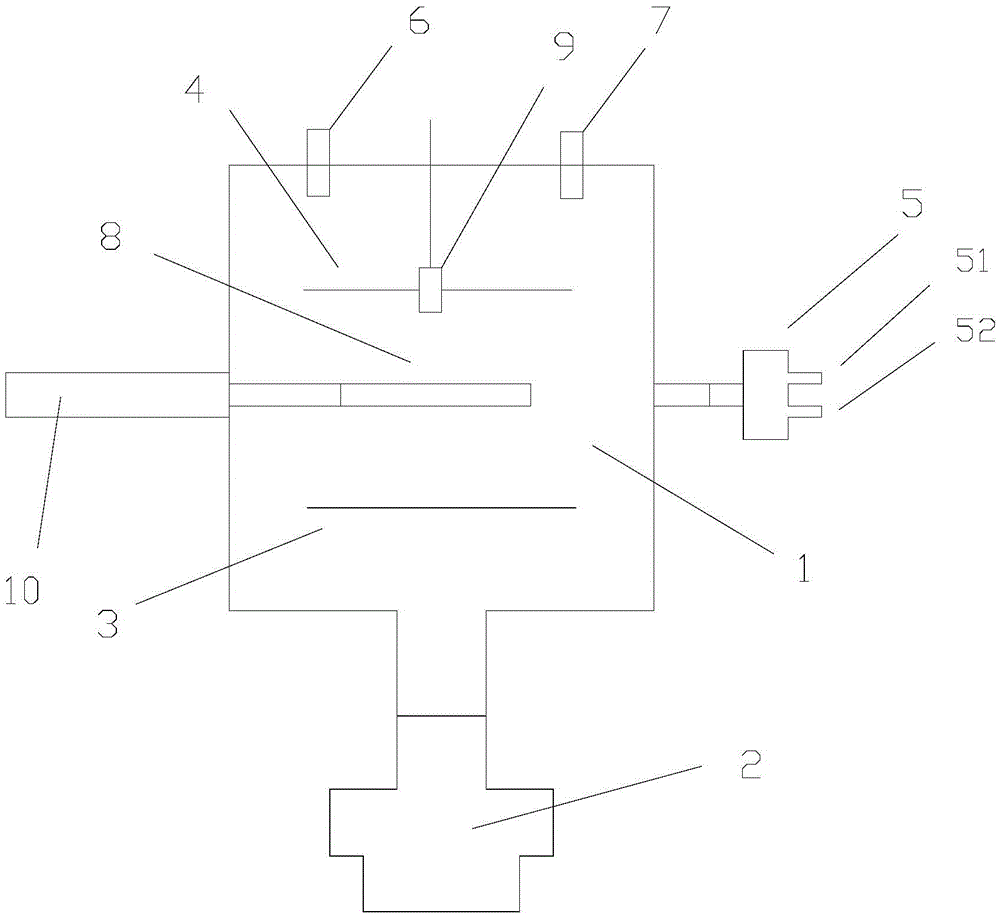

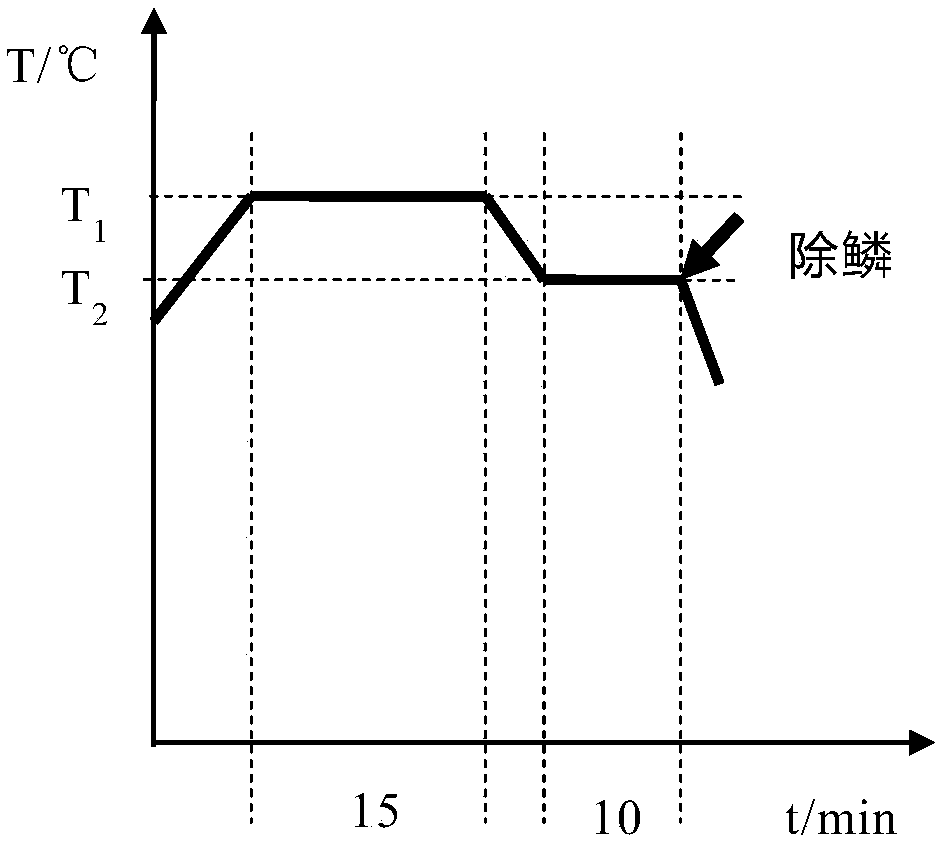

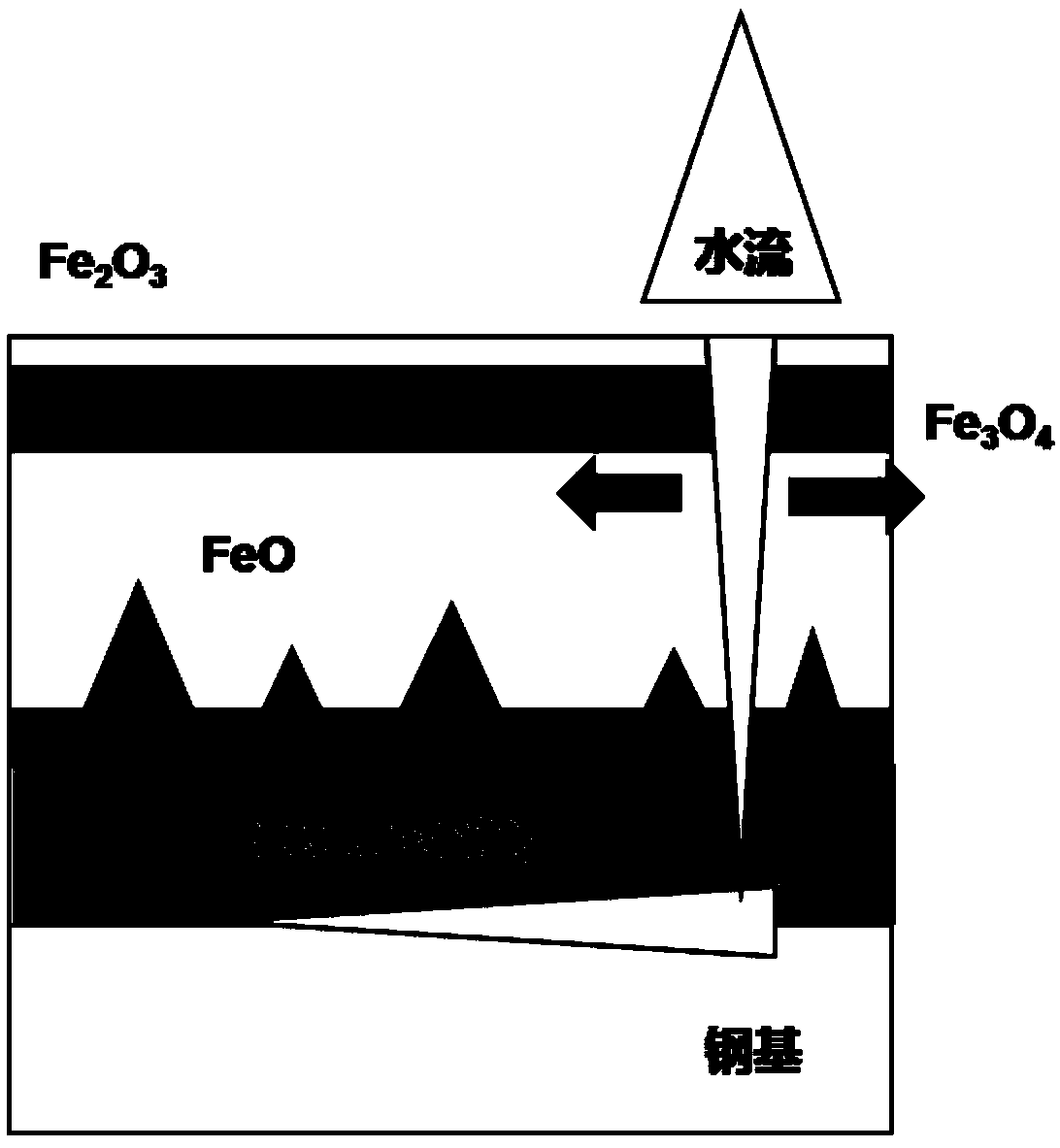

The invention discloses 1,000 MPa level hot-rolled TRIP steel based on the CSP process. The 1,000 MPa level hot-rolled TRIP steel comprises chemical elements and components including, by weight percent, 0.16%-0.20% of carbon, 1.60%-1.80% of silicon, 1.50%-1.60% of manganese, 0.20%-0.24% of vanadium, smaller than or equal to 0.008% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.015%-0.060% of acid soluble aluminum, 0.015%-0.025% of nitrogen and the balance iron and inevitable impurities. The steel manufacturing method comprises converter smelting, refining, sheet billet continuouscasting, continuous casting blank uniform heating, high-pressure water descaling, controlled rolling, controlled cooling and coiling. Through the V-N adding microalloying component design, a ferrite phase and a bainite phase are strengthened, meanwhile, carbon concentration is not reduced, stability of retained austenite is maintained, and good strength and plasticity matching is achieved.

Owner:武汉钢铁有限公司

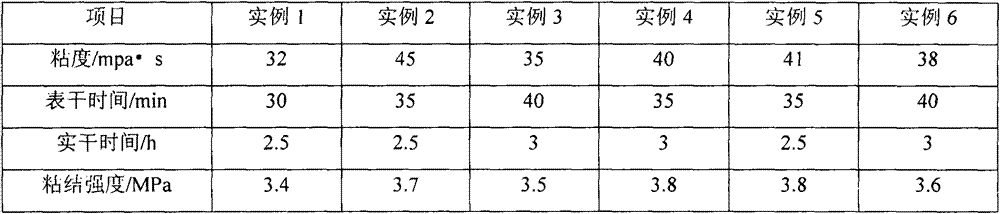

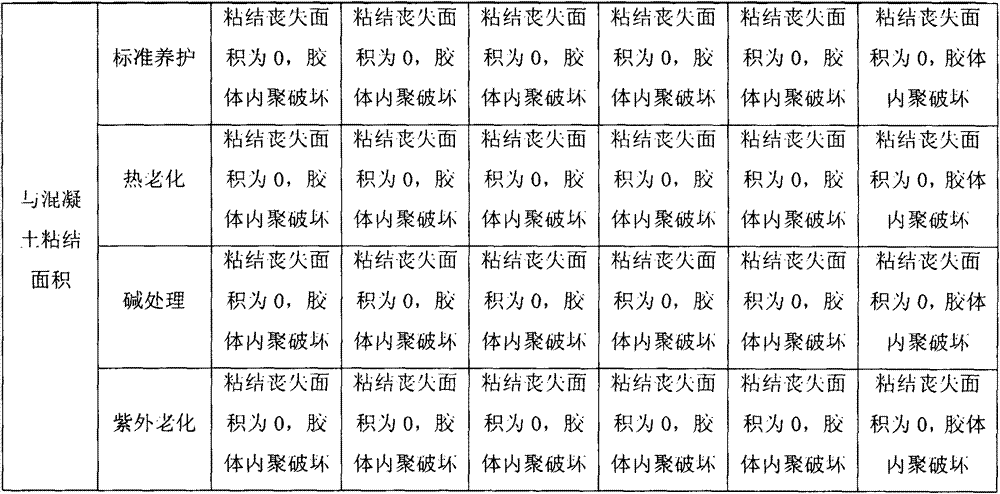

Interface agent for high-speed railway ballastless track polyurethane caulking material and preparation method thereof

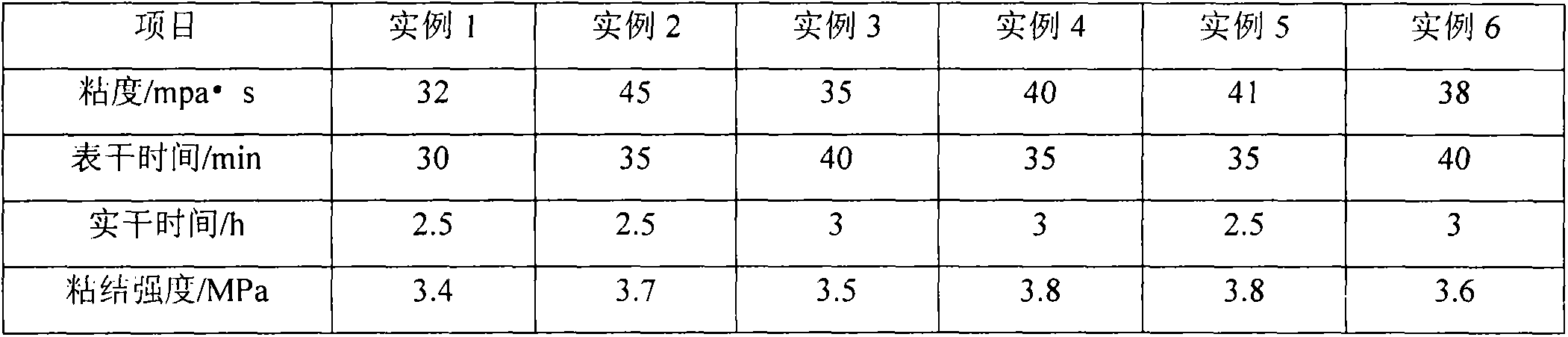

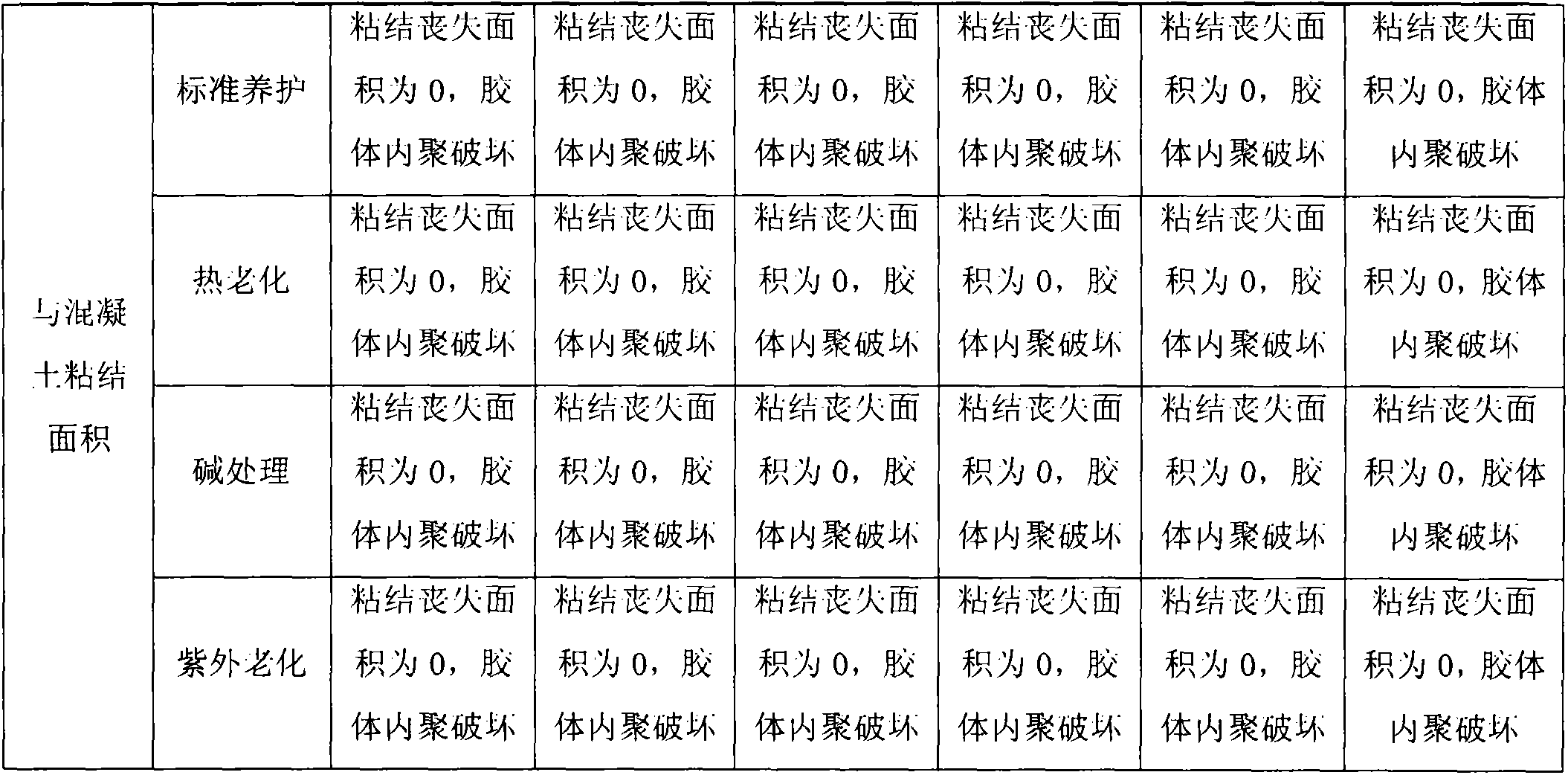

The invention relates to an interface agent for a high-speed railway ballastless track polyurethane caulking material and a preparation method thereof. The interface agent comprises the following raw materials in parts by weight: 100 parts of isocyanate prepolymers, 80-120 parts of solvents, 0.1-0.5 part of catalysts, 0.5-2.5 parts of water removal agents and 0.5-2.5 parts of anti-aging agents. The preparation method comprises the following two steps of: (1) slowly dripping polyhydric alcohol to isocyanate at the temperature of (85+ / -5) DEG C, then increasing the temperature to (90+ / -5) DEG C for continuous reaction, when the content of NCO groups is 14%-16%, adding organic silicon coupling agents, and reacting till the content of the NCO groups is 10%-12% so as to obtain a prepolymer; (2) adding the solvents, the catalysts, the water removal agents and the anti-aging agents to the prepolymer, uniformly stirring, and debubbling in vacuum (at vacuum degree less than or equal to -0.09MPa) to obtain the interface agent for the polyurethane caulking material. The interface agent disclosed by the invention has the characteristics of low viscosity, good impregnation property, high toughness, excellent hydrolysis-resistant property and alkali-resistant property, excellent adhesive property with concrete and the polyurethane caulking material, and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

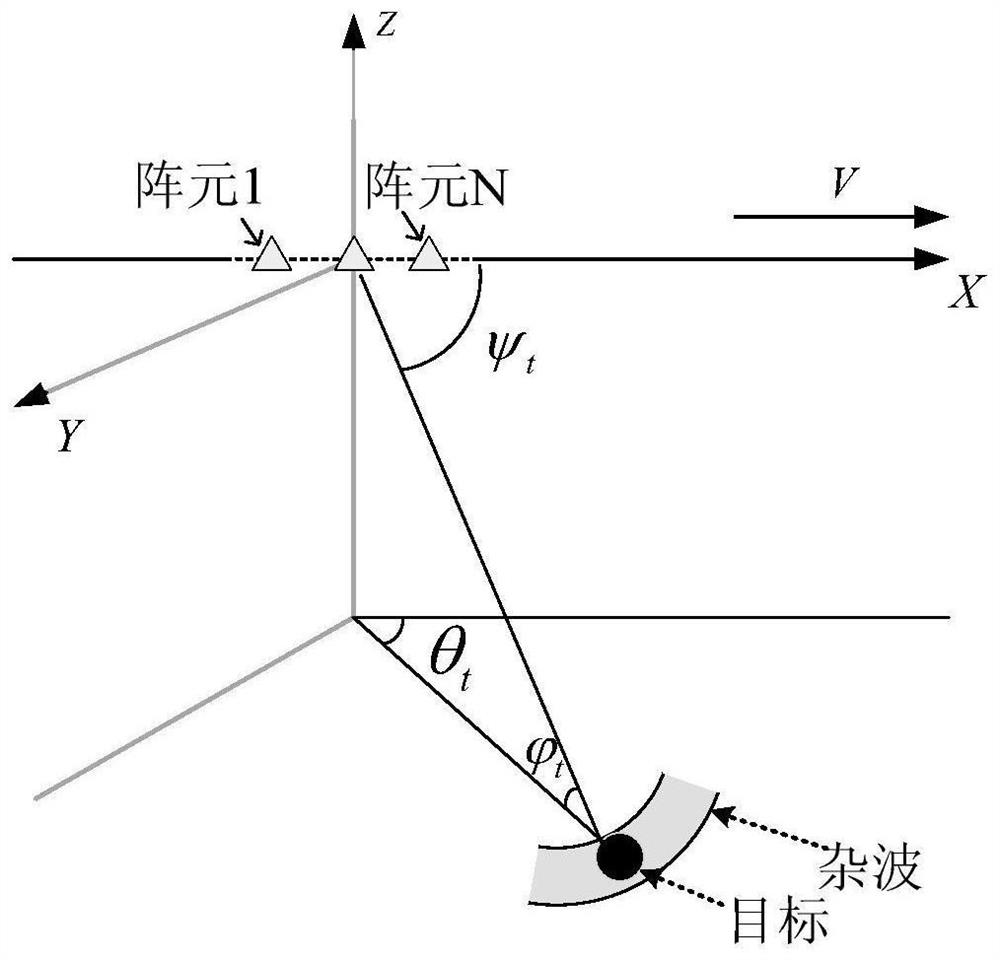

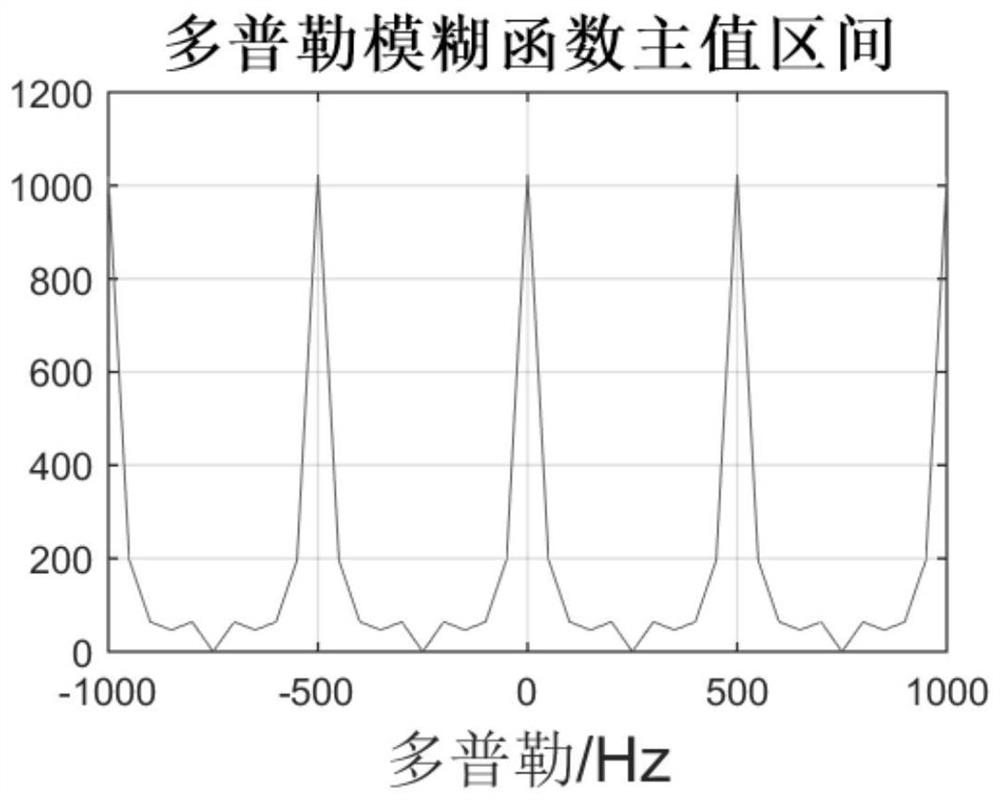

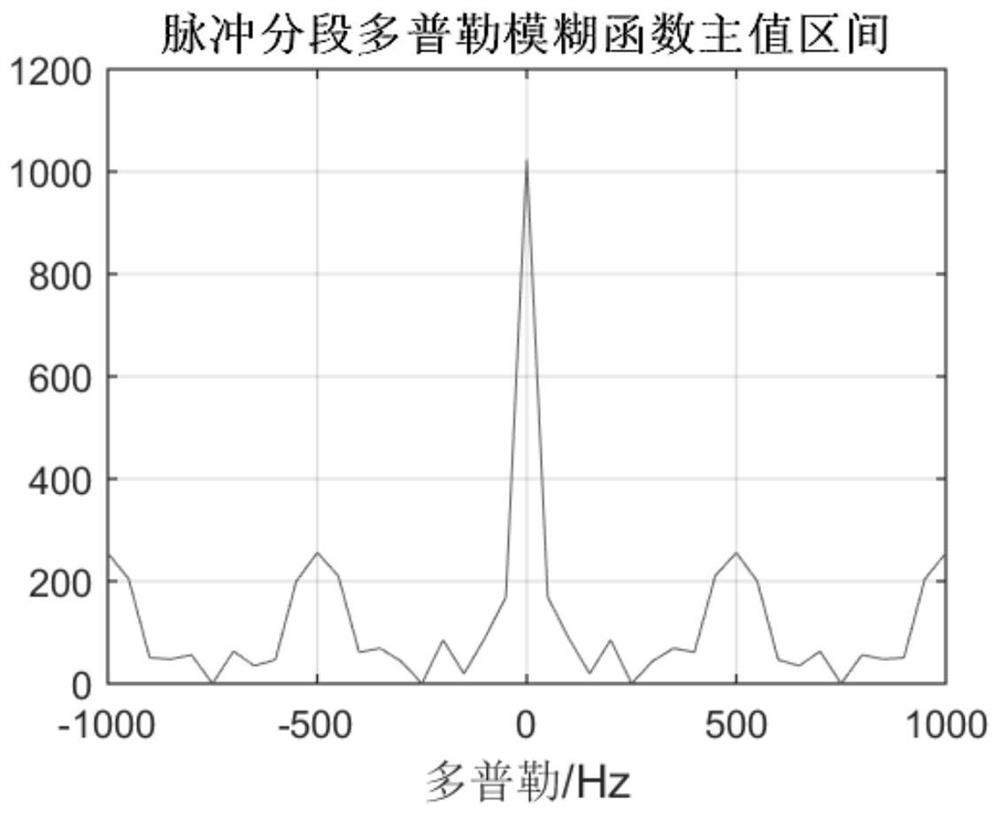

Pulse segmentation coding method for eliminating radar target blind speed

PendingCN111880171AIncrease minimum detectable speedSimple methodRadio wave reradiation/reflectionICT adaptationSelf adaptiveFrequency domain

The invention belongs to the technical field of radars, and discloses a pulse segment coding method for eliminating radar target blind speed, which comprises the following steps: determining a slow time linear phase phi m (k) and a corresponding transmitting signal sm (t); segmenting the pulse, and adding a random phase or a fixed phase to each segment of pulse to obtain a slow-time linear phase phi'm (k) after the phase is added and a corresponding transmitting signal s'm (t); enabling s'm (t) to reach the nth receiving array element after target scattering to obtain an echo signal smn (t); superposing the echo signals to obtain an output signal Sn (t) of the nth receiving array element; performing down-conversion and matched filtering on the Sn (t) to obtain echo signals Xn, i (t) aftermatched filtering and a fuzzy function of a corresponding DDMA radar; performing FFT on the Xn, i (t) to obtain a frequency domain signal znk ', i, and performing clutter suppression by adopting a space-time adaptive processing method; according to the method, the Doppler ambiguity problem of the DDMA MIMO radar can be solved, the target blind speed is eliminated, the mode of accurately controlling the phase is expanded, the performance deviation caused by random phase contingency is weakened, and the minimum detectable speed is better.

Owner:XIDIAN UNIV

CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel and fabrication method

ActiveCN107475627AGood strength and plasticity matchingReduce the chance of residuesMetal rolling arrangementsManganeseHigh pressure water

The invention discloses CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel. The CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the chemical element ingredients of, in percentage by weight, 0.14-0.16% of carbon, 0.90-1.20% of silicon, 1.20-1.40% of manganese, 0.07-0.10% of phosphorus, less than or equal to 0.005% of sulphur, 0.015-0.060% of acid soluble aluminium and the balance ferrum and inevitable impurities. The fabrication method of the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the following steps of converter smelting, refined smelting, thin plate billet continuous casting, continuous-casting billet soaking, high-pressure water descaling, controlled rolling, controlled cooling and rolling up. The economic C-Si-Mn-P ingredient design is adopted, a metallographic structure is composed of 50-65% of ferrite, 25-40% of bainite and 5-20% of residual austenite; the yield strength is 390-450 MPa, the strength of extension is 600-680 MPa, and the elongation A80 is 28-35%; and the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel has good high-plasticity matching.

Owner:武汉钢铁有限公司

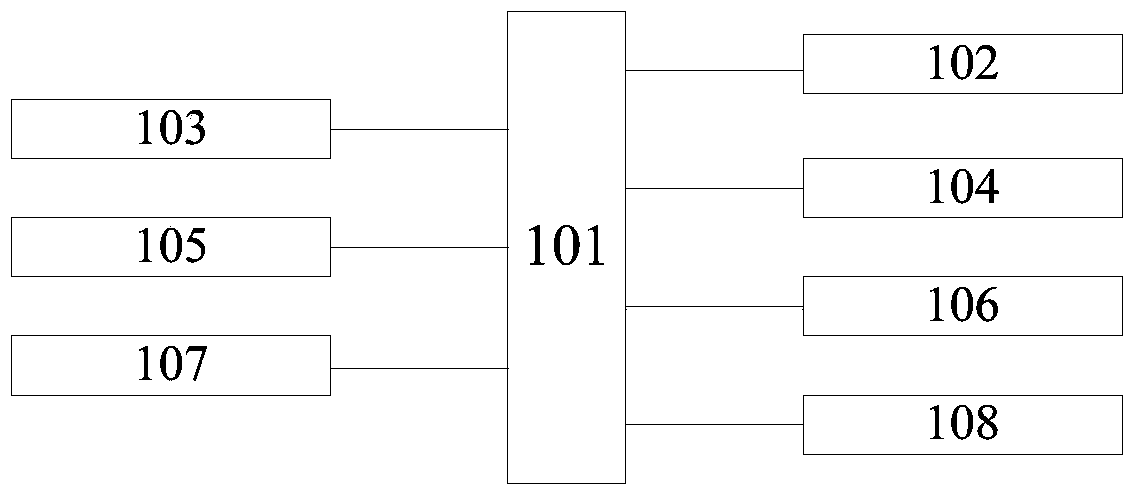

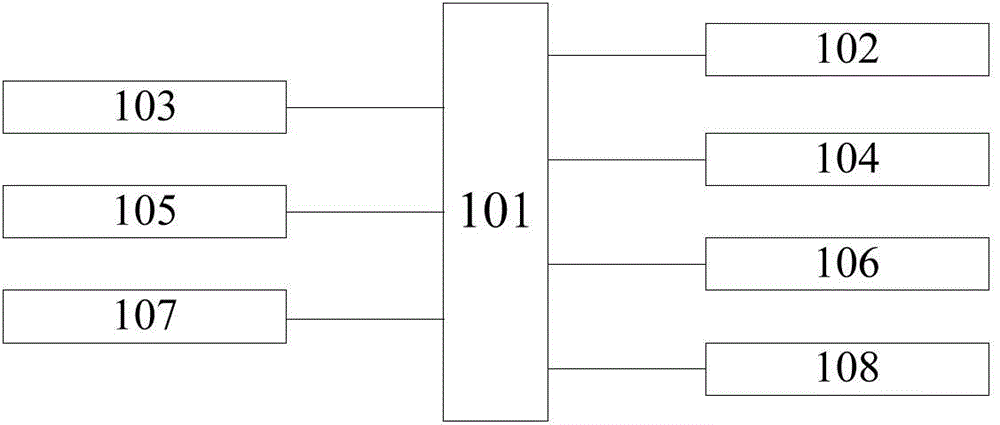

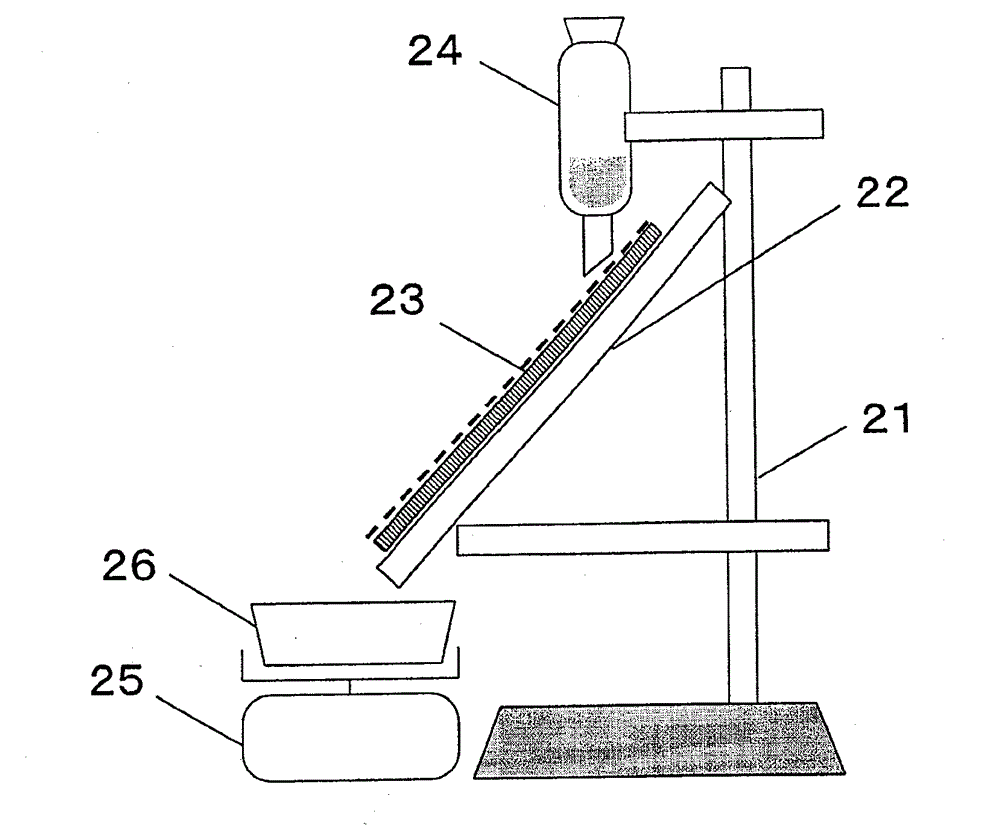

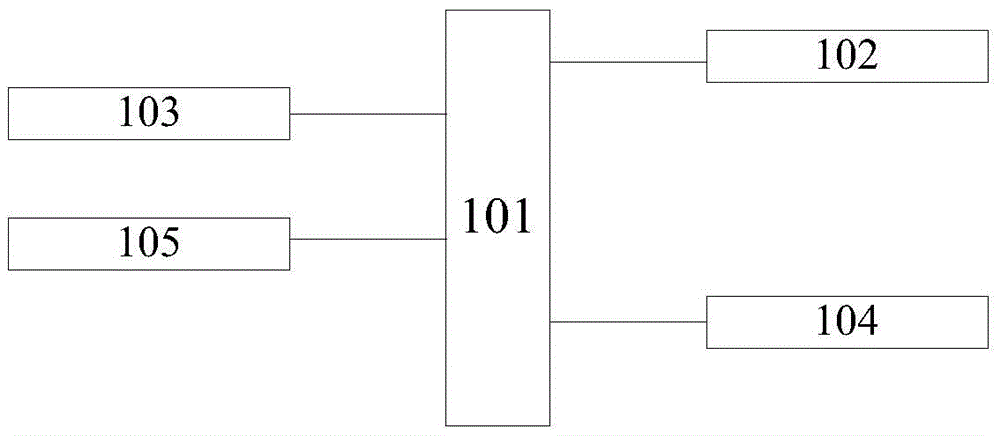

Vacuum evaporation equipment for inorganic material

ActiveCN103757599AImproved precision of vacuum depositionImprove qualityVacuum evaporation coatingSputtering coatingAutomatic train controlAutomatic control

The invention provides vacuum evaporation equipment for inorganic material, which comprises a vacuum evaporation chamber and an automatic control system. In the vacuum evaporation equipment provided by the invention, each module collects various parameter signals in the vacuum evaporation chamber and sends various parameter signals to a main control machine; the main control machine processes the various received parameter signals according to various preset parameters to obtain feedback signals and feeds back the feedback signals to corresponding control modules; the corresponding control modules carry out automatic regulation and control on corresponding parts according to the corresponding feedback signals so as to achieve automatic control on inorganic material vacuum coating. The vacuum evaporation equipment for the inorganic material not only saves a great quantity of labor, but also, more importantly, can achieve effective monitoring on the inorganic material vacuum evaporation process and achieves improvement on the inorganic material vacuum evaporation accuracy and quality, and speed increasing.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Vacuum evaporation equipment for organic material

InactiveCN103726023AImproved precision of vacuum depositionImprove qualityVacuum evaporation coatingSputtering coatingAutomatic controlControl system

The invention provides vacuum evaporation equipment for an organic material. The vacuum evaporation equipment comprises a vacuum evaporation chamber and an automatic control system. In the vacuum evaporation equipment, all modules collect all parameter signals in the vacuum evaporation chamber and transmit the parameter signals to a chief controller, according to the preset parameters, the chief controller processes the received parameter signals so as to obtain feedback signals, the feedback signals are fed back to corresponding control modules, and the corresponding control modules automatically regulate and control corresponding parts according to corresponding feedback signals, so that organic material vacuum coating is automatically controlled, a large amount of manpower is saved, the vacuum evaporation process for the organic material can be monitored effectively, and the accuracy, quality and speed of vacuum evaporation for the organic material are improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

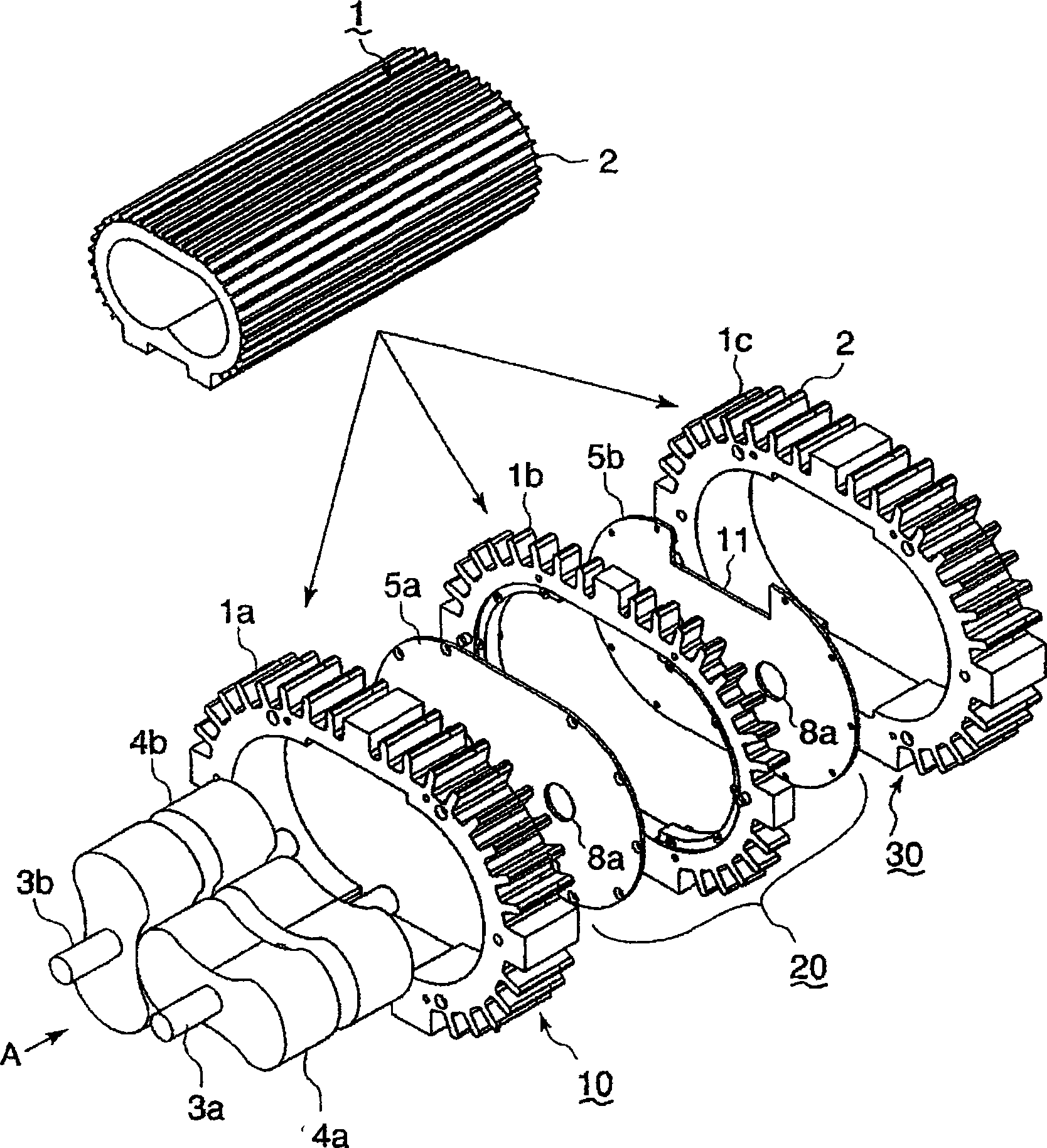

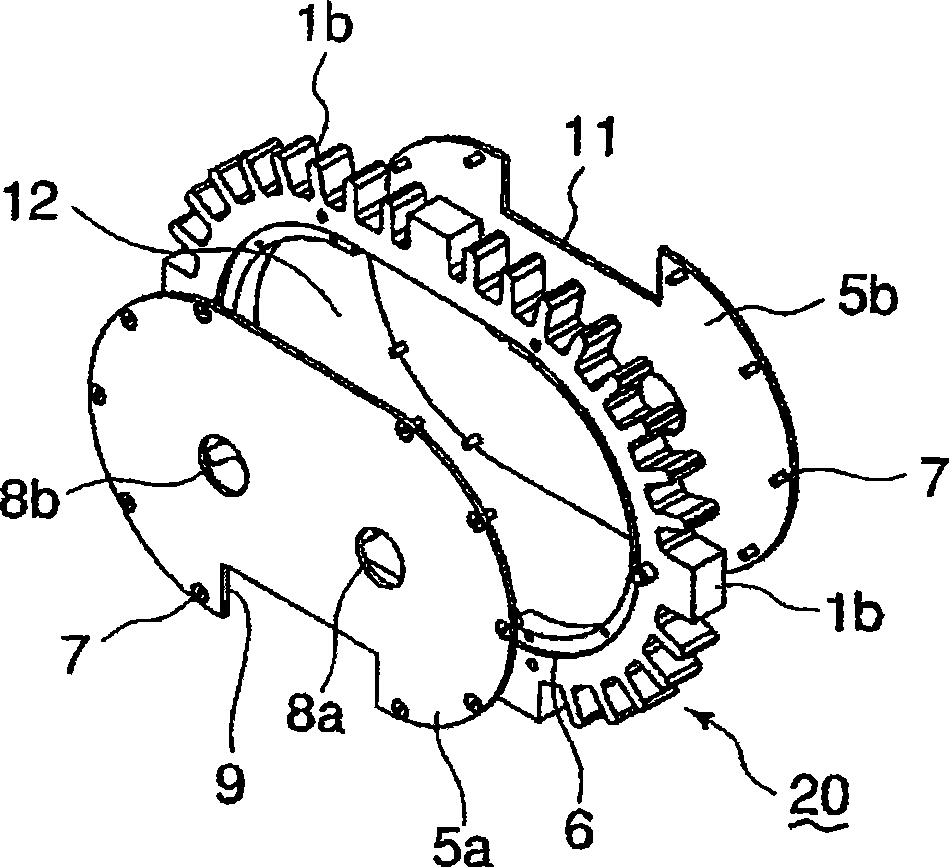

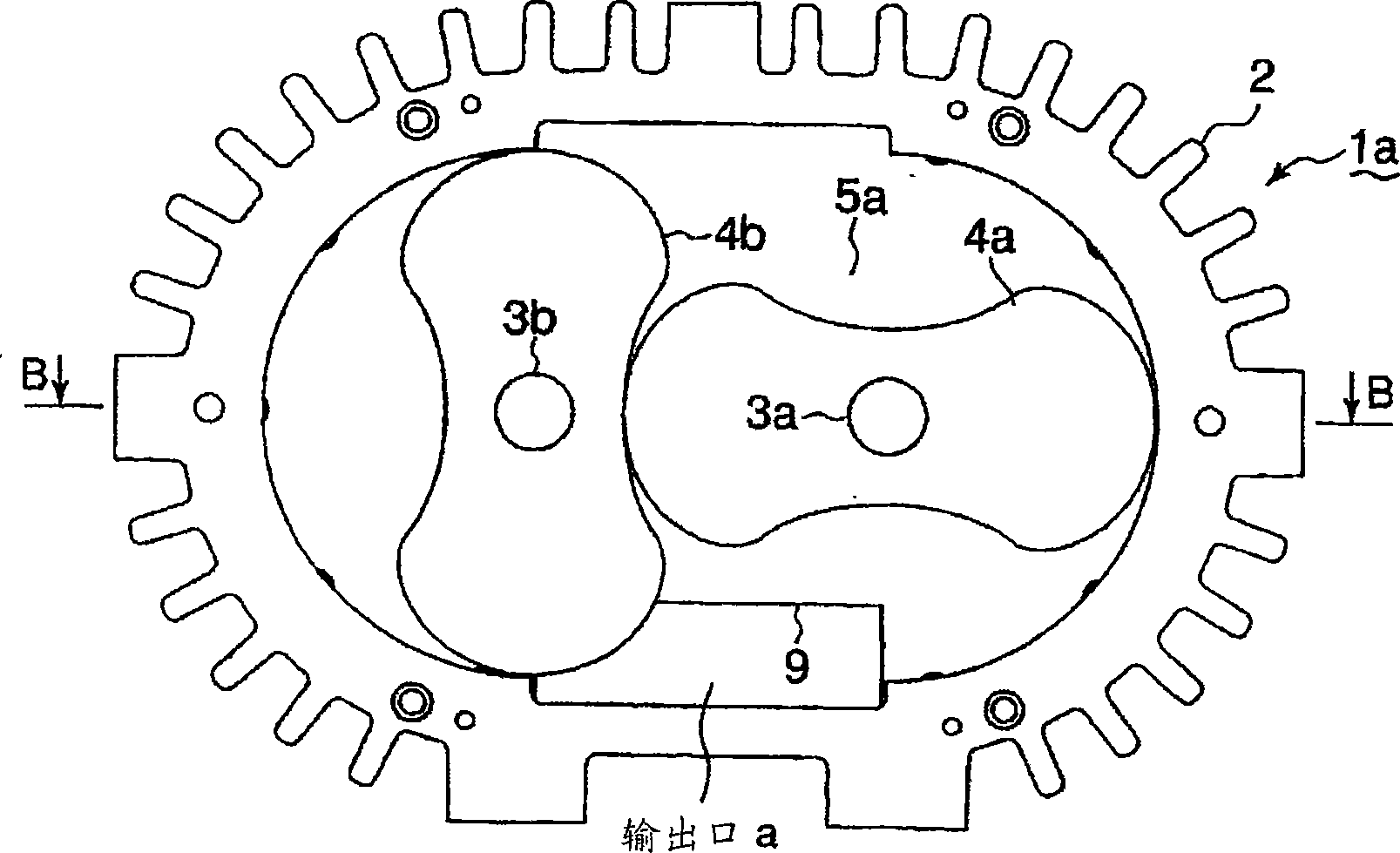

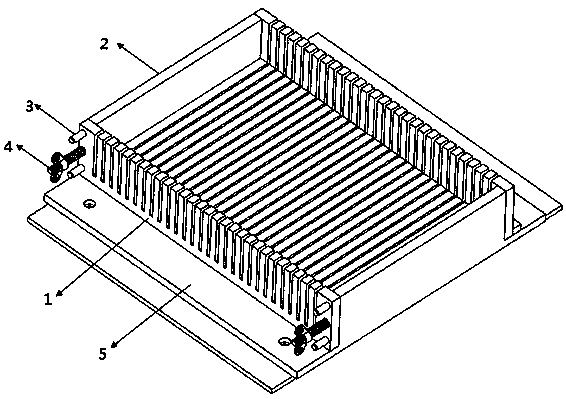

Multi-stage rotor pump and manufacturing process thereof

InactiveCN101545487AReduce production processLow costRotary piston pumpsRotary piston liquid enginesEngineeringHeat sink

The invention relates to a multi-stage rotor pump and the manufacturing process thereof. The multi-stage rotor pump is provided with a rotor shaft in the housing equipped with a plurality of rotor chamber, a multi-stage rotor is fixedly disposed on the rotor shaft. In order to produce the multi-stage rotor pump simply and with low cost, a hollow cylinder body with cross sections in the same shape is formed. When the cylinder is formed, radiating ribs extending along the longitudinal axis direction are formed on the outer circumferential surface of the cylinder simultaneously, the cross section interposing with the longitudinal axis cuts the cylinder which is used as a plurality of rotor housing. Rotor shafts are configured inside the plurality of rotor housing, and a multi-stage rotor is fixedly disposed on the rotor shafts inside each rotor housing. Because the separation board opened with rotor shaft through holes covers the inlet side and the outlet side of the rotor housing, a fluid path communicating the outlets of the front and the rear rotor housing with the inlet is formed on the separation wall.

Owner:ANEST IWATA CORP

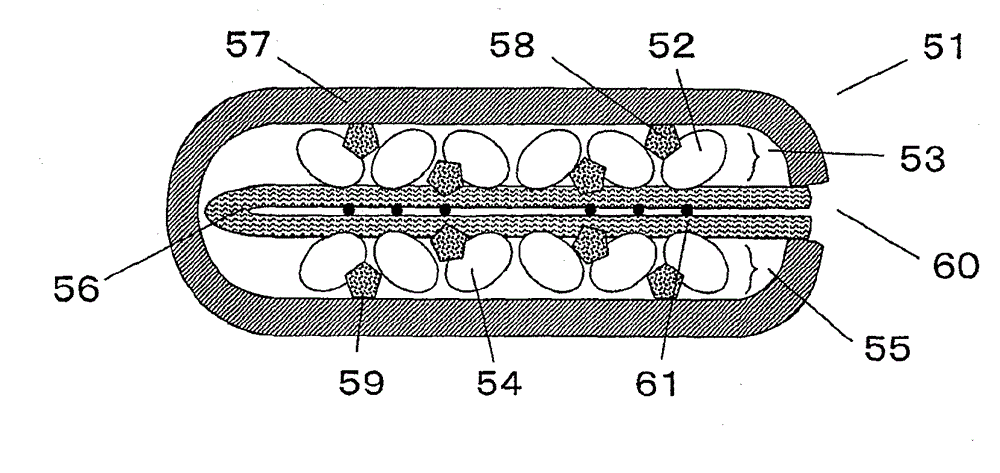

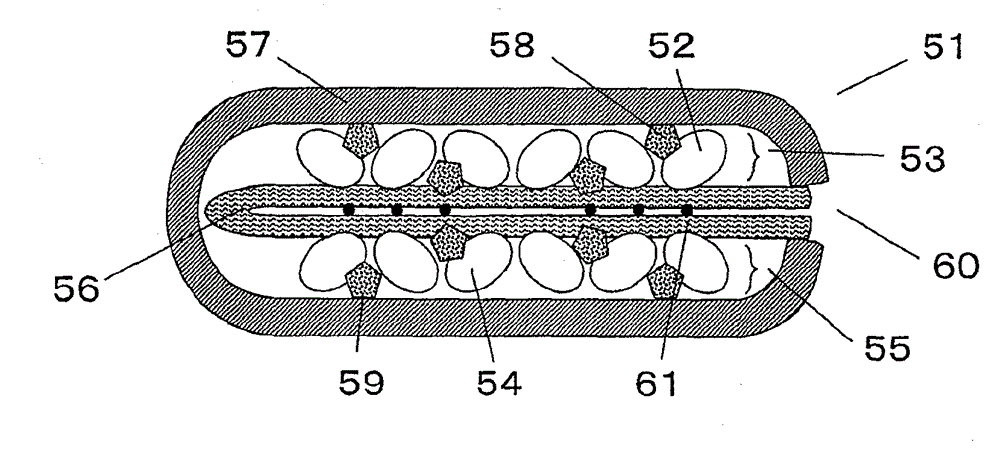

Water absorbent sheet

ActiveCN102802580AImprove performanceManufacturing can be efficientAbsorbent padsBandagesPolymer scienceNonwoven fabric

The invention relates to a water absorbent sheet having a structure wherein an absorbent layer that contains a water absorbent resin and an adhesive is held between hydrophilic nonwoven fabrics. The water absorbent sheet is characterized by satisfying the conditions (1) and (2) described below, and having a structure wherein the absorbent layer is divided into a primary absorbent layer and a secondary absorbent layer by a base layer that is obtained by bonding and laminating two or more air-permeable bases using an adhesive. (1) The weight of the base layer is not less than 25 g / m<2>. (2) The adjacent air-permeable bases are bonded together with 0.1-50 g / m<2> of the adhesive. The water absorbent sheet can be formed thin and prevents a gel blocking phenomenon and liquid leakage, while securing the fundamental properties required for water absorbent sheets at high levels, even though the water absorbent sheet contains extremely little pulp.

Owner:SUMITOMO SEIKA CHEM CO LTD

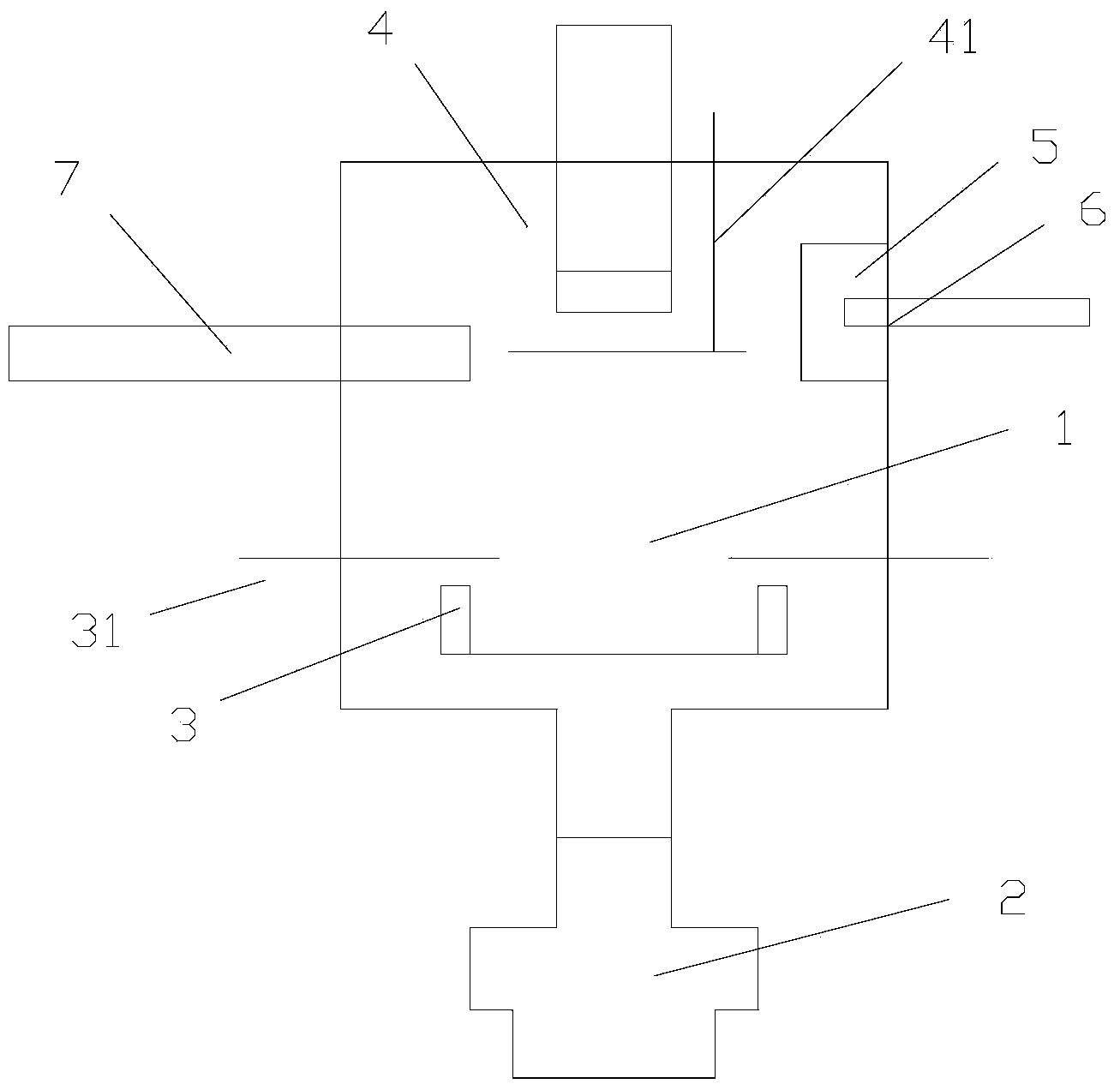

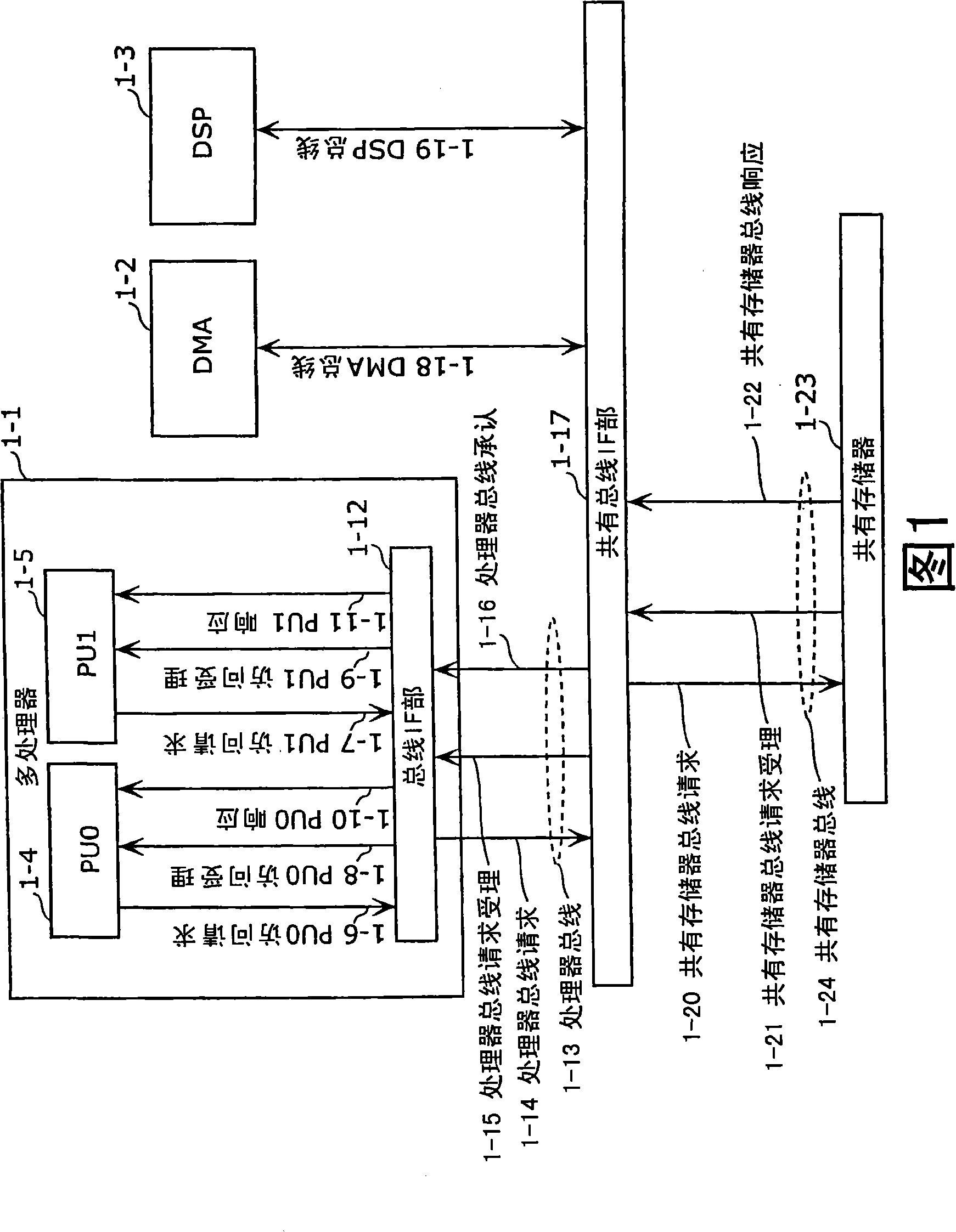

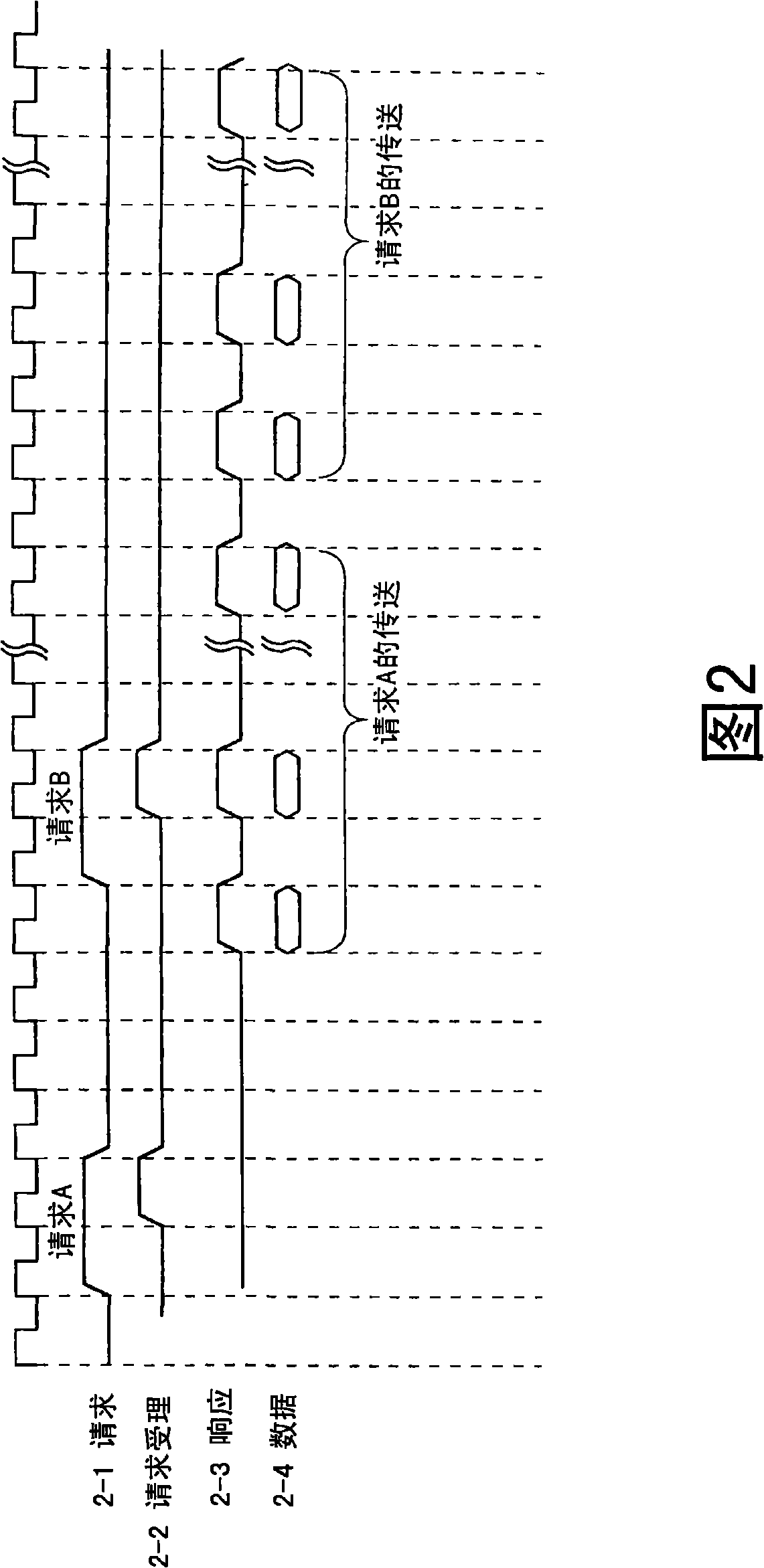

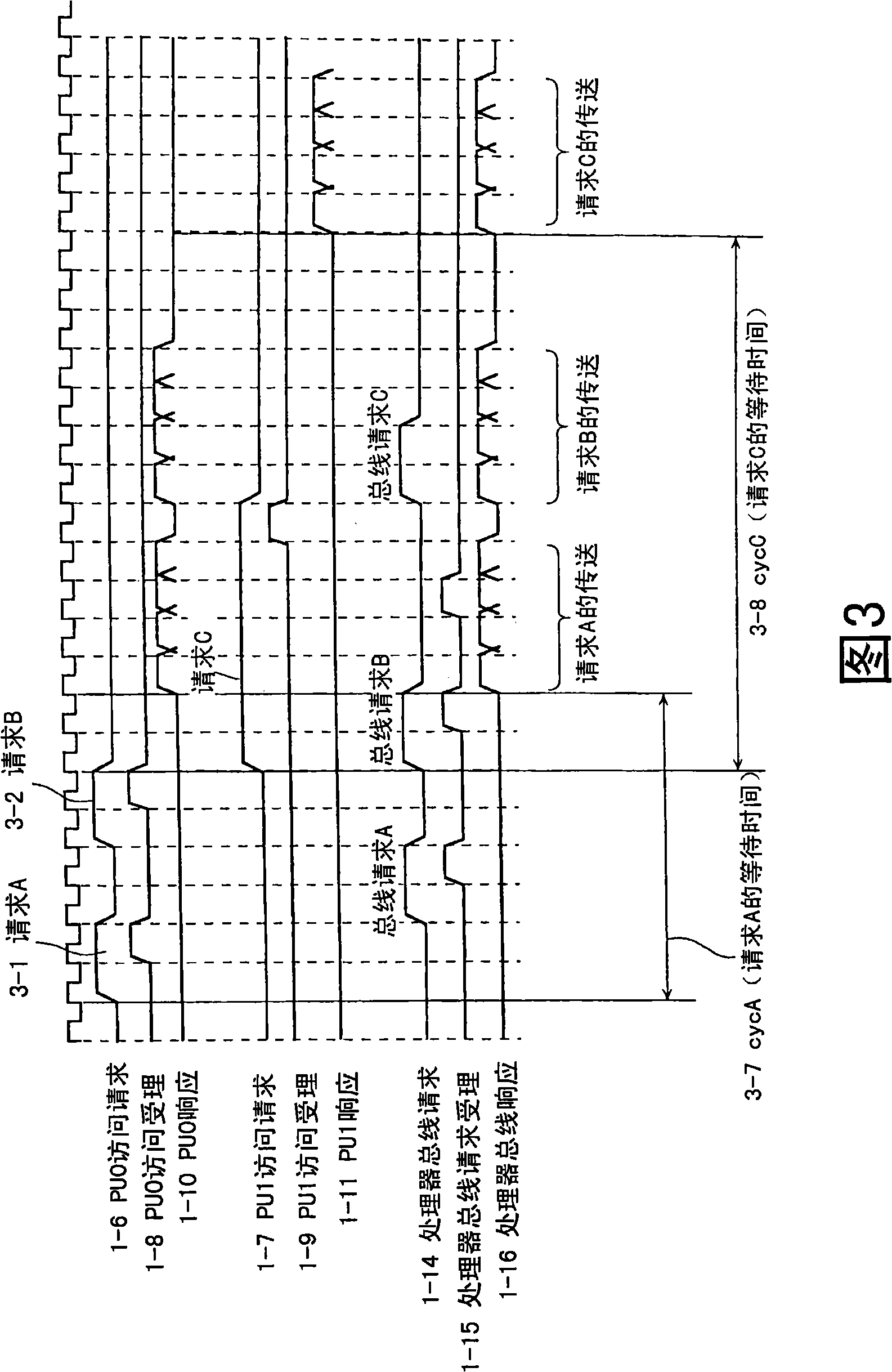

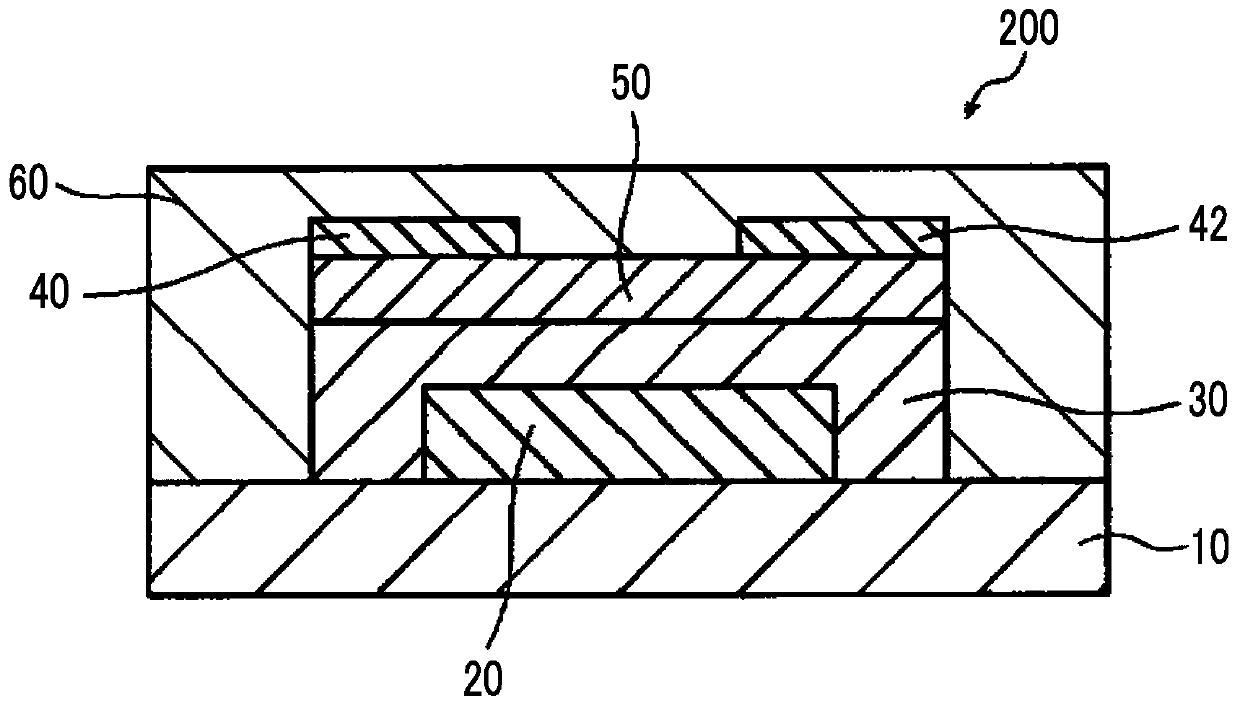

Processor system, bus controlling method, and semiconductor device

InactiveCN101324870AAccess performance equalizationLimit the number of consecutive executionsDigital computer detailsElectric digital data processingMulti processorBus mastering

Provided is a simply structured multiprocessor system which equally distributes access performance for accessing a shared memory among plural master units accessing the shared memory. The multiprocessor system includes plural master units PU 0 and PU 1 each of which issues an access request for accessing the shared memory, a bus IF unit 4 - 10 which accesses a bus by a split transaction scheme and separately executes a request phase for accepting the access request; and a transfer phase for executing data transfer in response to the accepted access request. In the case where one of the master units consecutively issues plural access requests without an interval of a predetermined time period, the bus IF unit 4 - 10 restricts the number of consecutive transfer phase executions corresponding to the plural access requests to be not more than N. The bus control method and the semiconductor are also provided.

Owner:PANASONIC CORP

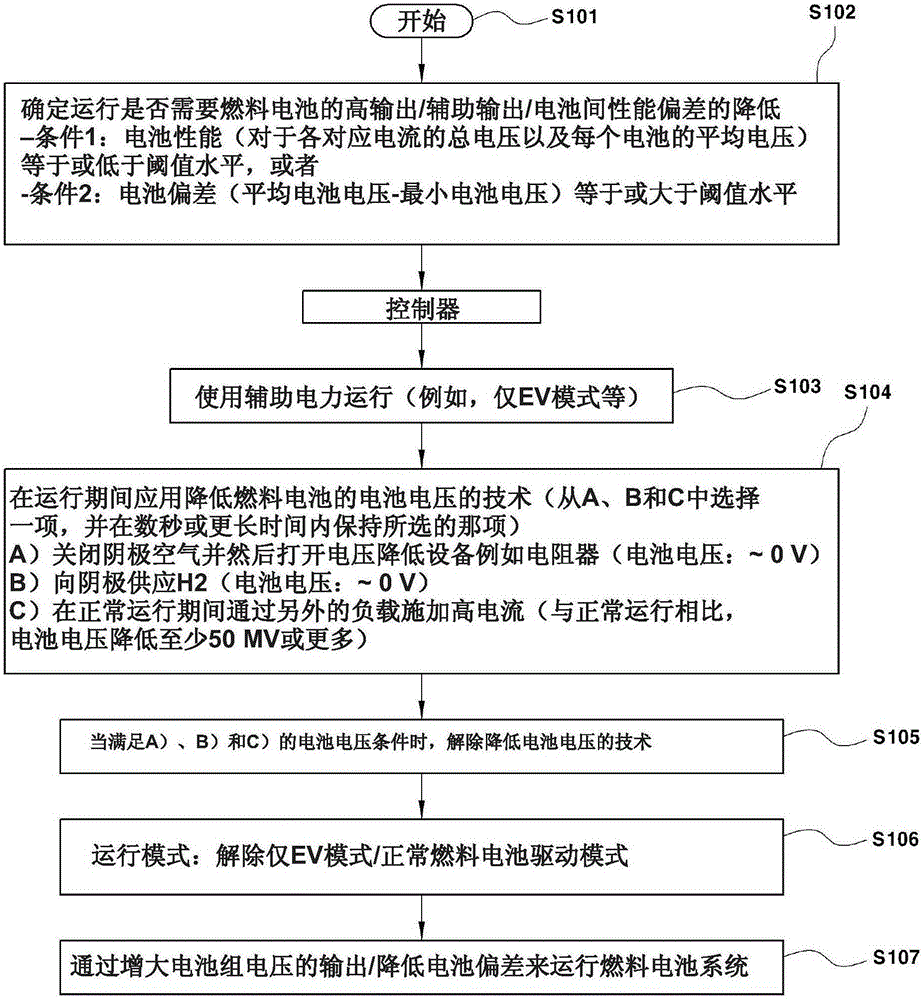

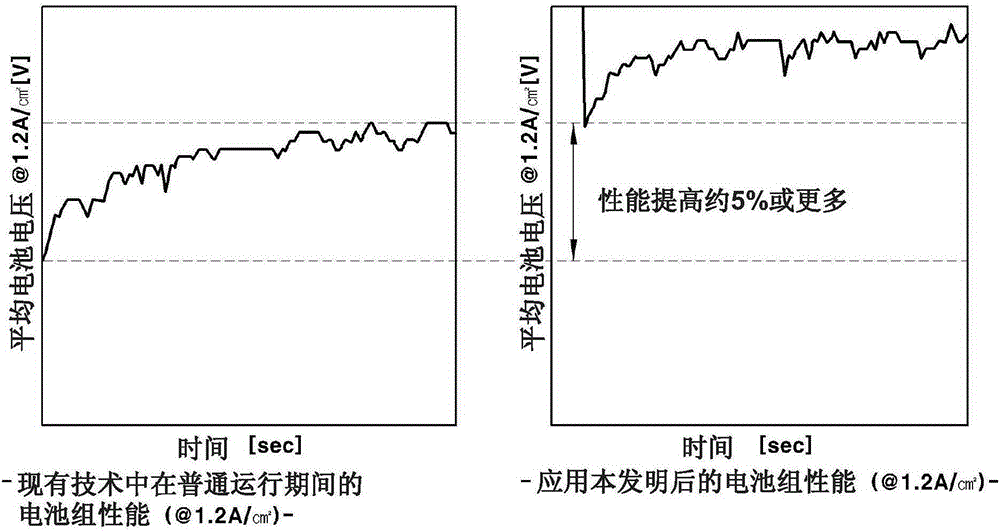

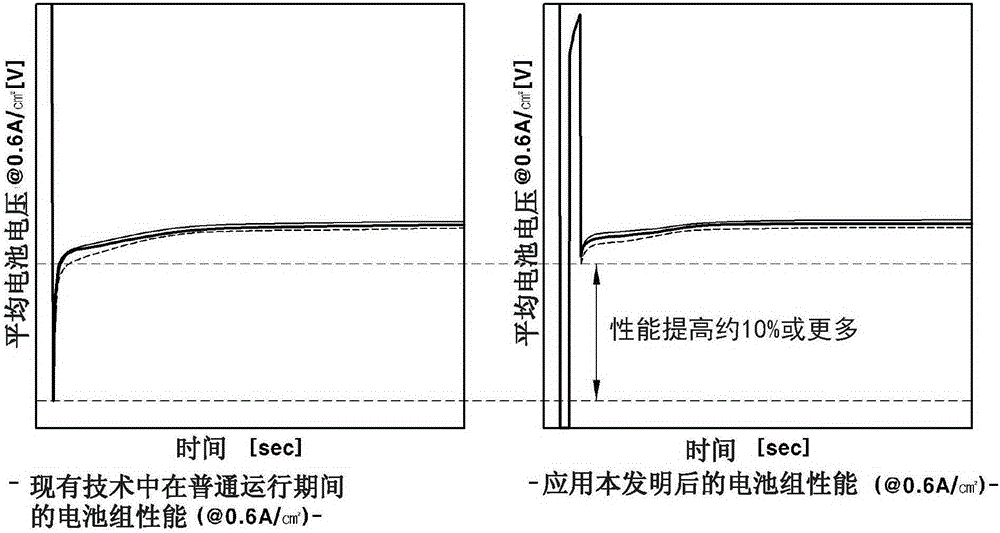

Device And Method For Controlling Operation Of Fuel Cell System

ActiveCN106299417AImprove performancePerformance deviation is smallElectric devicesFuel cell controlFuel cellsHysteresis phenomenon

A device and a method are provided for controlling the operation of a fuel cell system to improve a momentary output of a fuel cell system and decrease a performance deviation between fuel cells. The device momentarily reduces a cell voltage of a fuel cell or changes a fuel cell system to a state close to a shut-down, return the fuel cell system to a normal condition again, and then enable the fuel cell system to be operated normally by applying the saw-tooth phenomenon and the hysteresis phenomenon. Thus, a momentary output of the fuel cell system is improved to performance of a highest output level or more expressible in a previous state and a performance deviation between fuel cells is decreased.

Owner:HYUNDAI MOTOR CO LTD

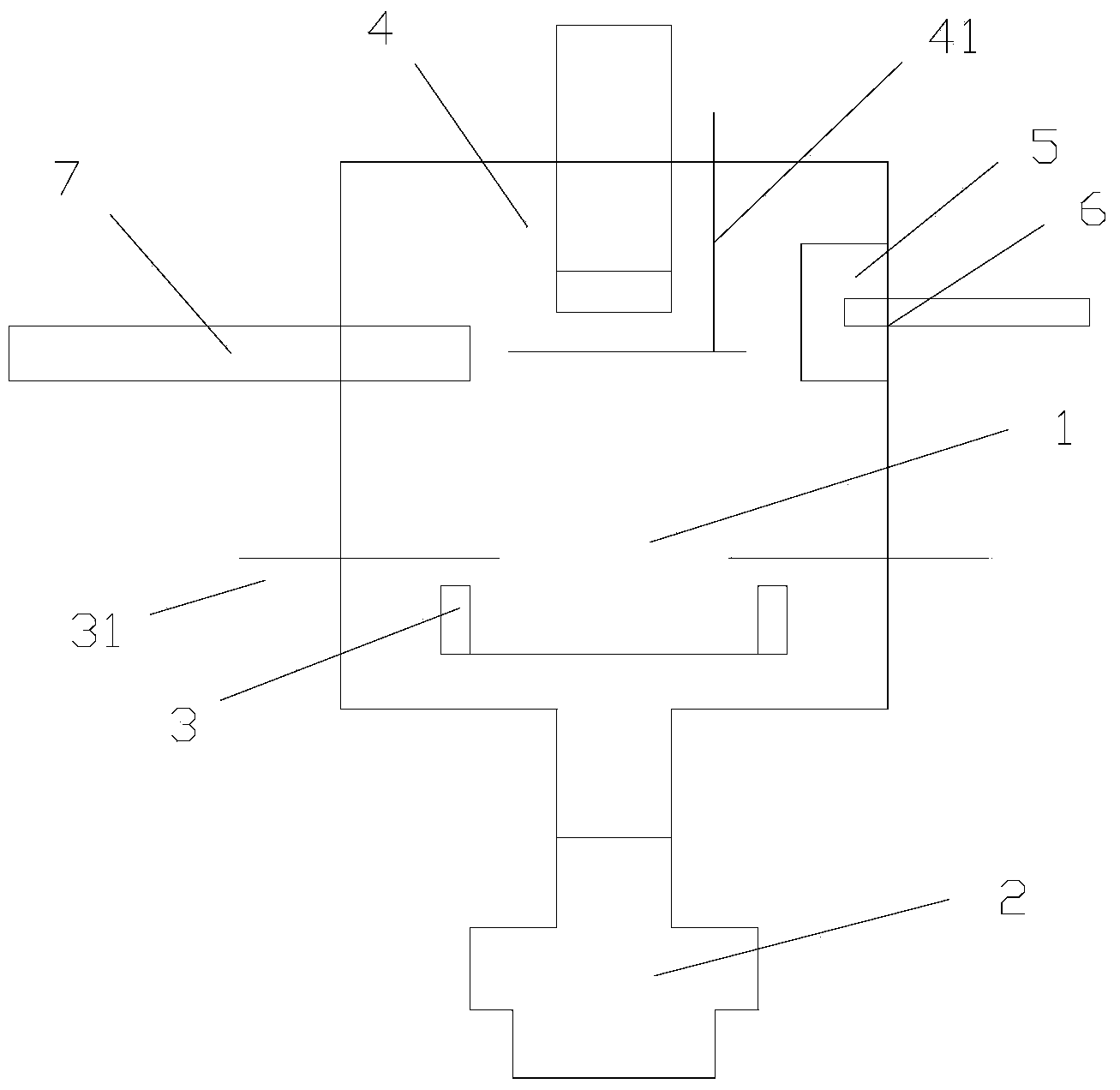

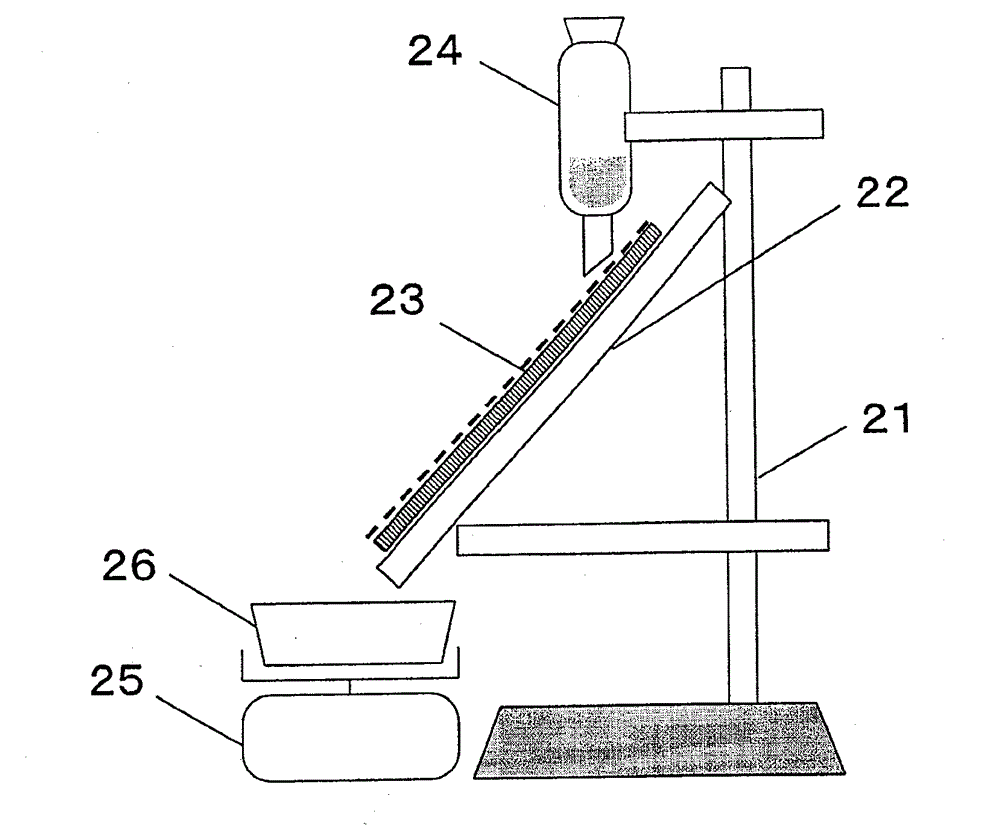

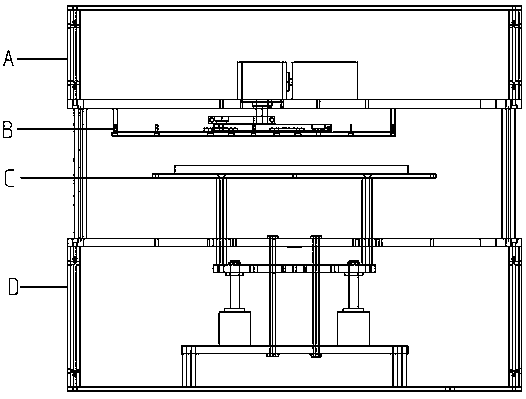

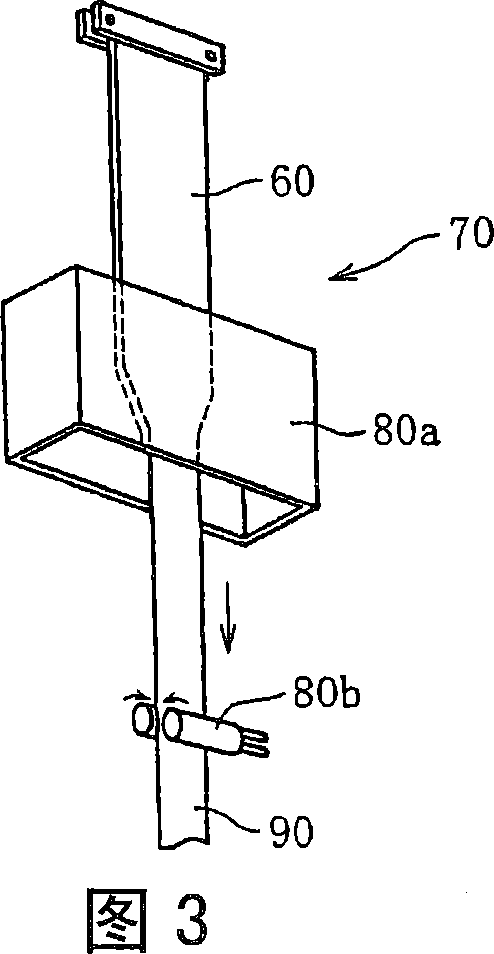

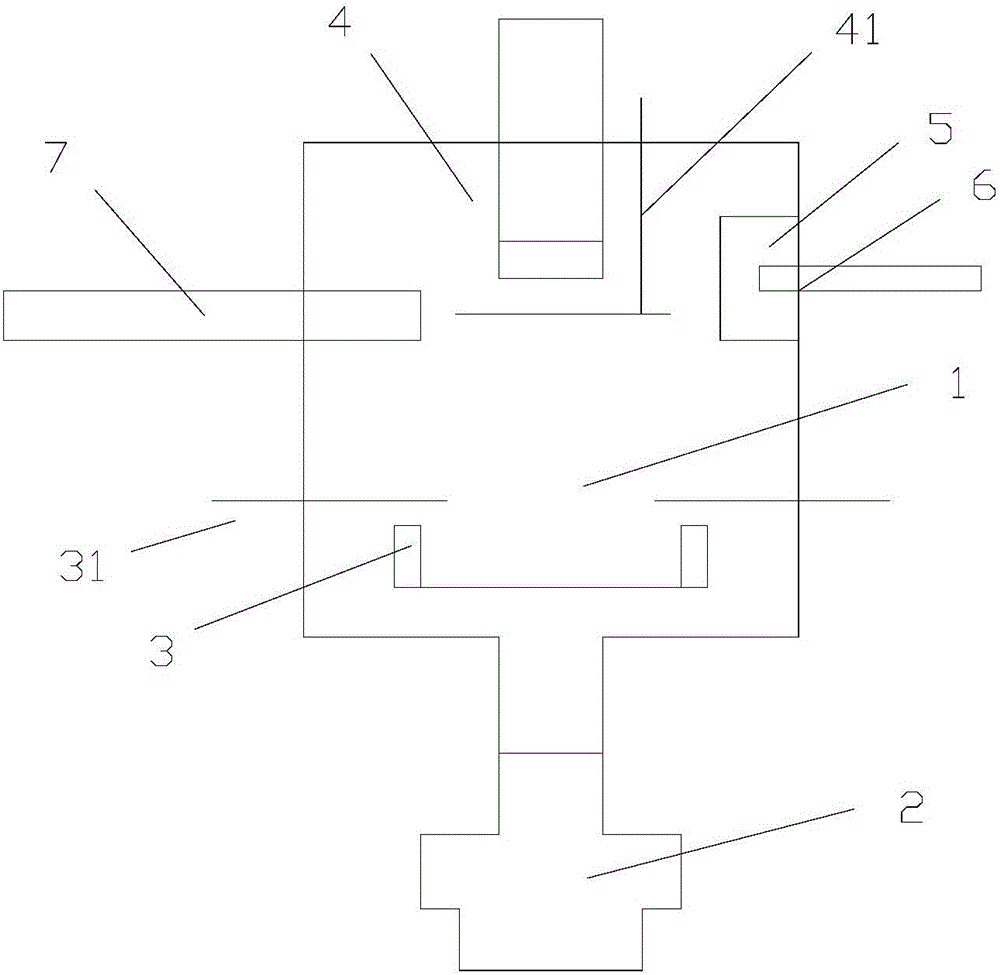

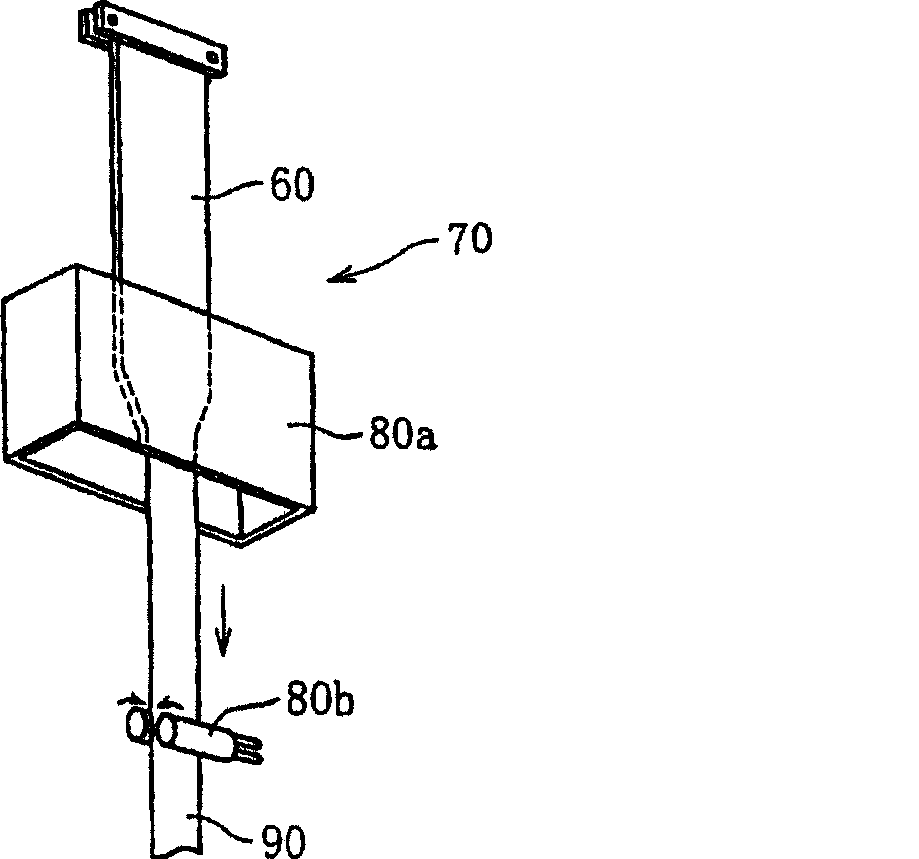

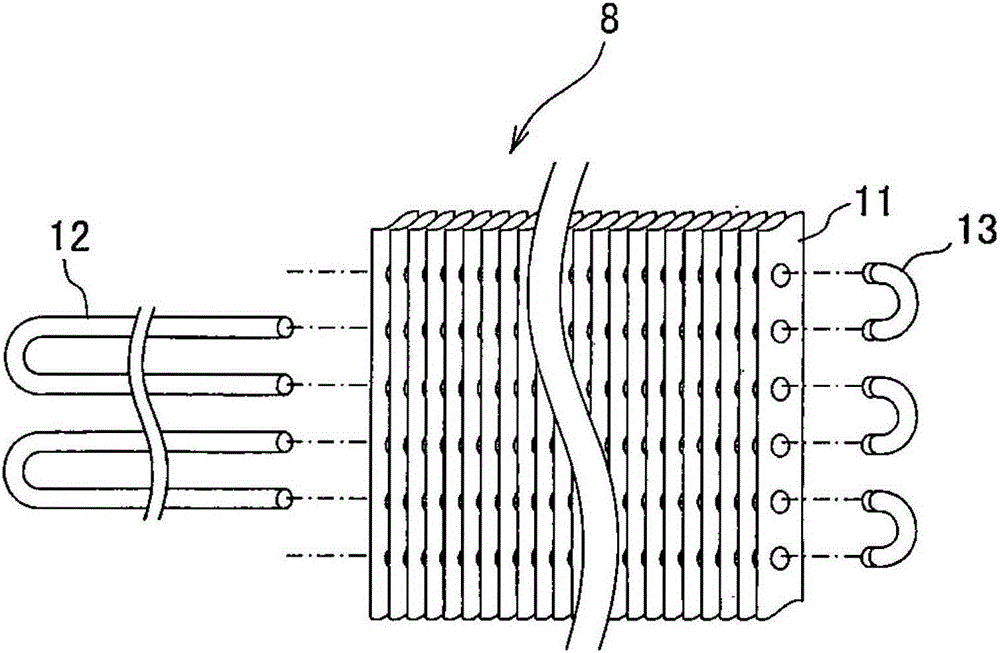

Method and device special for improving performance of sintered Nd-Fe-B magnets

ActiveCN108831657AImprove performanceIncrease profitInductances/transformers/magnets manufactureMagnetic materialsSintered magnetsMachining

The invention discloses a method and device special for improving the performance of sintered Nd-Fe-B magnets. The method is characterized in that one or two of an orientation surface, a non-orientation surface and a pressing surface of green billets prepared through molding of a press and isostatic pressing are processed into finished product shapes and corresponding sizes through a special device, then the green billets are subjected to normal sintering and aging, and the obtained magnets are processed into finished products through traditional mechanical processing. The special device is composed of a reciprocating cutting device (A), a cutting tool (B), green billet fixing tool (C) and a reciprocating lifting mechanism (D). The deviation of sintered magnet composition and magnet performance can be reduced, magnet performance loss in traditional mechanical processing is reduced, and the overall magnet performance of the magnets is thus improved. Meanwhile, damage to the green billets in the green billet processing process can be reduced, the ratio of waste powder which is difficult to recycle and generated in the processing process is reduced, and the comprehensive utilization rate of magnet powder is improved.

Owner:YANTAI DONGXING MAGNETIC MATERIALS INC

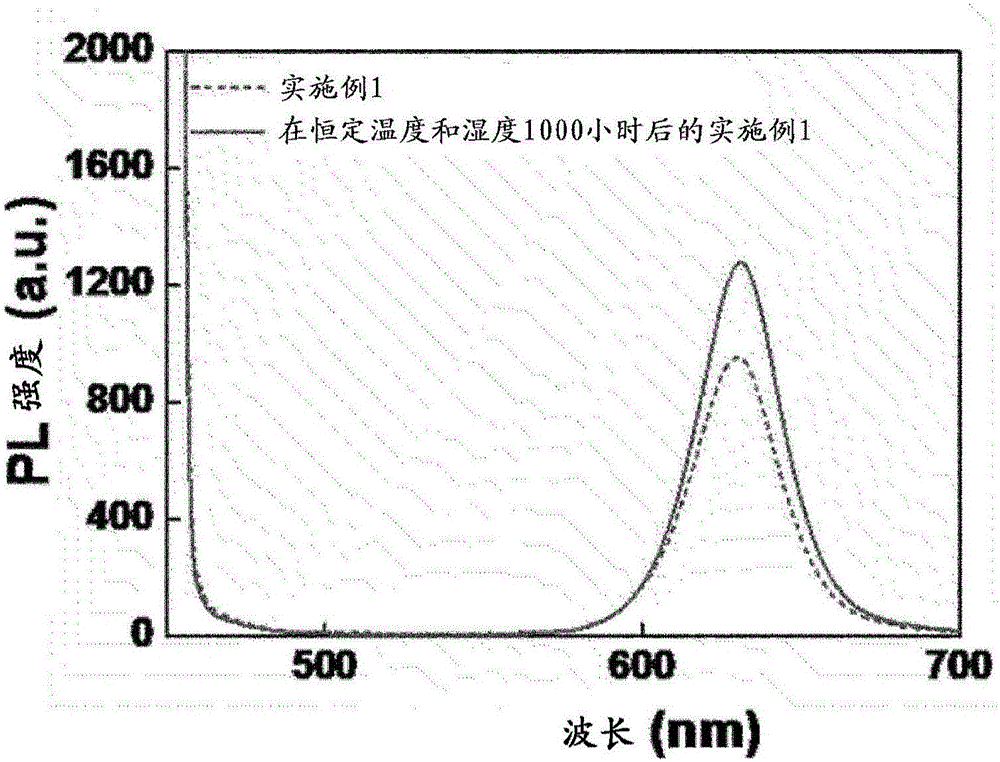

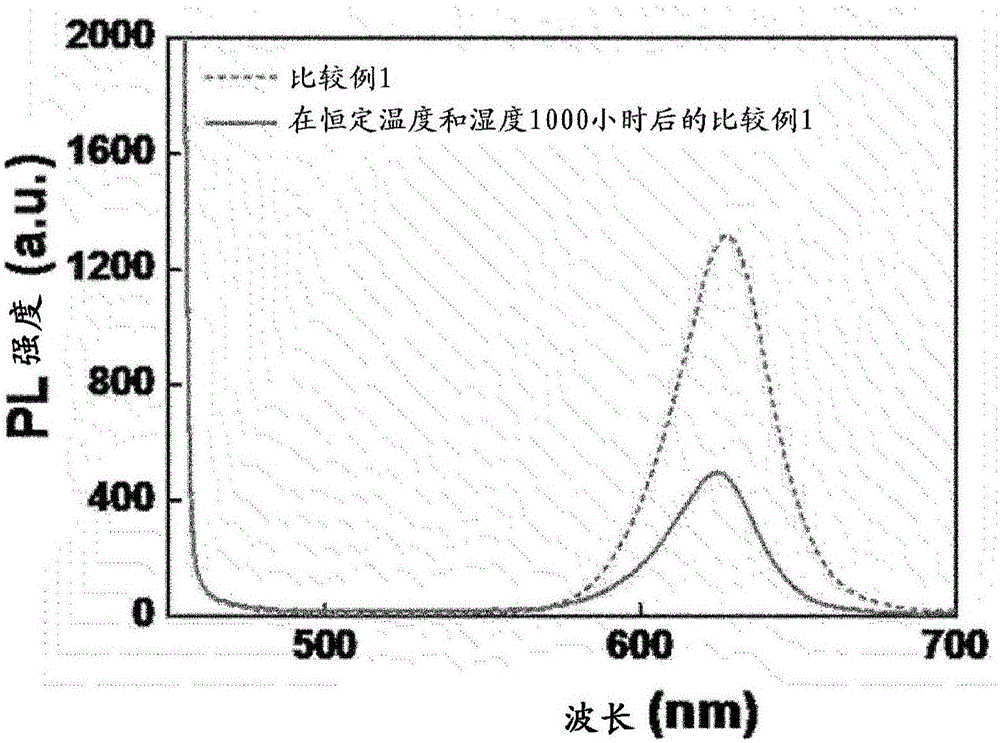

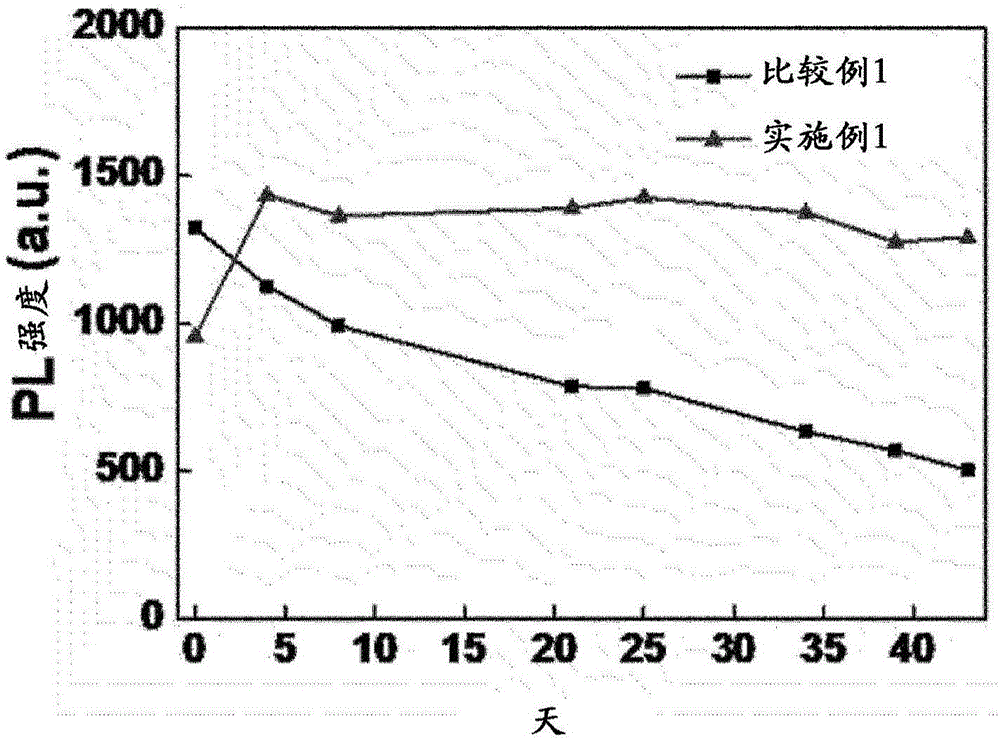

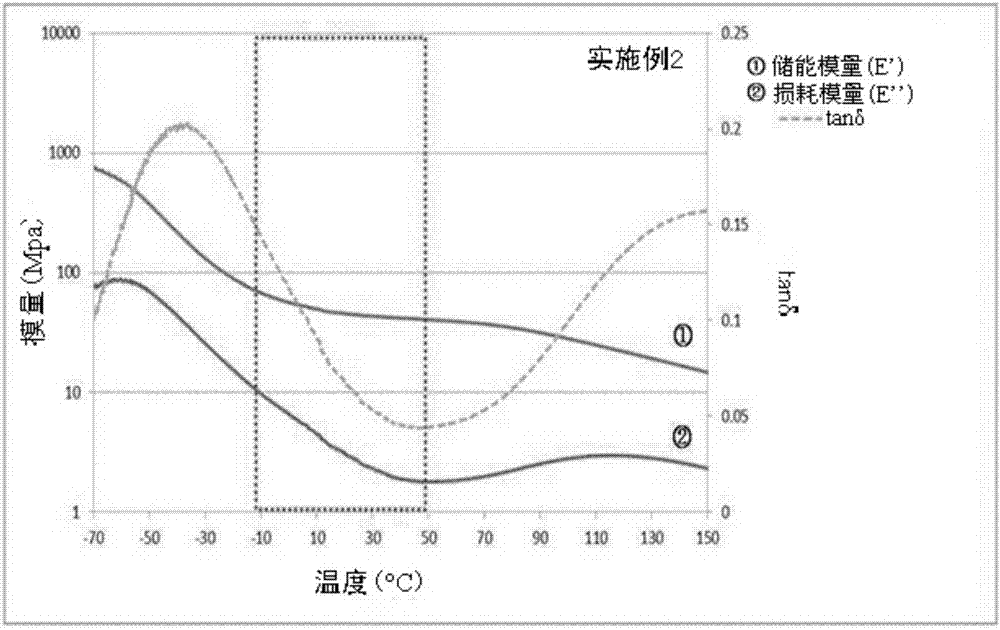

Adhesive composition, adhesive film, brightness enhancement film, and backlight unit comprising same

InactiveCN106661401AInhibit deteriorationExcellent external barrier propertiesNon-macromolecular adhesive additivesDiffusing elementsBrightness perceptionChemistry

Owner:LG CHEM LTD

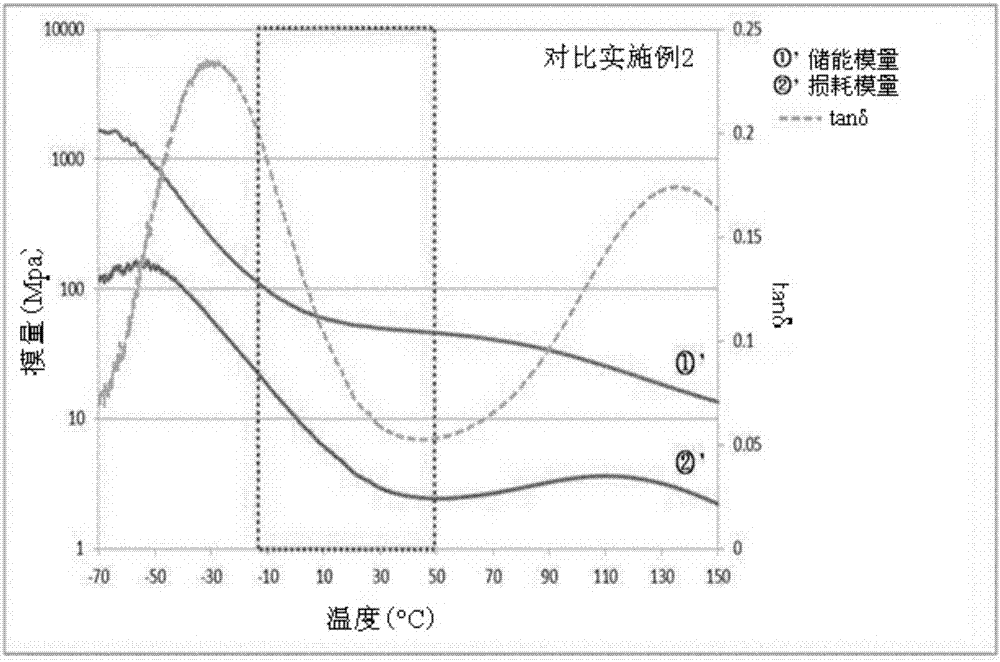

Resin Composition For Golf Ball Cover

InactiveCN106916279APerformance deviation is smallImproved recovery propertiesSolid ballsEngineeringGolf Ball

The present invention provides a resin composition for a golf ball cover, wherein, since the resin composition for the golf ball cover according to the present invention minimizes changes in physical properties due to temperature changes and improves restitution characteristics, the resin composition for the golf ball cover may reduce performance deviations of a golf ball due to seasonal temperature changes and may improve a spin rate of the golf ball.

Owner:SKC CO LTD

1000mpa grade hot-rolled trip steel based on csp process and its manufacturing method

ActiveCN107557692BGuaranteed stabilityNo reduction in carbon intensityHeat treatment process controlThin slabManganese

The invention discloses 1,000 MPa level hot-rolled TRIP steel based on the CSP process. The 1,000 MPa level hot-rolled TRIP steel comprises chemical elements and components including, by weight percent, 0.16%-0.20% of carbon, 1.60%-1.80% of silicon, 1.50%-1.60% of manganese, 0.20%-0.24% of vanadium, smaller than or equal to 0.008% of phosphorus, smaller than or equal to 0.005% of sulfur, 0.015%-0.060% of acid soluble aluminum, 0.015%-0.025% of nitrogen and the balance iron and inevitable impurities. The steel manufacturing method comprises converter smelting, refining, sheet billet continuouscasting, continuous casting blank uniform heating, high-pressure water descaling, controlled rolling, controlled cooling and coiling. Through the V-N adding microalloying component design, a ferrite phase and a bainite phase are strengthened, meanwhile, carbon concentration is not reduced, stability of retained austenite is maintained, and good strength and plasticity matching is achieved.

Owner:武汉钢铁有限公司

Modularized smokeless firework propellant and preparation method thereof

ActiveCN102219621BSolve residual problemsSimplify the charging processNitrated explosive compositionsNitrocelluloseFireworks

The invention discloses a modularized smokeless fireworks propellant, which contains nitrocellulose, has a large number of tiny pores inside, and has a block shape. The size and shape of the propellant are determined according to the caliber and shape of the firework launching tube. The preparation method of this modular smokeless fireworks propellant is firstly to mix the organic binder and the granular micro-pore fireworks, and then the mixed material is prepared into a block solid by molding, and then dried Methods to drive out the volatile components in the block medicine. Compared with the granular micro-pore fireworks powder, this modular smokeless firework propellant completely solves the problem of the launch residue of the granular charge, simplifies the operation of the propellant charge, and makes the finished product more stable and consistent. , In addition, the mechanical friction between particles is avoided, and the safety of the manufacture, transportation and storage of fireworks products is improved.

Owner:NANJING UNIV OF SCI & TECH

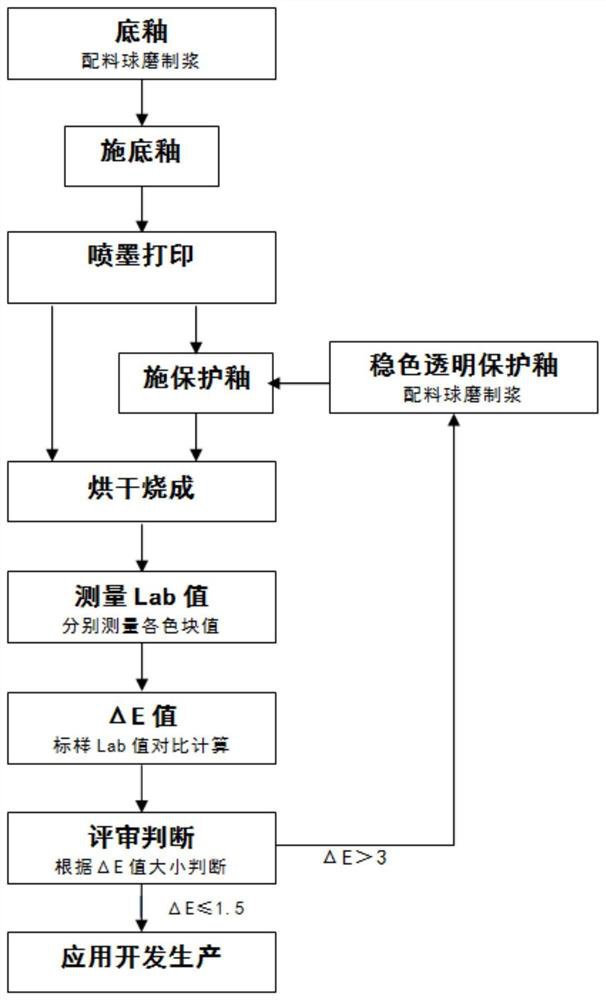

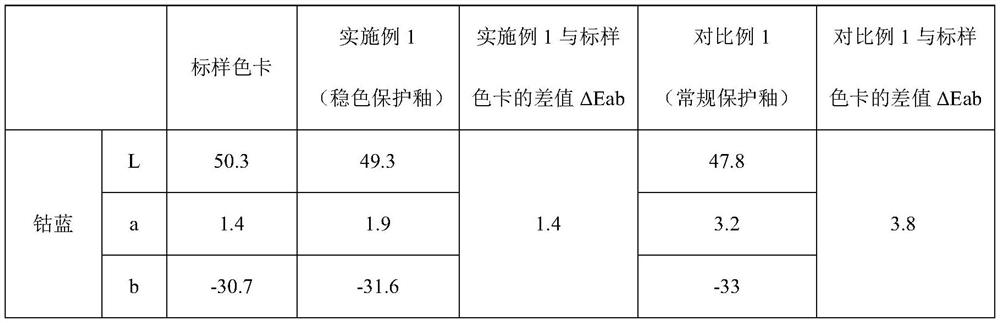

Color-stabilizing protective glaze, ceramic tile and preparation method of ceramic tile

ActiveCN114873916AExtended Melting Firing TemperaturePerformance deviation is smallCeramic materials productionFritGlaze

The invention discloses a color-stabilizing protective glaze, a ceramic tile and a preparation method of the color-stabilizing protective glaze, and the color-stabilizing protective glaze is prepared from the following raw materials in parts by weight: 15-24 parts of calcined soil, 8-17 parts of wollastonite, 10-35 parts of high-temperature frit, 20-30 parts of matte transparent frit and 10-30 parts of low-temperature transparent frit. The matting temperature of the protective glaze is adjusted by adding the calcined soil, the firing temperature is reduced and the firing time is shortened by adding the wollastonite, and meanwhile, the high-temperature frit, the matte transparent frit and the low-temperature transparent frit are introduced in a high proportion, so that the melting firing temperature of the glaze is expanded, the effect deviation of the glaze under different firing systems is small, and the service life of the glaze is prolonged. And the color development stability of the ink-jet ink under different conditions is ensured. The color-stabilizing protective glaze provided by the invention not only can play a role in protecting a decorative pattern layer and prolonging the service life, but also can stabilize the natural color of decorative ink, and the color of a decorative pattern is not influenced by the change of using process parameters, so that the color-stabilizing protective glaze is beneficial to repeated production on line.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +2

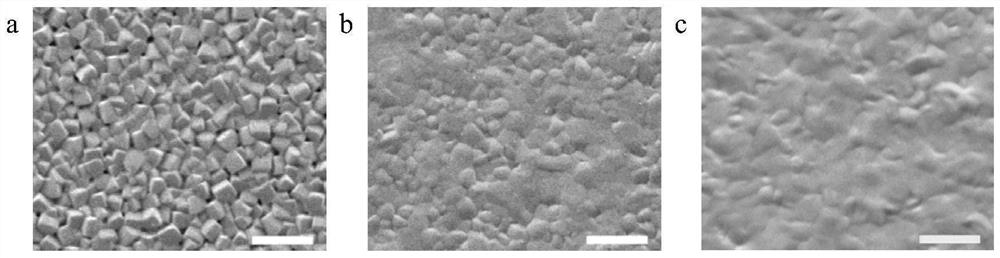

Microcrystalline organic semiconductor film, organic semiconductor transistor, and method for producing organic semiconductor transistor

ActiveCN109791983ASuppression of Performance BiasReduce power consumptionTransistorOrganic chemistryOrganic semiconductorSemiconductor

Owner:FUJIFILM CORP

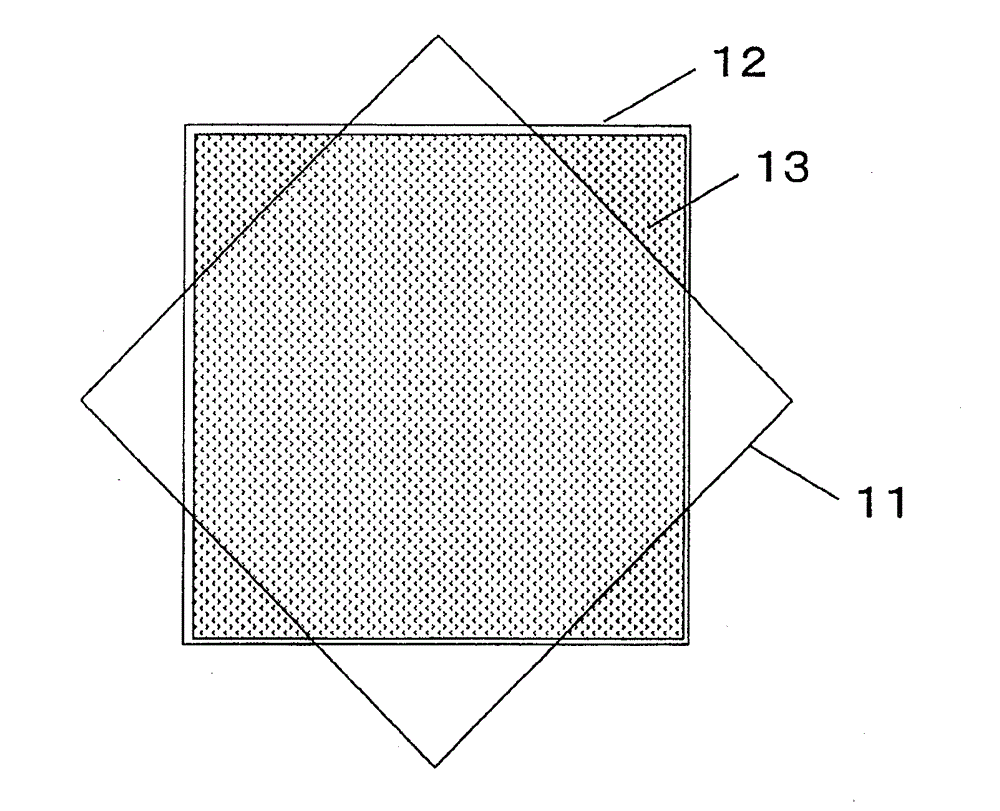

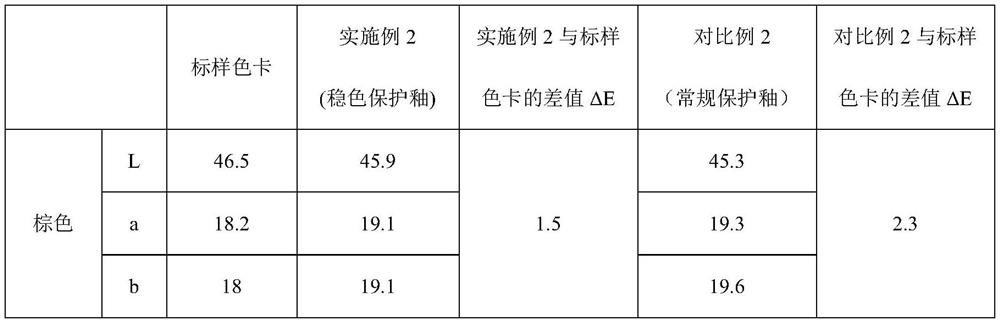

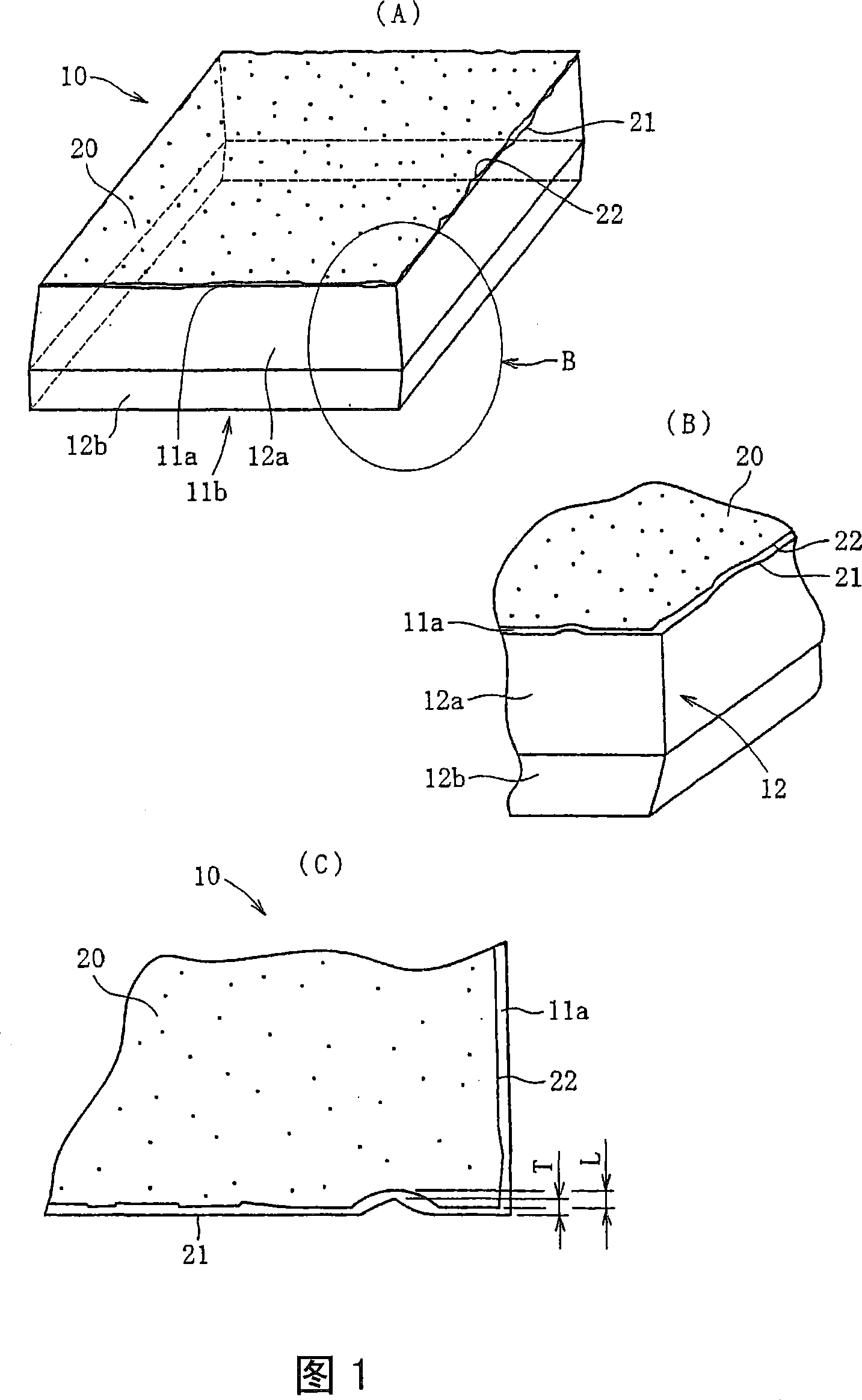

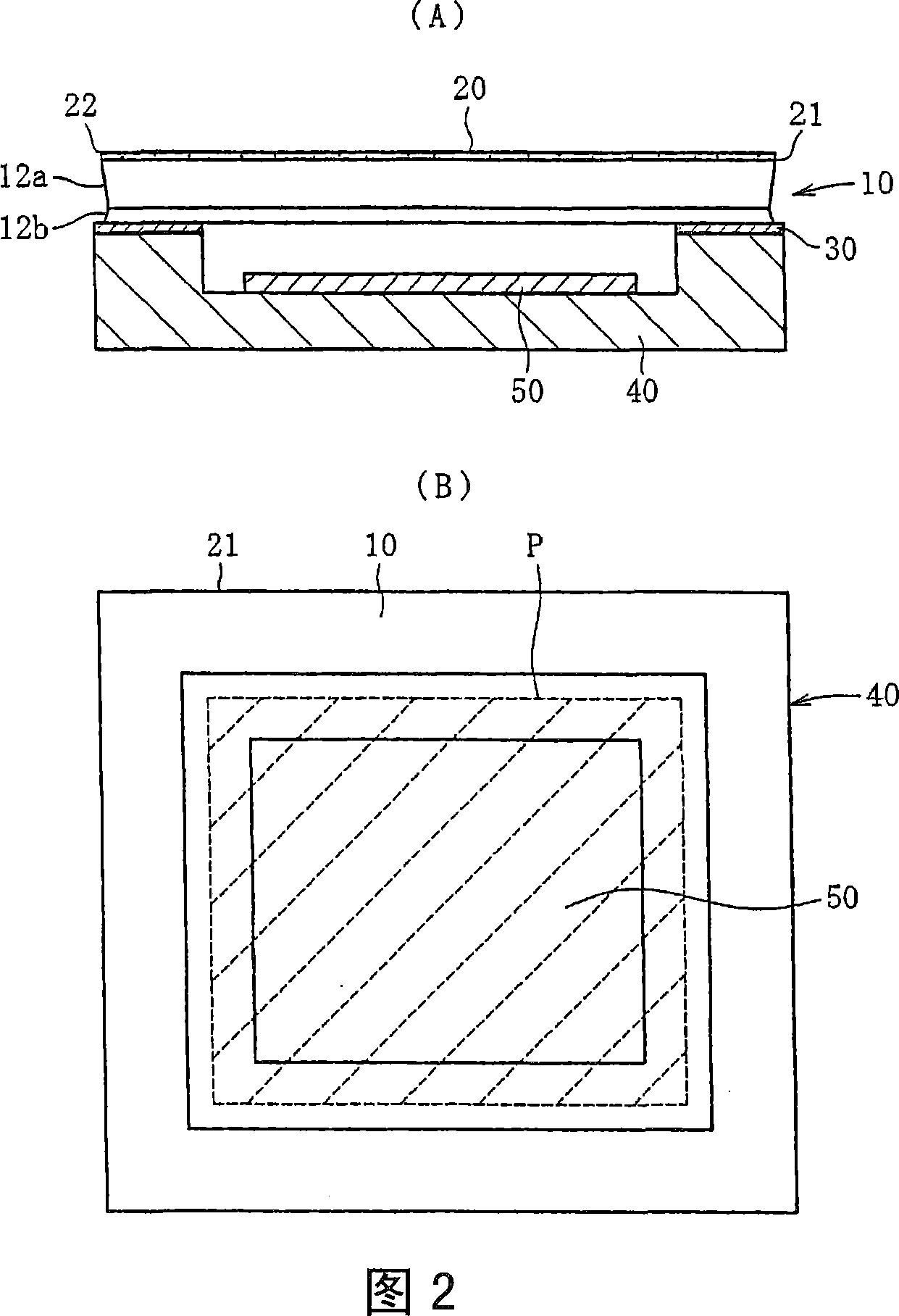

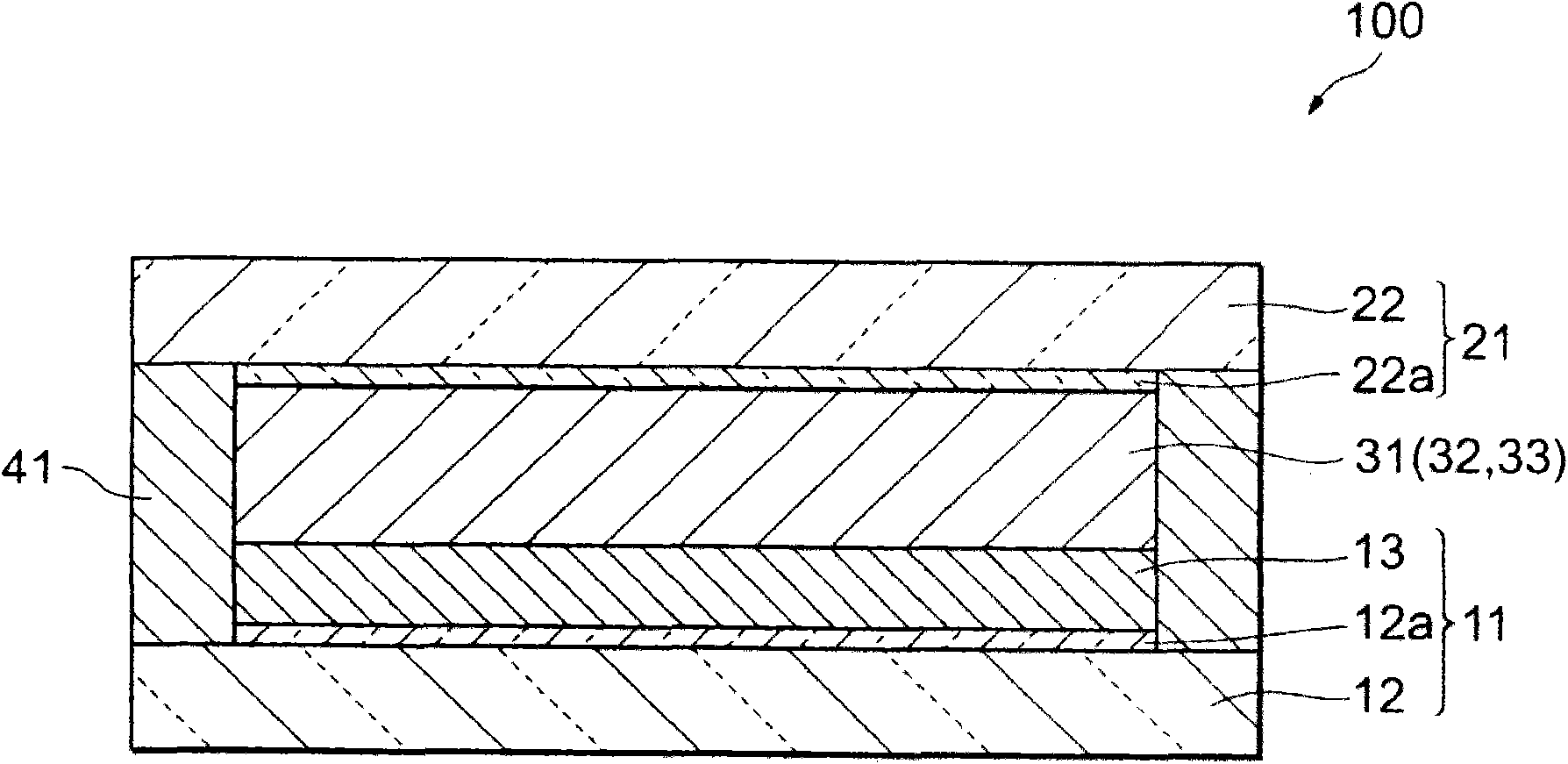

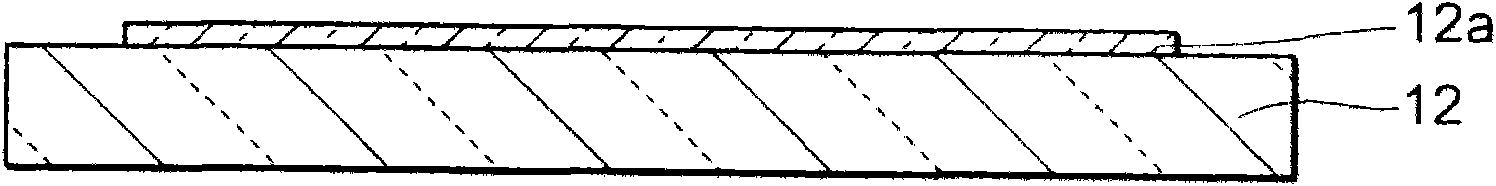

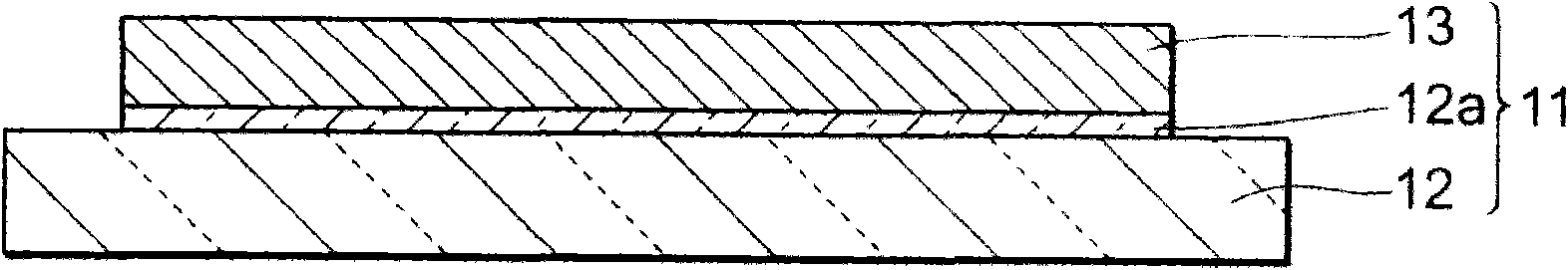

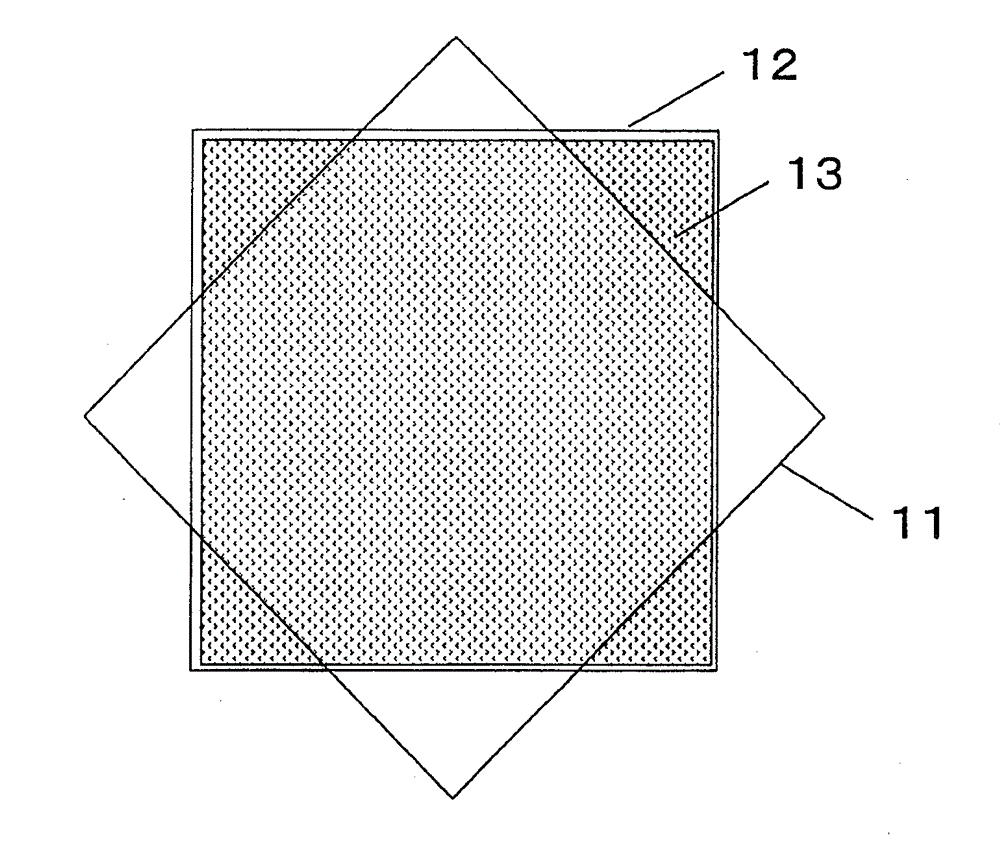

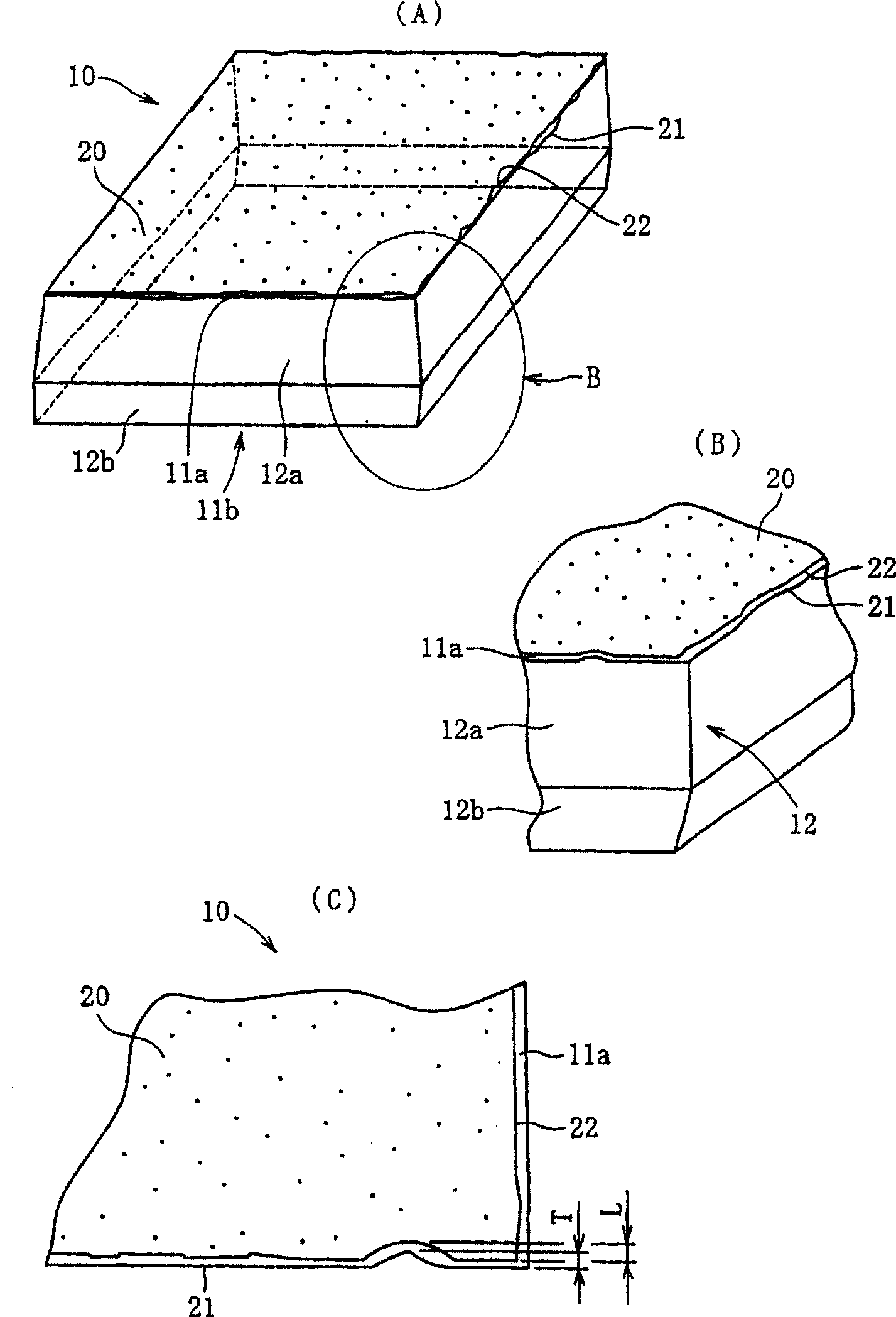

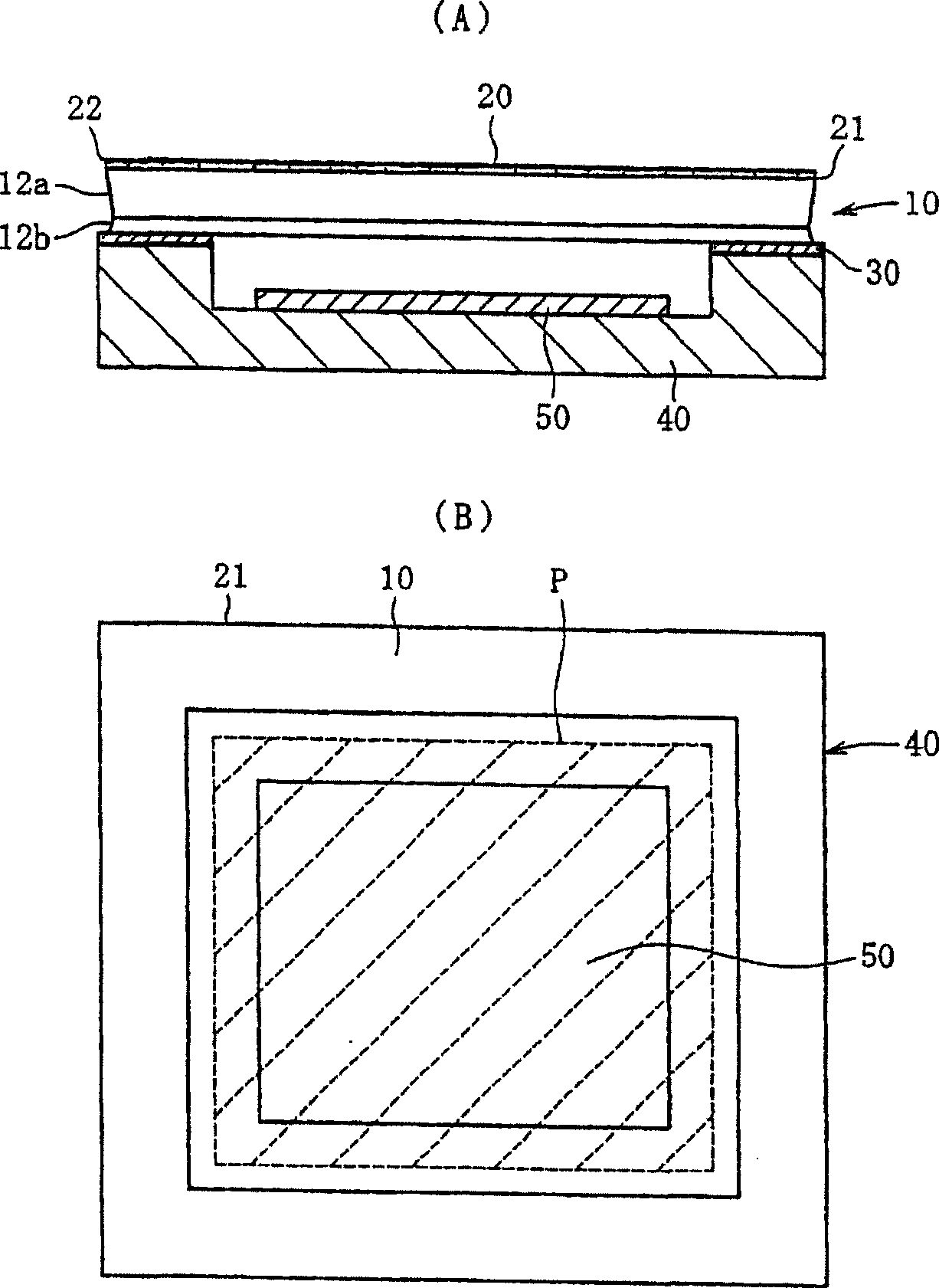

Cover glass for solid imaging device, and its manufacturing method

ActiveCN1993830ANot easy to peel offIncrease credibilitySolid-state devicesSemiconductor devicesFlat glassHeat resistance

Cover glass (10) for solid image pickup device comprising a flat glass plate made of an inorganic oxide glass and, superimposed on the front and back, viewed in the direction of plate thickness, thereof, first translucent plane (11a) and second translucent plane (11b), wherein the first translucent plane (11a) is provided with thin film (20), and wherein an unevenness is provided at extreme edge (22) of the thin film (20) positioned at an outer edge on the first translucent plane (11a) of the flat glass plate, the unevenness having projection dimension (L) ranging from 0.5 to 50 m, the projection dimension (L) defined as extending from, on a plane parallel to the first translucent plane (11a), the most recessed position to the most protrudent position. Such a cover glass is produced through a process comprising the steps of melting a glass raw material mixture in a heat resistant vessel, molding the thus molten glass into a plate glass, providing the plate glass with a thin film and fracturing the plate glass with the thin film into small glass pieces.

Owner:NIPPON ELECTRIC GLASS CO LTD

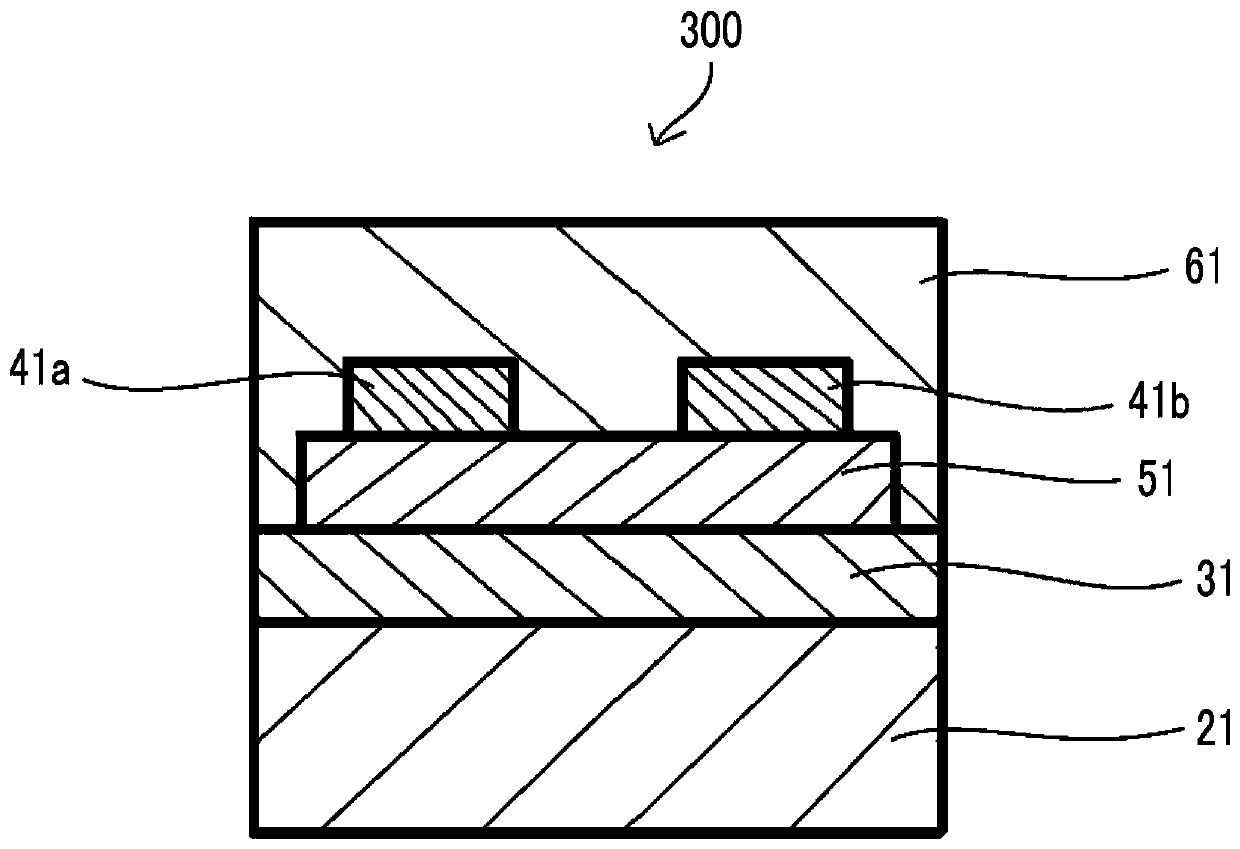

Photoelectric conversion device and manufacturing method of the same

InactiveCN101853890AImprove photoelectric conversion efficiencyPerformance deviation is smallElectrolytic capacitorsFinal product manufactureEngineeringPhotoelectric conversion

The invention provides a photoelectric conversion device that has excellent photoelectric conversion efficiency and enhanced reliability without wide variations in performance. A manufacturing method of a photoelectric conversion device that includes a working electrode having a dye-supported metal oxide layer, a counter electrode disposed so as to face the working electrode, and an electrolyte layer enclosed between the working electrode and the counter electrode, includes: a step of preparing an electrolyte sheet in which an electrolyte is retained by a reticulated support member; and a step of enclosing the electrolyte sheet between the working electrode and the counter electrode.

Owner:TDK CORPARATION

Inorganic material vacuum evaporation equipment

ActiveCN103757599BImproved precision of vacuum depositionImprove qualityVacuum evaporation coatingSputtering coatingAutomatic controlControl system

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

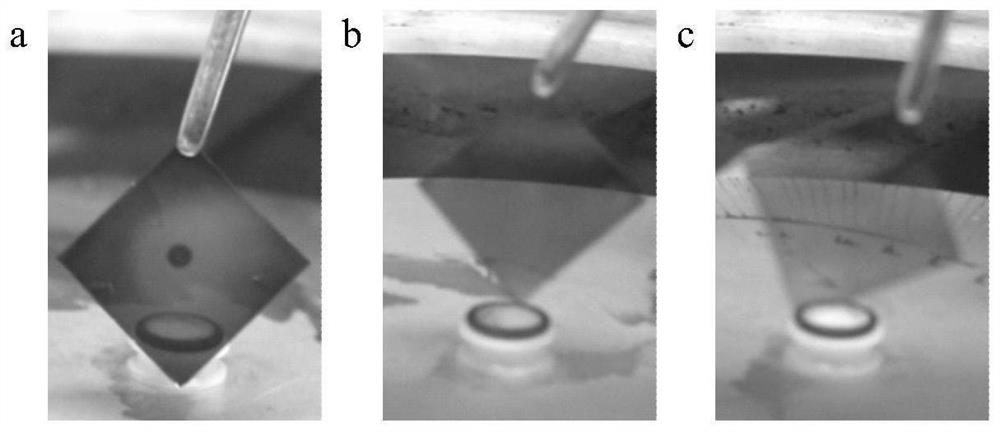

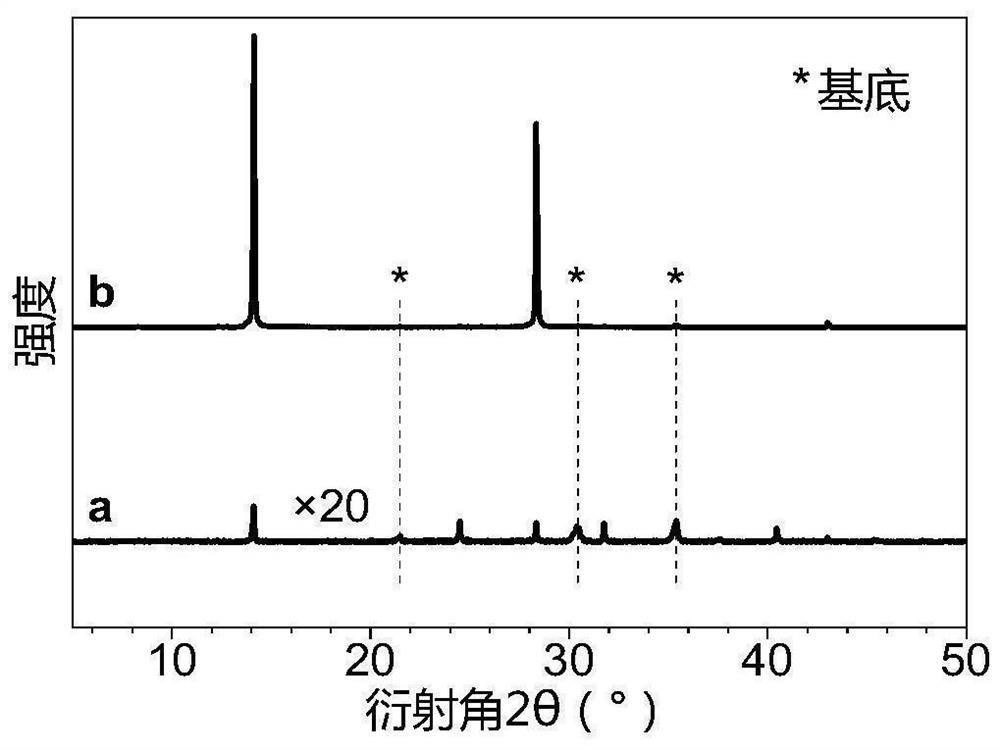

Preparation method and application of improved tin-based perovskite thin film

PendingCN113991018ASlow crystallization rateHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingThioketoneElectrical battery

The invention discloses a preparation method and application of an improved tin-based perovskite thin film. The preparation method comprises the following steps: preparing a hole transport layer on cleaned conductive glass; preparing a precursor solution containing a cyclic thioketone compound and a tin-based perovskite material; spin-coating the precursor solution, generating a perovskite thin film in one step by using an anti-solvent, and carrying out annealing to obtain the tin-based perovskite thin film. The cyclic thioketone compound is introduced into the coating precursor solution and can effectively coordinate with tin ions, so that the crystallization rate of a tin-based perovskite material is greatly slowed down, and the smooth and compact tin-based perovskite thin film with passivated surface defects is obtained; according to the tin-based perovskite solar cell prepared from the thin film, the photoelectric conversion performance, the stability and the process repeatability of the tin-based perovskite solar cell are remarkably improved, and the maximum photoelectric conversion efficiency exceeds 12%.

Owner:SHANGHAI TECH UNIV

Water absorbent sheet

ActiveCN102802580BImprove performanceManufacturing can be efficientAbsorbent padsBandagesEngineeringNonwoven fabric

A water-absorbent sheet comprising a structure in which an absorbent layer containing a water-absorbent resin and an adhesive is sandwiched with a hydrophilic nonwoven fabric, wherein the water-absorbent sheet has a structure in which the absorbent layer is fractionated into a primary absorbent layer and a secondary absorbent layer with a substrate layer formed by laminating two or more layers of a substrate having breathability adhered together with an adhesive, wherein the substrate layer satisfies the following requirements (1) and (2): (1) the substrate layer having a basis weight of 25 g / m 2 or more; and (2) the substrates having breathability being adhered therebetween with an adhesive in an amount of from 0.1 to 50 g / m 2 . The water-absorbent sheet of the present invention exhibits some excellent effects that the water-absorbent sheet is capable of accomplishing thinning and avoidance of gel blocking phenomenon and liquid leakage, while obtaining basic properties as a water-absorbent sheet at a high level, even for a water-absorbent sheet containing a very small amount of pulps.

Owner:SUMITOMO SEIKA CHEM CO LTD

Cover glass for solid imaging device, and its manufacturing method

ActiveCN100470814CNot easy to peel offIncrease credibilitySolid-state devicesSemiconductor devicesFlat glassHeat resistance

Cover glass (10) for solid image pickup device comprising a flat glass plate made of an inorganic oxide glass and, superimposed on the front and back, viewed in the direction of plate thickness, thereof, first translucent plane (11a) and second translucent plane (11b), wherein the first translucent plane (11a) is provided with thin film (20), and wherein an unevenness is provided at extreme edge (22) of the thin film (20) positioned at an outer edge on the first translucent plane (11a) of the flat glass plate, the unevenness having projection dimension (L) ranging from 0.5 to 50 m, the projection dimension (L) defined as extending from, on a plane parallel to the first translucent plane (11a), the most recessed position to the most protrudent position. Such a cover glass is produced through a process comprising the steps of melting a glass raw material mixture in a heat resistant vessel, molding the thus molten glass into a plate glass, providing the plate glass with a thin film and fracturing the plate glass with the thin film into small glass pieces.

Owner:NIPPON ELECTRIC GLASS CO LTD

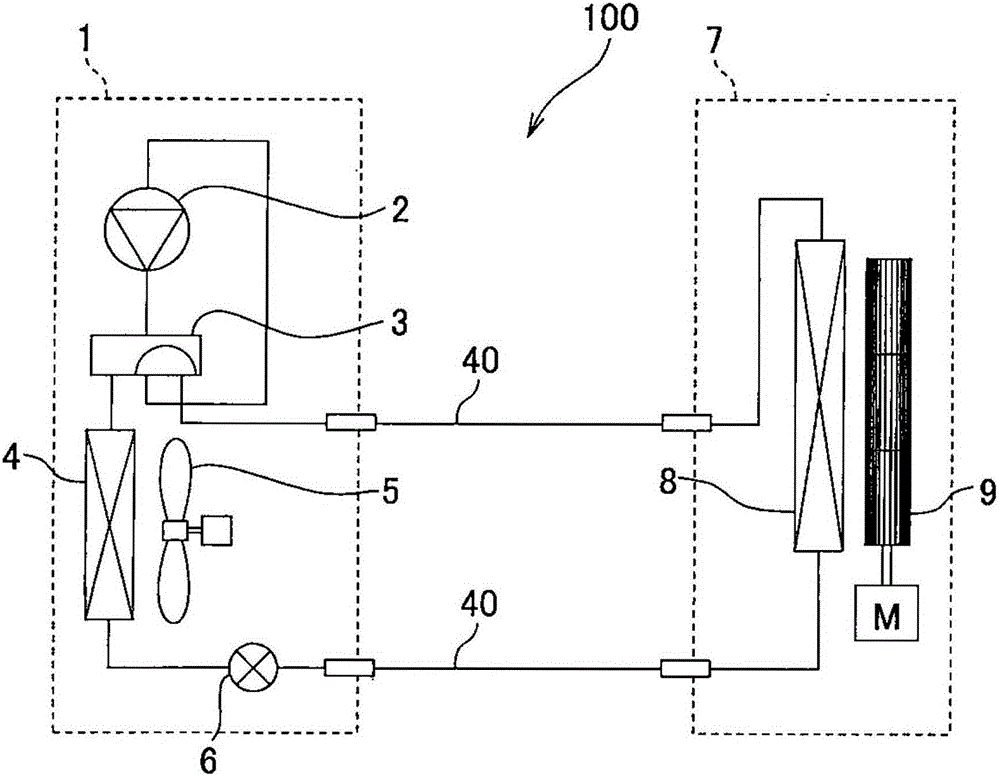

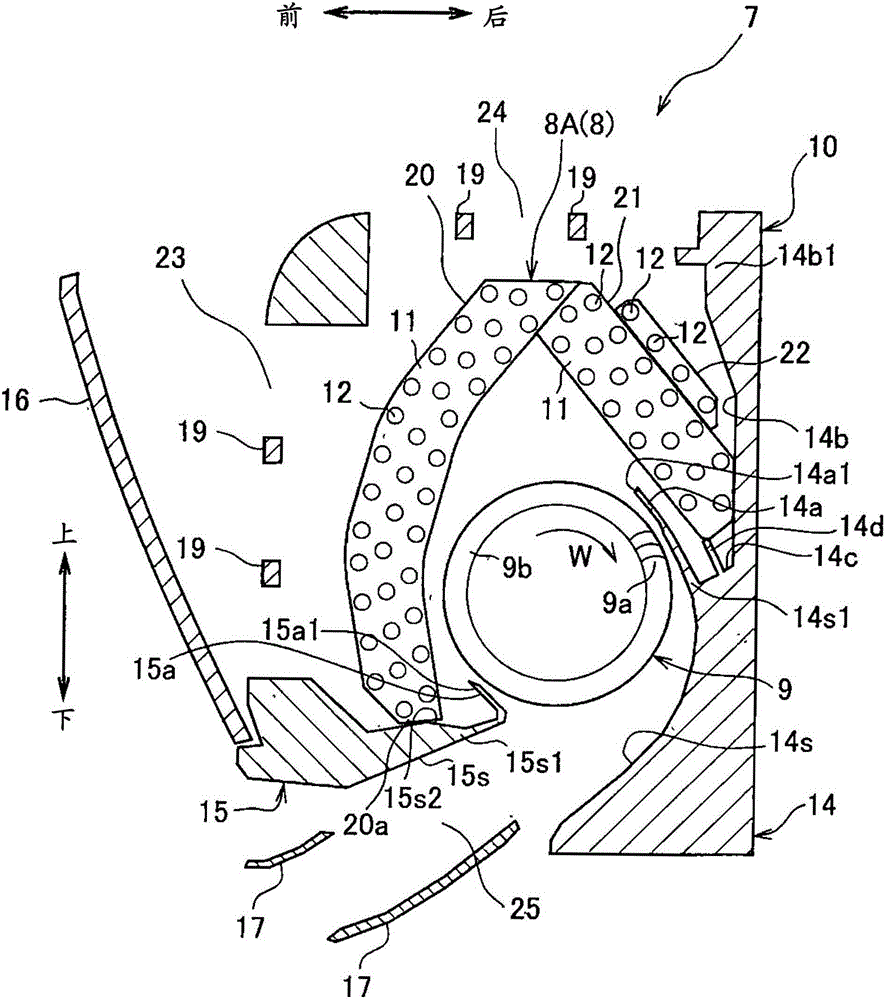

air conditioner

InactiveCN103574774BPerformance deviation is smallUneven distribution of wind speedLighting and heating apparatusNoise suppressionShortest distanceEngineering

The invention provides an air conditioner which can reduce imbalance of wind speed distribution in a heat exchanger, avoid reduction of heat exchange performance or increase of noise and has smaller performance deviation. The distance from the lower edge part (22a1) of a back side auxiliary heat exchanger (22) along the orthorhombic direction relative to the arrangement of a heat transfer pipe (12) to a flow path wall surface (14b) is set to be L1, a shortest distance between the back side auxiliary heat exchanger (22) and the flow path wall surface (14b) is set to be L2, and the distance between a back side main heat transfer device (21) and the front end (14a1) of a back nose part (14a) is set to be L3, meeting 0.4< (L2 / L1)<0.6, and 0.55<(L3 / L1).

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

A kind of interface agent for high-speed railway ballastless track polyurethane caulking material and preparation method thereof

The invention relates to an interface agent for a high-speed railway ballastless track polyurethane caulking material and a preparation method thereof. The interface agent comprises the following raw materials in parts by weight: 100 parts of isocyanate prepolymers, 80-120 parts of solvents, 0.1-0.5 part of catalysts, 0.5-2.5 parts of water removal agents and 0.5-2.5 parts of anti-aging agents. The preparation method comprises the following two steps of: (1) slowly dripping polyhydric alcohol to isocyanate at the temperature of (85+ / -5) DEG C, then increasing the temperature to (90+ / -5) DEG C for continuous reaction, when the content of NCO groups is 14%-16%, adding organic silicon coupling agents, and reacting till the content of the NCO groups is 10%-12% so as to obtain a prepolymer; (2) adding the solvents, the catalysts, the water removal agents and the anti-aging agents to the prepolymer, uniformly stirring, and debubbling in vacuum (at vacuum degree less than or equal to -0.09MPa) to obtain the interface agent for the polyurethane caulking material. The interface agent disclosed by the invention has the characteristics of low viscosity, good impregnation property, high toughness, excellent hydrolysis-resistant property and alkali-resistant property, excellent adhesive property with concrete and the polyurethane caulking material, and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Substrate pretreatment equipment

ActiveCN103762310BRealize automatic regulationImprove preprocessing qualitySolid-state devicesVacuum evaporation coatingAutomatic train controlAutomatic control

The invention provides a substrate preprocessing equipment, which includes a substrate preprocessing chamber and an automatic control system. In the substrate pretreatment equipment provided by the present invention, each module such as the vacuum system control module, gas flow control module, power control module, substrate platform control module, and transfer and handover module collects various parameter signals in the substrate pretreatment room, And send each parameter signal to the control switchboard. The control switchboard processes the received parameter signals according to the preset parameters to obtain a feedback signal, and feeds the feedback signal back to the corresponding control module. The corresponding The control module then automatically regulates corresponding components, such as vacuum equipment, air inlet devices, substrate platforms, etc., based on corresponding feedback signals to achieve automatic control of substrate preprocessing, which not only saves a lot of manpower, but more importantly, can Realize effective monitoring of the substrate pretreatment process, thereby improving the accuracy, quality and speed of substrate pretreatment.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

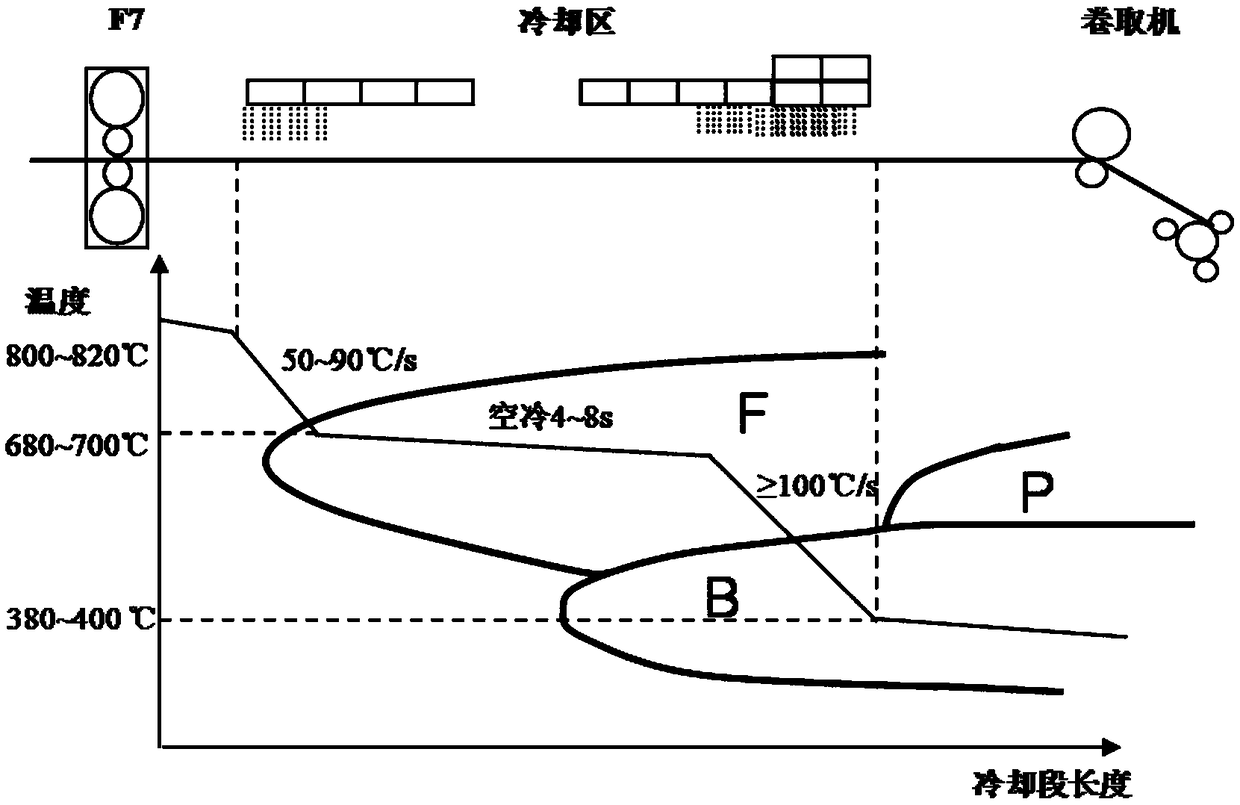

600mpa grade hot-rolled trip steel based on csp process and its manufacturing method

ActiveCN107475627BGood strength and plasticity matchingReduce the chance of residuesMetal rolling arrangementsThin slabChemical element

The invention discloses CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel. The CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the chemical element ingredients of, in percentage by weight, 0.14-0.16% of carbon, 0.90-1.20% of silicon, 1.20-1.40% of manganese, 0.07-0.10% of phosphorus, less than or equal to 0.005% of sulphur, 0.015-0.060% of acid soluble aluminium and the balance ferrum and inevitable impurities. The fabrication method of the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel comprises the following steps of converter smelting, refined smelting, thin plate billet continuous casting, continuous-casting billet soaking, high-pressure water descaling, controlled rolling, controlled cooling and rolling up. The economic C-Si-Mn-P ingredient design is adopted, a metallographic structure is composed of 50-65% of ferrite, 25-40% of bainite and 5-20% of residual austenite; the yield strength is 390-450 MPa, the strength of extension is 600-680 MPa, and the elongation A80 is 28-35%; and the CSP-procedure-based 600 MPa-grade hot-rolled TRIP steel has good high-plasticity matching.

Owner:武汉钢铁有限公司

800mpa grade hot-rolled trip steel based on csp process and its manufacturing method

ActiveCN107488814BGood strength and plasticity matchingReduce the chance of residuesChemical elementManganese

Owner:武汉钢铁有限公司

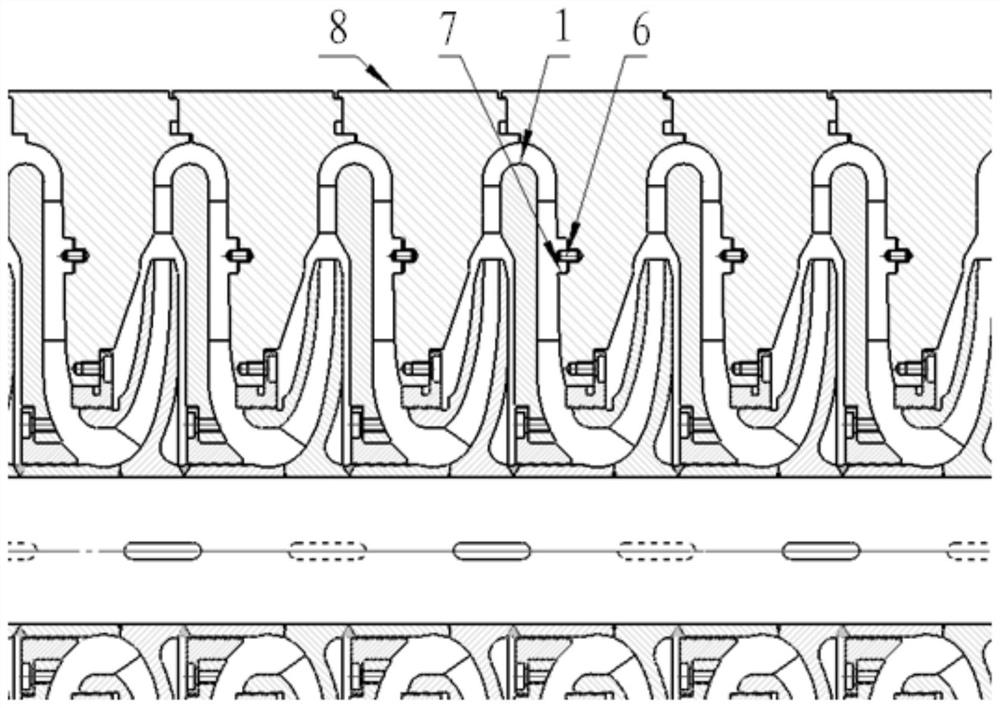

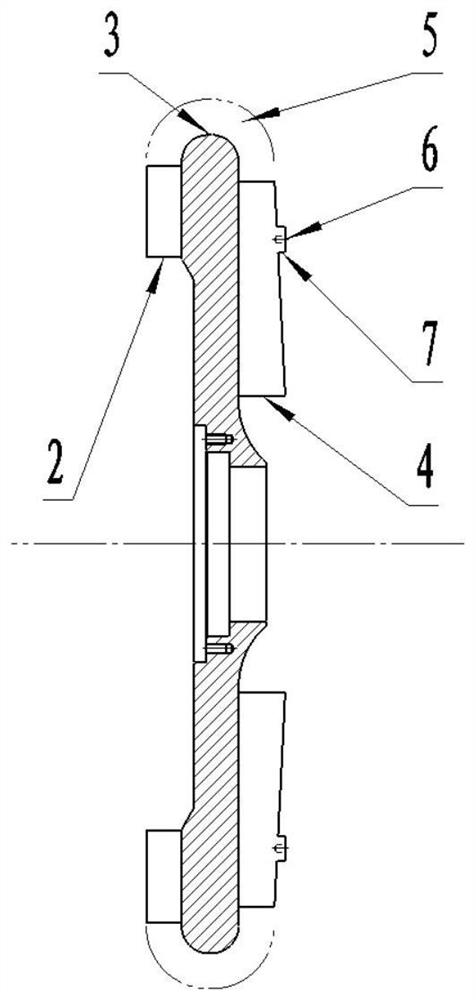

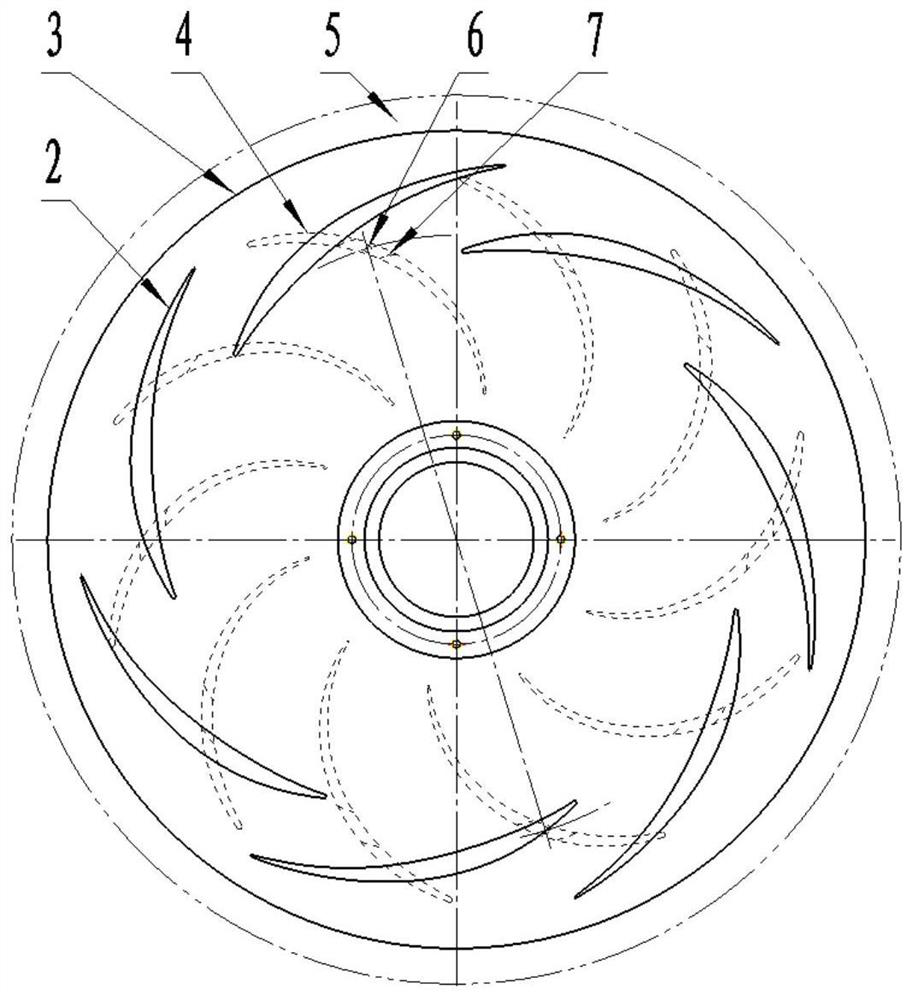

A kind of multistage centrifugal pump guide vane and its processing method

ActiveCN110081024BPerformance deviation is smallGuaranteed performancePump componentsPumpsEngineeringMechanical engineering

The invention provides a guide vane of a multistage centrifugal pump, the guide vane is a curved guide vane, and the curved guide vane is combined with the middle section to form a flow passage for fluid passing between the two. The curved guide vane includes a forward guide vane, a rear cover plate, an anti guide vane, and a vaneless bend formed by flowing from the forward guide vane to the reverse guide vane. The forward guide vane and the reverse guide vane are respectively arranged on the The front and back of the rear cover form an integral body with the rear cover, anti-rotation pin holes are arranged on the anti-rotation vane blades in the axial direction, and anti-rotation pins are arranged in the anti-rotation pin holes to prevent the rotor from driving the guide vanes to rotate . The invention also provides a processing method for guide vanes of multistage centrifugal pumps. The invention provides a guide vane of a multistage centrifugal pump and a processing method thereof, which can reduce the deviation of the hydraulic performance of the whole pump and can precisely control the hydraulic performance.

Owner:SHENYANG BLOWER WORKS GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com