A kind of interface agent for high-speed railway ballastless track polyurethane caulking material and preparation method thereof

A ballastless track and caulking material technology, applied in the field of building materials, can solve the problems of poor bonding strength, high material viscosity, falling off, etc., and achieve the effects of small deviation in material properties, high bonding strength, and strong wetting ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

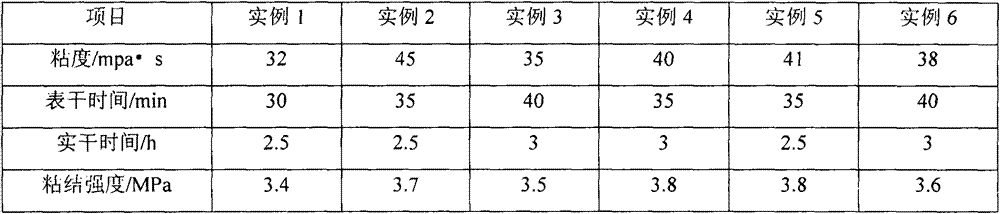

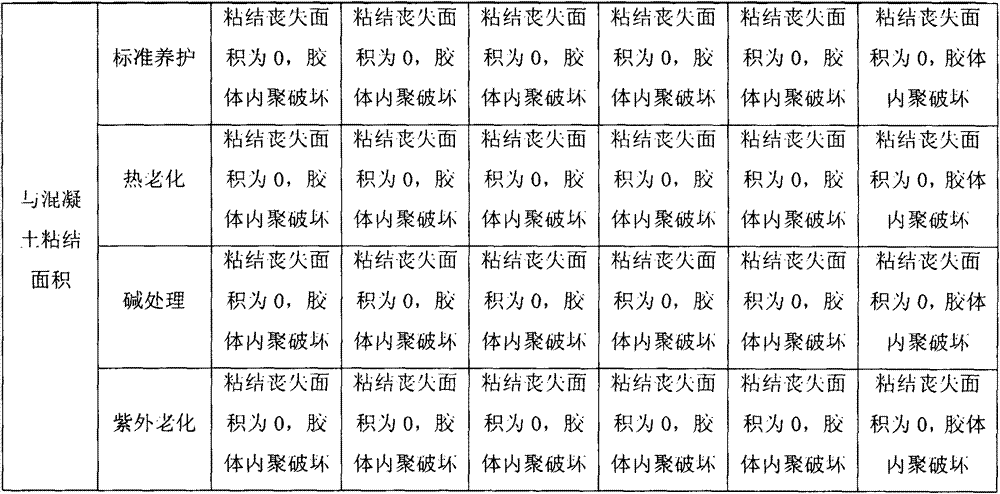

Examples

Embodiment 1

[0032] A high-speed railway ballastless track polyurethane caulking material interface agent and preparation method thereof, comprising the following steps:

[0033] Dehydration treatment: dehydrate the fatty acid dimer diol, polyether ester diol and tetrahydrofuran copolyether diol in vacuum (vacuum degree ≤ -0.09MPa) at 120°C to water content ≤ 0.05%, and cool down and seal for storage.

[0034] Preparation of prepolymer: put 30 parts of TDI trimer into the reaction kettle, heat to 85°C, start to drop 35 parts of fatty acid dimer diol, 15 parts of polyether ester diol and 15 parts of tetrahydrofuran copolyether diol After 1.5 hours, the dropwise addition was completed, and the temperature was raised to 90°C. After reacting for 0.5 hours, the NCO group content was tested every 0.5 hours until the value was 16%, and N-β (aminoethyl)- 5 parts of γ-aminopropyltrioxymethylsilane, after continuing to react for 1 hour, test the NCO group content every 0.5 hours until the value is 1...

Embodiment 2

[0037] A high-speed railway ballastless track polyurethane caulking material interface agent and preparation method thereof, comprising the following steps:

[0038] Dehydration treatment: Dehydrate fatty acid dimer diol, polyether ester diol and hydrogenated hydroxyl-terminated polybutadiene at 120°C in vacuum (vacuum degree ≤ -0.09MPa) to water content ≤ 0.05%, cool down and seal for storage.

[0039] Preparation of prepolymer: Put 25 parts of MDI-100 into the reaction kettle, heat to 80°C, and start to drop 25 parts of fatty acid dimer diol, 20 parts of polyether ester diol and 20 parts of tetrahydrofuran copolyether diol in sequence After 2 hours, the dropwise addition was completed, and the temperature was raised to 85°C. After reacting for 0.5 hours, the NCO group content was tested every 0.5 hours until the value was 14%, and N-β (aminoethyl)-γ- 10 parts of aminopropyltrioxyethylsilane, after continuing to react for 1 hour, test the NCO group content every 0.5 hours unt...

Embodiment 3

[0042] A high-speed railway ballastless track polyurethane caulking material interface agent and preparation method thereof, comprising the following steps:

[0043] Dehydration treatment: Dehydrate fatty acid dimer diol, polyether ester diol, tetrahydrofuran copolyether diol and hydrogenated hydroxyl-terminated polybutadiene at 120°C in vacuum (vacuum degree ≤ -0.09MPa) to water content ≤ 0.05 %, cooled and sealed for storage.

[0044] Preparation of prepolymer: Put 10 parts of MDI-100 into the reaction kettle, heat to 80°C, start to add 10 parts of polyether ester diol and 10 parts of tetrahydrofuran copolyether diol dropwise in sequence, and after 2 hours, the dropwise addition is completed. Rising to 85°C, after reacting for 0.5h, test the NCO group content every 0.5h, until the value is 15%, add N-β(aminoethyl)-γ-aminopropyltrioxyethylsilane 1 After continuing to react for 1 hour, test the NCO group content every 0.5 hours until the value is 11%, and then cool down and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com