Method and device special for improving performance of sintered Nd-Fe-B magnets

A special device, neodymium iron boron technology, applied in the direction of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of high oxygen and nitrogen content of magnets, reduced magnet performance, green body damage, etc., to achieve processing accuracy High, reduced machining volume, and reduced magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

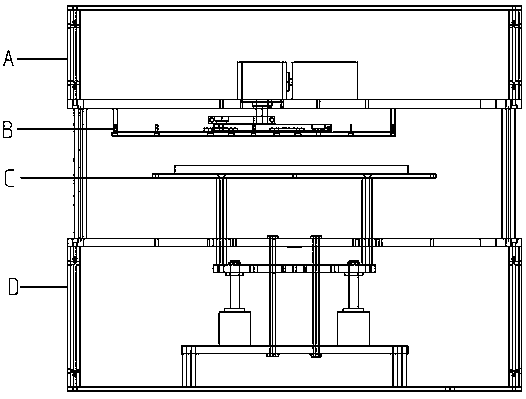

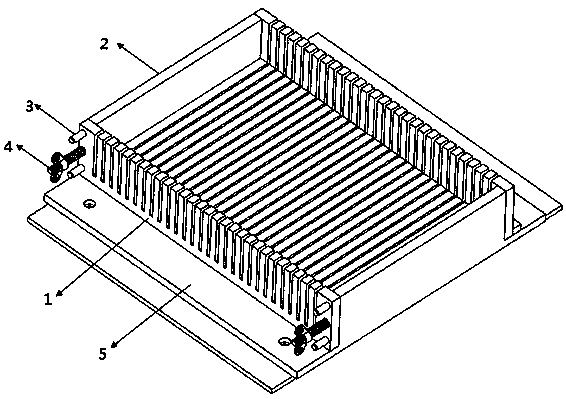

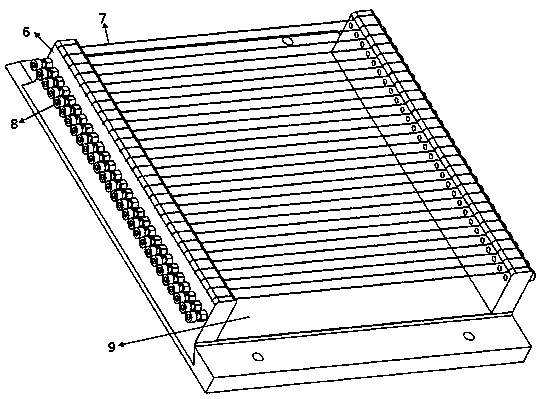

[0030] Example 1, the size of the produced product is: 10.0mm (non-oriented surface)*6.5mm (oriented surface)*8.0mm (pressed surface), and the non-oriented surface is processed into a finished product corresponding to the green state using the special device of the present invention The size, non-oriented face and pressed face of the sinter-aged blank are machined. Specific steps are as follows:

[0031]The magnetic powder with an average particle size X50=4.0μm is pressed into a green body with a press under the condition of a 2.0T magnetic field, and then isostatically pressed at 150Mpa. The density after isostatic pressing is about 4.5g / cm3, and the green body size is 79.3mm ( Non-oriented surface)*38.2mm (oriented surface)*44.8mm (pressed surface), the unit weight of the green body is 610.7g; the magnetic powder composition is PrNd 31.10wt.%, Dy1.50wt.%, B0.95wt.%, Co 1.05 wt .%, Al 0.51wt.%, Cu 0.15wt.%, Ga 0.12wt.%, Ti 0.11wt.%, the balance is Fe and unavoidable impurit...

Embodiment 2

[0034] Example 2, the product size is: 10.0mm (non-oriented surface) * 6.5mm (oriented surface) * 8.0mm (pressed surface), in the green state, the orientation surface and the non-oriented surface are processed into finished products with special equipment shape and size. Specific steps are as follows:

[0035] The magnetic powder with an average particle size X50=4.0μm is pressed into a green body with a press under the condition of a 2.0T magnetic field, and then isostatically pressed at 400Mpa. The density after isostatic pressing is about 5.5g / cm3, and the green body size is 75.7mm ( Non-oriented surface)*33.9mm (oriented surface)*43.2mm (pressed surface), the unit weight of the green body is 609.7g; the magnetic powder composition is PrNd 31.10wt.%, Dy1.50wt.%, B0.95wt.%, Co 1.05 wt .%, Al 0.51wt.%, Cu 0.15wt.%, Ga 0.12wt.%, Ti 0.11wt.%, the balance is Fe and unavoidable impurity elements; place the green body on the base of the green body fixing tool, Step 1: Select the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com