Patents

Literature

96 results about "Green state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

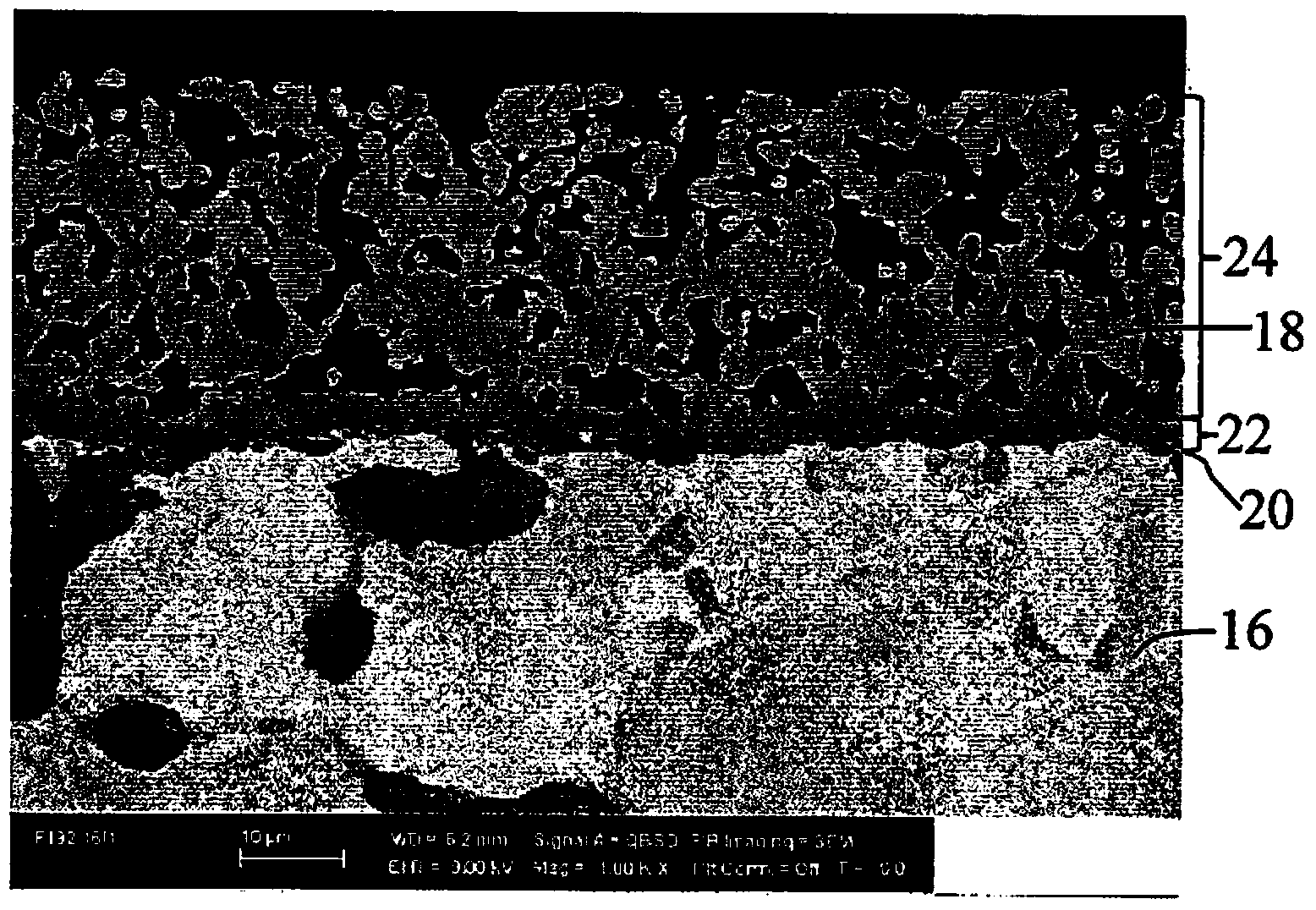

Metal-supported electrochemical cell and method for fabricating same

InactiveUS20120186976A1Short durationReduce the number of stepsCellsFinal product manufactureOptoelectronicsOxygen

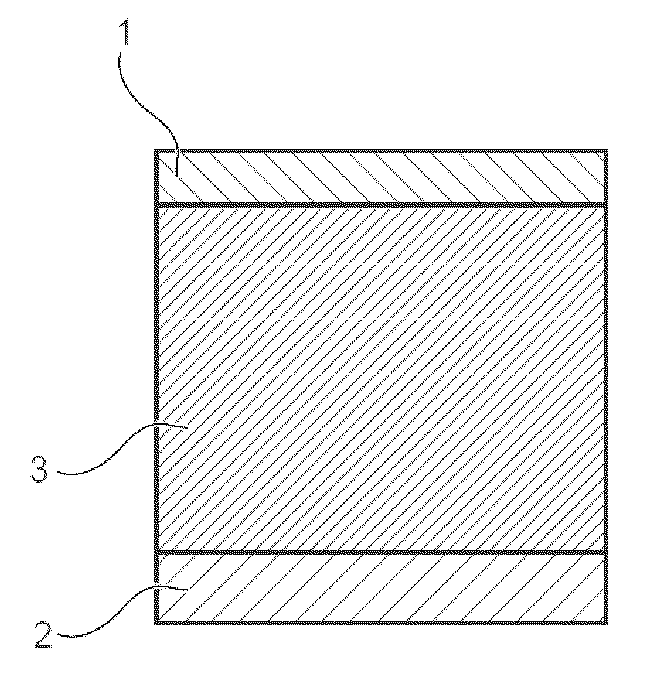

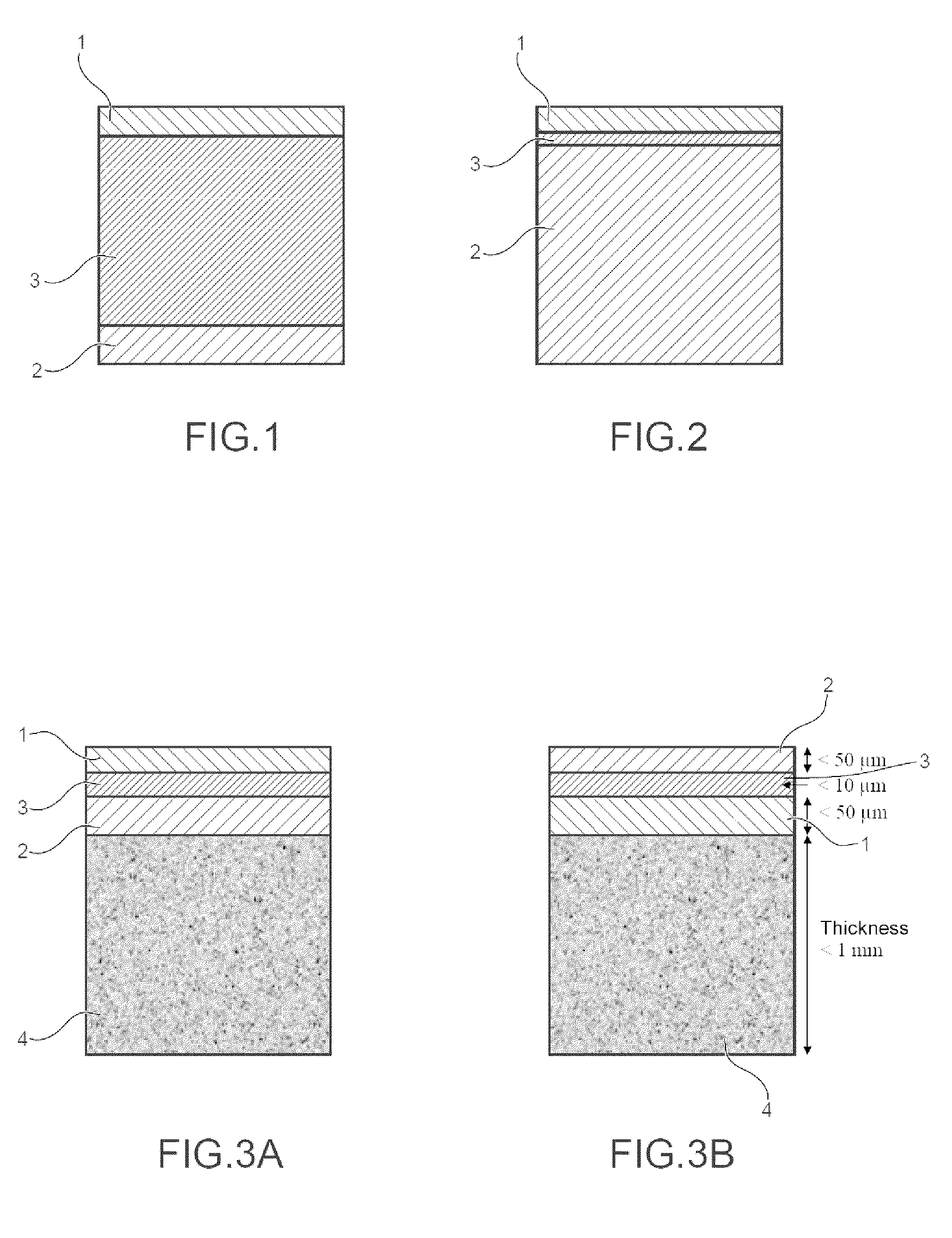

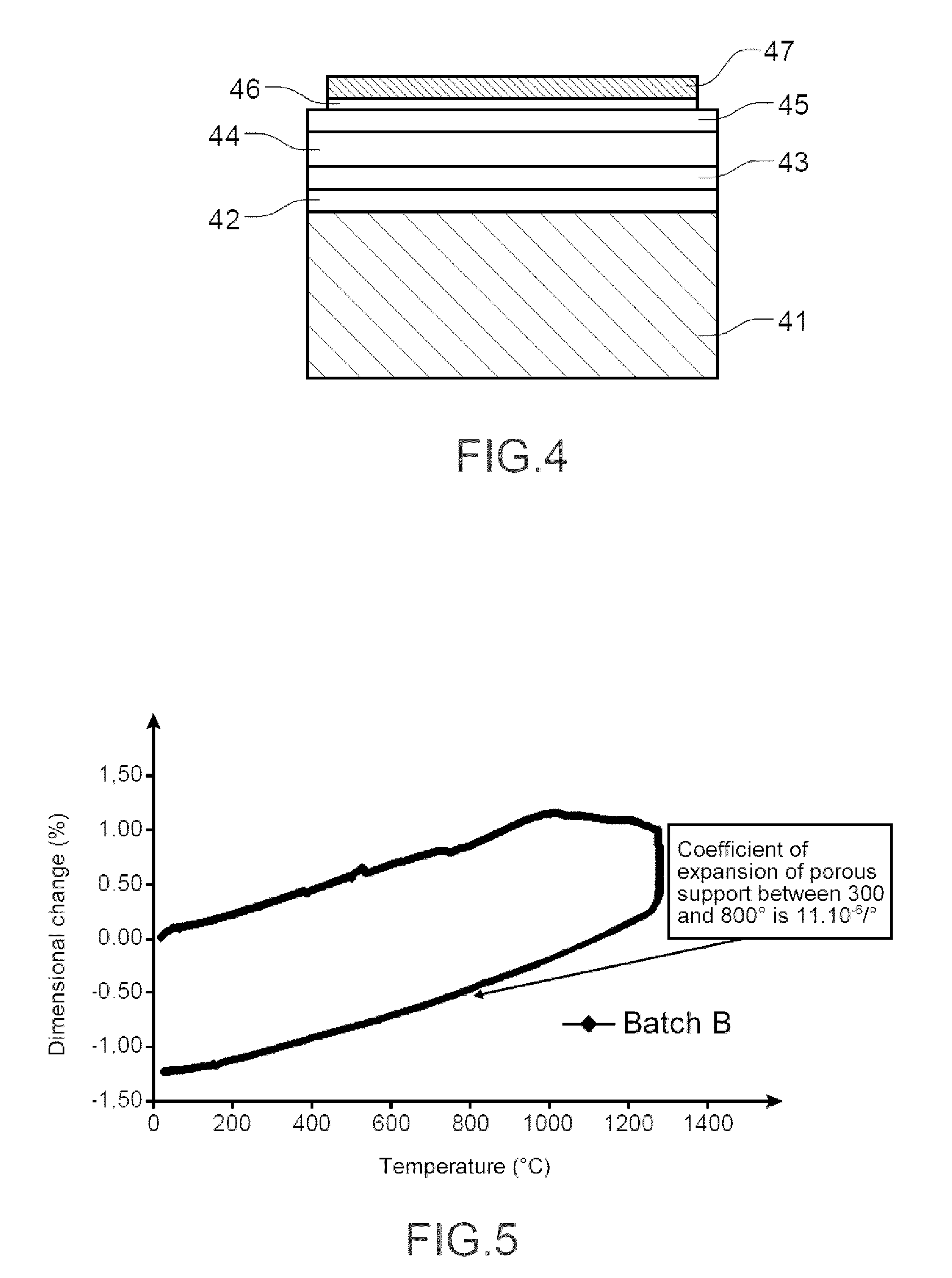

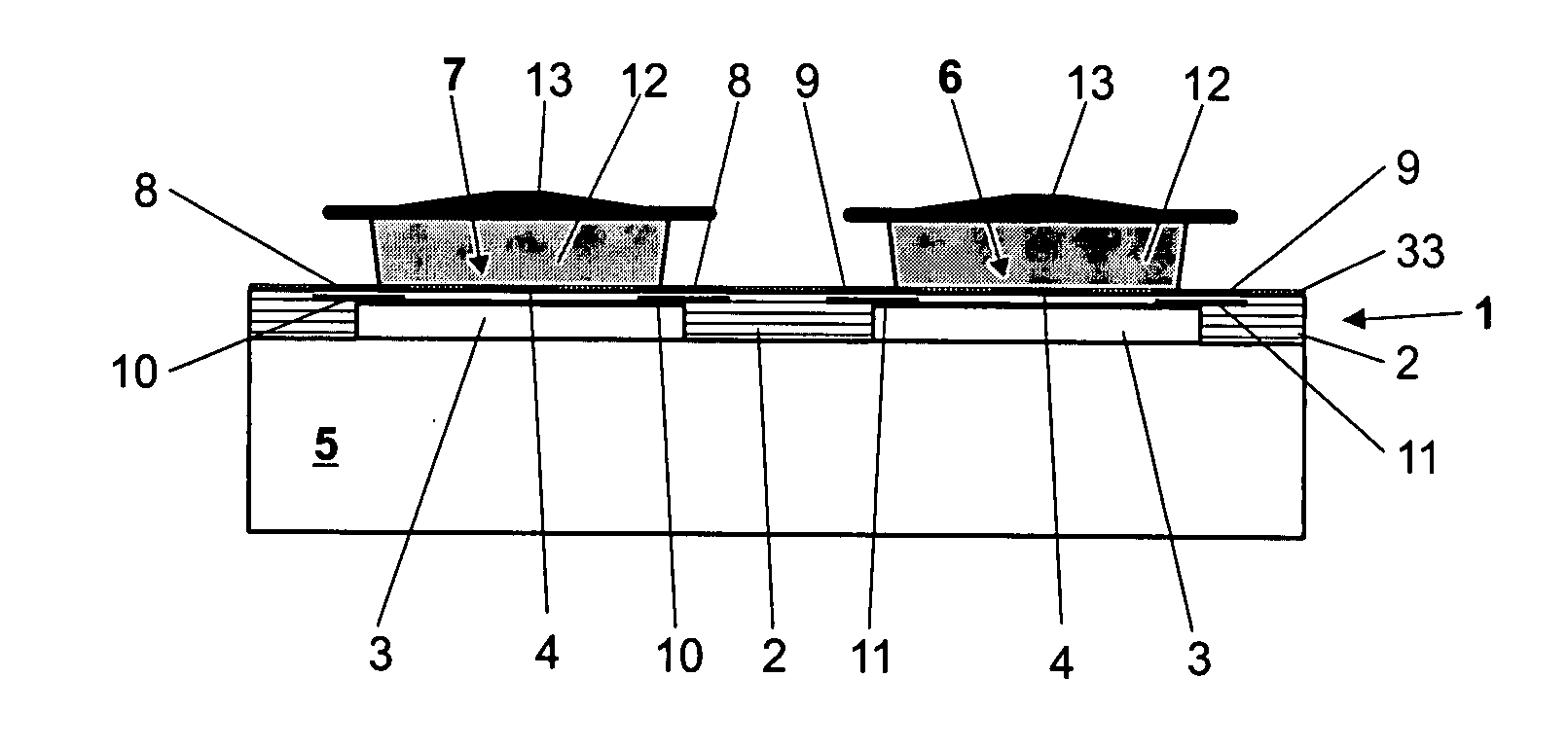

A metal-supported electrochemical cell is provided. The cell may contain a porous metal support comprising a first- and a second-main surfaces, a porous thermomechanical adaptive layer on the second main surface, a porous layer that is a barrier against the diffusion of chromium on the porous thermomechanical adaptive layer, this porous barrier layer being in stabilised zirconia and / or substituted ceria, and in a mixed oxide of spinel structure, a porous hydrogen electrode layer on the porous barrier layer, a dense electrolyte layer on the porous hydrogen electrode layer; a dense or porous reaction barrier layer on the dense electrolyte layer, and a porous oxygen or air electrode layer on the reaction barrier layer. A method for fabricating a metal-supported electrochemical cell is also provided. The method may comprise a step for the simultaneous sintering of the green support and of all the previously deposited layers in the green state.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

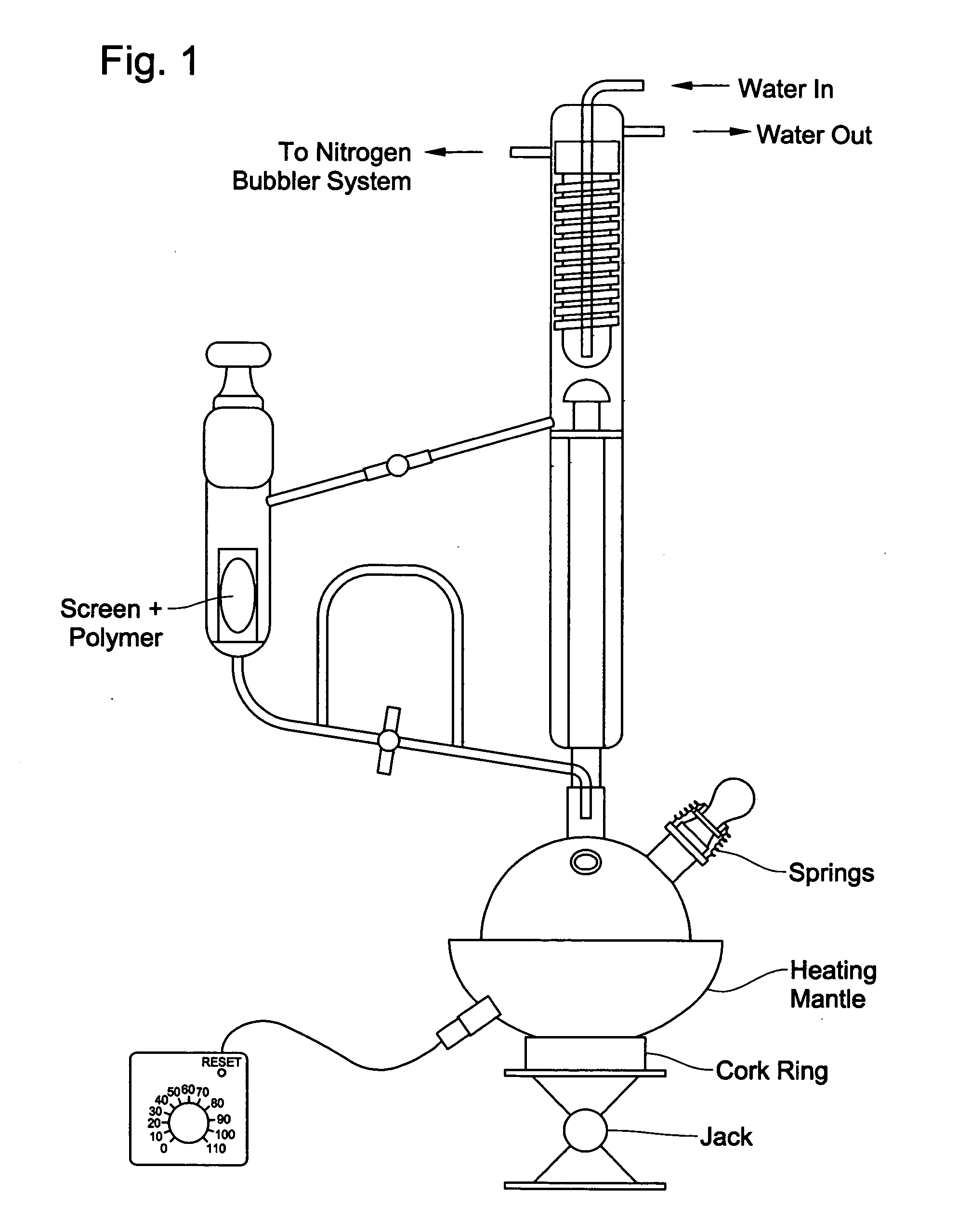

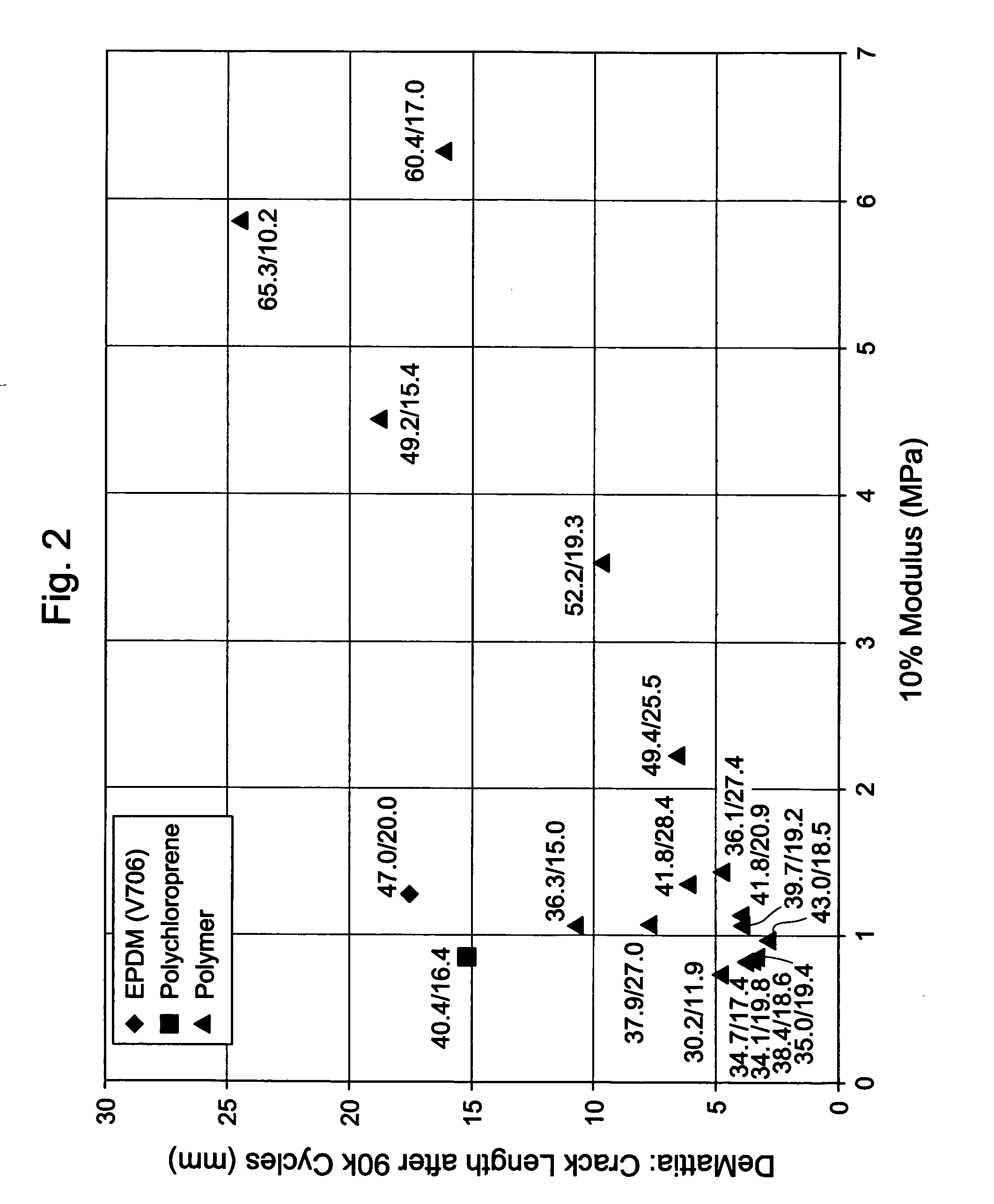

Process for making dynamically-loaded articles comprising propylene-based elastomers, composition for use in such processes, and article made using such processes

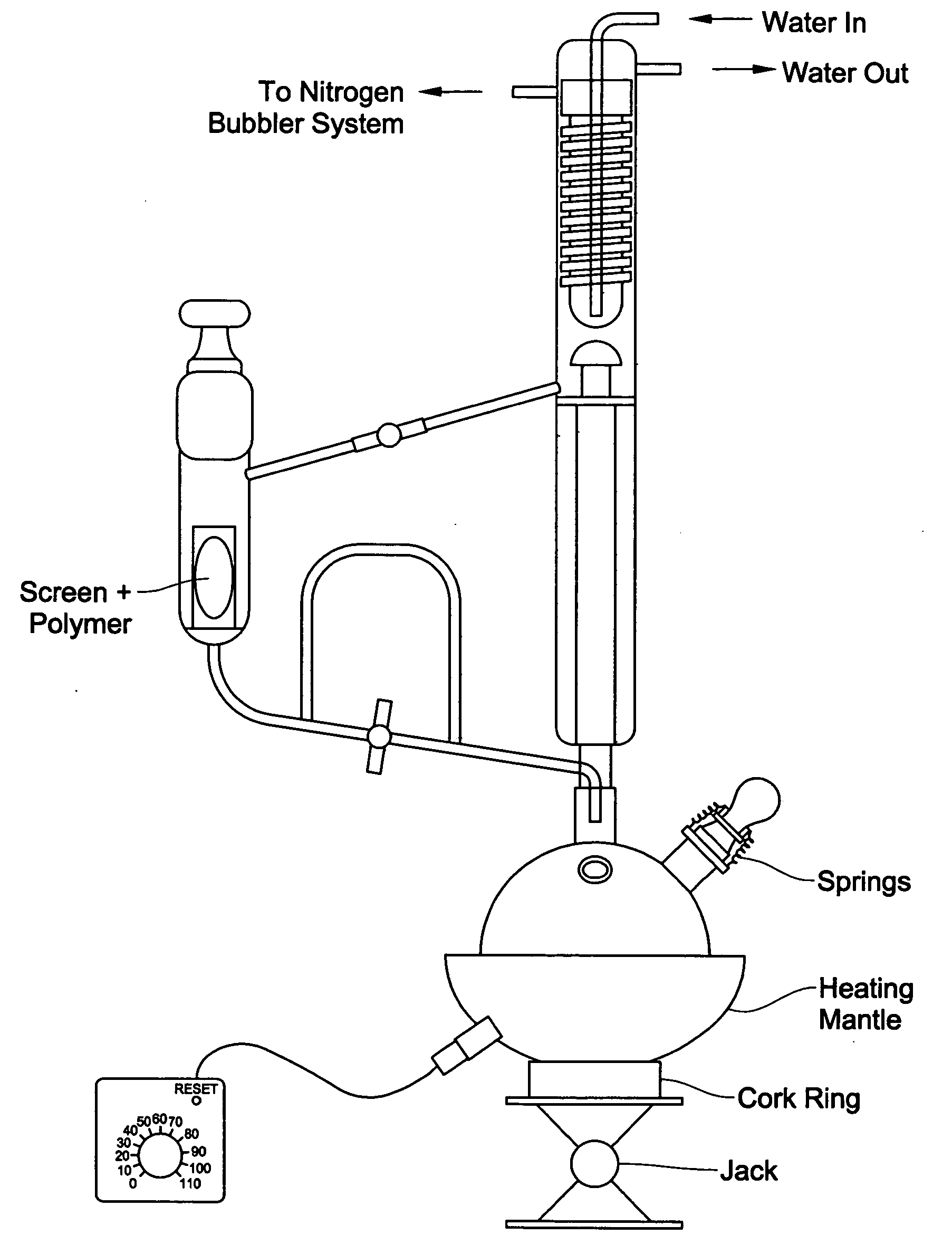

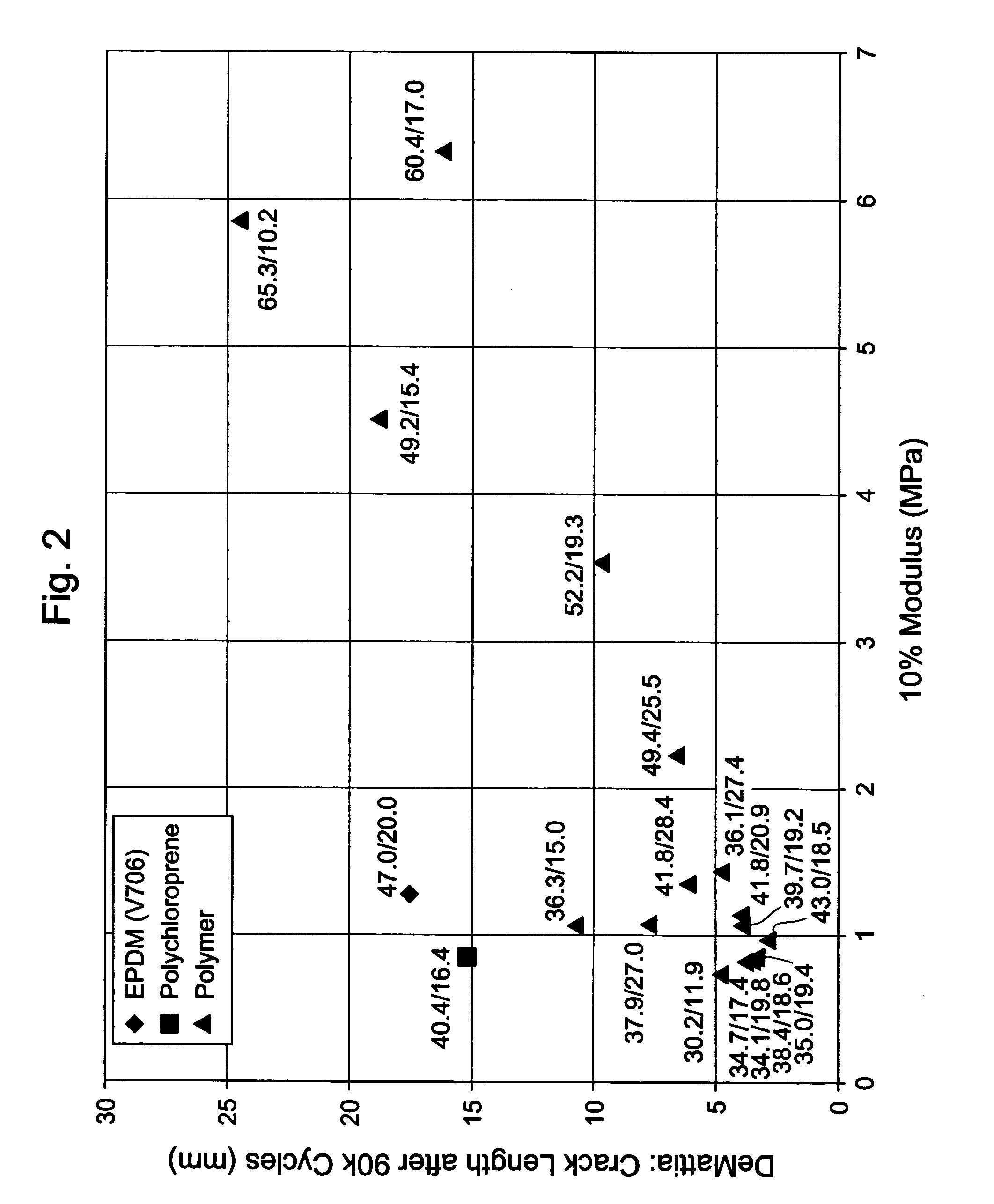

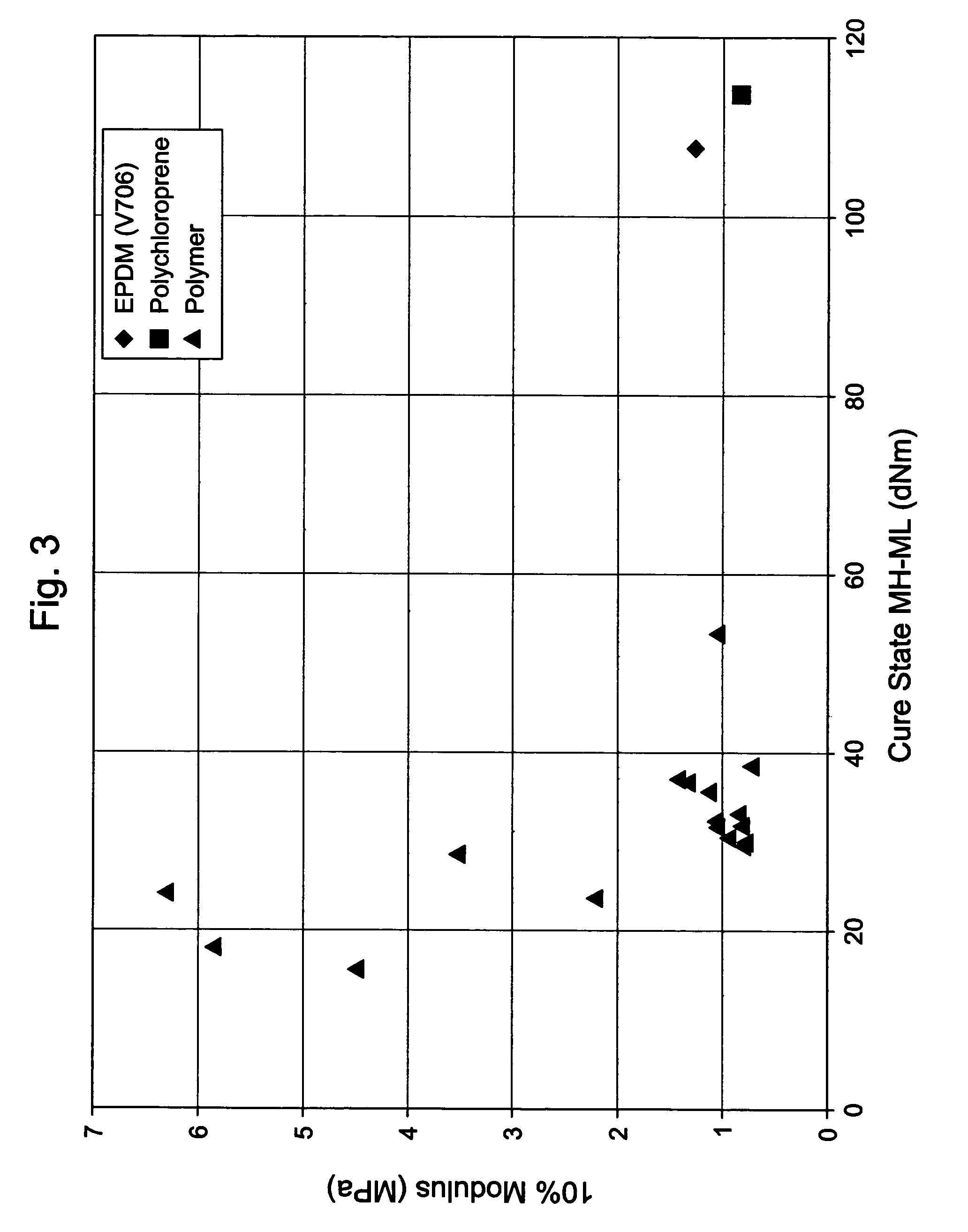

The invention relates to a process for making an article subject to dynamic loading, the process comprises: (i) shaping a polymer-containing composition in the green state, the composition comprising (a) a continuous phase of a polymeric component of at least 15 wt %, based on the total weight of the polymer component of a propylene elastomer having a heat of fusion of less than 70 J / g and an isotactic triad tacticity of 50 to 99% and optionally containing units derived from a diene, the polymeric component having a density of less than 0.9 g / cm3 and (b) from 20 to 120 phr, preferably 30 to 100 phr, most preferably 40 to 90 phr based on the total weight of the polymer component of a reinforcing filler component; and (c) a peroxide curative. The composition is combined with a fibrous reinforcement which is then cured to a cure state as determined by ODR @ 170° C., 30 min MH-ML of from 5 to 80 dNm. The invention especially relates to such processes when providing under Demattia testing conditions a crack length of less than 15 mm at room temperature over 90K cycles, preferably 10 mm, more preferably 7 mm, and most preferably 4 mm, and a 10% modulus of 0.7 to 10 MPa, preferably 1.4 to 9 MPa and most preferably 2 to 8 MPa.

Owner:EXXONMOBIL CHEM PAT INC

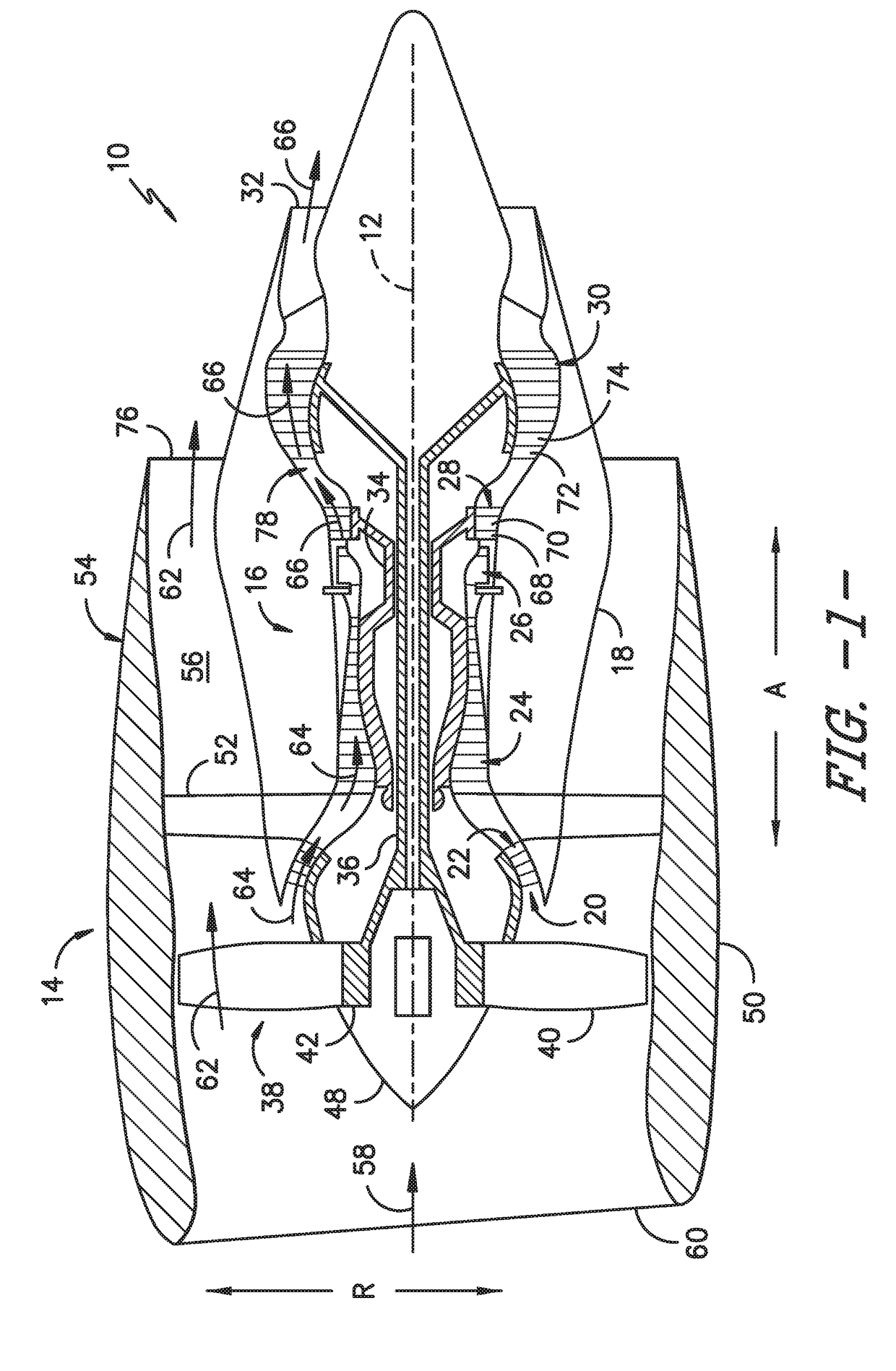

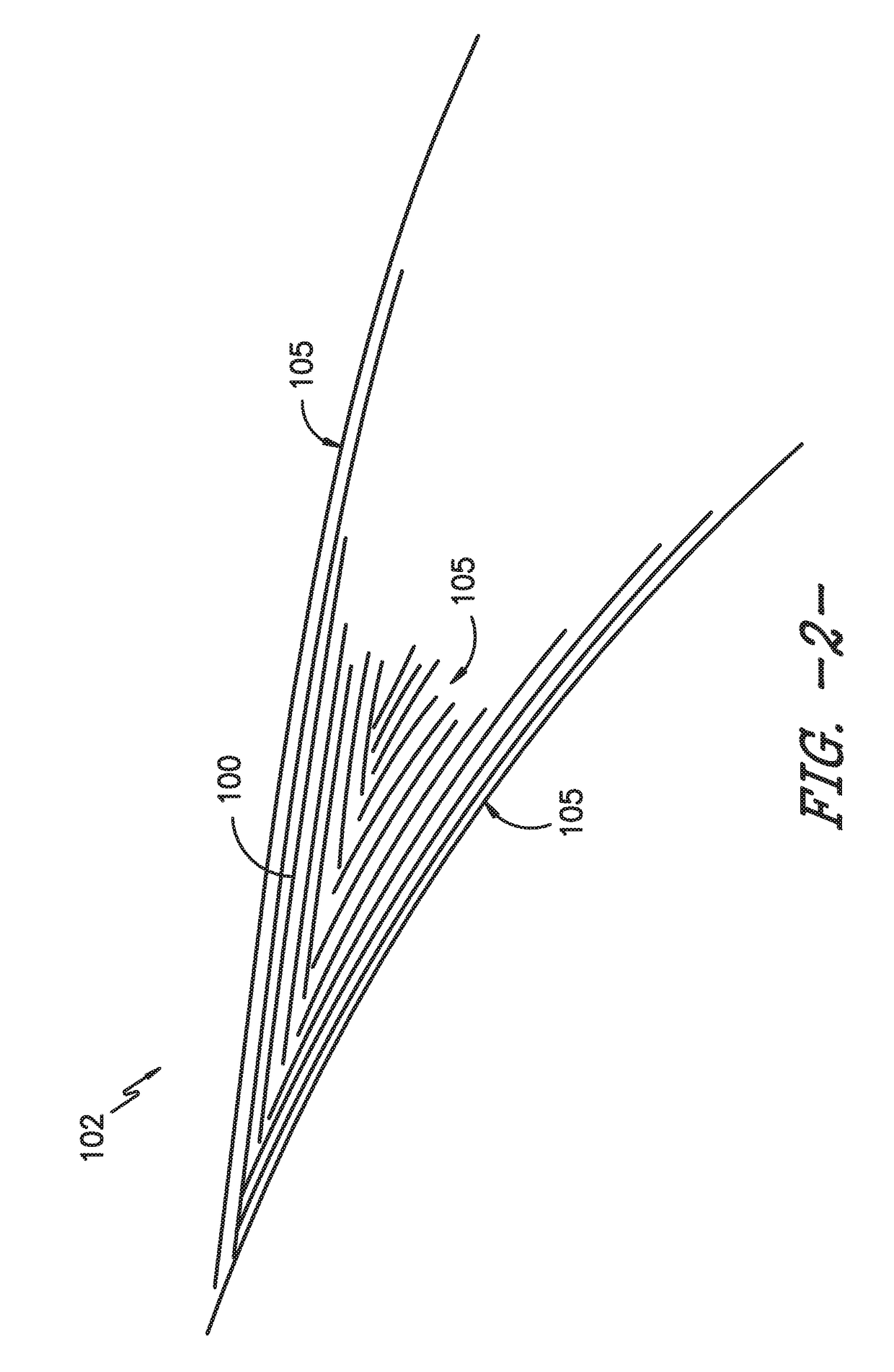

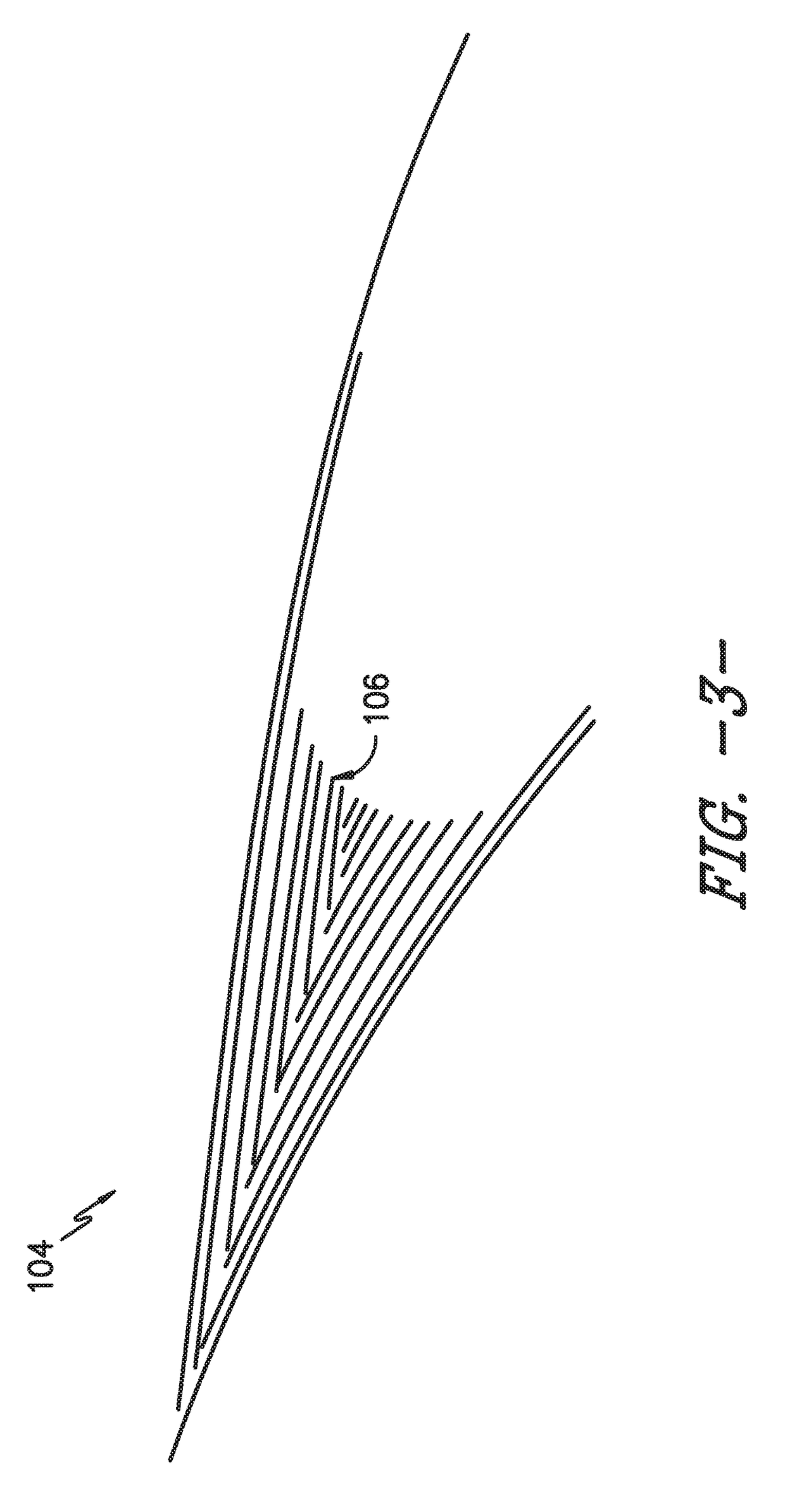

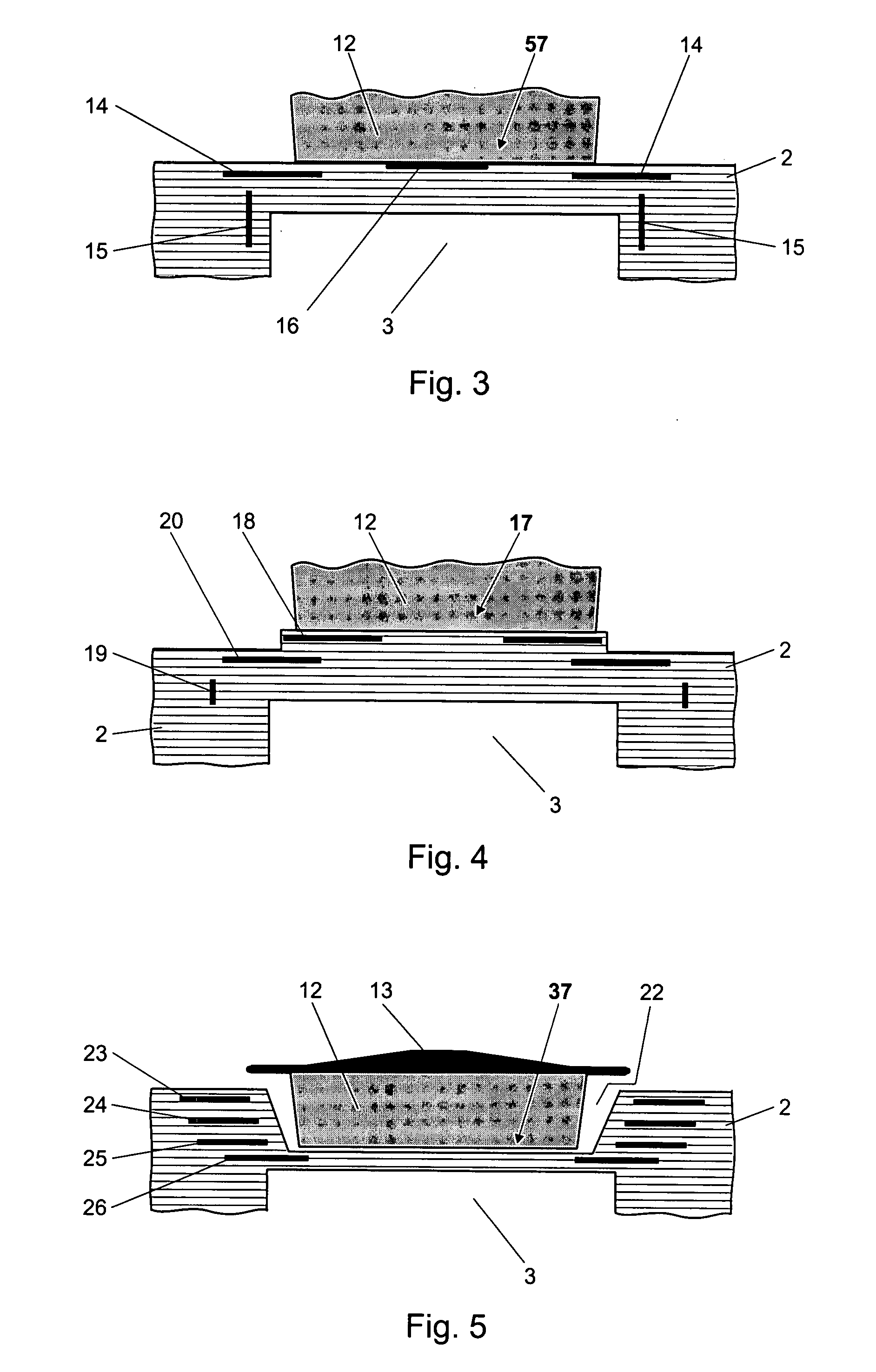

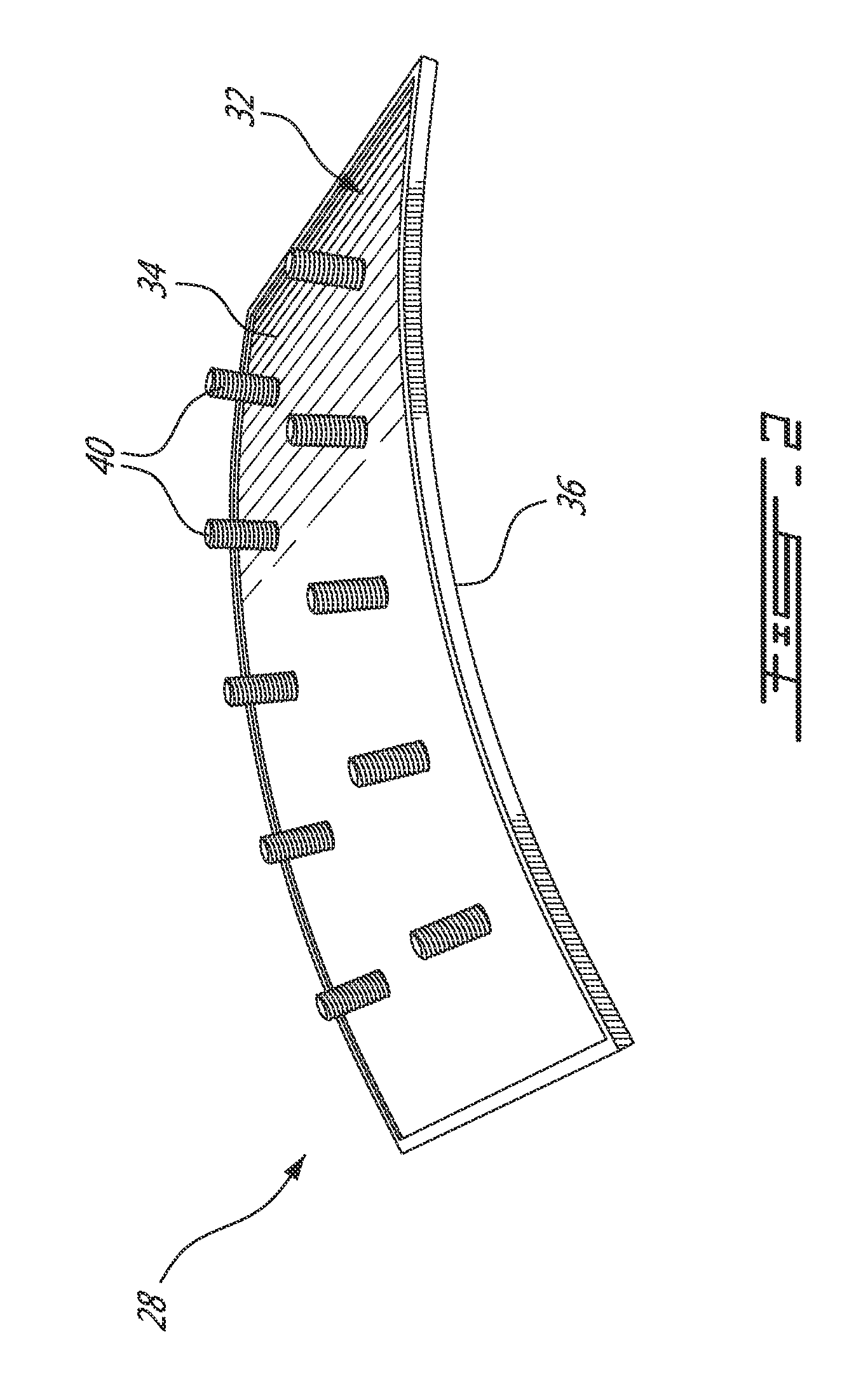

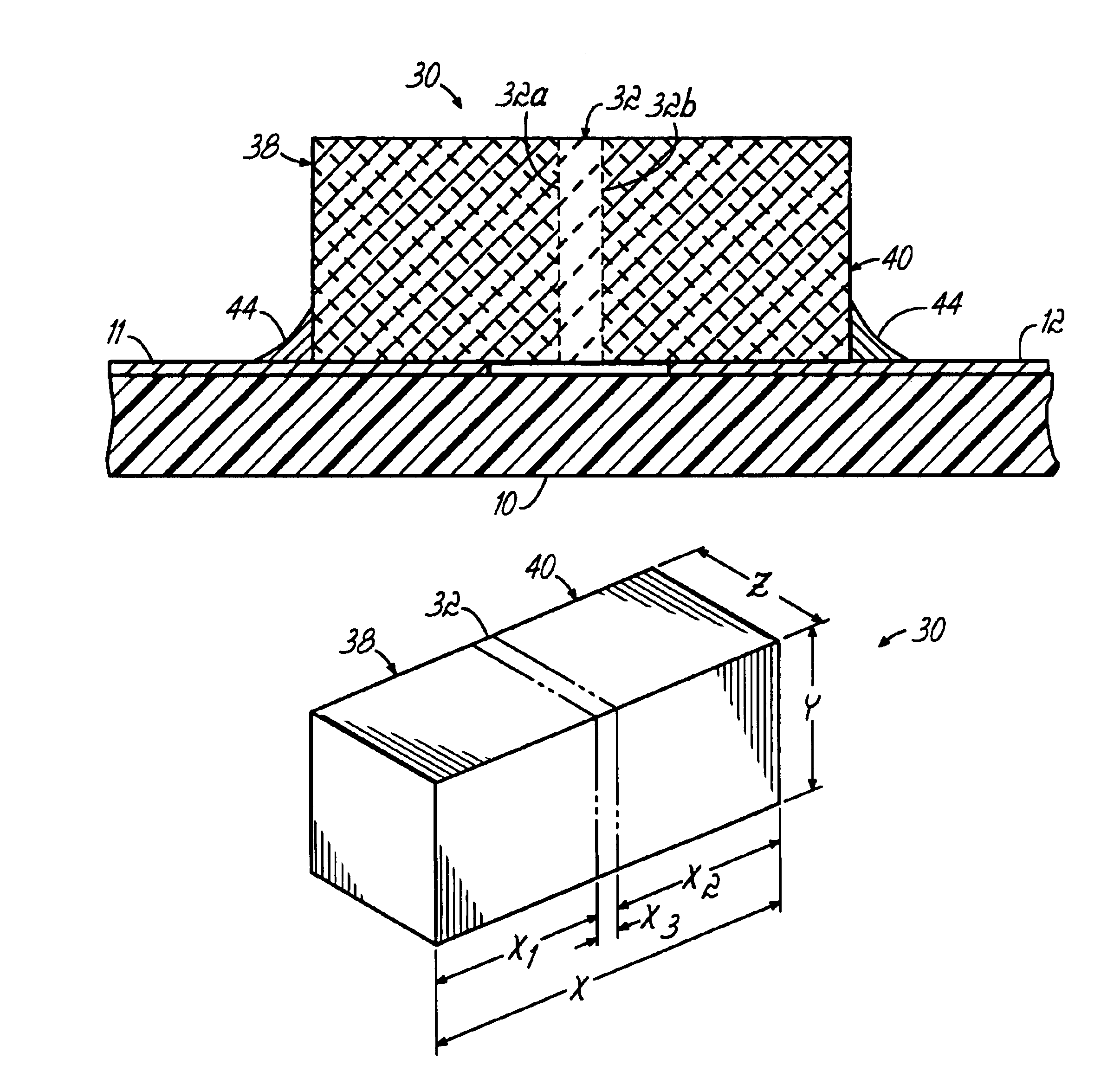

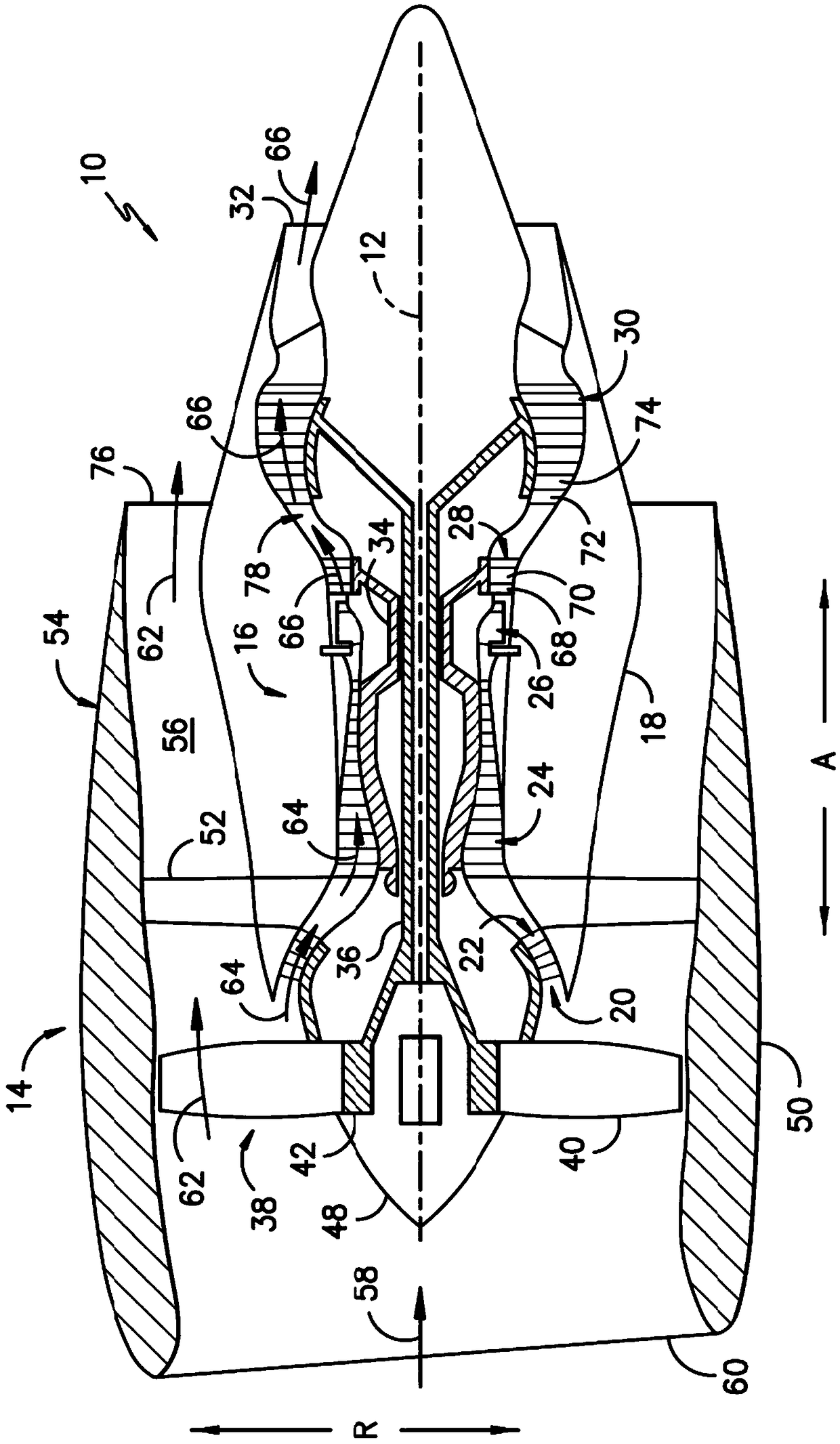

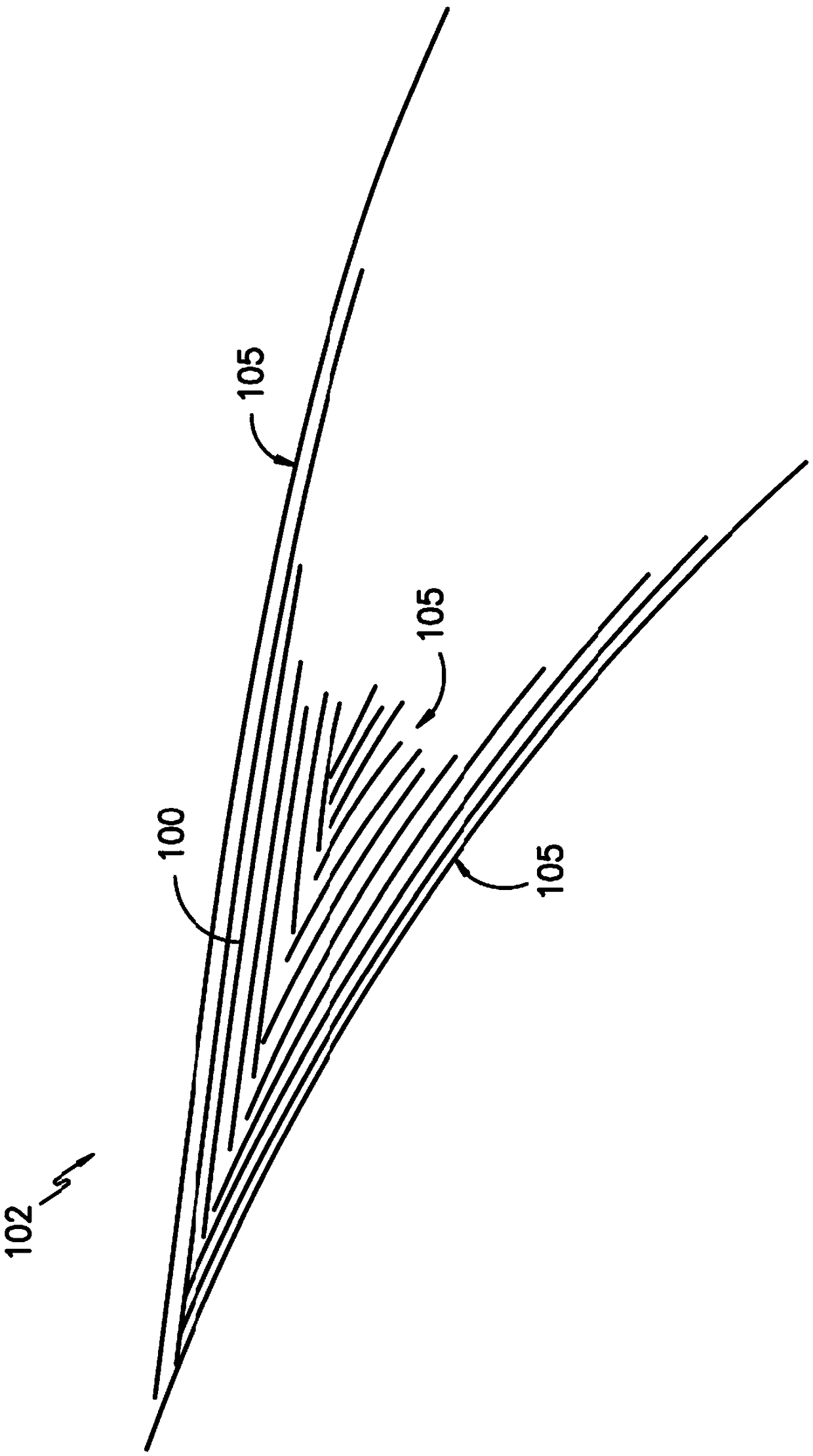

Shaped composite ply layups and methods for shaping composite ply layups

Ply layups and methods for forming composite components are provided. For example, a method for forming a composite component comprises laying up a plurality of composite plies to form a composite ply layup; partially processing the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing the green state layup and the one or more sub-assemblies to form the composite component. In an exemplary embodiment, the composite component is a turbine nozzle airfoil. Another exemplary method comprises laying up a plurality of composite plies to form a composite ply layup; compacting the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing the green state layup and the one or more sub-assemblies to form the composite component.

Owner:GENERAL ELECTRIC CO

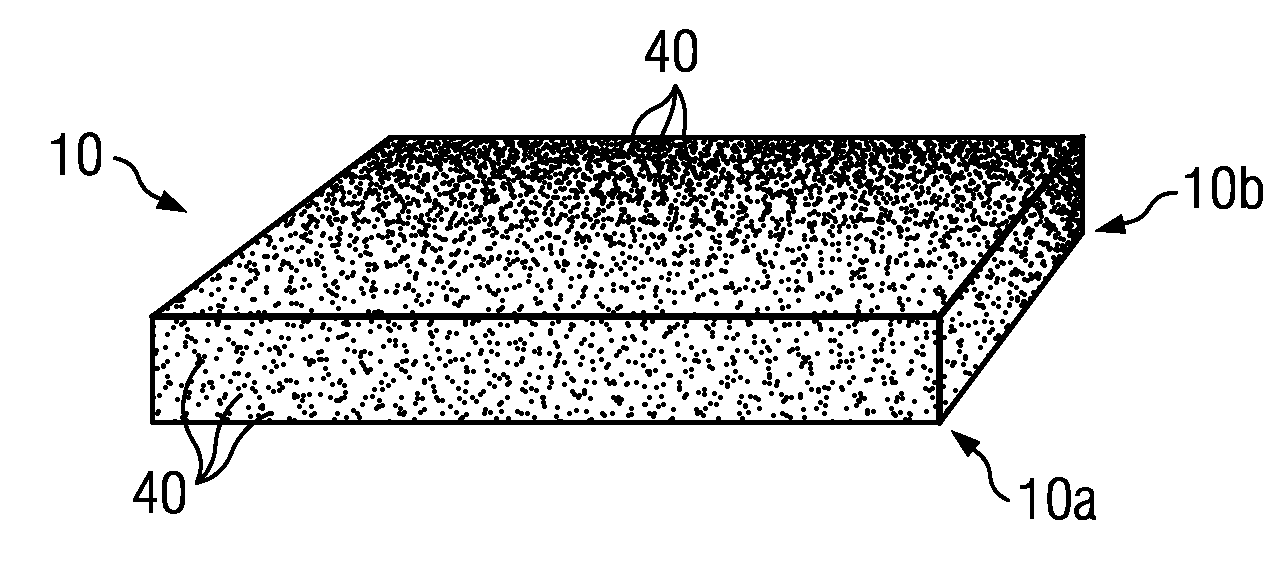

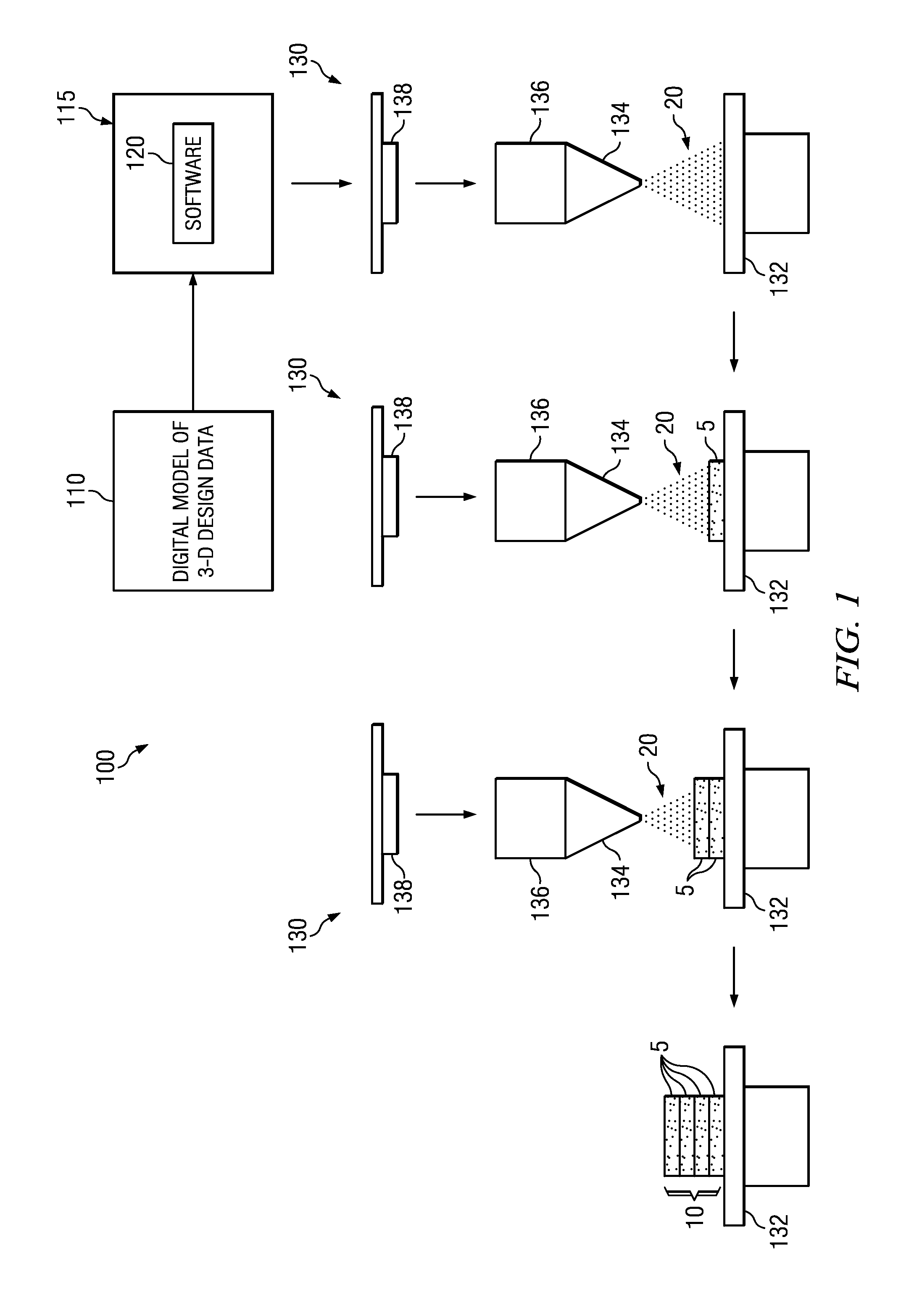

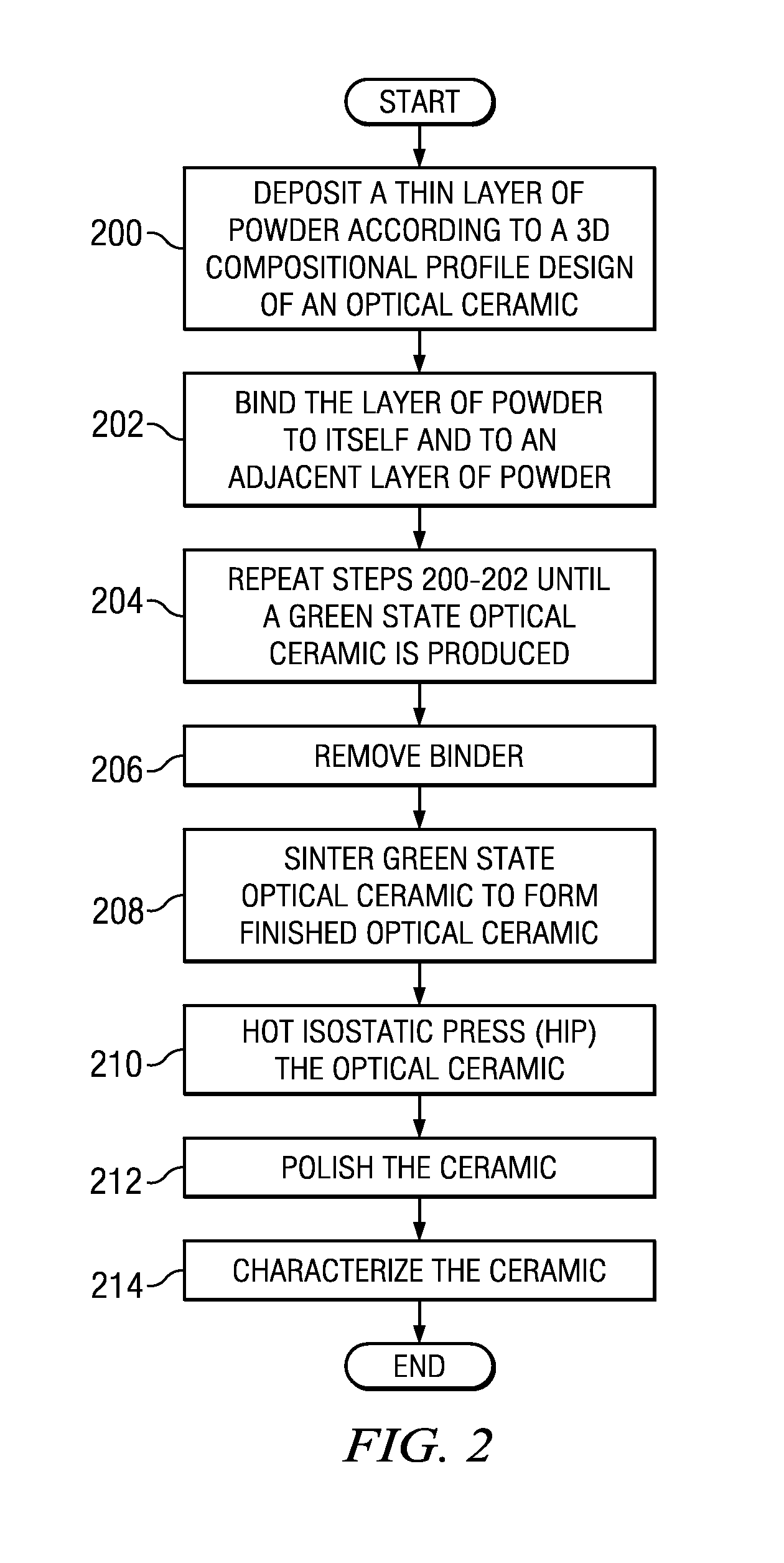

Method of fabricating optical ceramics containing compositionally tailored regions in three dimension

ActiveUS20120225767A1Non-uniform temperatureUniform lightOptical articlesOptical elementsDopantThin layer

In accordance with the present embodiment, a method for making an optical ceramic comprises depositing a plurality of thin layers of powder. The powder comprises a first optical material powder having a first dopant level, and a second optical material powder. The first and second optical material powders are deposited for each layer based on the first dopant level and according to data associated with a three-dimensional (3D) compositional profile design of an optical ceramic. The method further comprises binding the first and second optical material powders of each thin layer to each other and each thin layer with an adjacent layer such that a green state optical ceramic is produced based on the 3D compositional profile design. The method further comprises densifying the green state optical ceramic to obtain the optical ceramic.

Owner:RAYTHEON CO

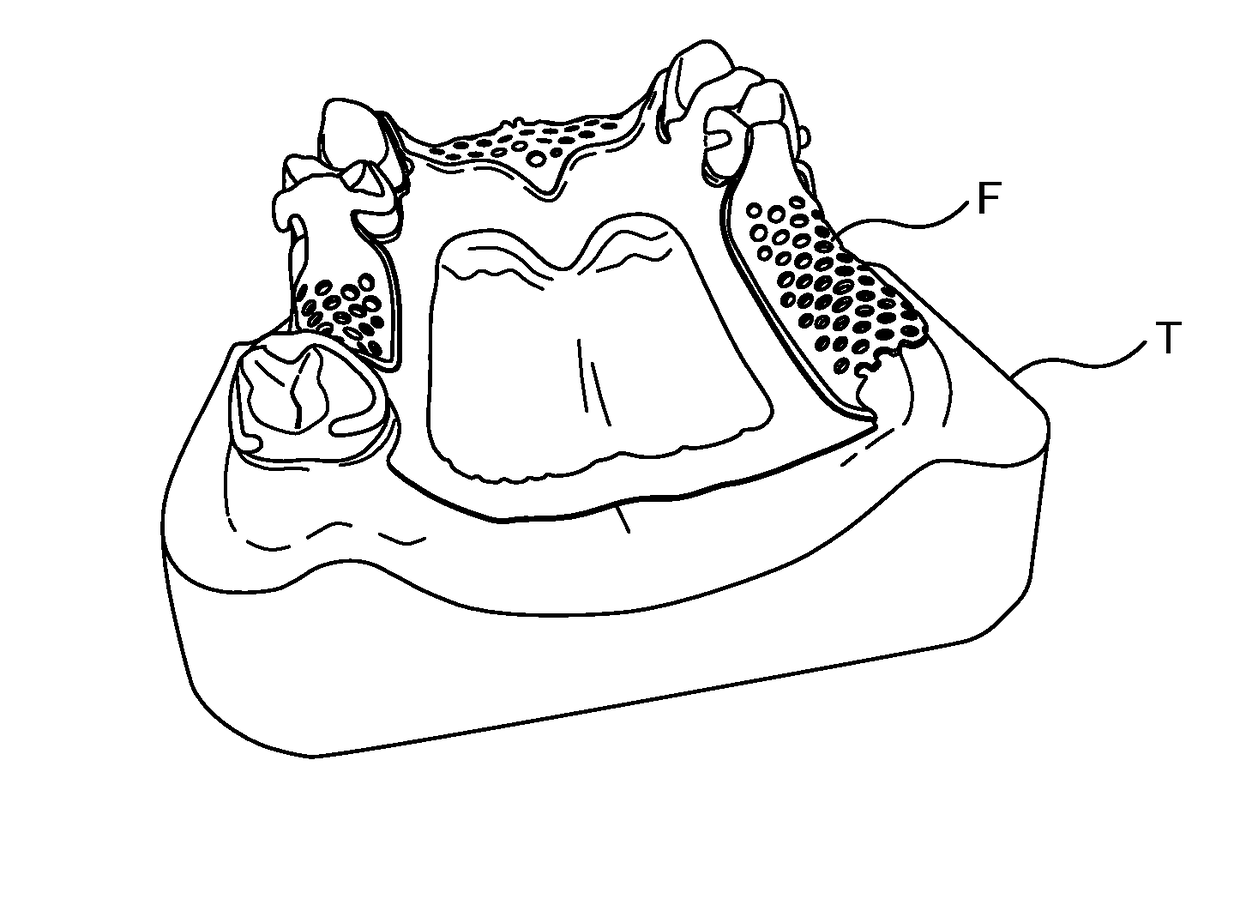

Method For Coloring Ceramics Via Collidal Dispersion

ActiveUS20130231239A1Maintain colloidal stabilityFacilitate homogenous solutionDentistry preparationsMedical preparationsOrganic solventColloid

Coloring in a slip casting process by which a ceramic slurry is cast into green state bodies. It is during this slip casting that a coloring solution consisting of metallic salts is introduced to the slurry and subsequently slip-cast. A coloring solution may comprise for example a metallic salt, a solvent, an organic solvent such as derivatives of propylene oxides, and an acid can be introduced to the slip casting process. Such a coloring solution can be added to the slip casting process. The solution is thoroughly mixed with the ceramic slurry, after which the ceramic body is cast, dried and finally subjected to a sintering process. After final sinter, the resulting ceramic body possesses an innate color that is homogenous throughout its composition. The method is especially useful for coloring zirconia dental restorations.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

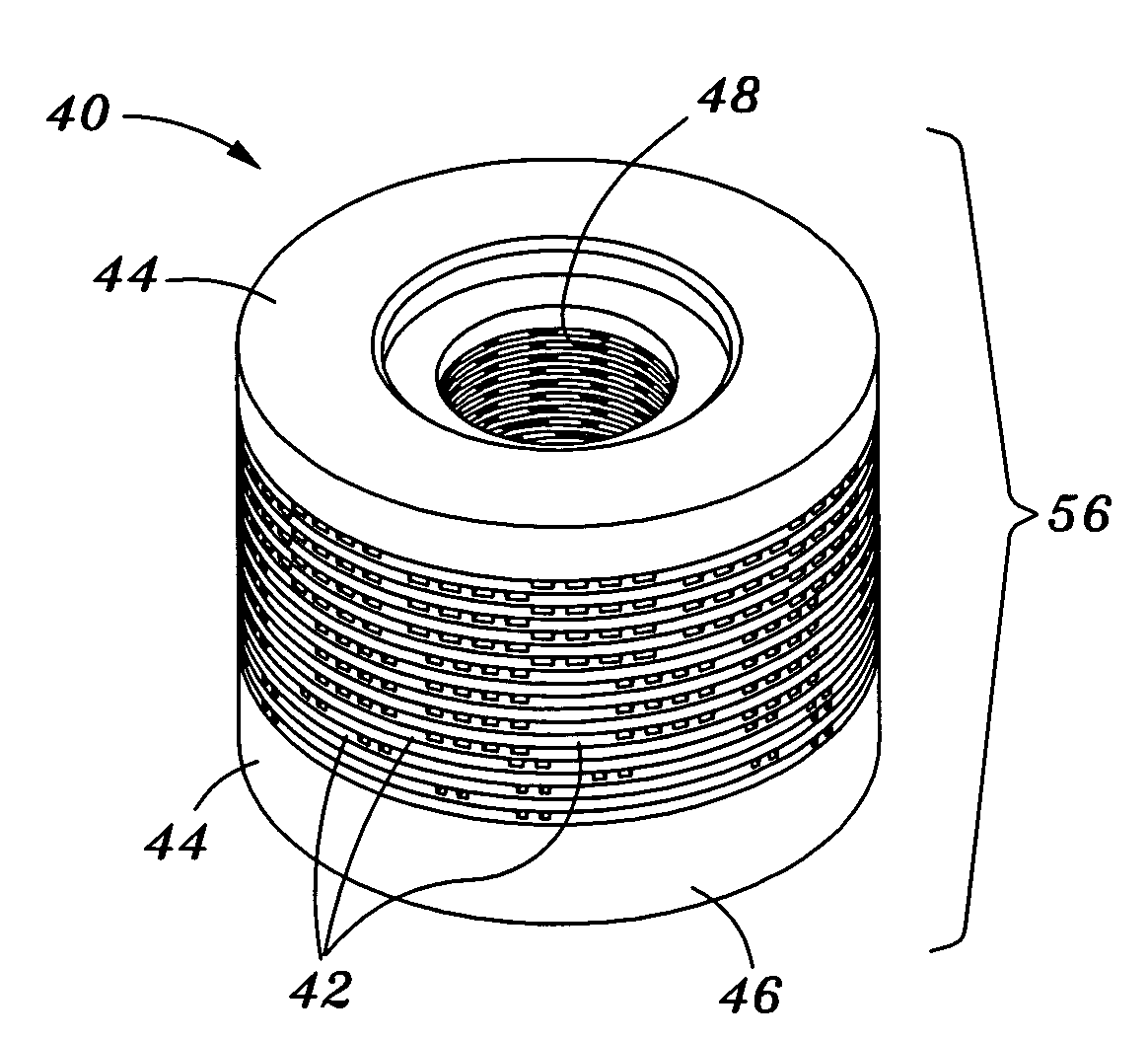

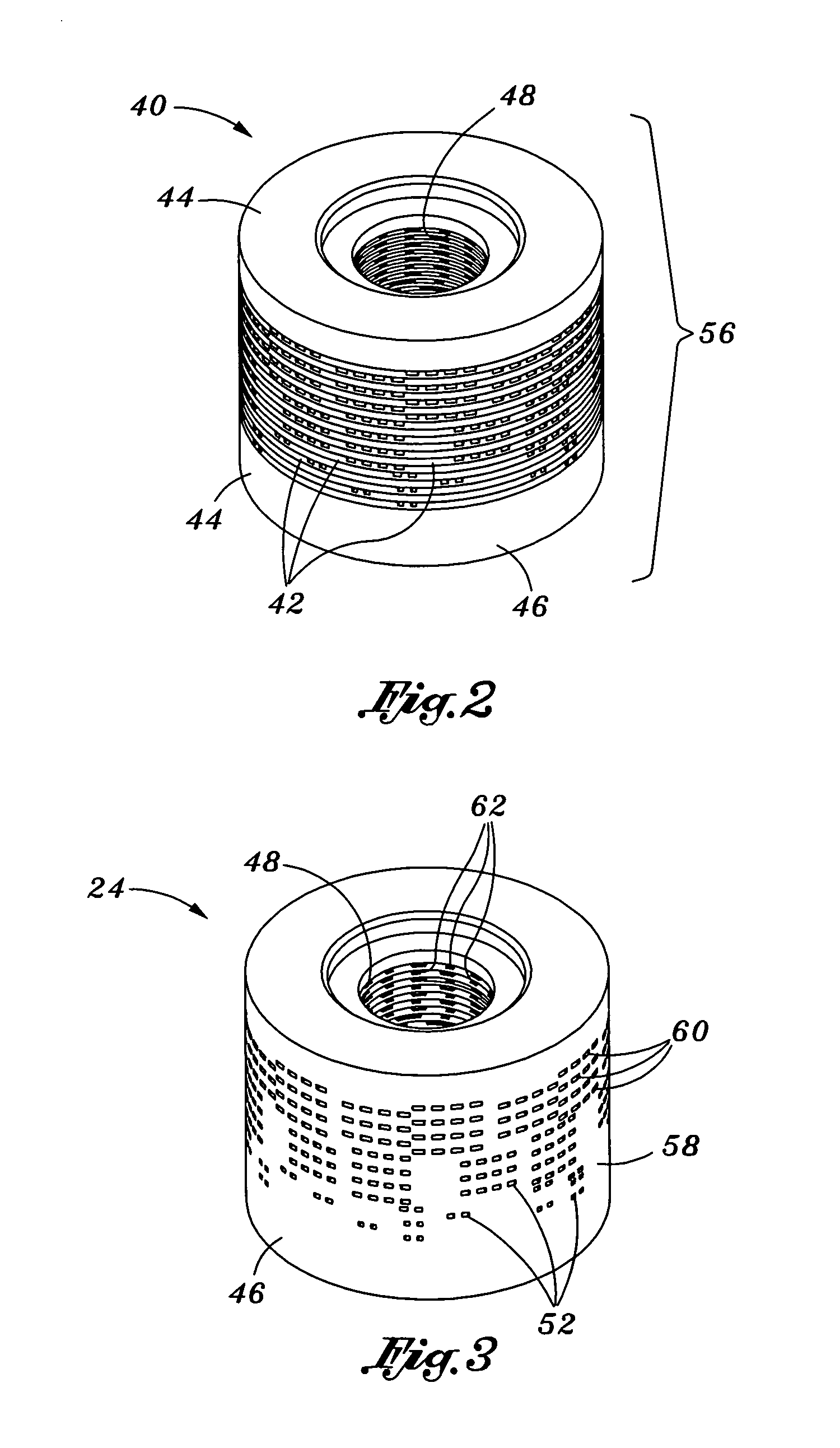

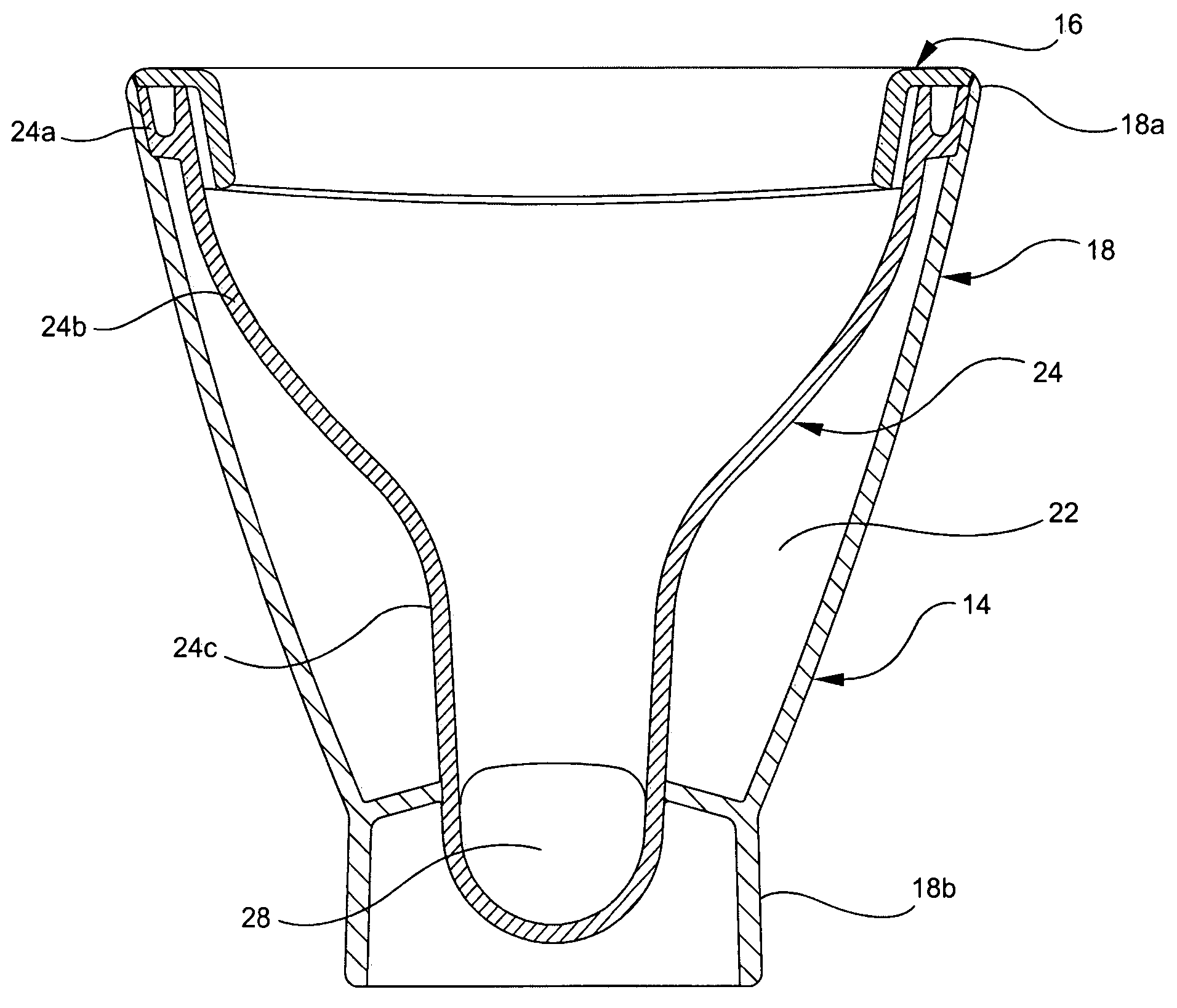

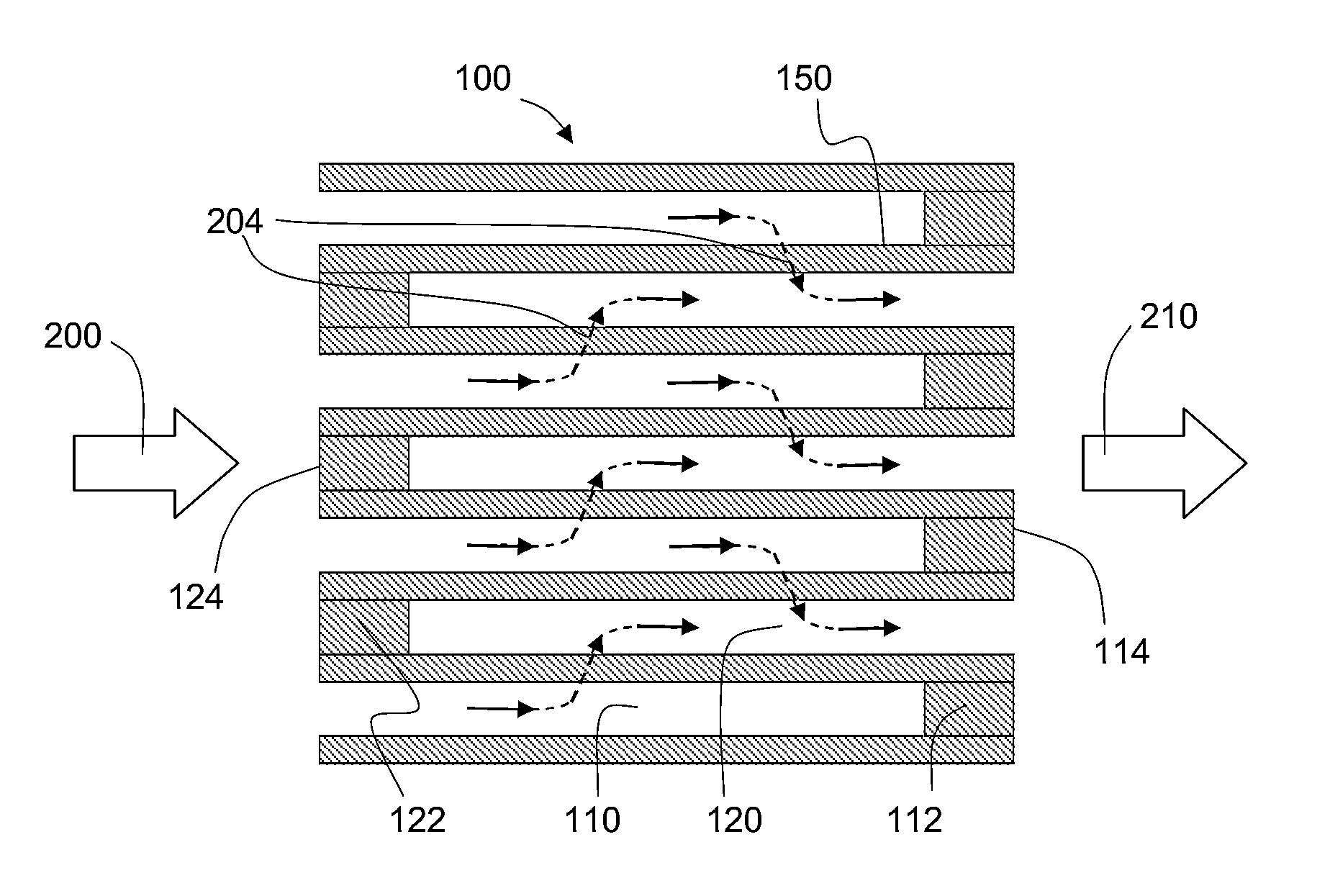

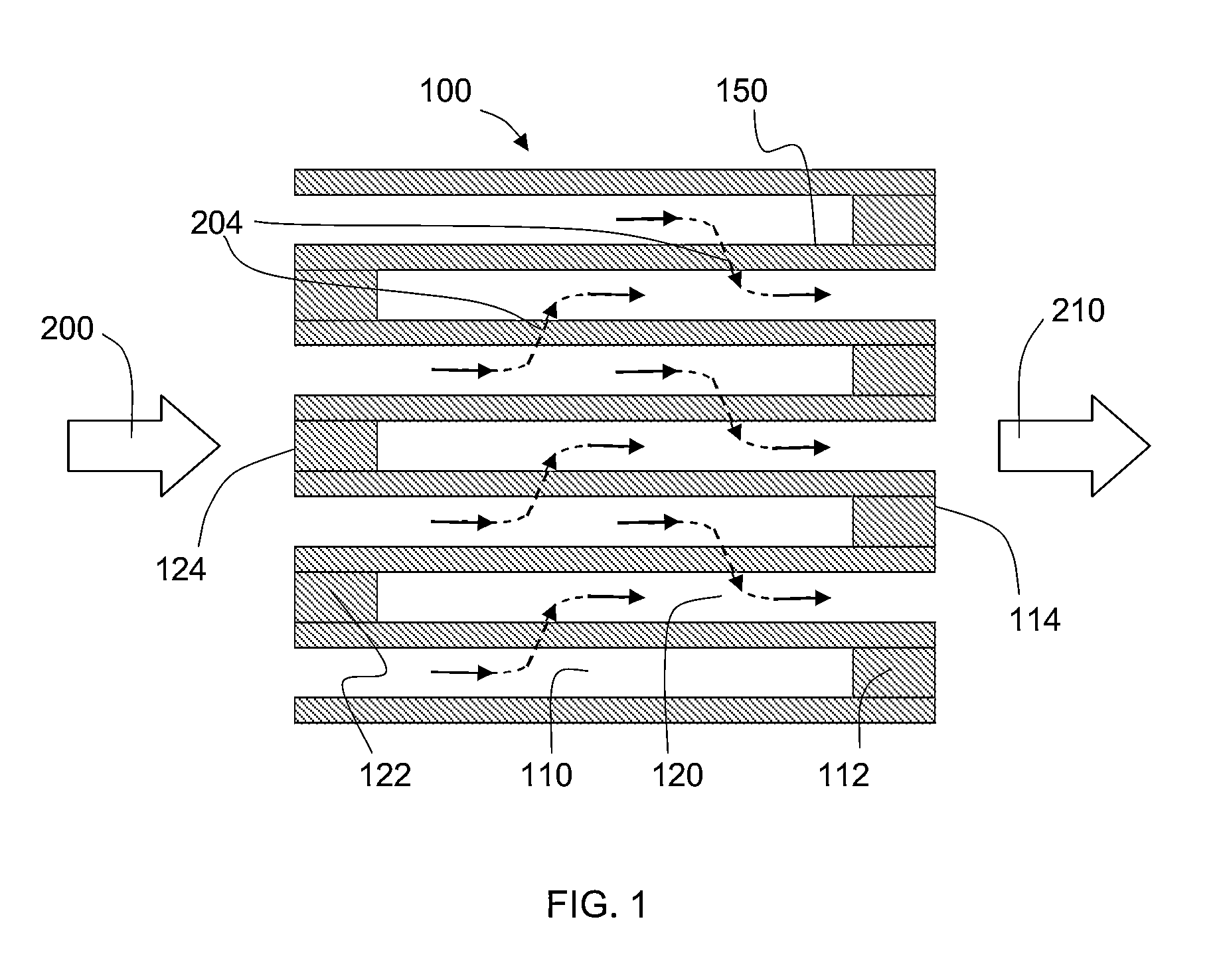

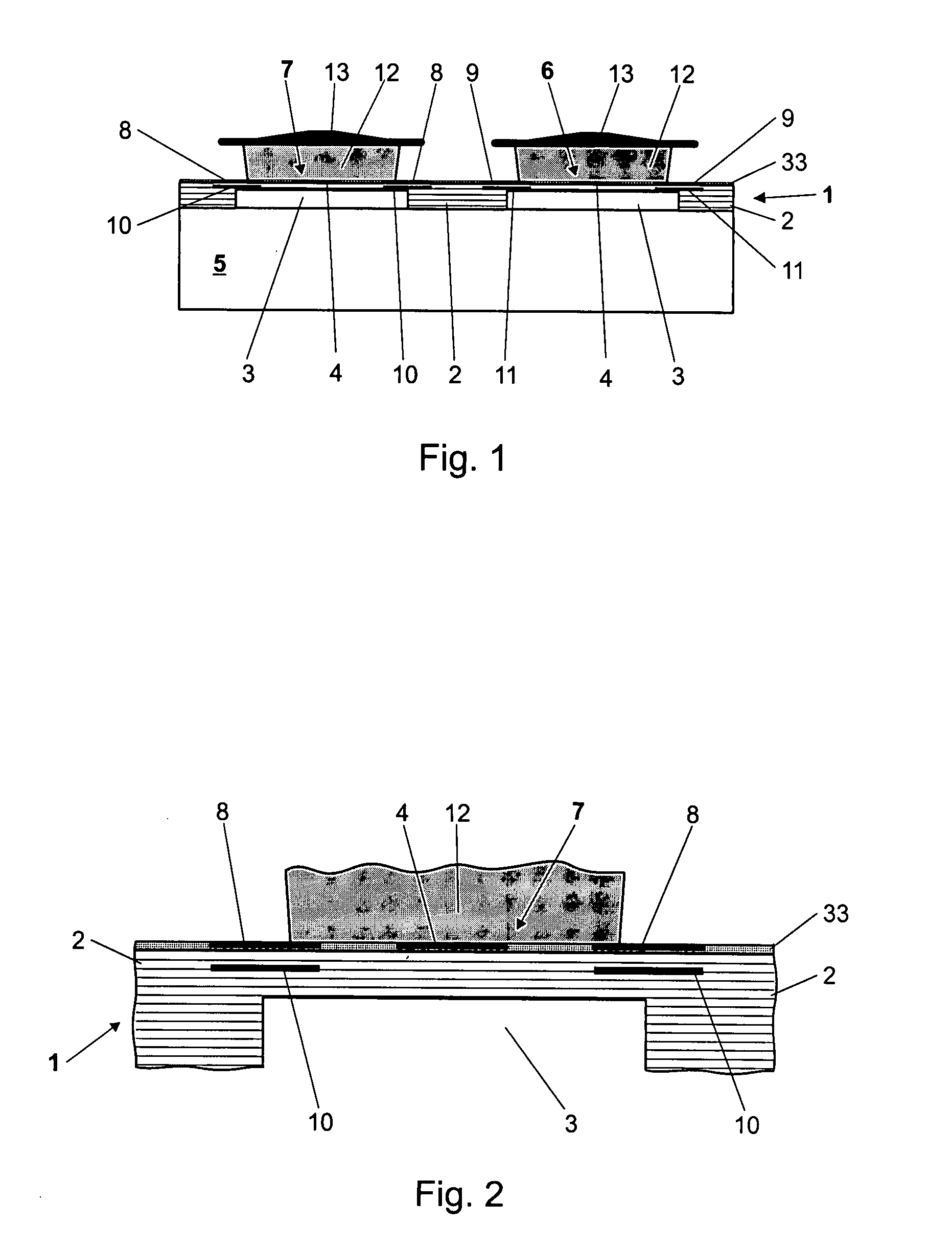

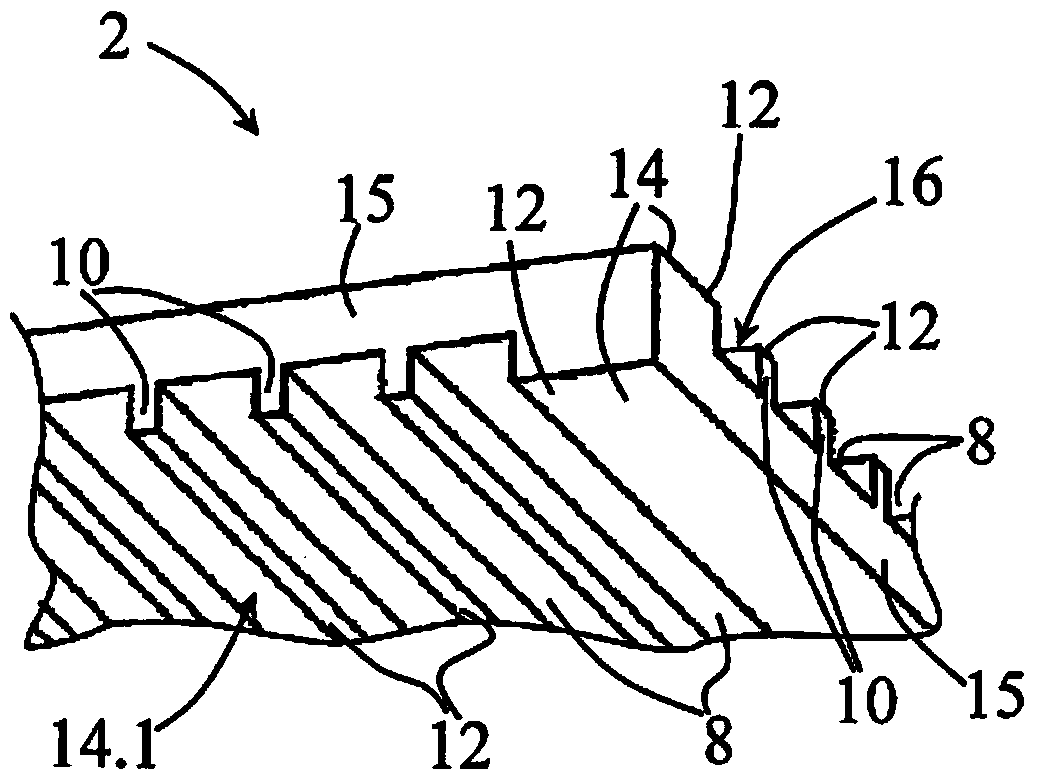

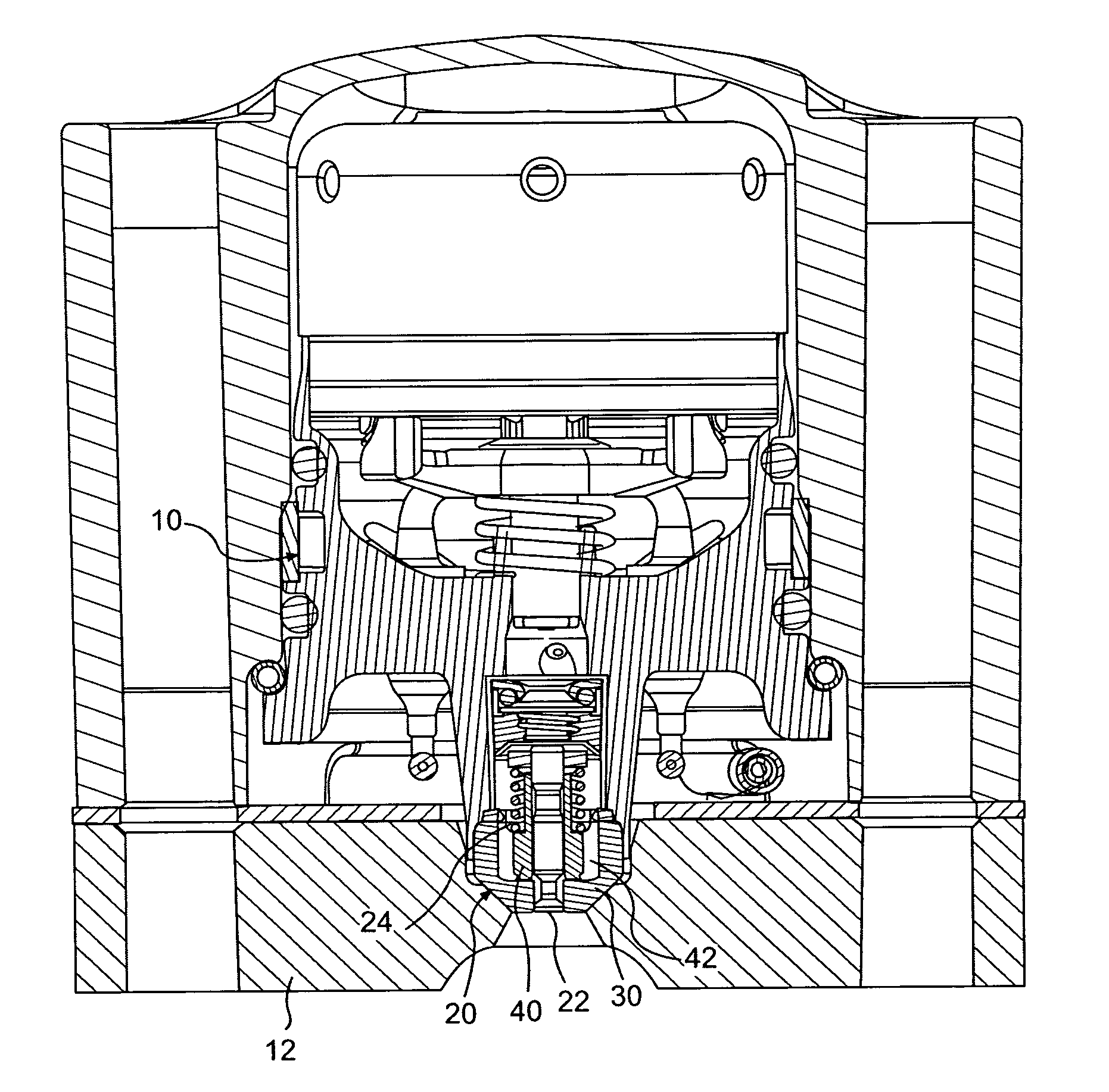

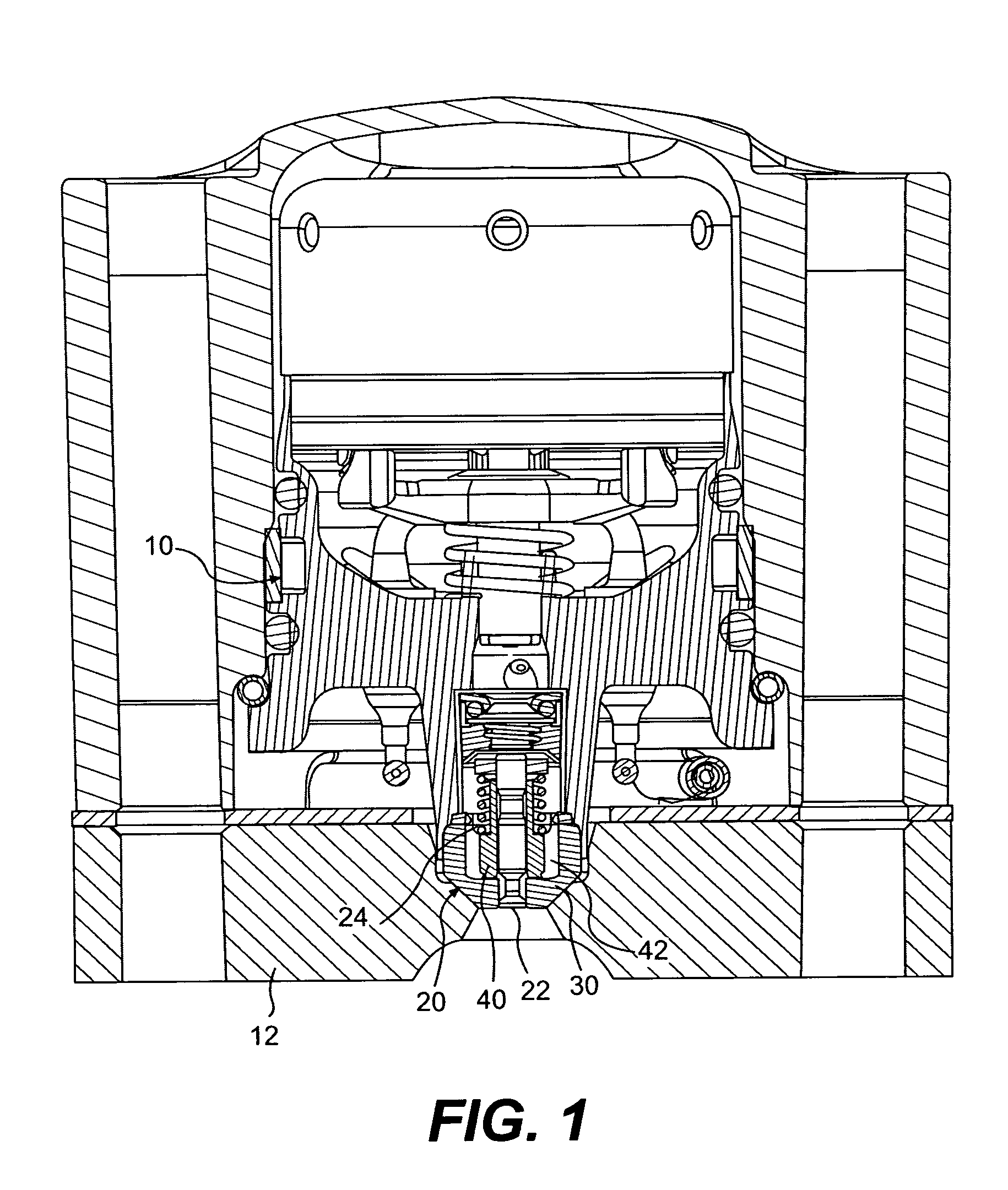

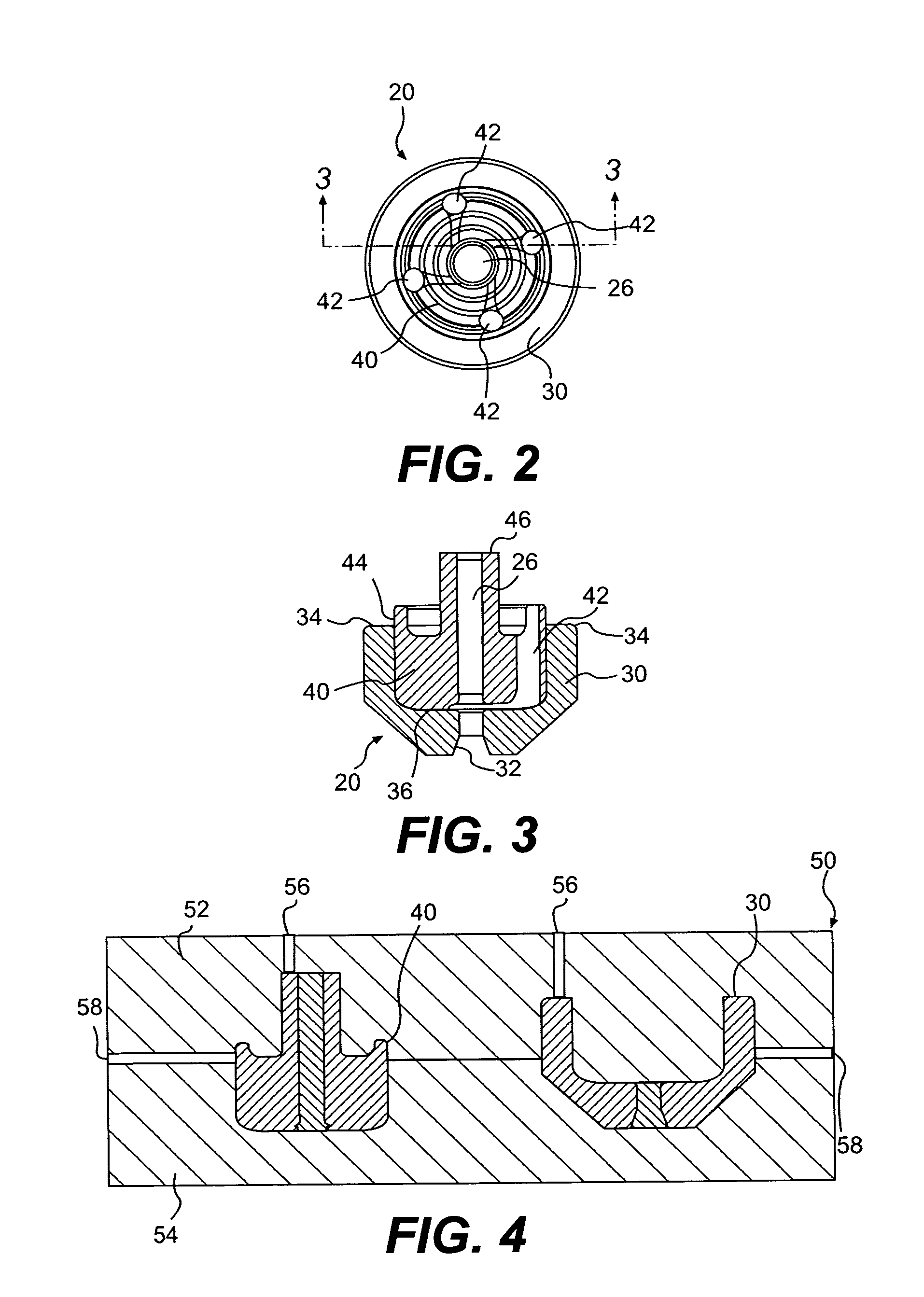

Fluid control device and method of making it

InactiveUS20050016604A1Good process repeatabilityEasy to produceValve members for absorbing fluid energySlide valveFluid controlEngineering

Disclosed is a rigid annular valve structure comprised of individual green state discs having partial or complete passages formed therein. The series of green state discs are assembled in an axially aligned stack such that the partial passages of adjacent ones of the green state discs cooperate to collectively define a plurality of substantially radial device passageways for fluid flowing therethrough. The disc passages are formed in the discs prior to the assembly into the stack. The assembled green state discs are heated as a unit in order to simultaneously harden the individual green state discs and to fuse the individual green state discs together to form the rigid annular valve structure. After heating, the rigid annular valve structure may be machined to define interior and exterior peripheries and end faces such that the rigid annular valve structure is suitable for use in a valve assembly.

Owner:CONTROL COMPONENTS INC

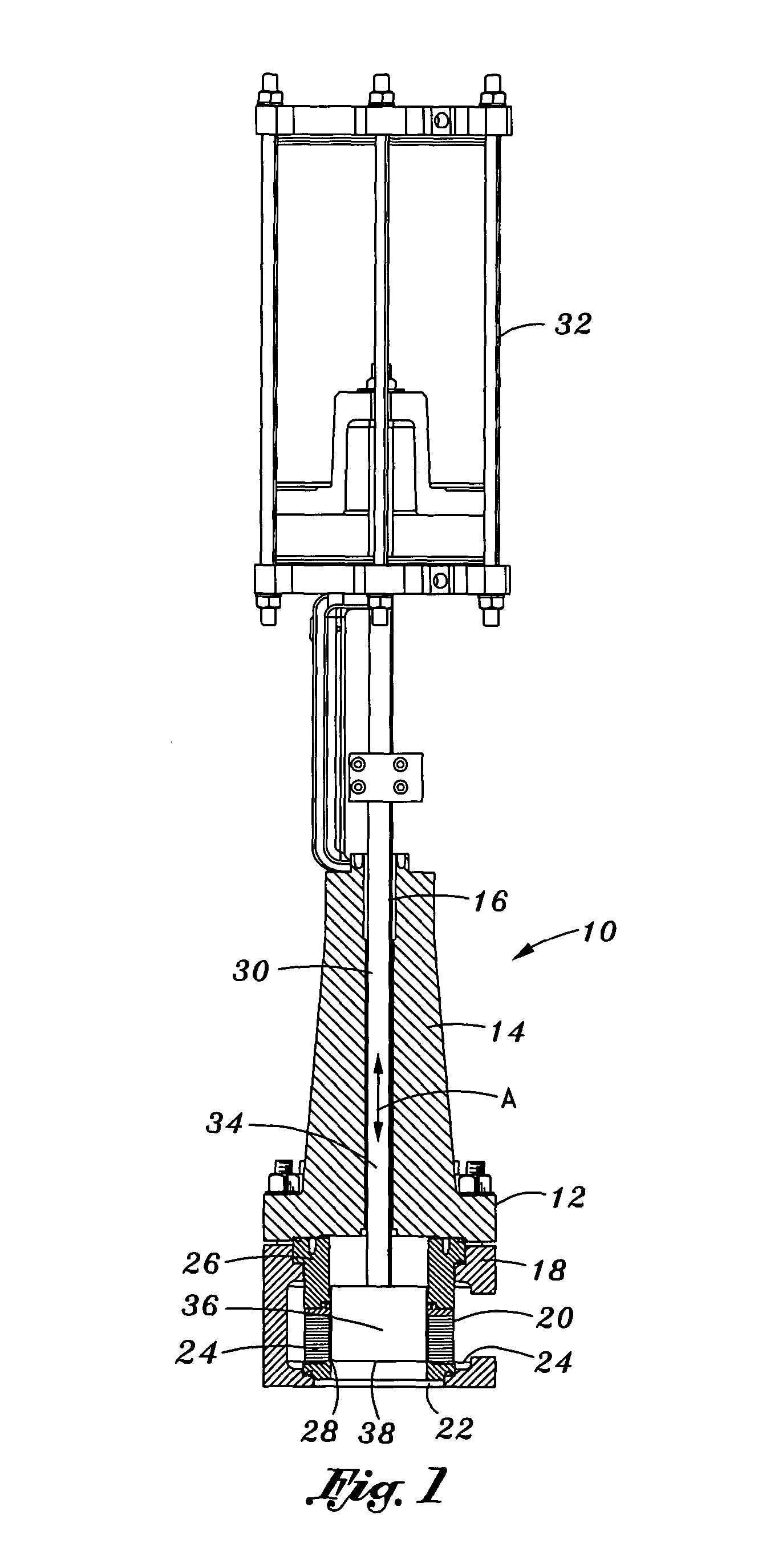

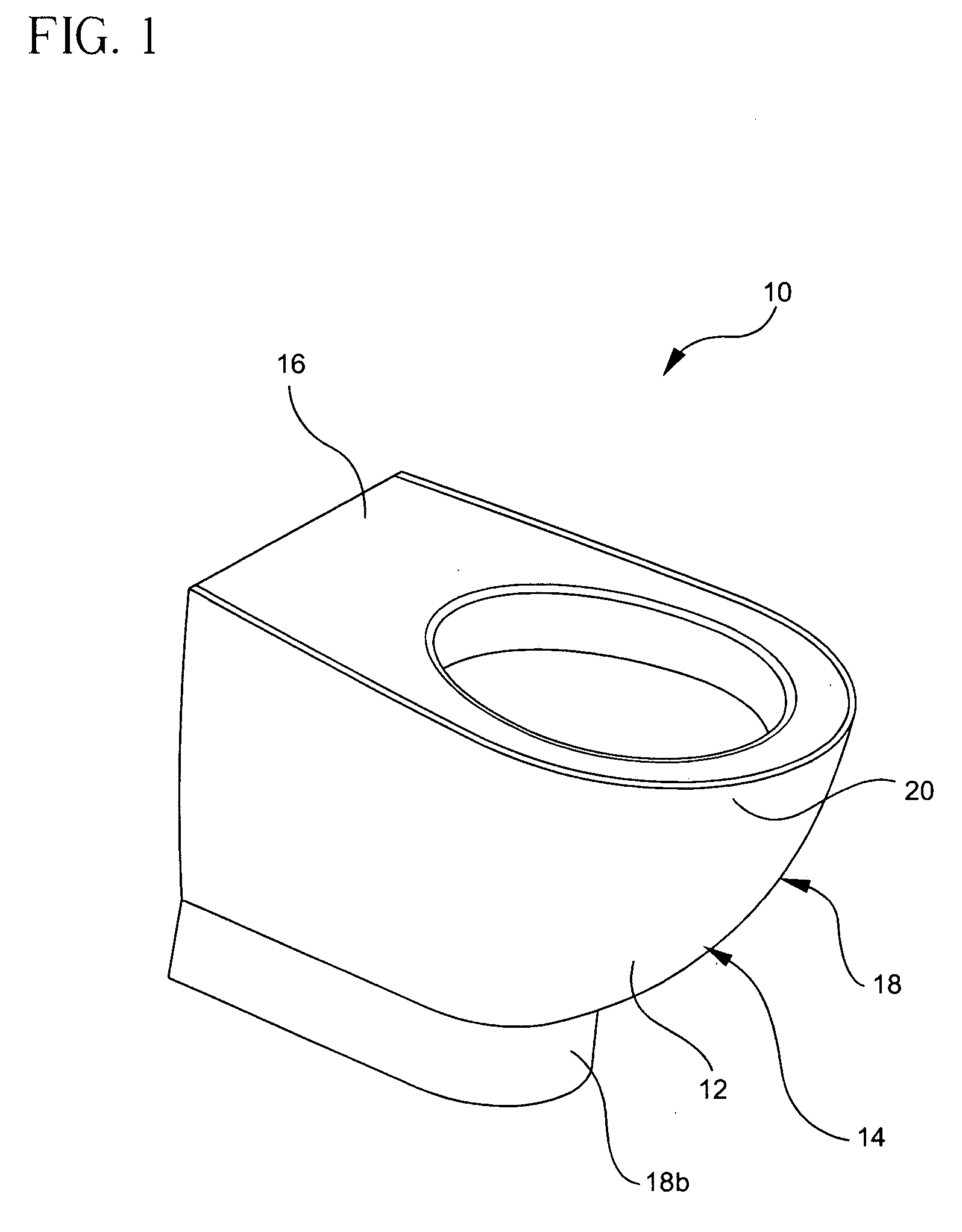

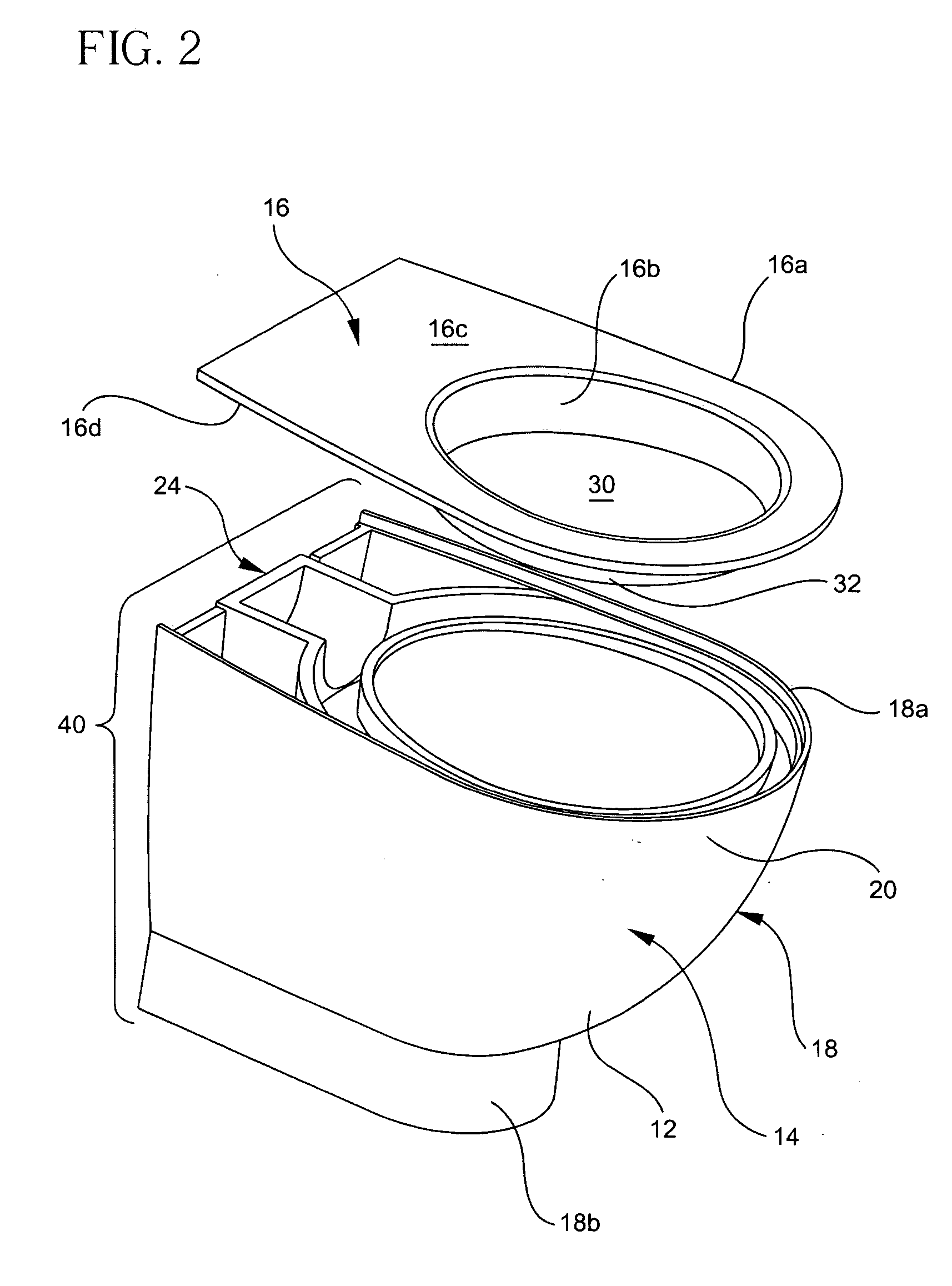

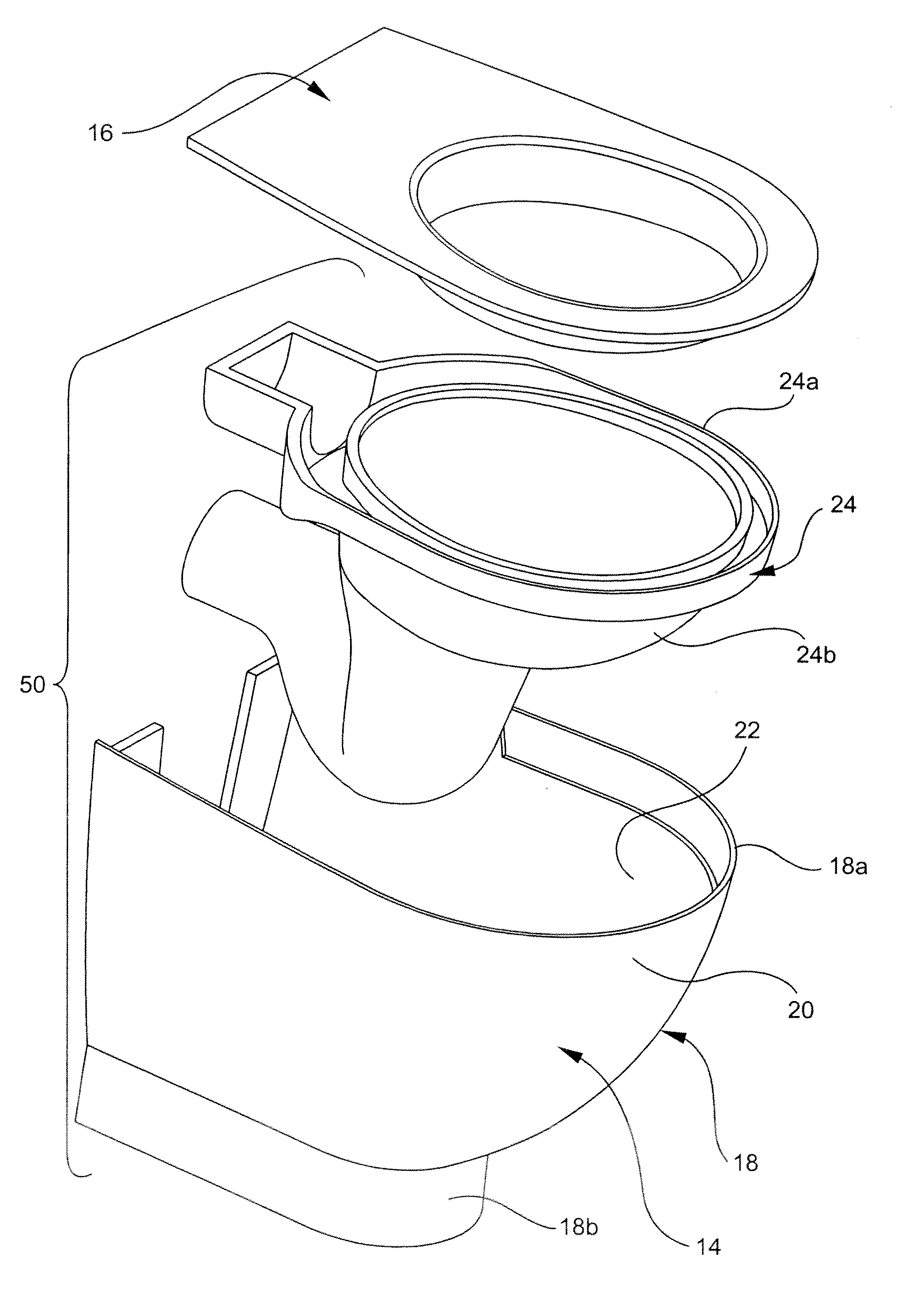

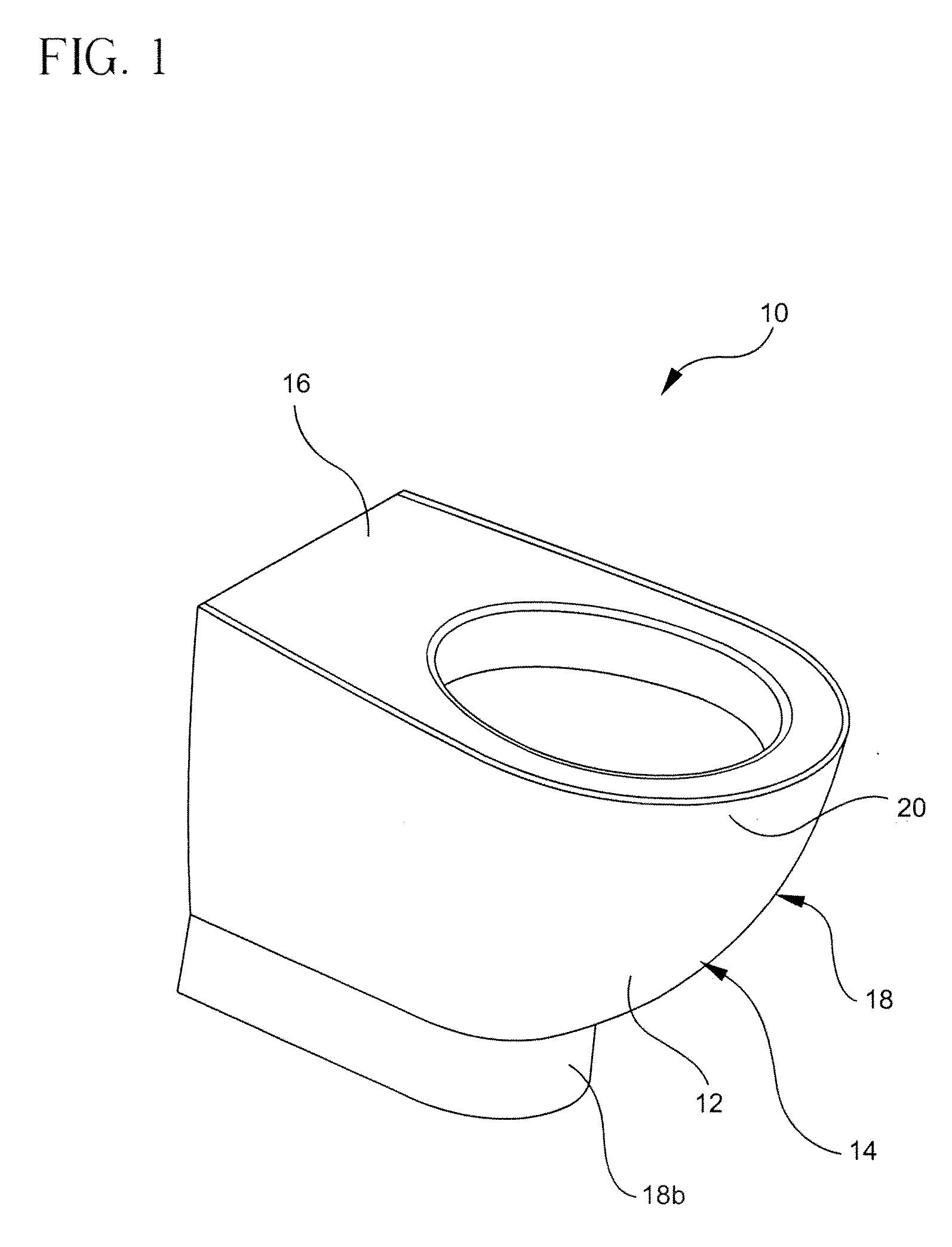

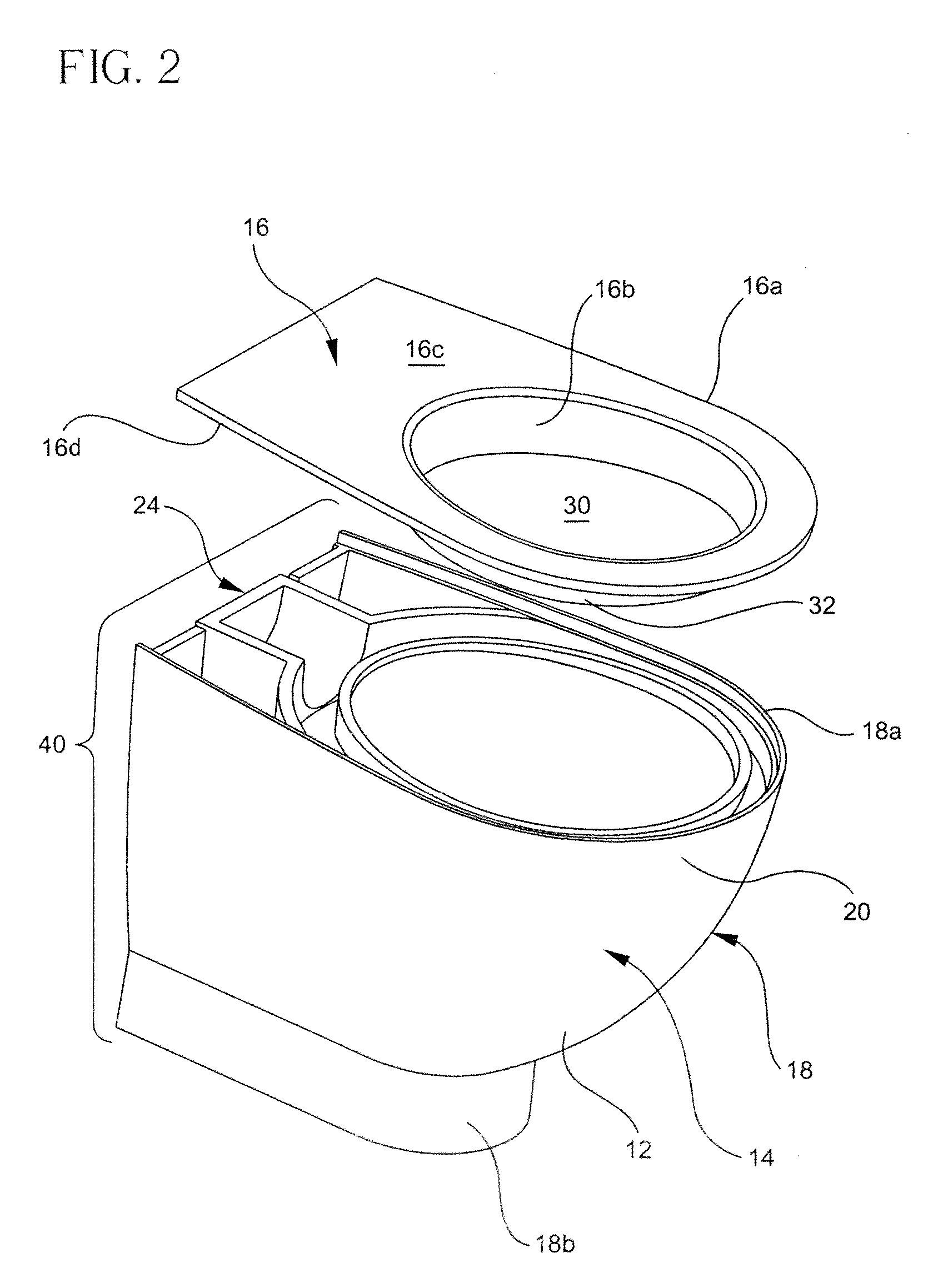

System and method for casting toilet bowls

ActiveUS20050115042A1Manufacturing can be simplified and expeditedIncrease choiceConfectionerySweetmeatsFlush toiletMechanical engineering

The present invention provides an improved system and method for casting toilets. In the disclosed method, at least one of a shell, engine and rim configuration for a toilet is provided, wherein the configuration is selected from a plurality of shell, engine and rim configurations defined by a corresponding plurality of shell, engine and rim molds. Each mold defines a casting space therewithin for casting the selected configuration therefrom. Each shell configuration includes a hollow housing space for disposition of a unique sanitaryware performance engine configuration therewithin. While still greenware, the cast engine is disposed in the shell housing space to form at least one shell and engine assembly thereby. Subsequently, and while also in a green state, the cast rim is assembled with the shell and engine assembly and the entire shell, engine and rim assembly is fired to form a single integral piece of sanitaryware. In the corresponding system, a series of casting stations is provided that defines a casting sequence, wherein each said station performs a specific casting step. The selected configuration is sequentially directed to at least one station selected from the series of stations where at least one casting step is performed. Sequential direction and casting steps are repeated until a predetermined number of toilets are produced.

Owner:AMERICAN STANDARD INC

Rhenium tantalum metal alloy

InactiveUS6902809B1High temperature strengthImprove ductilityBlade accessoriesRocket engine plantsRheniumMetal alloy

The present invention provides a method for preparing a rhenium-tantalum alloy with improved strength and ductility characteristics. The method includes mixing powders of rhenium and tantalum with a weight ration of approximately 97% rhenium to approximately 3% tantalum. The powdered blend is then compressed to a green state. The green compress of rhenium and tantalum is then sintered such that tantalum goes into solid solution with rhenium. The sintered material is then cold rolled. The cold rolling disperses oxides away from concentrations in the alloy grain boundaries. If desired, the alloy may then be annealed. The result is a rhenium-tantalum alloy that displays improved high temperature strength and ductility over pure rhenium materials. The present alloy is particularly suited to fabrication of rocketry components such as valve bodies, poppets, seats, and nozzles.

Owner:HONEYWELL INT INC

Method for coloring ceramics via colloidal dispersion

ActiveUS9365459B2Maintain colloidal stabilityFacilitate homogenous solutionImpression capsDentistry preparationsOrganic solventSlurry

Coloring in a slip casting process by which a ceramic slurry is cast into green state bodies. It is during this slip casting that a coloring solution consisting of metallic salts is introduced to the slurry and subsequently slip-cast. A coloring solution may comprise for example a metallic salt, a solvent, an organic solvent such as derivatives of propylene oxides, and an acid can be introduced to the slip casting process. Such a coloring solution can be added to the slip casting process. The solution is thoroughly mixed with the ceramic slurry, after which the ceramic body is cast, dried and finally subjected to a sintering process. After final sinter, the resulting ceramic body possesses an innate color that is homogenous throughout its composition. The method is especially useful for coloring zirconia dental restorations.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

Cellular Ceramic Article and Method For Manufacturing The Same

A method and apparatus to treat a dried unfired article comprising a ceramic precursor composition substantially held together by a binder, to be resistant to binder soluble solvent based processing. The method includes depositing a fluid on the article surface, and polymerizing the deposited fluid to form a polymer thin layer on the surface. The fluid may be an aerosol, a vapor, a fog, a mist, a smoke, or combinations thereof. An apparatus to perform the method and an article resistant to binder soluble solvent based processing are also provided. The article can be an unfired honeycomb body that includes a dried composition of ceramic precursor substantially held together by a binder and a layer disposed on a surface of the unfired honeycomb body. The surface to be exposed in the green state to a binder soluble solvent and the layer protects the binder from solubilization by the solvent.

Owner:CORNING INC

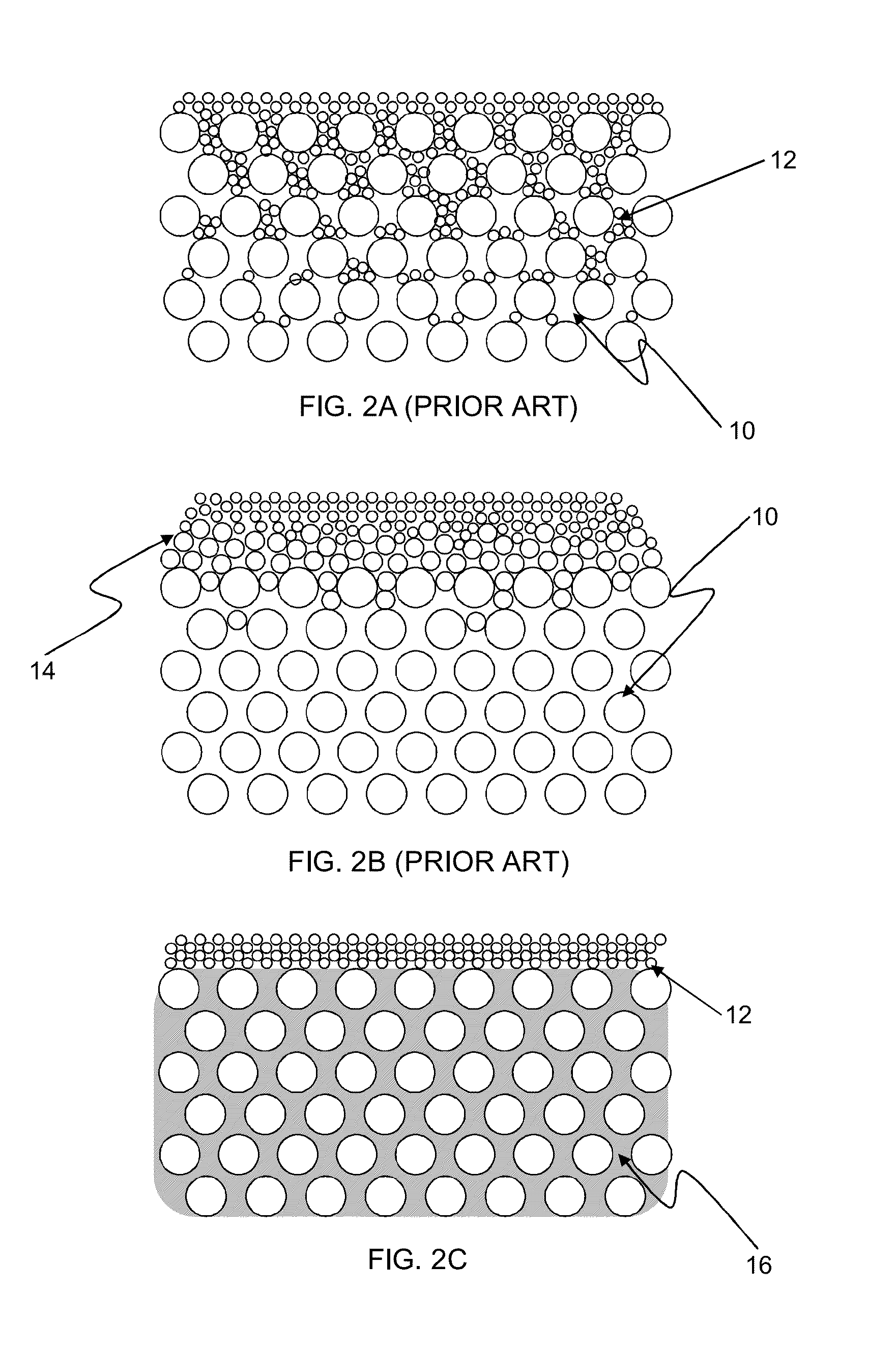

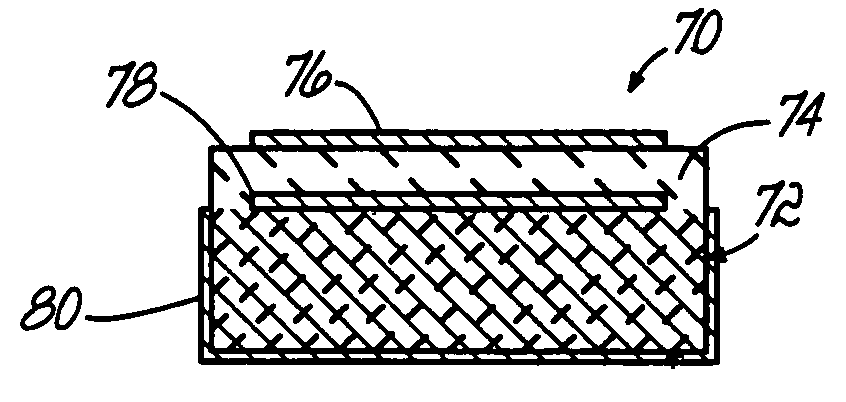

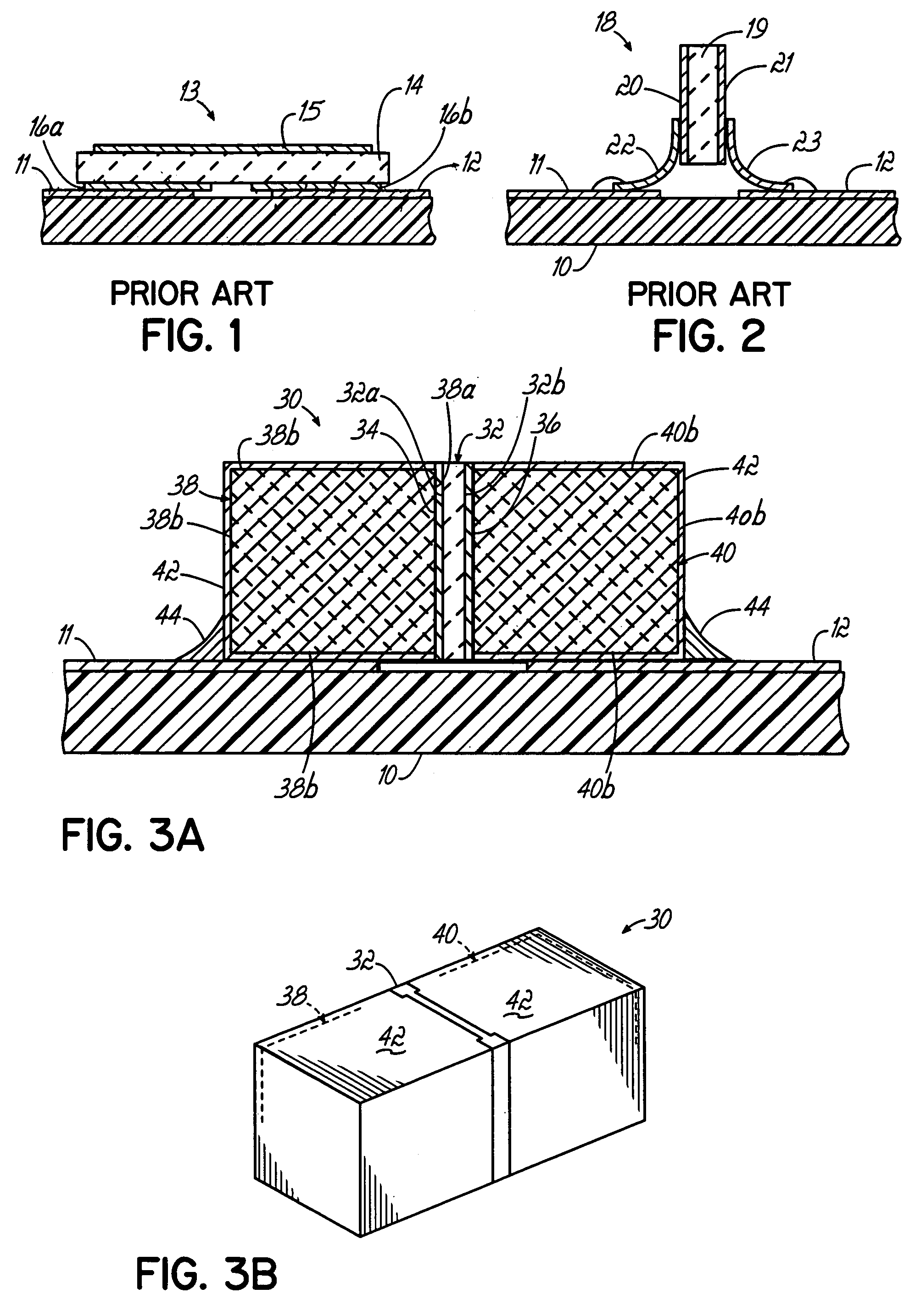

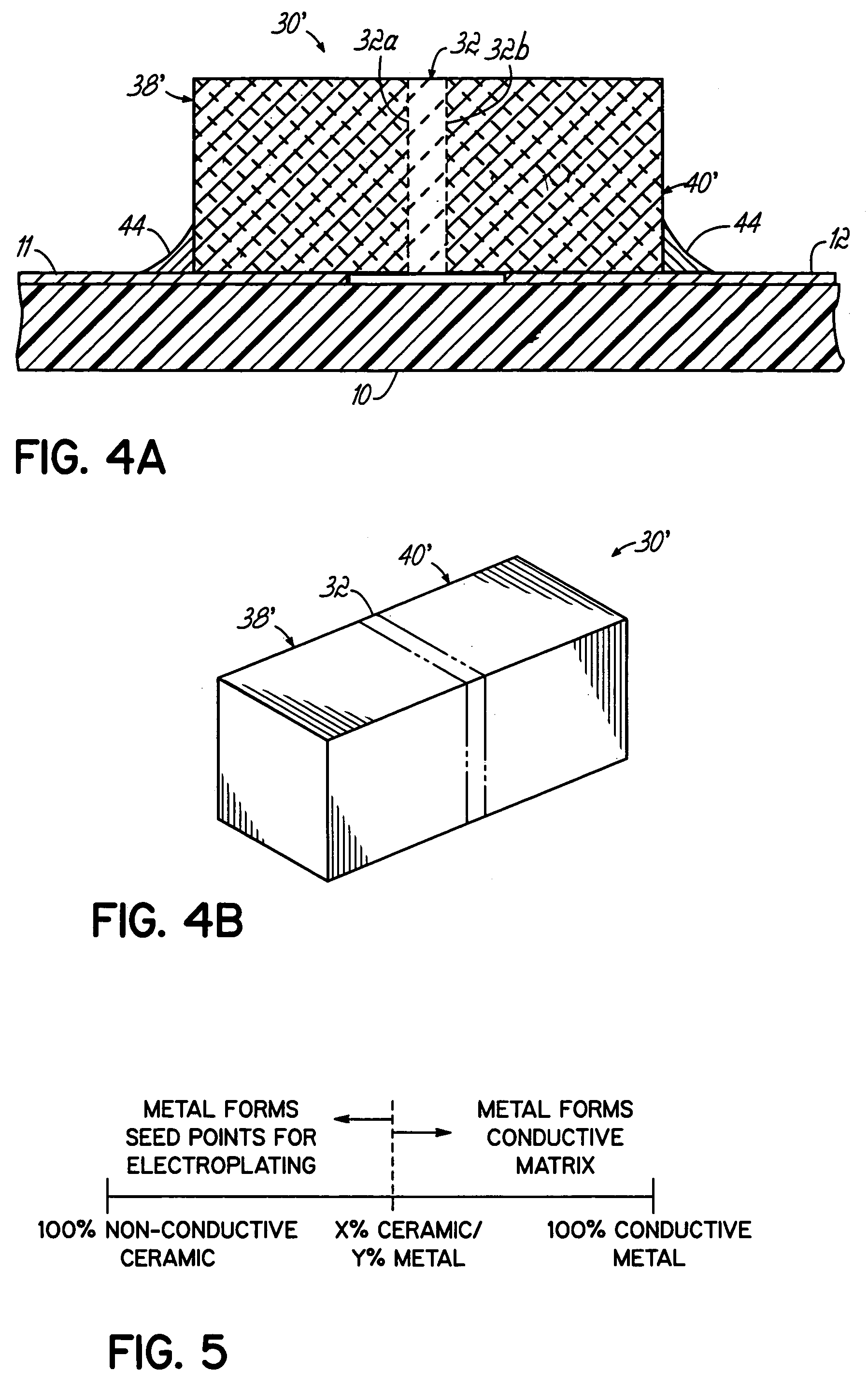

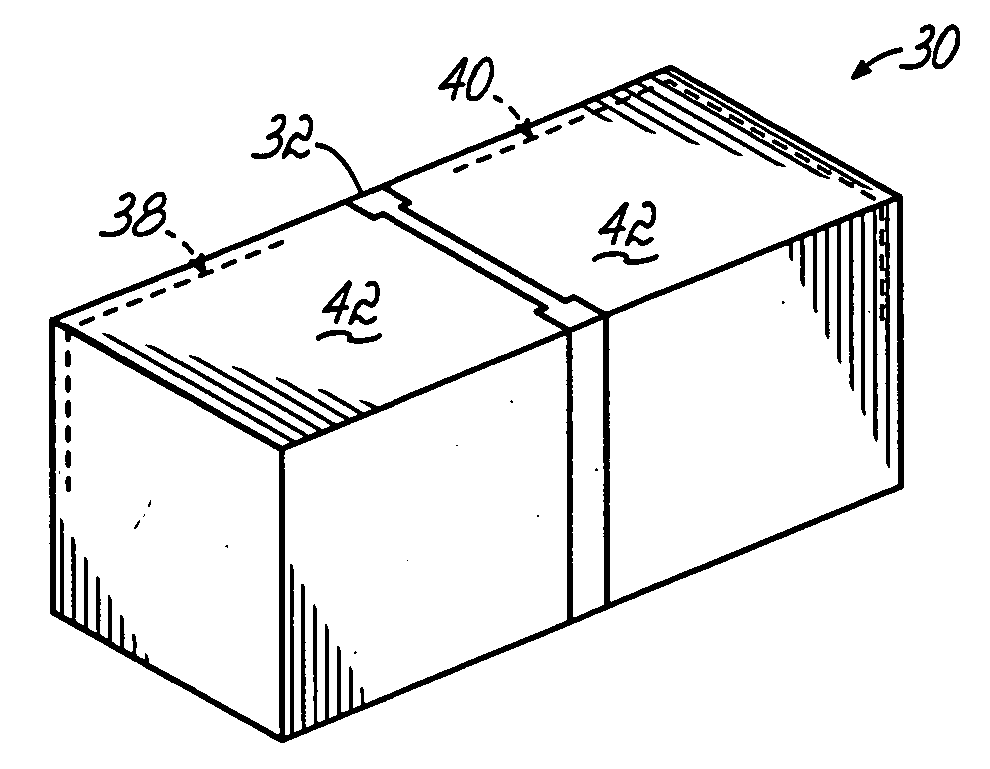

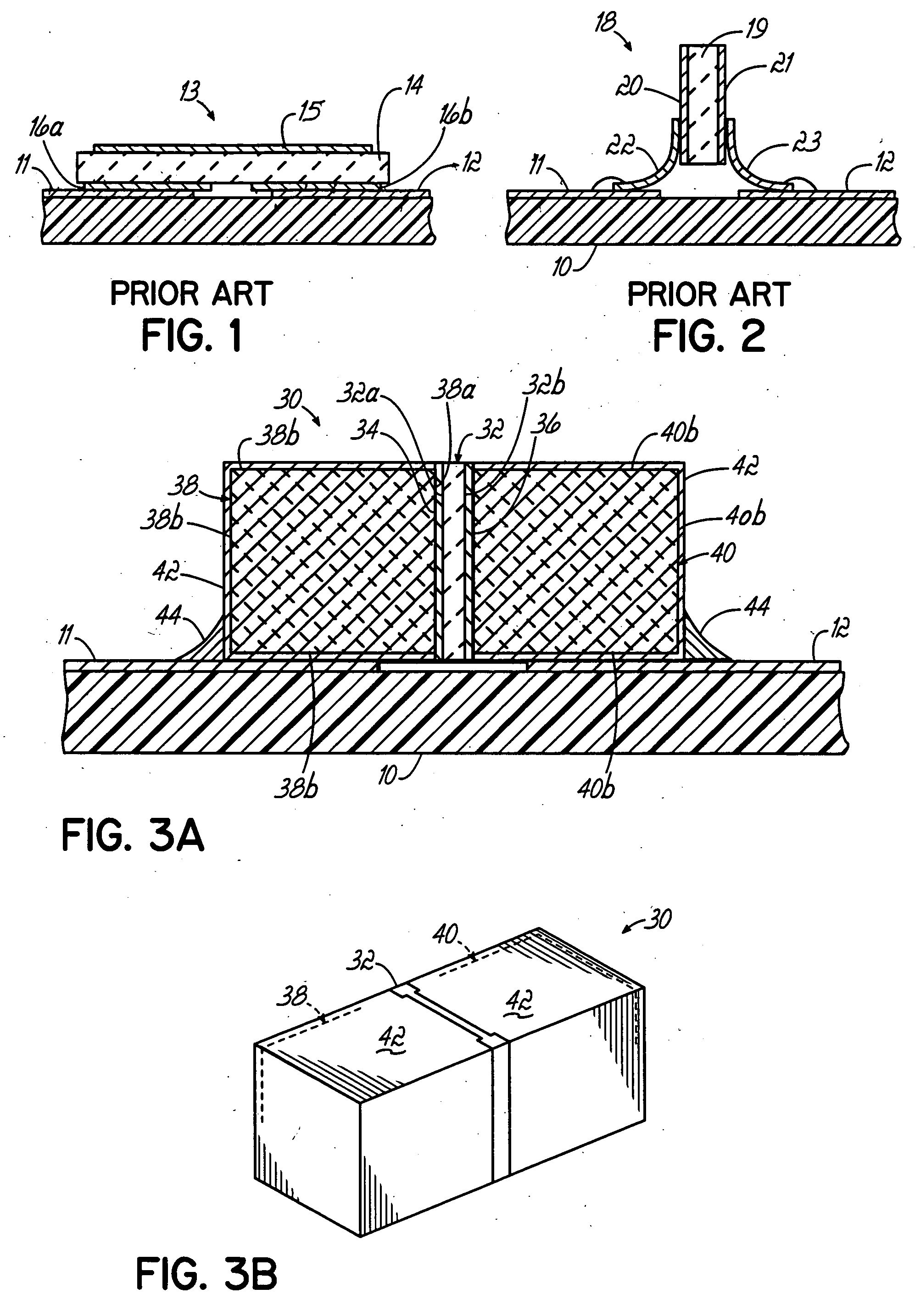

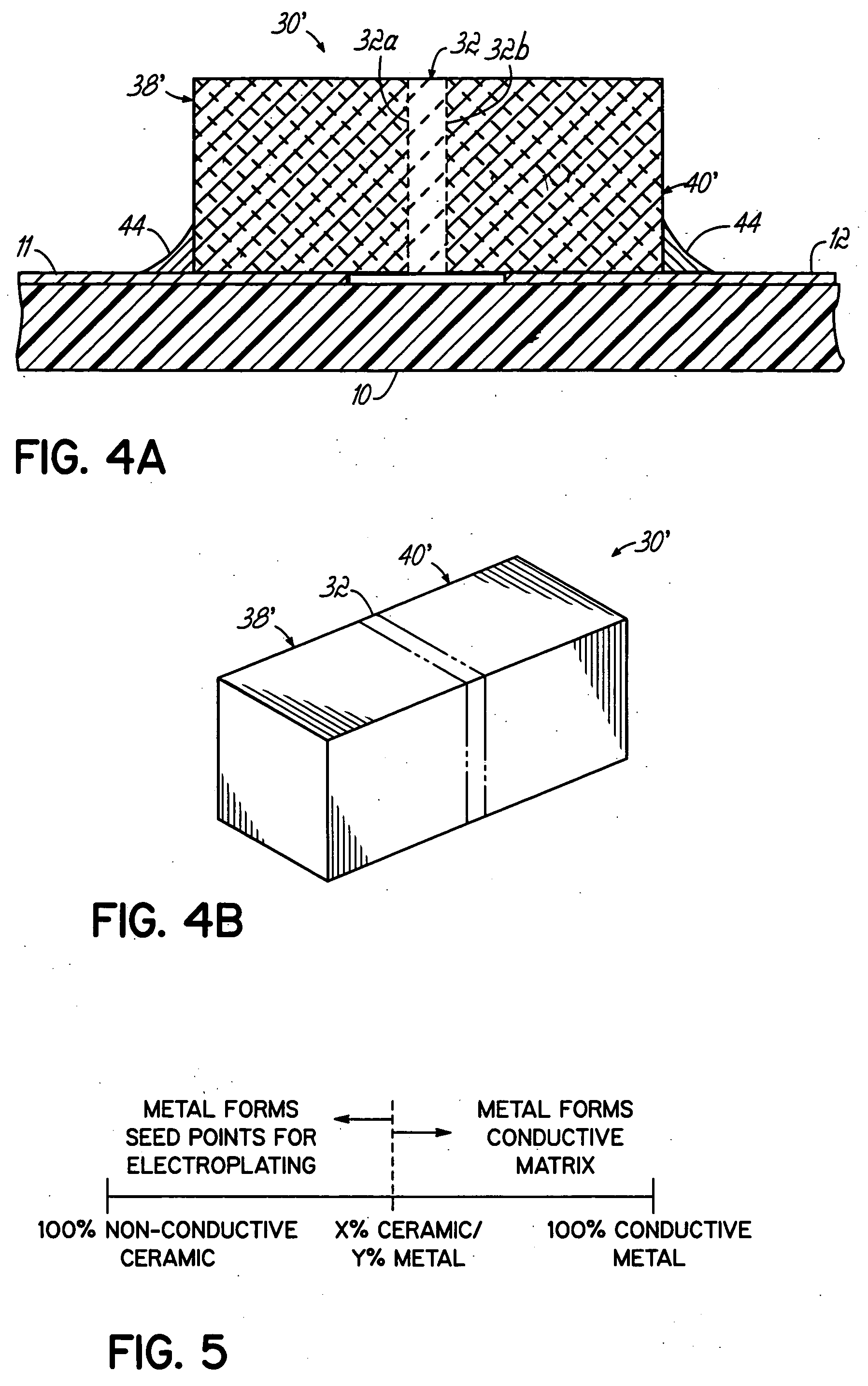

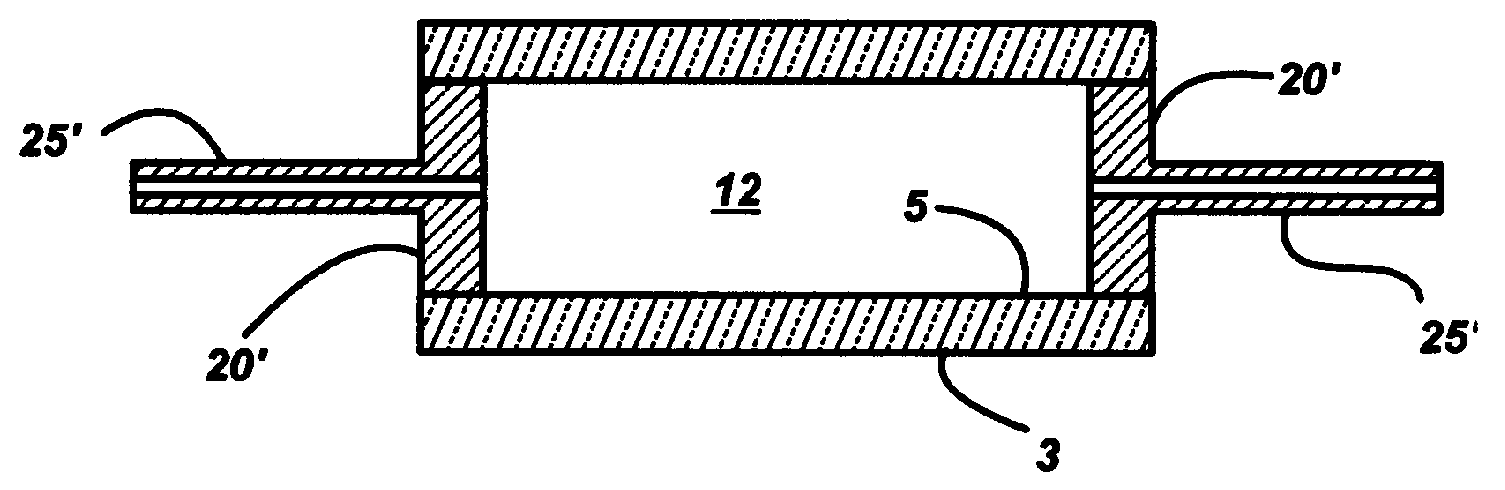

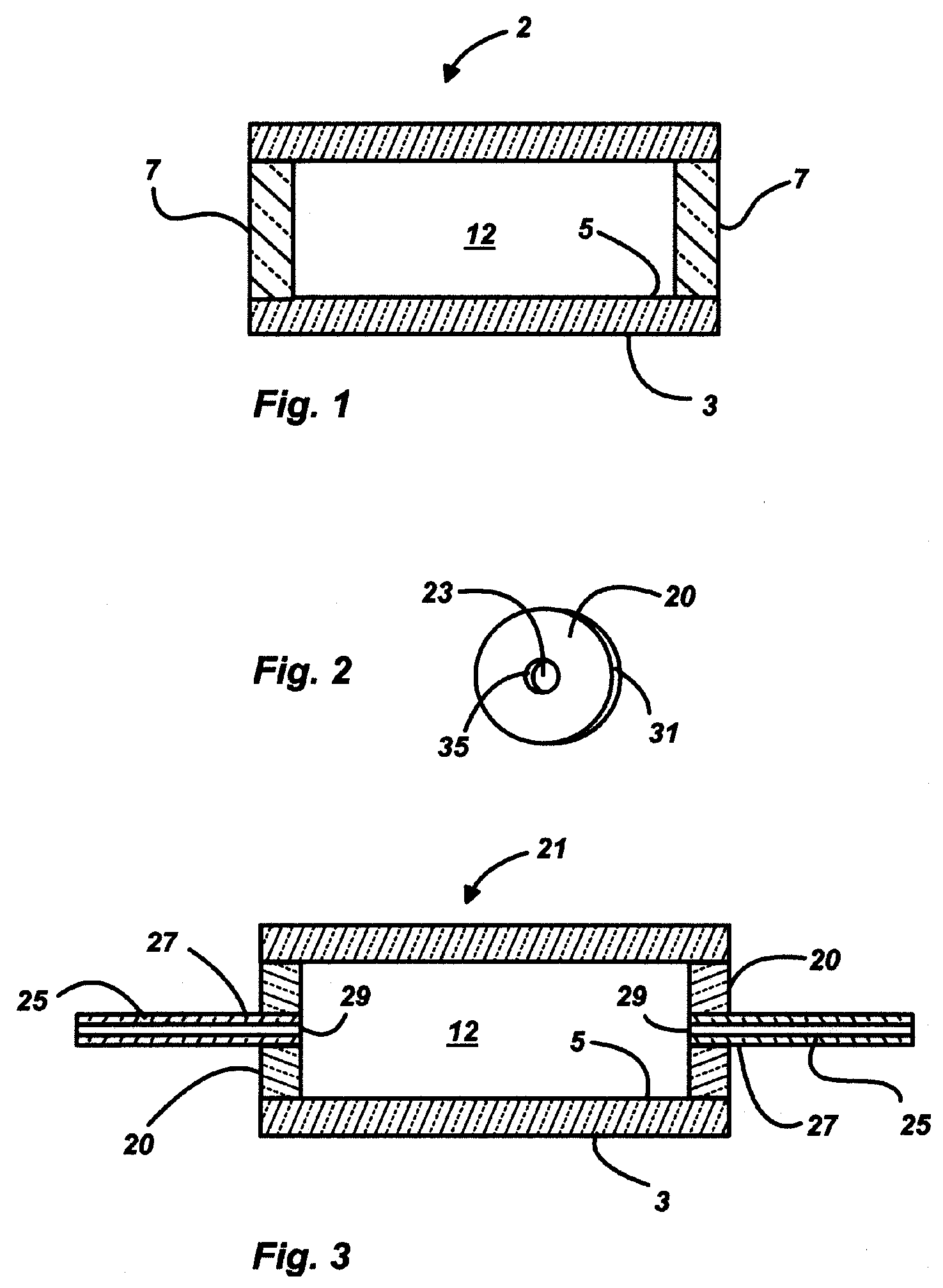

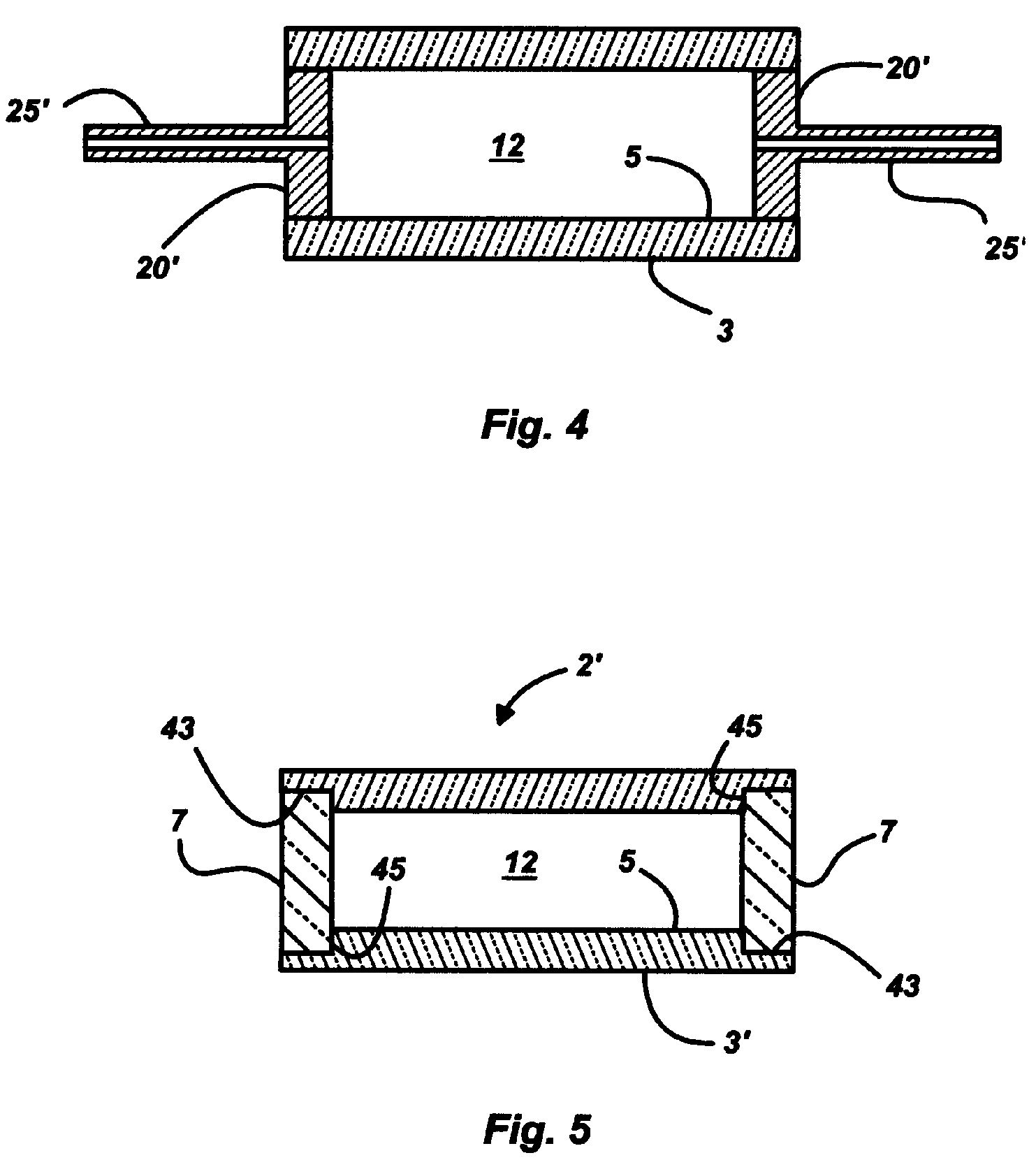

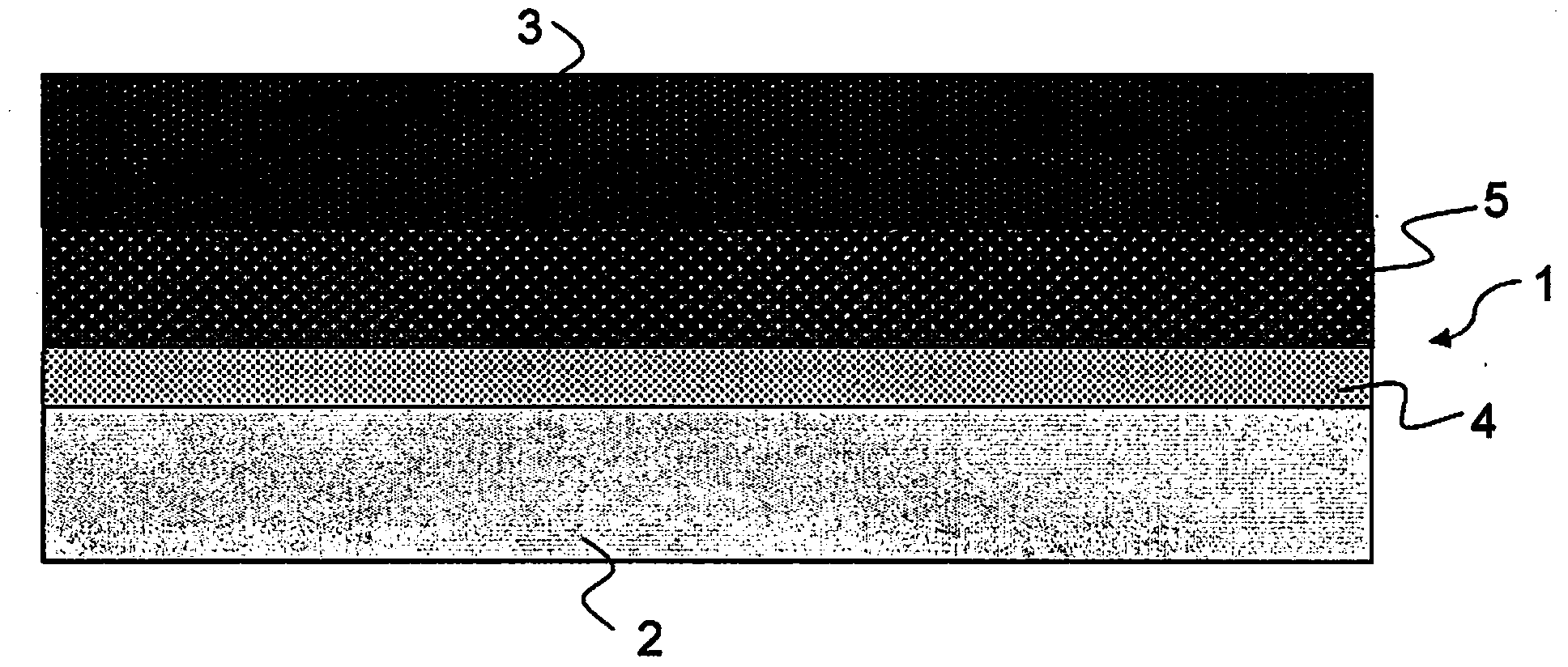

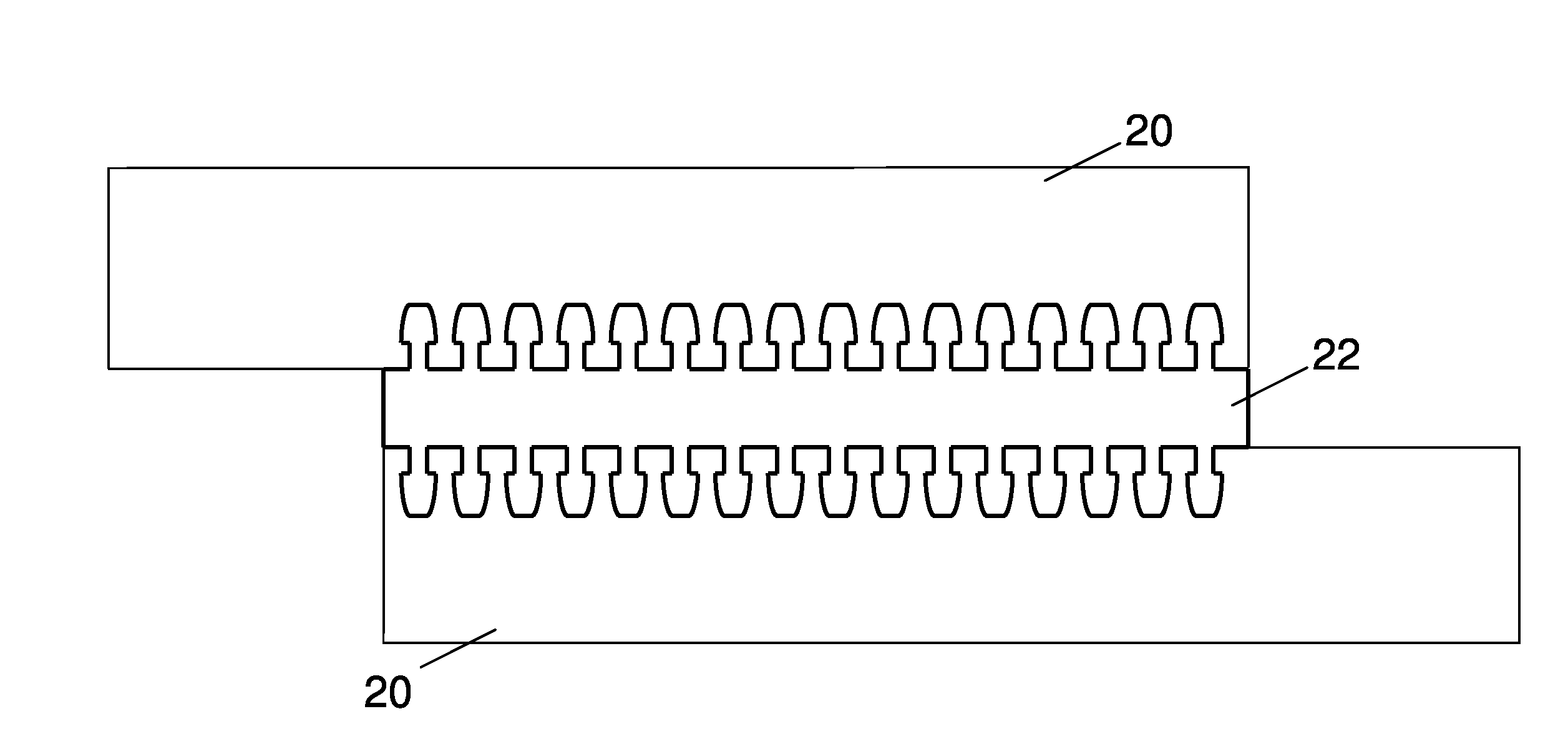

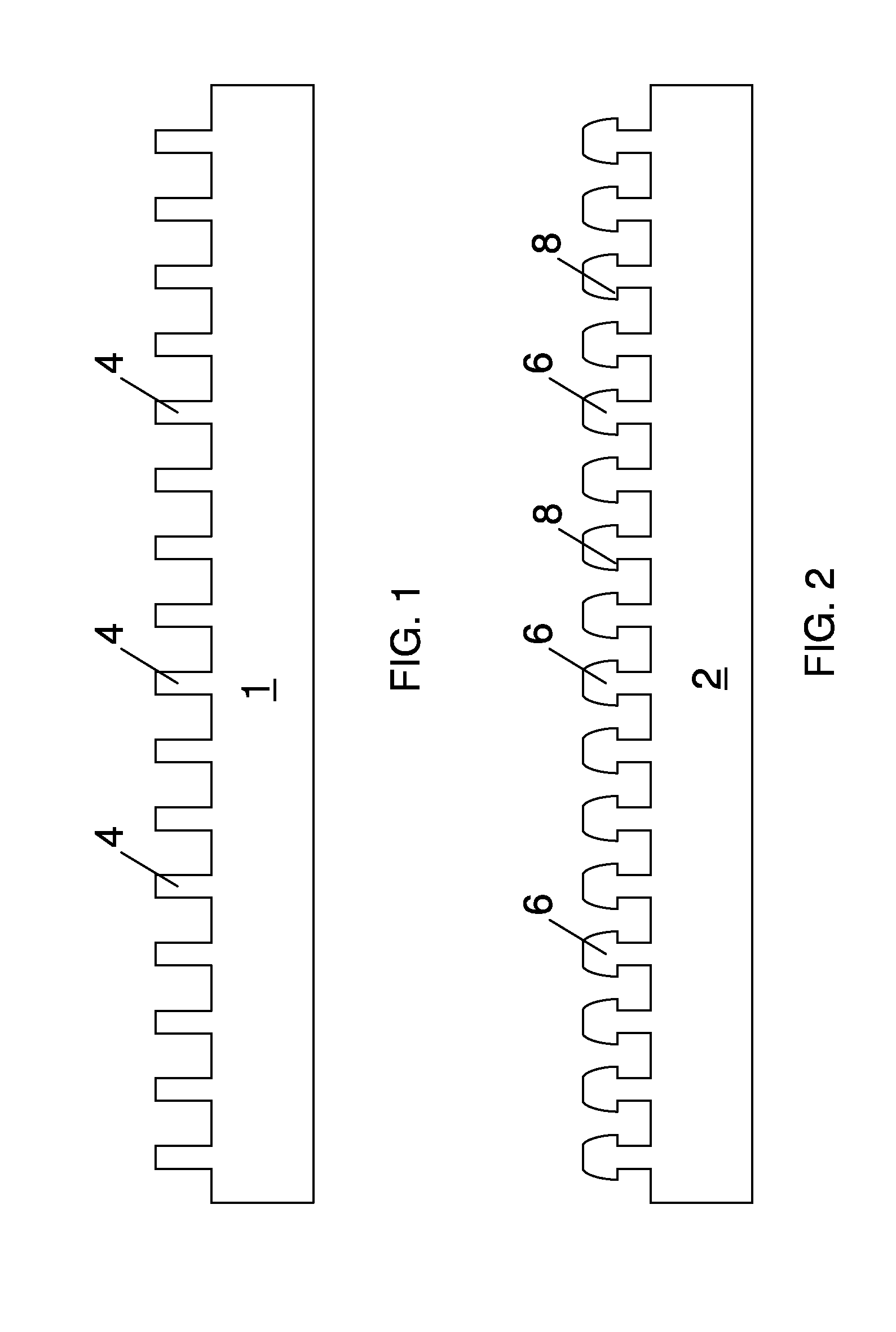

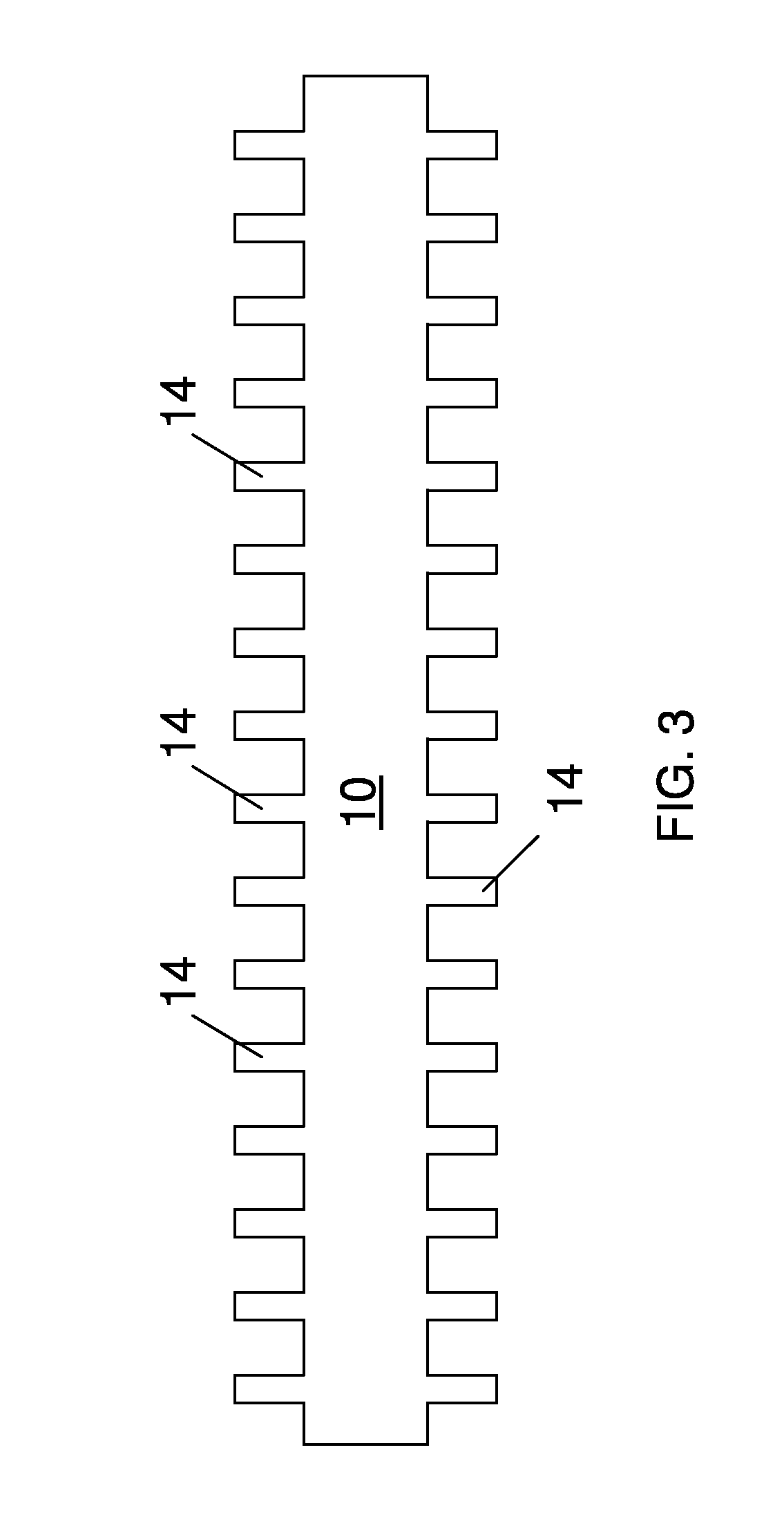

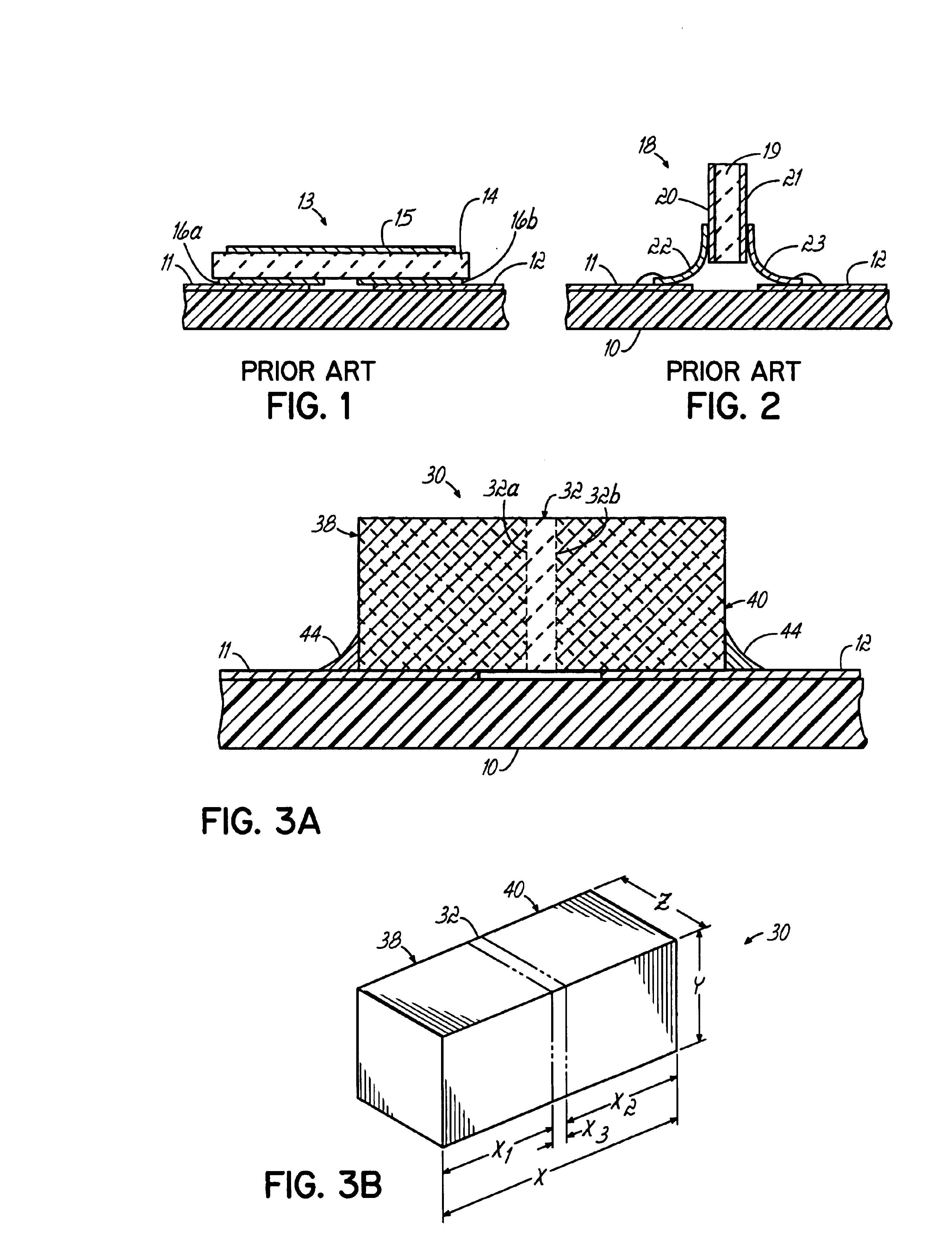

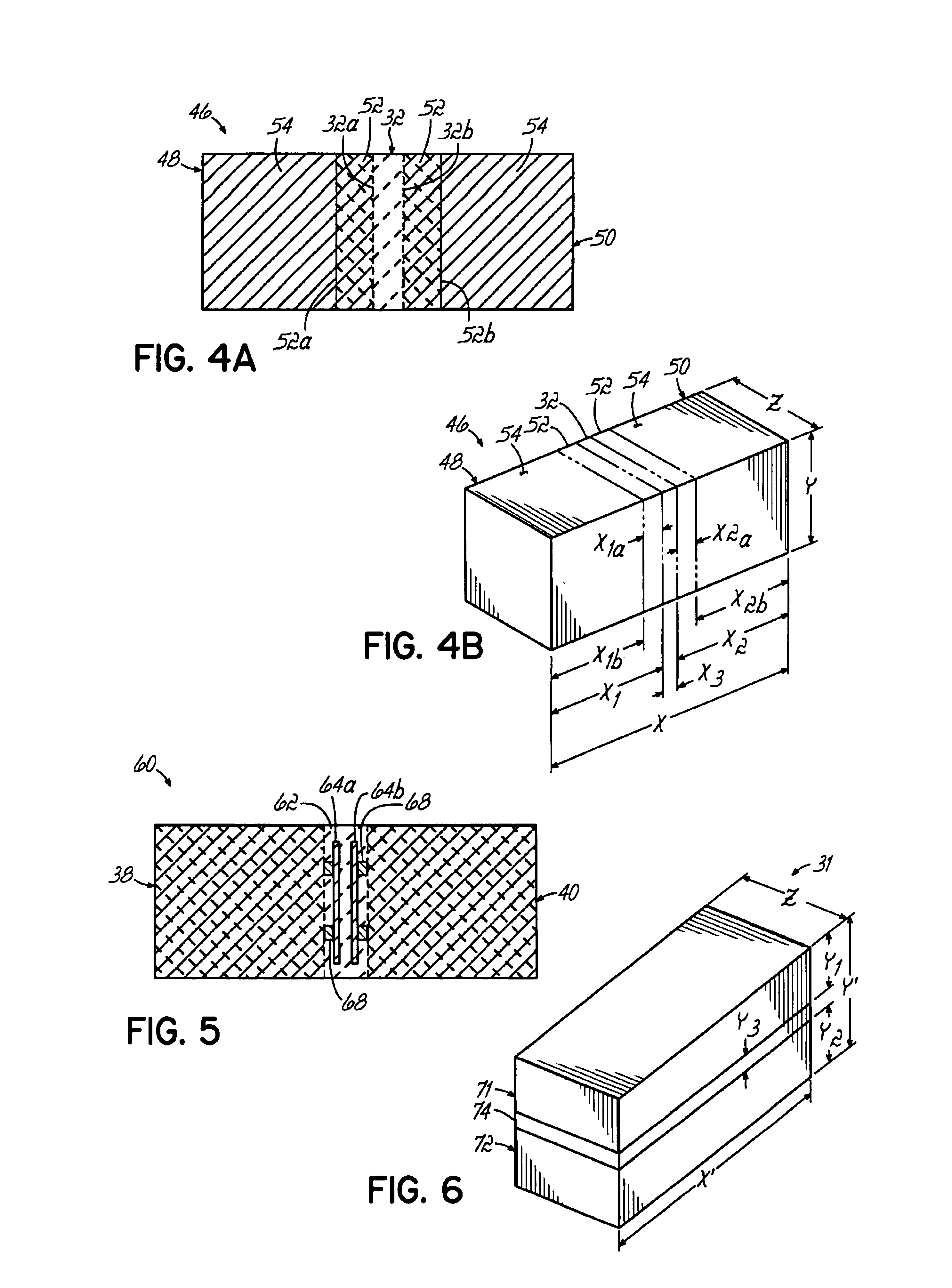

Method of making single layer capacitor

InactiveUS6969647B2Improve structural strengthEasy and inexpensive to manufactureFixed capacitor electrodesThin/thick film capacitorDielectricCapacitance

A method of making a monolithic or essentially monolithic single layer capacitor with high structural strength and capacitance. Sheets of green-state ceramic dielectric material and ceramic / metal composite material are laminated together, diced into individual chips, and fired to sinter the ceramic together. The composite material may contain an amount of metal sufficient to render the composite conductive whereby the composite may be used for one or both electrodes and for mounting the capacitor to the pc board. Alternatively, the composite material may contain an amount of metal insufficient to render the composite conductive but sufficient to act as seed points for an electroplating process wherein the composite is preferentially coated with conductive metal, and the coated composite is mounted to the pc board and the coating provides an electrical connection to an internal electrode. Vertically-oriented surface mountable capacitors and hybrid capacitors are provided.

Owner:PRESIDIO COMPONENTS

Single layer capacitor

InactiveUS20050057887A1Improve structural strengthEasy and inexpensive to manufactureFixed capacitor electrodesThin/thick film capacitorCapacitanceDielectric

A method of making a monolithic or essentially monolithic single layer capacitor with high structural strength and capacitance. Sheets of green-state ceramic dielectric material and ceramic / metal composite material are laminated together, diced into individual chips, and fired to sinter the ceramic together. The composite material may contain an amount of metal sufficient to render the composite conductive whereby the composite may be used for one or both electrodes and for mounting the capacitor to the pc board. Alternatively, the composite material may contain an amount of metal insufficient to render the composite conductive but sufficient to act as seed points for an electroplating process wherein the composite is preferentially coated with conductive metal, and the coated composite is mounted to the pc board and the coating provides an electrical connection to an internal electrode. Vertically-oriented surface mountable capacitors and hybrid capacitors are provided.

Owner:PRESIDIO COMPONENTS

Thermoanalytical sensor

ActiveUS20080080586A1High sensitivityIncrease structural flexibilityThermometers using electric/magnetic elementsUsing electrical meansTemperature controlHeat flow

Thermoanalytical sensor for calorimetric measurements which cooperates with a temperature control device and comprises at least one measurement position formed on the sensor, a heat flow path established between the temperature control device and the at least one measurement position, and at least one temperature-measuring element, characterized in that the sensor has a plurality of layers which are formed substantially by ceramic elements that have been solidly bonded to each other by undergoing a sintering process together and which in their green state can be provided with a structure, wherein at least a part of the ceramic elements are structured.

Owner:METTLER TOLEDO GMBH

Method of shaping green part and manufacturing method using same

A method of shaping a part in a green state obtained through powder injection molding, including placing a surface of the part in contact with a shaping surface of a setter with at least one section of the surface of the part not conforming to the shaping surface, and locally heating at least one area of each of the at least one section to deform the part until the at least one section conforms to the shaping surface. The part remains in the green state during the local heating. The part may be a heat shield panel for a gas turbine engine.

Owner:PRATT & WHITNEY CANADA CORP

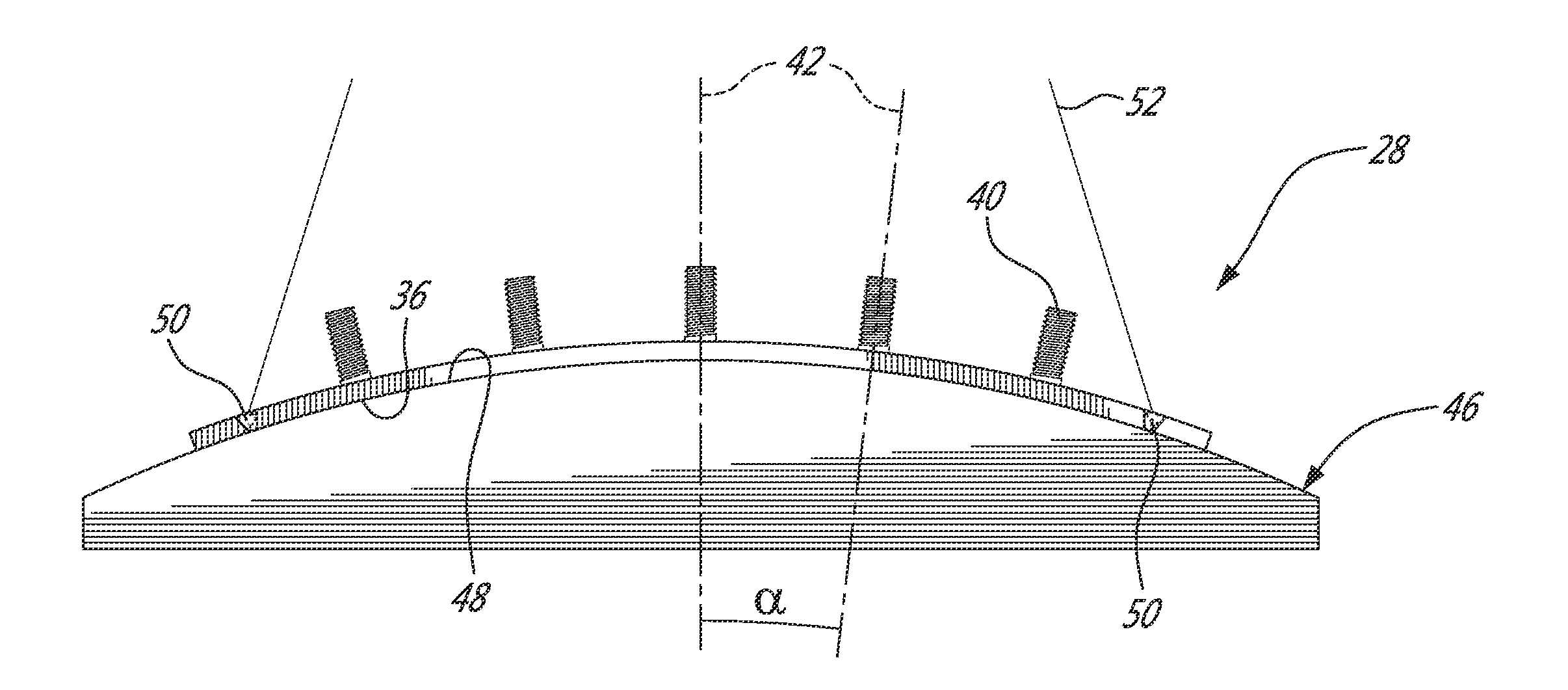

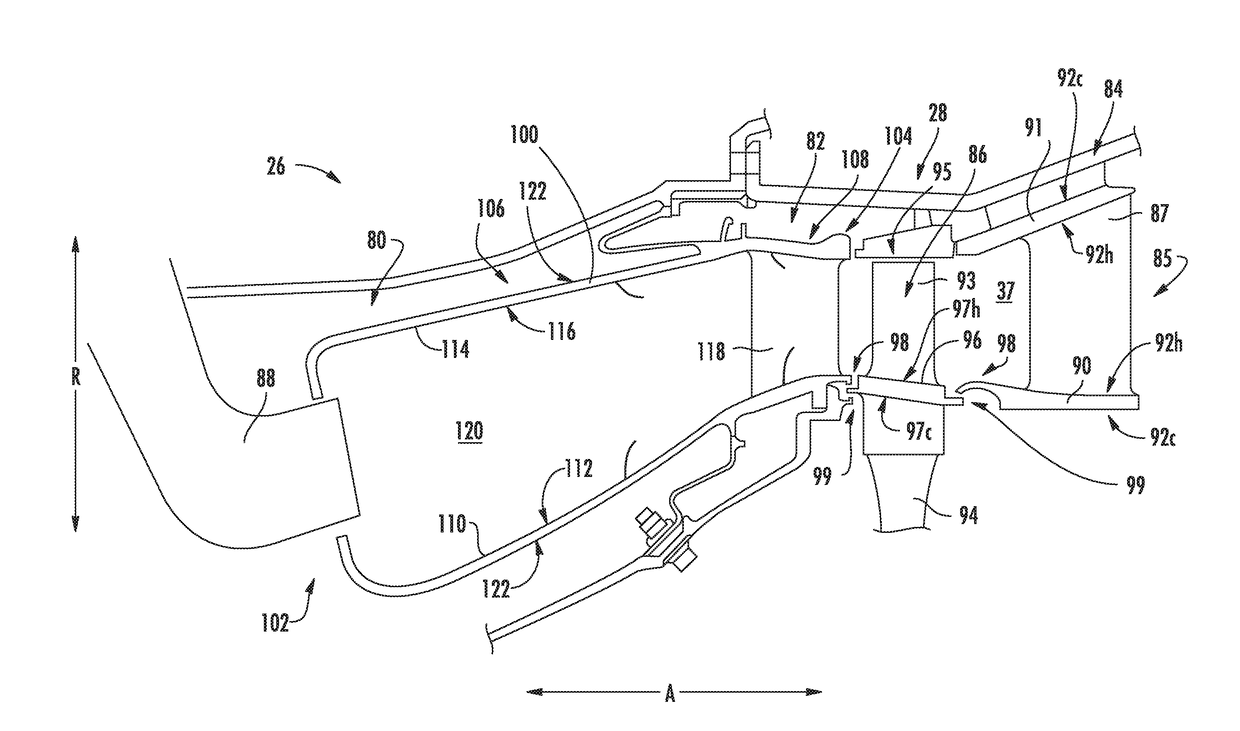

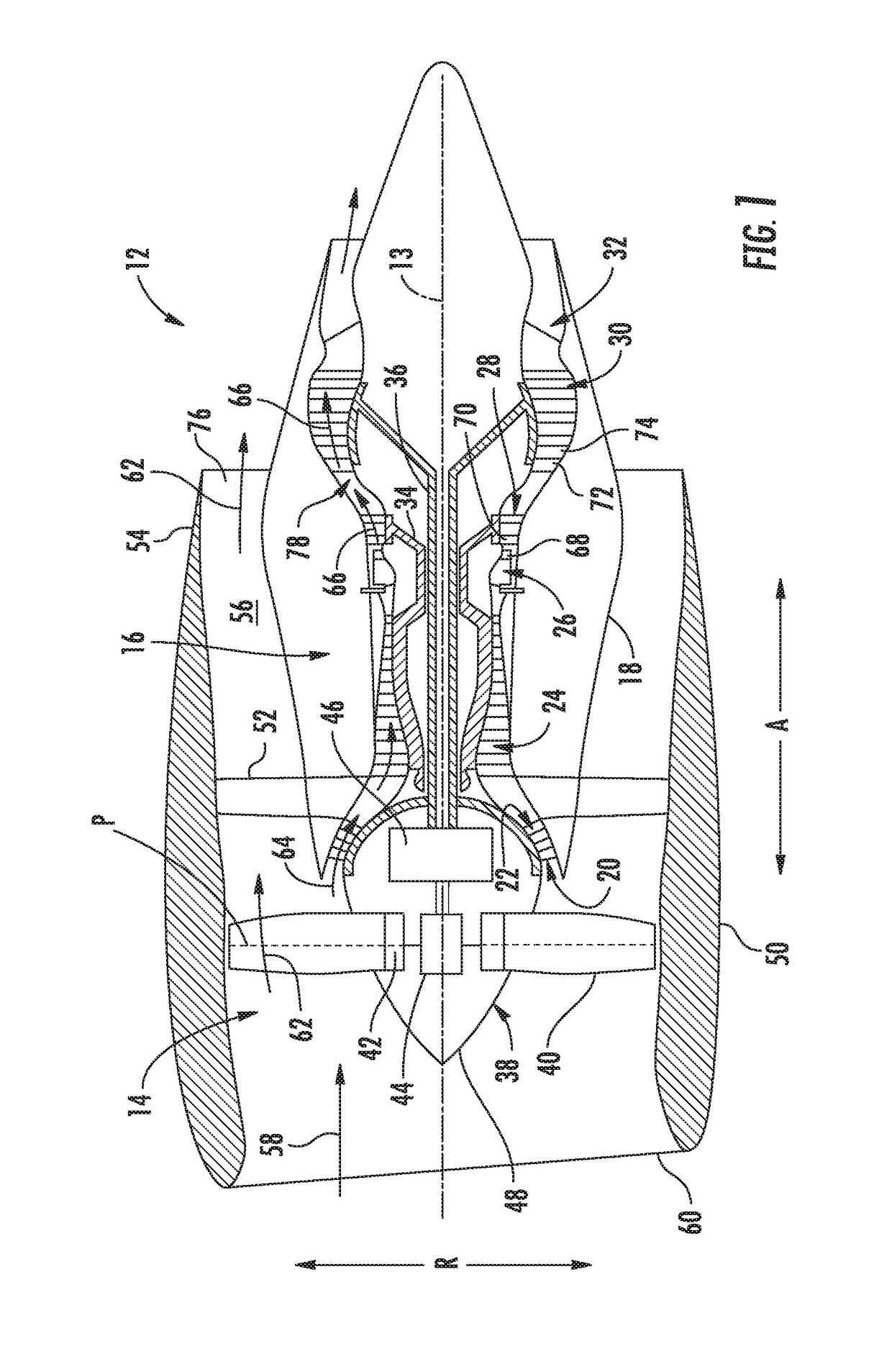

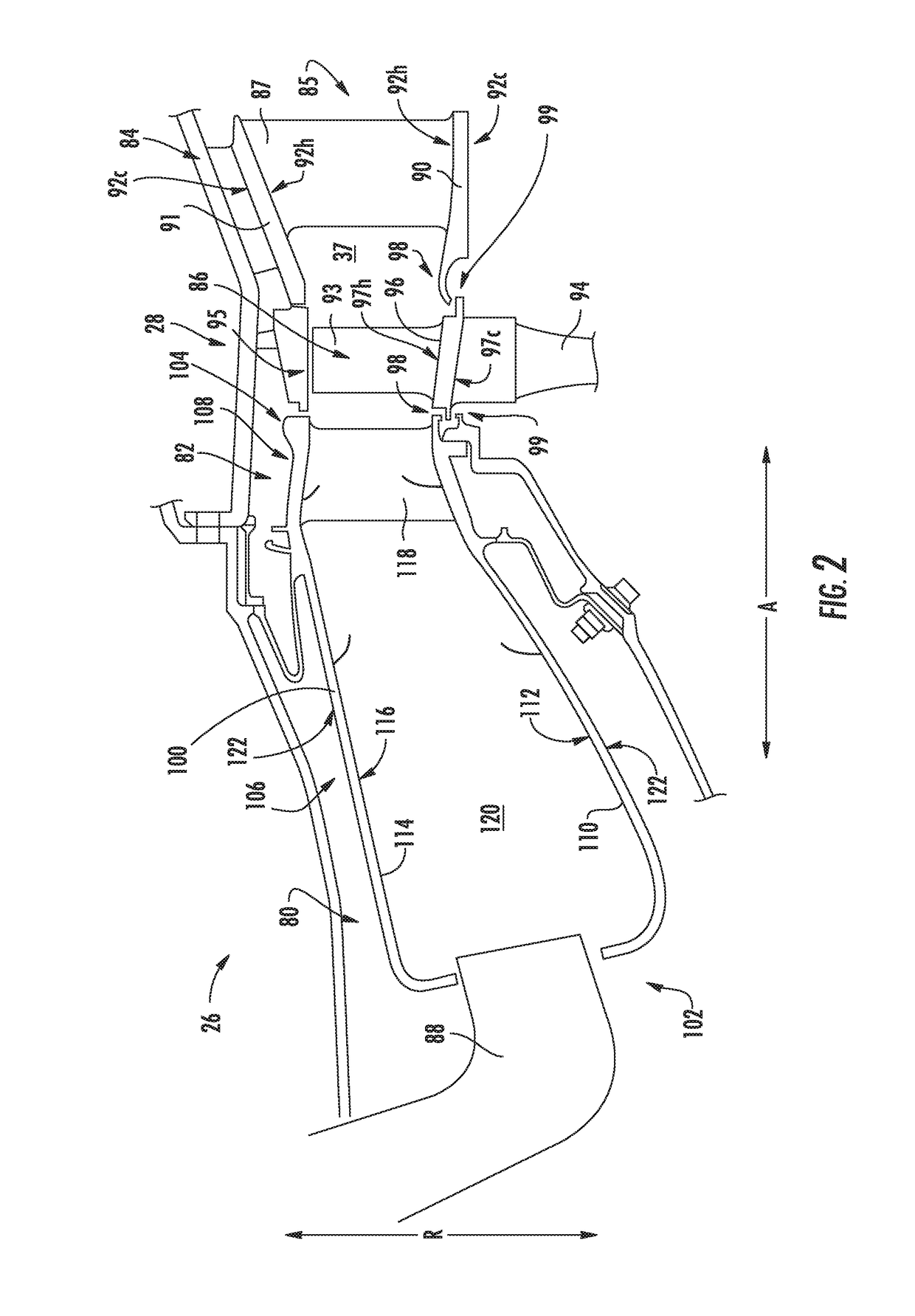

Ceramic Matrix Composite Component for a Gas Turbine Engine

InactiveUS20170370583A1Continuous combustion chamberEfficient propulsion technologiesCombustorSpray nozzle

Ceramic matrix composite (CMC) components and methods for forming CMC components of gas turbine engines are provided. In one embodiment, a CMC component for a gas turbine engine includes an inner wall defining a first inner surface; an outer wall defining a second inner surface; and a nozzle extending from the inner wall to the outer wall. The inner wall, outer wall, and nozzle are integrally formed from a CMC material such that the inner wall, outer wall, and nozzle are a single unitary component. An exemplary method for forming a CMC component includes laying up a plurality of plies of a CMC material; processing the plurality of plies to form a green state component; firing the green state component; and densifying the fired component to produce a final unitary component. The unitary component comprises a combustor liner portion and a combustor discharge nozzle stage portion.

Owner:GENERAL ELECTRIC CO

Method for manufacturing coloring ceramics via colloidal dispersion followed by conventional pressing techniques

ActiveUS9512317B2Maintain colloidal stabilityFacilitate homogenous solutionPigmenting treatmentImpression capsOrganic solventSlurry

A colored ceramic powder is produced from a mixture of coloring solutions consisting of metallic salts that are introduced to a ceramic slurry and subsequently dried. The coloring solution may comprise for example of chosen metallic salts, a solvent, an organic solvent such as derivatives of propylene oxides, an acid and a possible binder. Once all the constituents are thoroughly mixed to a homogeneous state, the slip is dried to a powder form, which spray drying equipment can be used. The dried powder can then be subjected to an isostatic or biaxial press manufacturing process to create a green state ceramic body. Once pressed, the ceramic body can be subjected to a sintering process. After final sinter, the resulting ceramic body possesses an innate color that is homogenous throughout its composition. The method is especially useful for coloring zirconia dental restorations.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

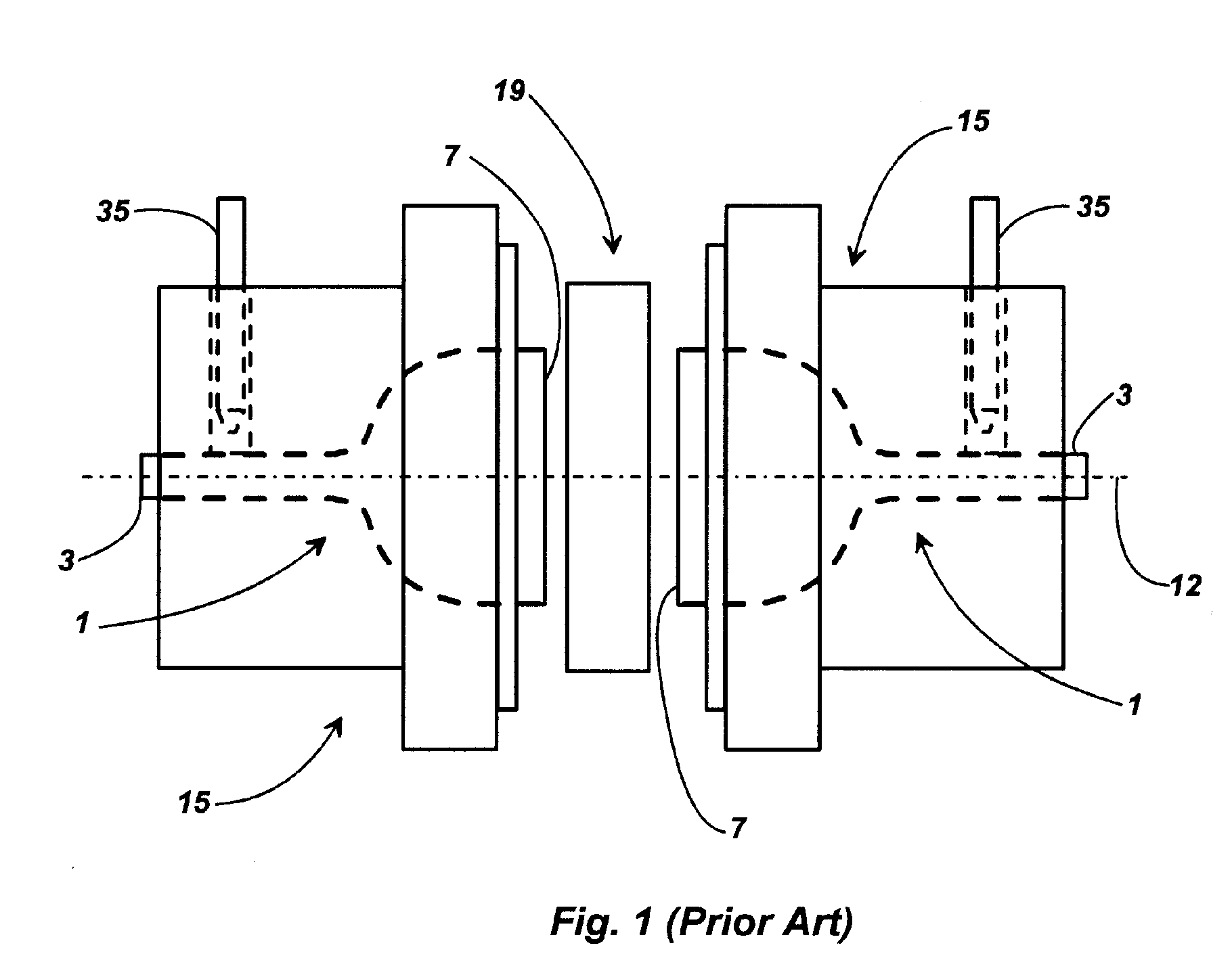

Ceramic Discharge Vessel with Expanded Reaction-Bonded Aluminum Oxide Member

InactiveUS20060138962A1Reduce decreaseReduced dimensionDischarge tube luminescnet screensElectroluminescent light sourcesHermetic sealAluminum metal

A ceramic discharge vessel is provided wherein the discharge vessel has a ceramic body and at least one expanded reaction-bonded aluminum oxide member hermetically sealed to the ceramic body. The method of making the discharge vessel includes (a) forming a ceramic body; (b) forming a reaction-bonded aluminum oxide member in a green state by compacting a mixture of aluminum metal and aluminum oxide powders; (c) assembling the ceramic body and the reaction-bonded aluminum oxide member in the green state to form an assembly; and (d) reaction sintering the assembly to cause the reaction-bonded aluminum oxide member to expand and form a hermetic seal with the ceramic body.

Owner:OSRAM SYLVANIA INC

Layer structure and use thereof to form a ceramic layer structure between an interconnect and a cathode of a high-temperature fuel cell

The invention relates to a layer structure that is formed between an interconnect and a cathode of a high-temperature fuel cell and that can be used to form a ceramic layer structure between an interconnect and a cathode. The interconnect is made of a metal alloy containing chromium. The aim of the invention is to provide a layer structure between an interconnect and a cathode of a high-temperature fuel cell, by means of which good protective function (against corrosion and against chromium evaporation), high electrical conductivity, and good thermal expansion behavior matched to the materials of an interconnect and of a cathode can be achieved. The layer structure is formed in the green state by a powdery spinel and at least one metal oxide from the group comprising CuO, NiO, CoOx, and MnOx as a sintering additive, and at least one powdery perovskite. Chromium is not contained in any of said chemical compounds. The fraction of contained spinel having the metal oxides as a sintering additive is reduced from the side facing the interconnect to the side facing the cathode, and the fraction of perovskite is reduced from the side facing the cathode to the side facing the interconnect.

Owner:PLANSEE SE +1

System and Method for Casting Toilet Bowls

ActiveUS20070124913A1Easy to manufactureManufacturing can be simplified and expeditedConfectionerySweetmeatsEngineeringMechanical engineering

The present invention provides an improved system and method for casting toilets. In the disclosed method, at least one of a shell, engine and rim configuration for a toilet is provided, wherein the configuration is selected from a plurality of shell, engine and rim configurations defined by a corresponding plurality of shell, engine and rim molds. Each mold defines a casting space therewithin for casting the selected configuration therefrom. Each shell configuration includes a hollow housing space for disposition of a unique sanitaryware performance engine configuration therewithin. While still greenware, the cast engine is disposed in the shell housing space to form at least one shell and engine assembly thereby. Subsequently, and while also in a green state, the cast rim is assembled with the shell and engine assembly and the entire shell, engine and rim assembly is fired to form a single integral piece of sanitaryware. In the corresponding system, a series of casting stations is provided that defines a casting sequence, wherein each said station performs a specific casting step. The selected configuration is sequentially directed to at least one station selected from the series of stations where at least one casting step is performed. Sequential direction and casting steps are repeated until a predetermined number of toilets are produced.

Owner:DAVIES GRAHAM +1

Process for Producing Shaped Metal Bodies Having a Structured Surface

InactiveUS20120153549A1Low production costCeramic shaping apparatusClaywaresInjection mouldingMaterials science

The present invention relates to a process for producing shaped metal bodies having a structured surface which can be used as joining elements in the “friction spot joining” process described in the EP application 09015014.5. The shaped metal bodies are produced by means of MIM technology, and are deformed further in the green state or in the brown state after injection moulding to give the desired components.

Owner:HELMHOLTZ ZENT GEESTHACHT ZENT FUER MATERIAL UND KUESTENFORSCHUNG

Reaction-bonded porous magnesia body

InactiveUS20050181928A1Small volume changeEasy to makeSemi-permeable membranesFiltration separationSemipermeable membraneCompound (substance)

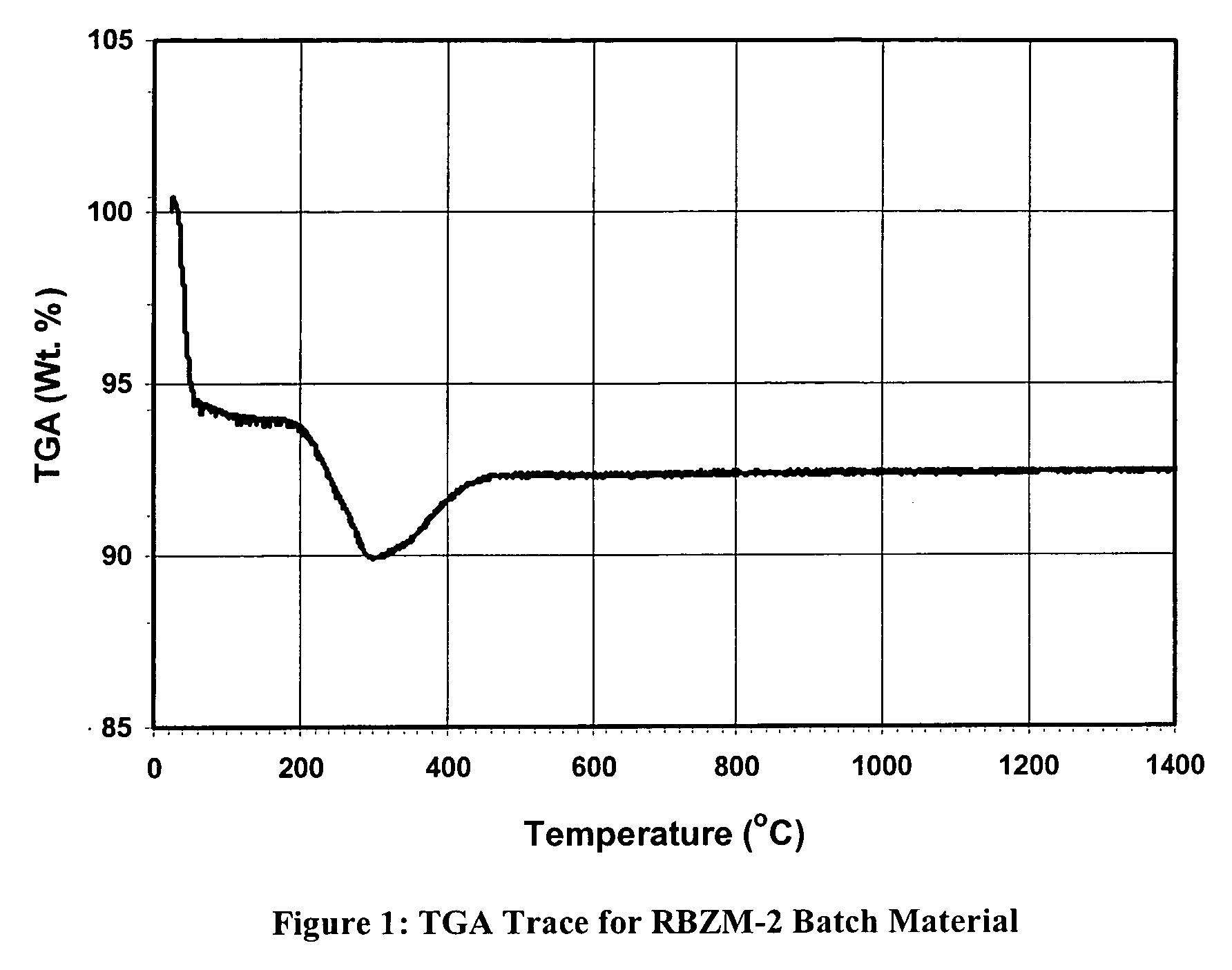

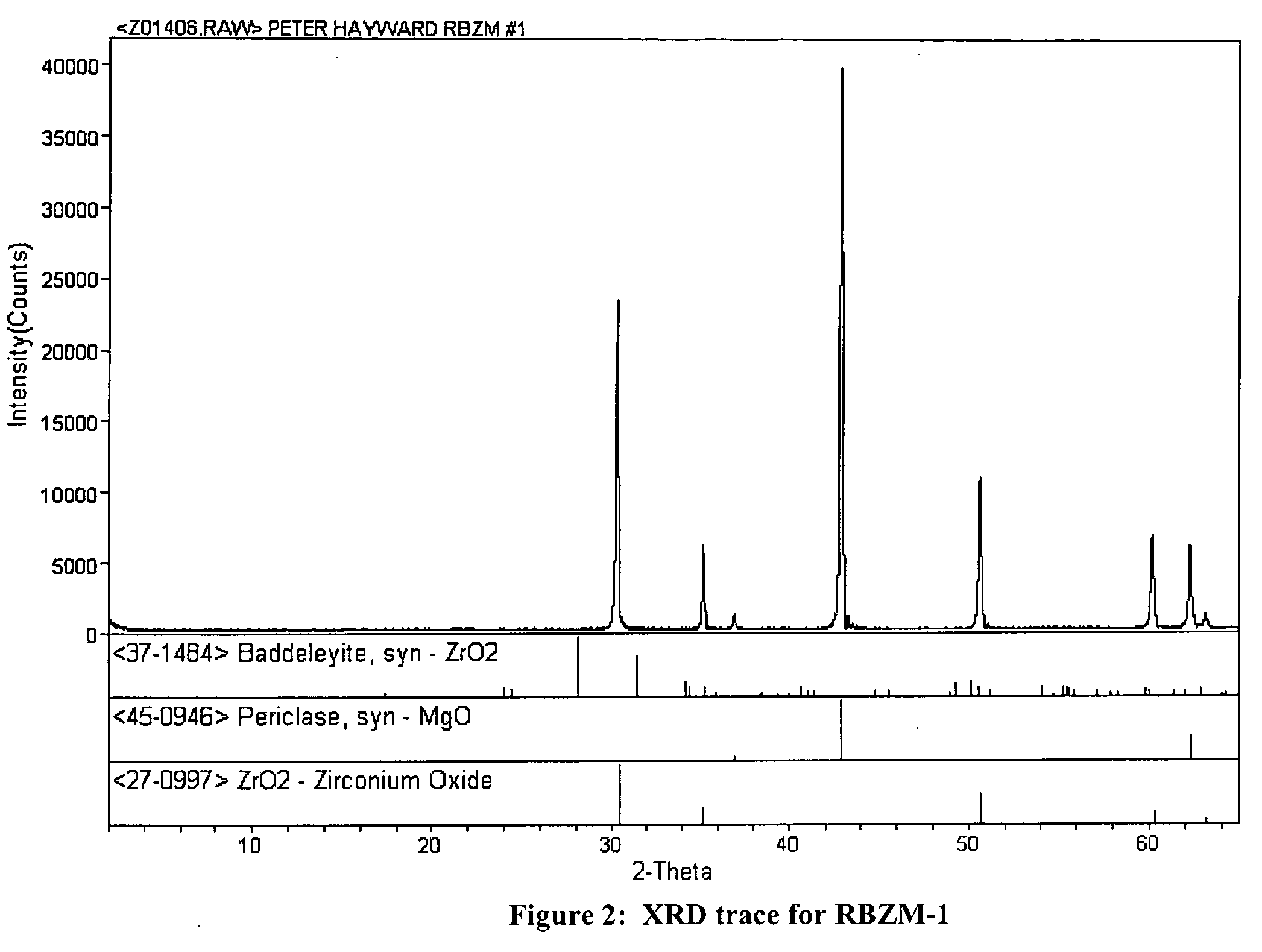

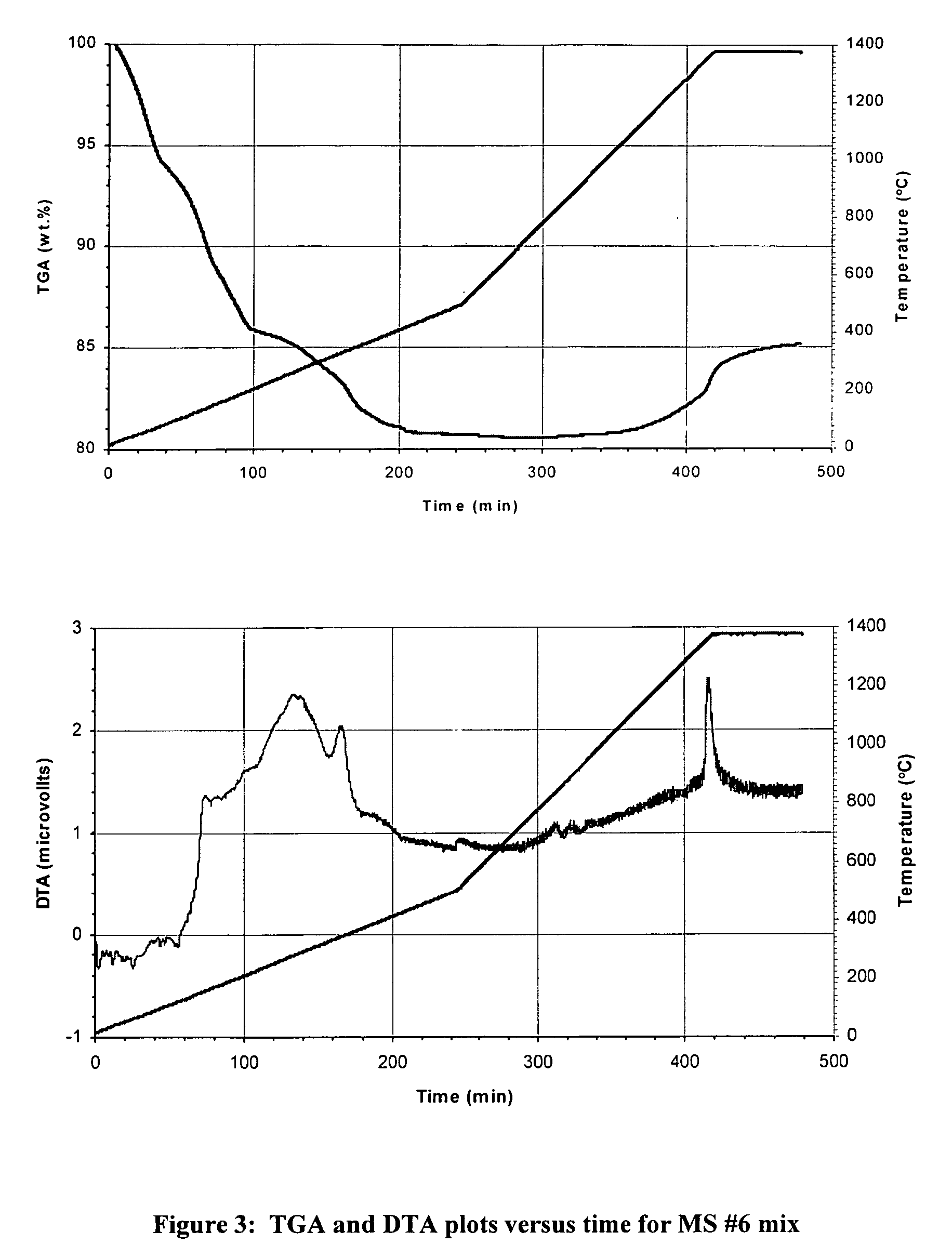

A porous reaction-bonded magnesia body with small or negligible shrinkage between the green state and the fired state. The body made by forming a green (i.e., unfired) body of mixed powders containing coarse grains of magnesia in combination with at least one reactive element, and optionally other ceramic oxides and / or compounds, followed by sintering in an oxidizing atmosphere. During sintering, oxidation and / or reaction of the element grain results in an overall volume change that is negligibly small or zero. The resulting body is highly porous, and may be used as a support for a semi-permeable membrane, especially relatively high coefficient of thermal expansion, high-temperature gas separation membranes.

Owner:CERAMEM

Process for making dynamically-loaded articles comprising propylene-based elastomers, composition for use in such processes, and article made using such processes

Owner:EXXONMOBIL CHEM PAT INC

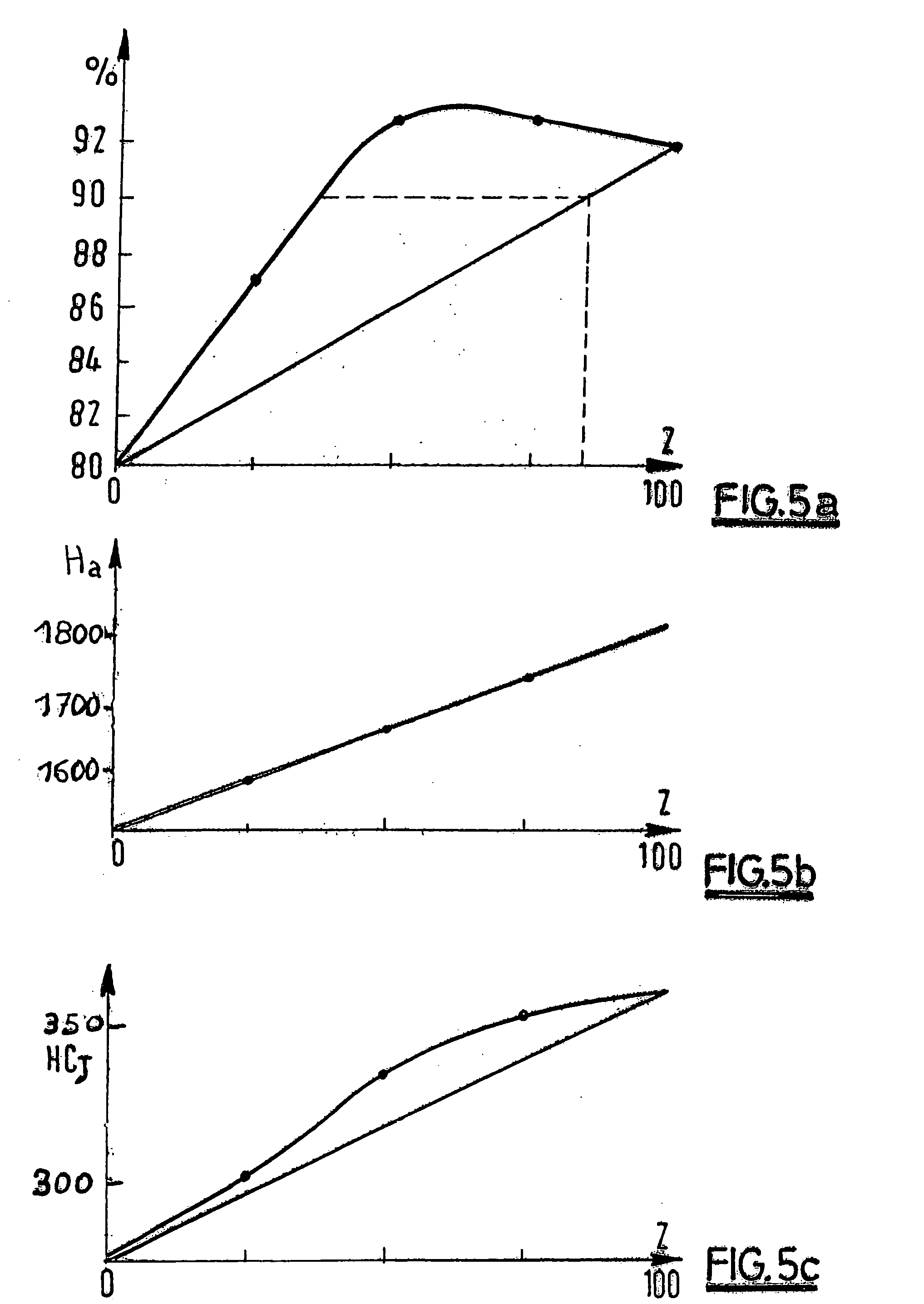

Manufacturing method for ferrite type magnets

InactiveUS20040151661A1Improve magnet performanceGood magnetic performanceIron oxides/hydroxidesInorganic material magnetismChemical compositionPowder mixture

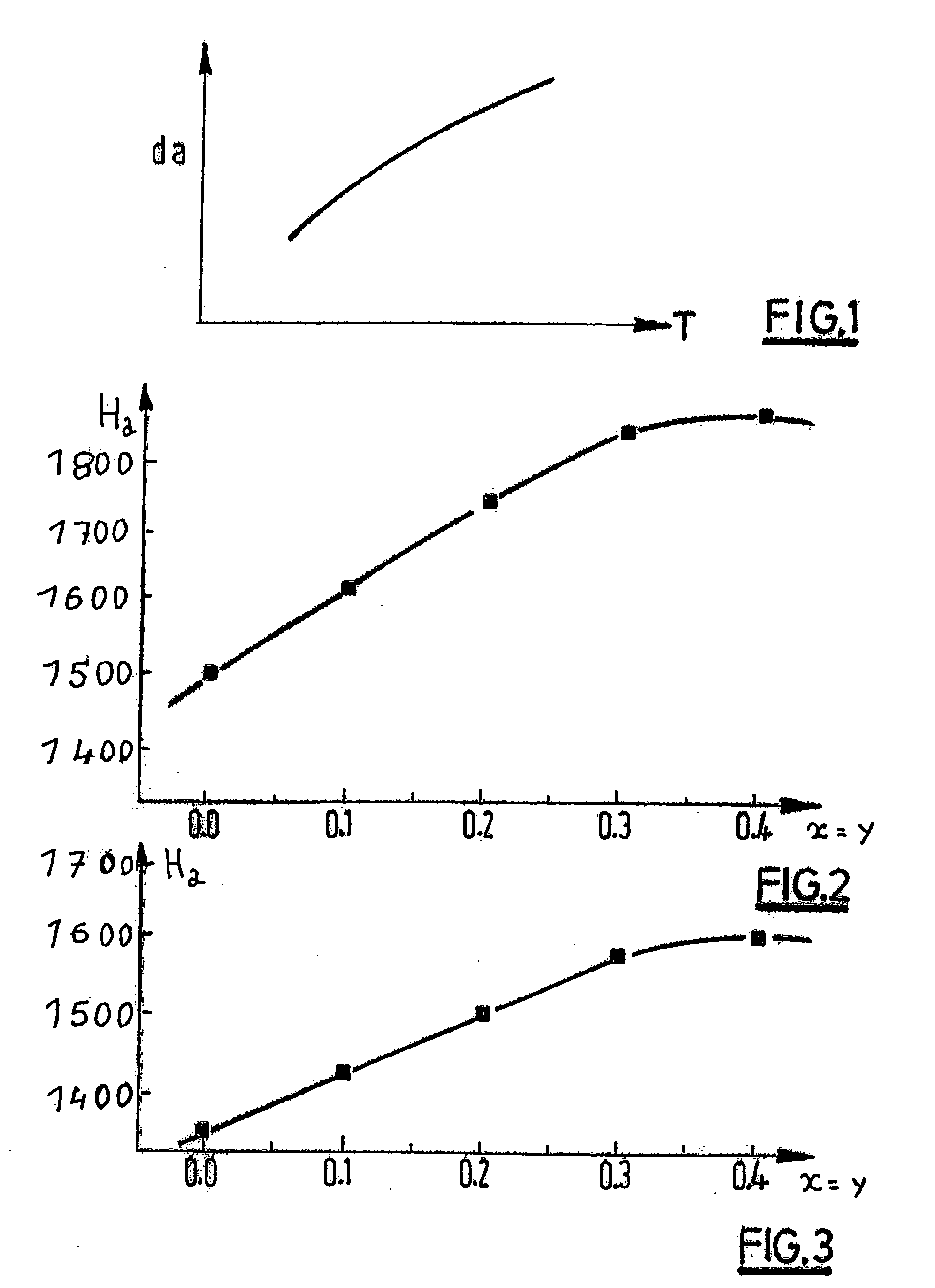

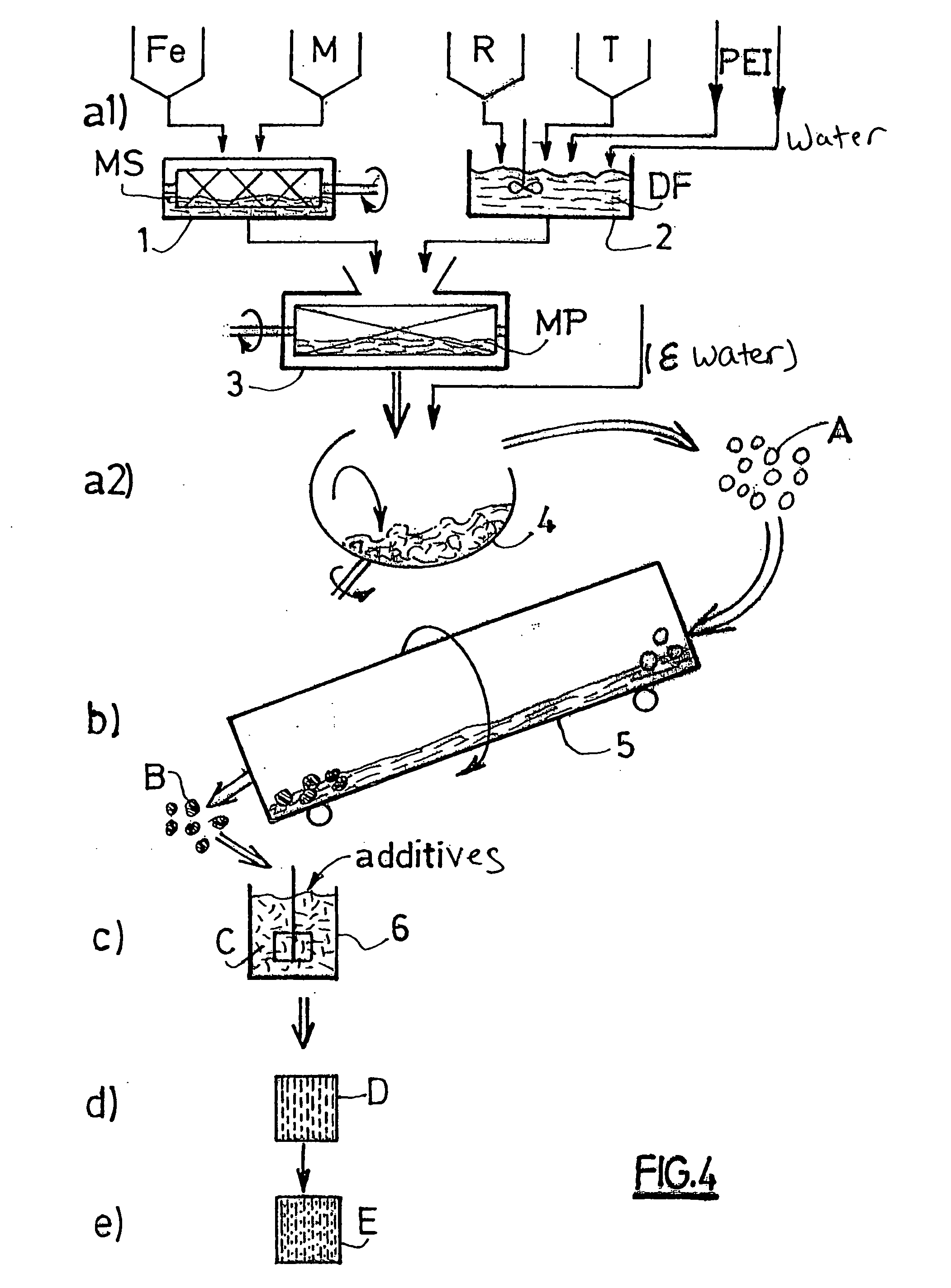

A method for making ferrite magnets of formula M1-xRxFe12-yTyO19 including: a1) forming a powder mixture MP of related raw materials, a2) transforming into granules in green state A, b) calcining the granules in green state to form clinker B, c) wet ding clinker B to obtain a homogeneous dispersion of fine particles C, d) concentrating and compressing the particles under an orienting magnetic field to form an anisotropic green compact D, and e) sintering the green compact to obtain a sintered element E. In step a1), MP is formed from a dry mixture MS of M and Fe powder elements and a dispersion DF of raw materials related to elements R and T, and in step b) the granules in green state are calcined to obtain a clinker B which is homogeneous in chemical composition and size and with apparent low density, between 2.5 and 3.5.

Owner:UGIMAG SA

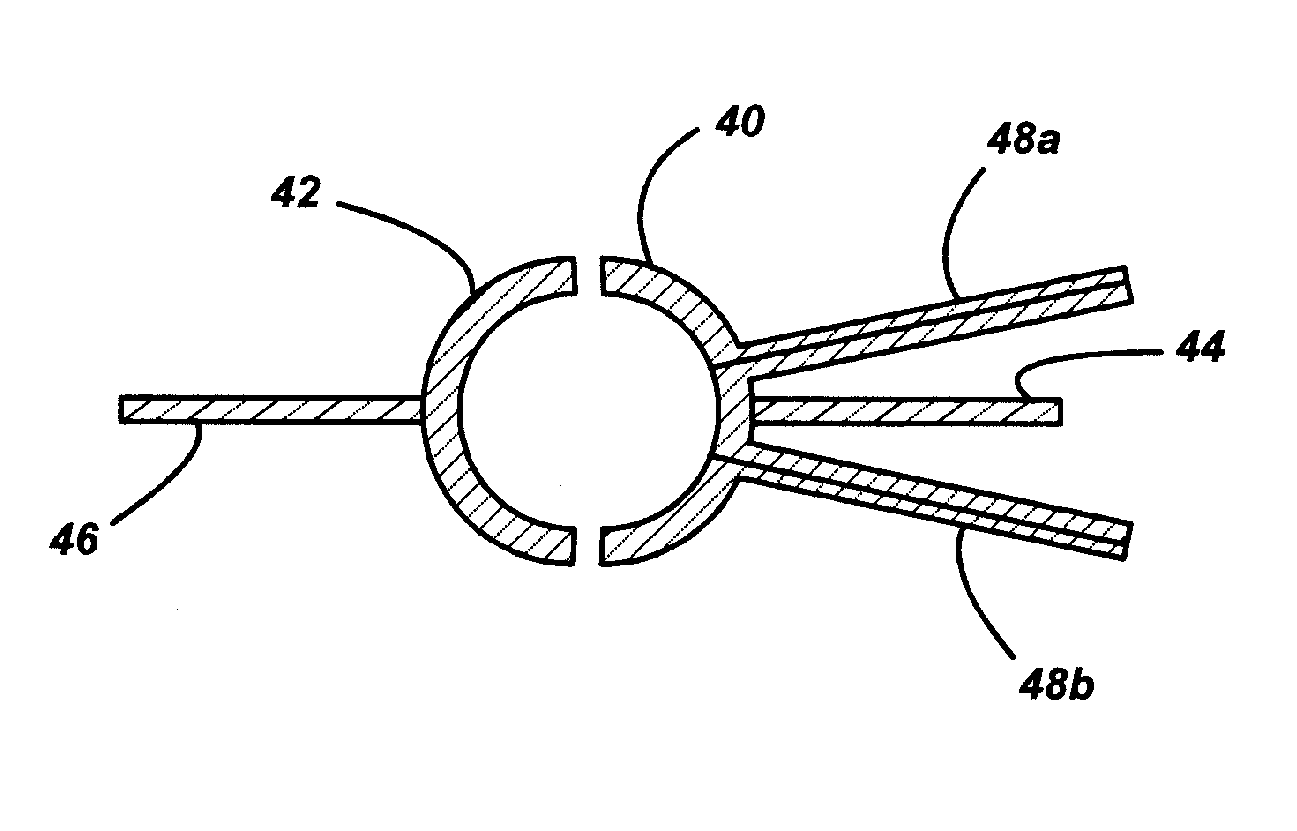

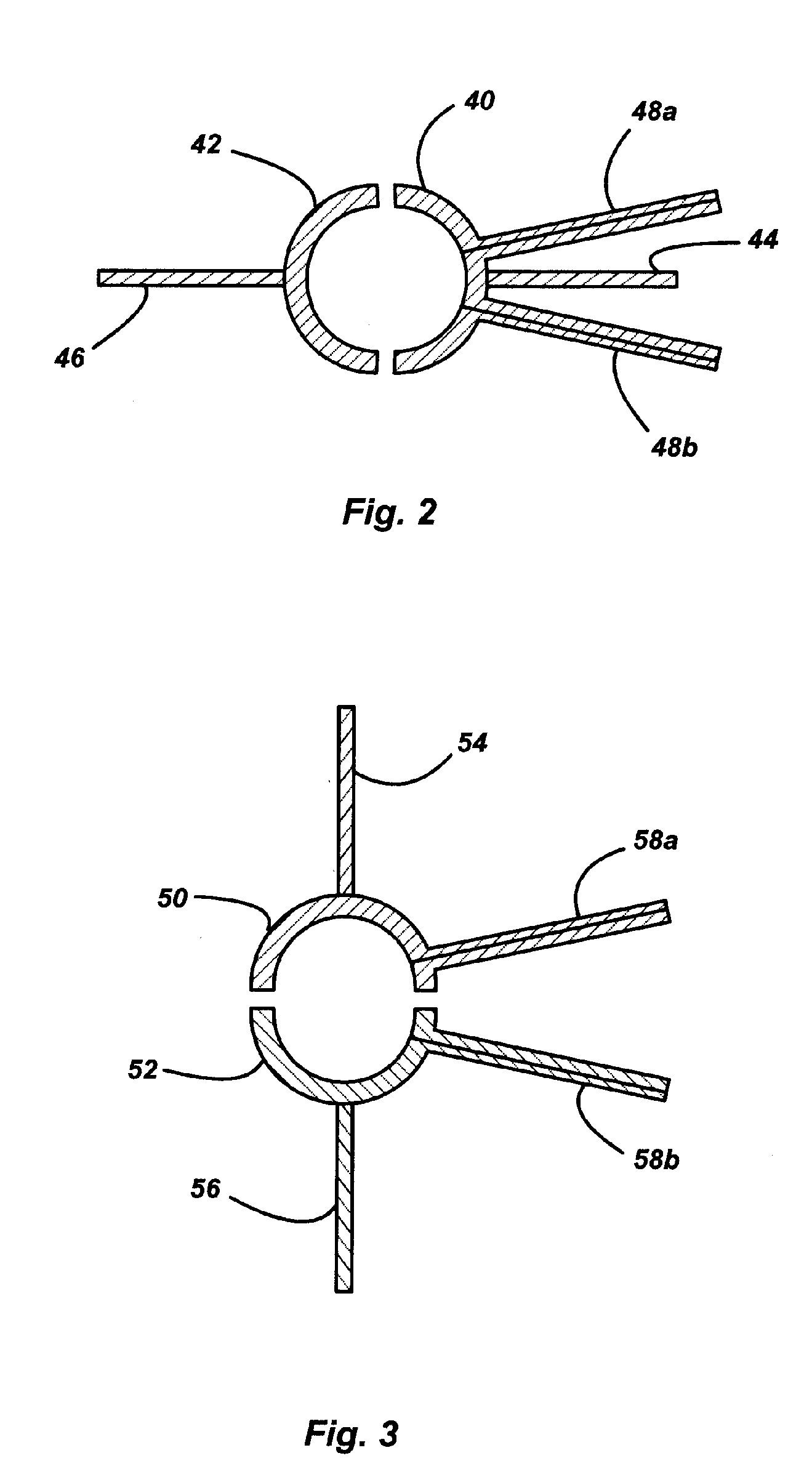

Green-state ceramic discharge vessel parts

InactiveUS20050215167A1Novel structureElectroluminescent light sourcesSealingMaterials scienceGreen state

A ceramic discharge vessel in a green state prior to assembly includes a first discharge vessel part in a green state, a second discharge vessel part in a green state, wherein the first and second discharge vessel parts form a discharge vessel when joined together, and a first capillary attached to the first discharge vessel part and a second capillary attached to one of the first and second discharge vessel parts. To facilitate joining the first and second discharge vessel parts, a first removable handle is temporarily attached to the first discharge vessel part for maneuvering the first discharge vessel part, and a second removable handle is temporarily attached to the second discharge vessel part for maneuvering the second discharge vessel part.

Owner:OSRAM SYLVANIA INC

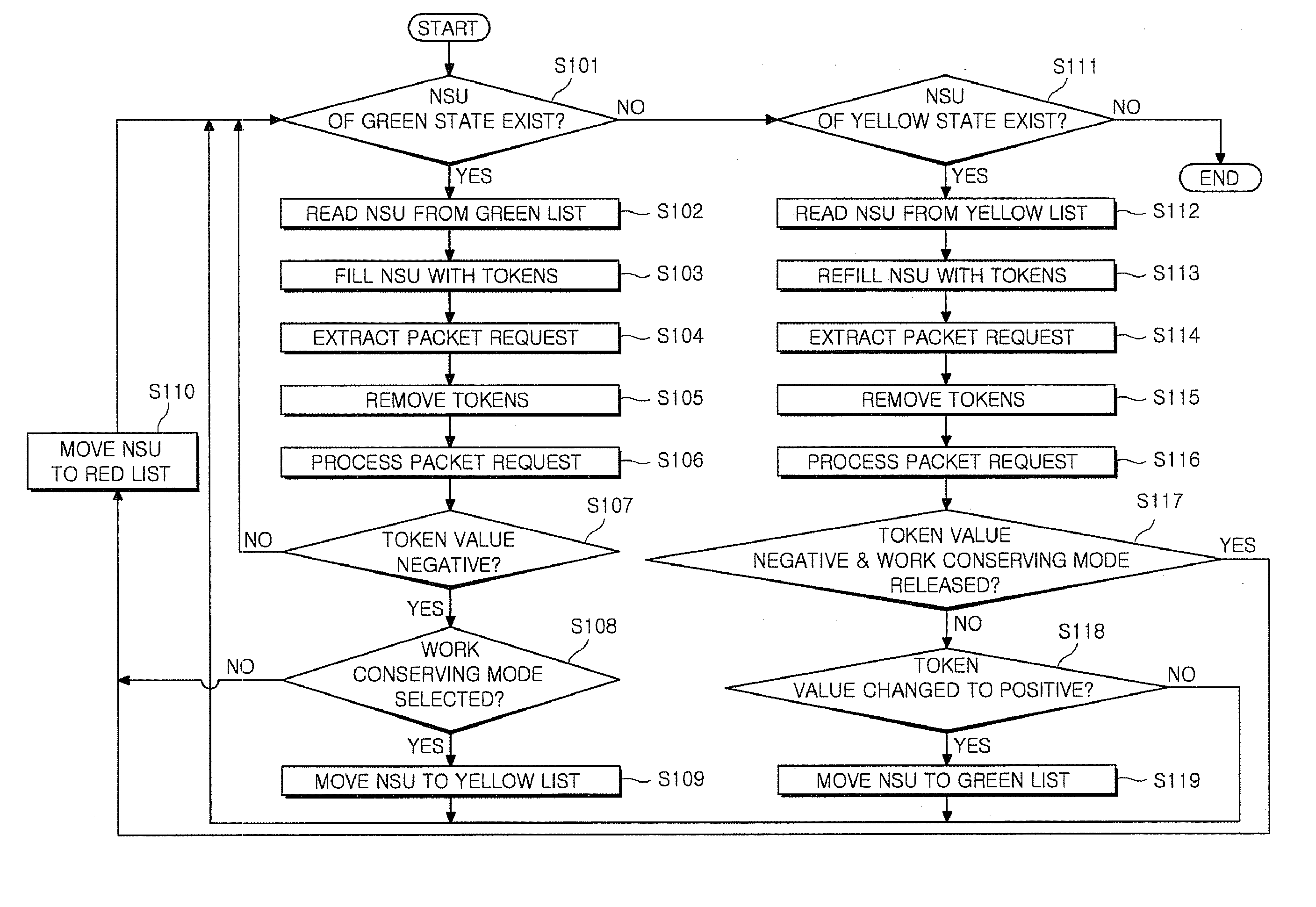

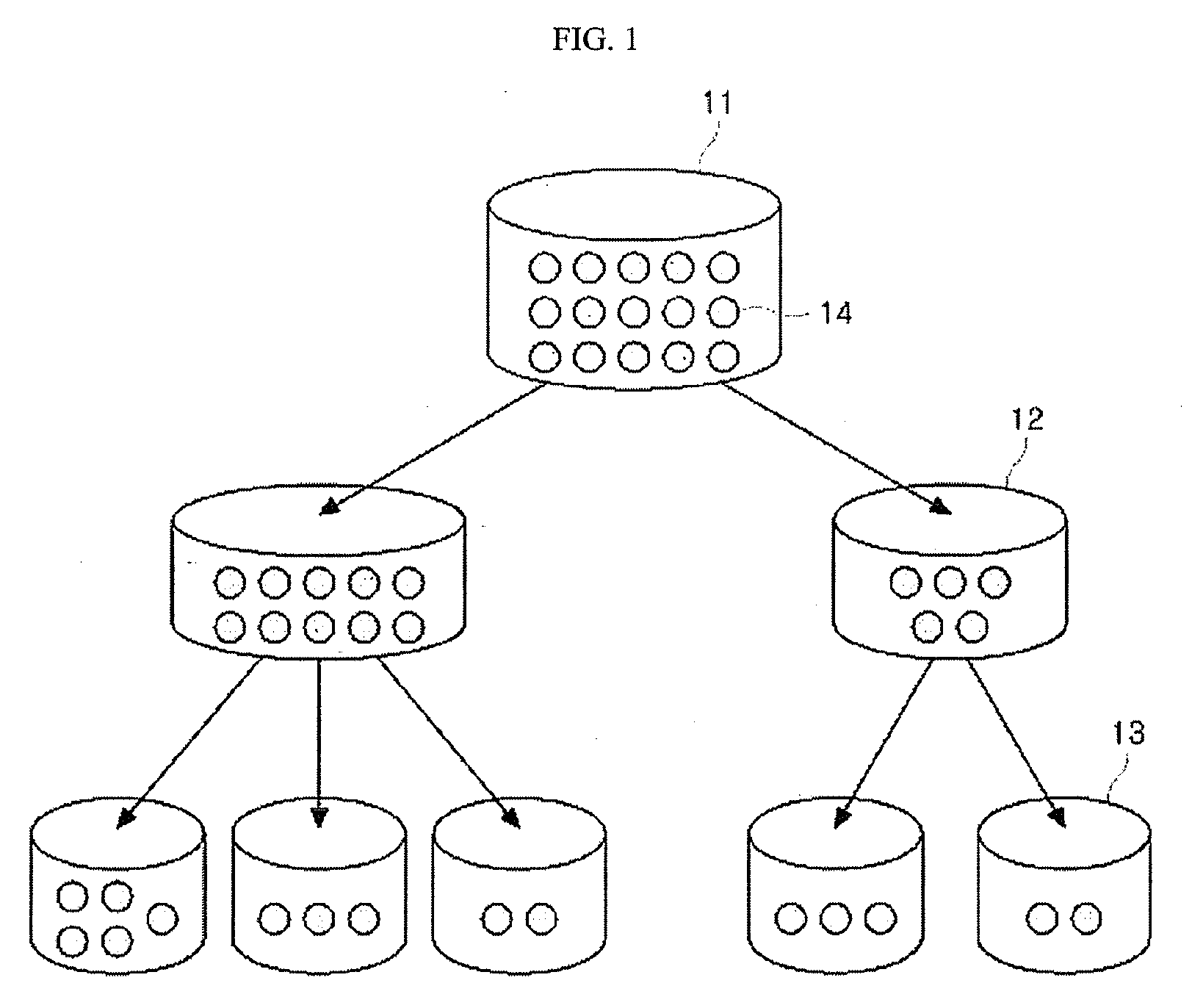

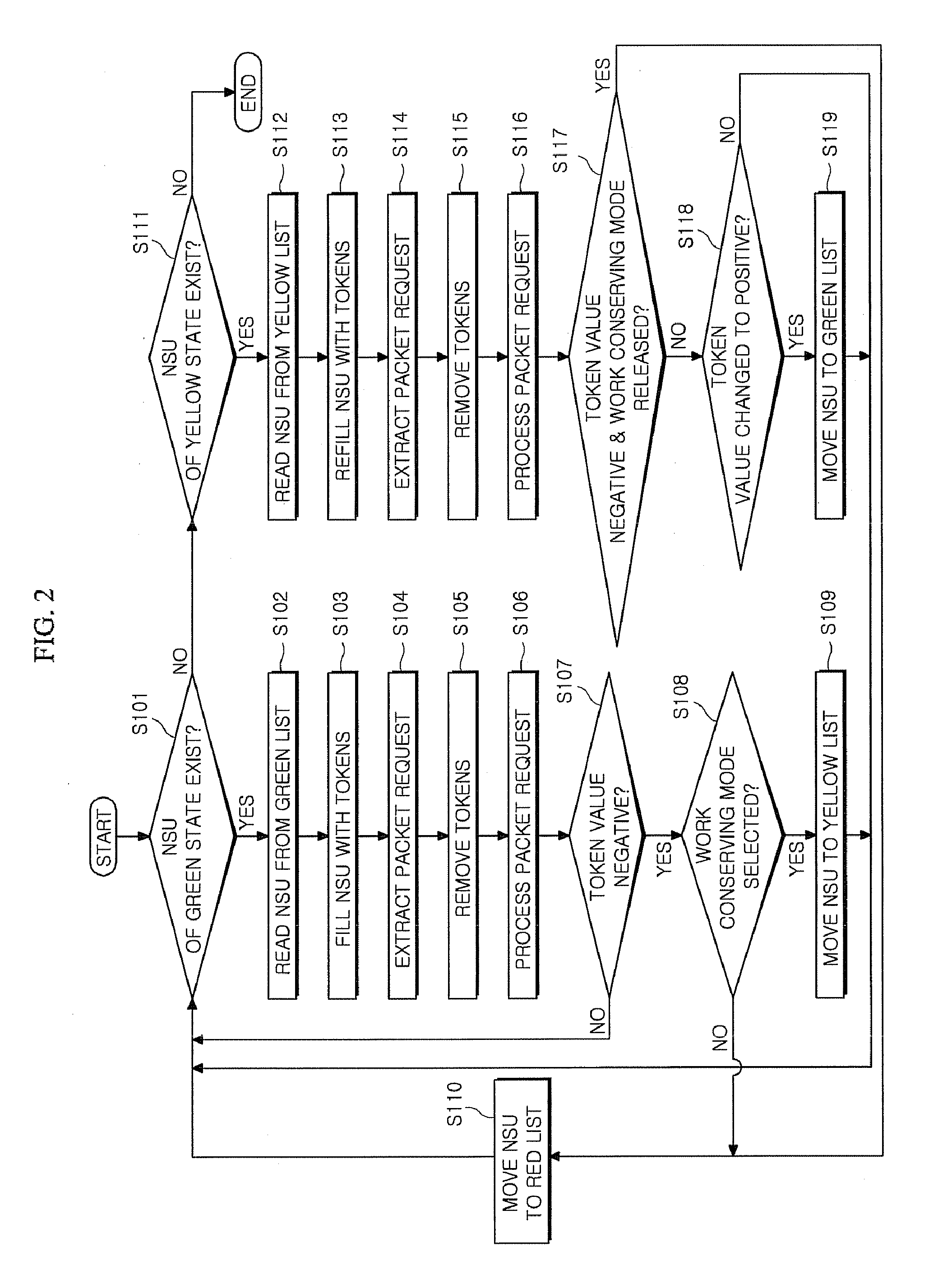

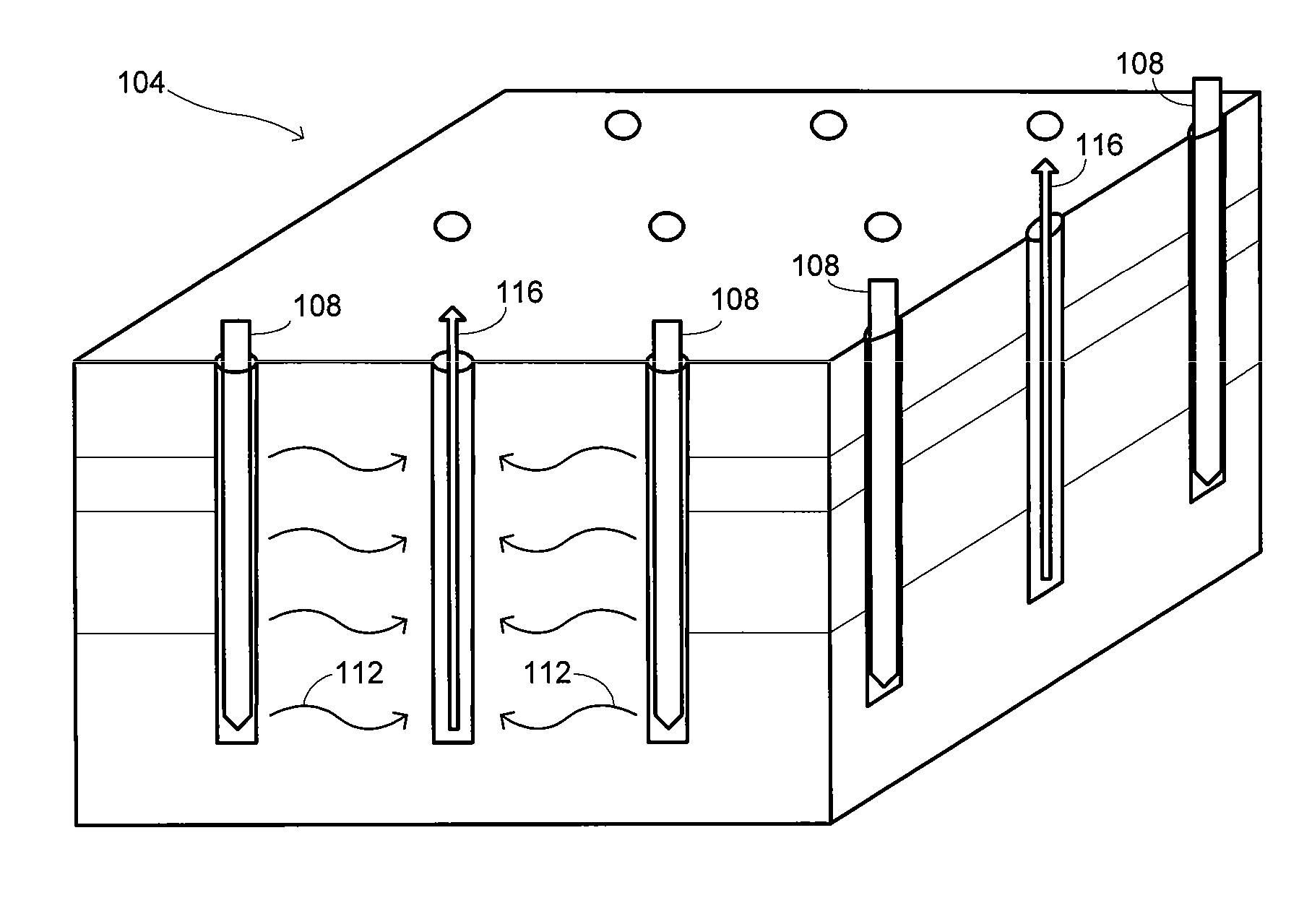

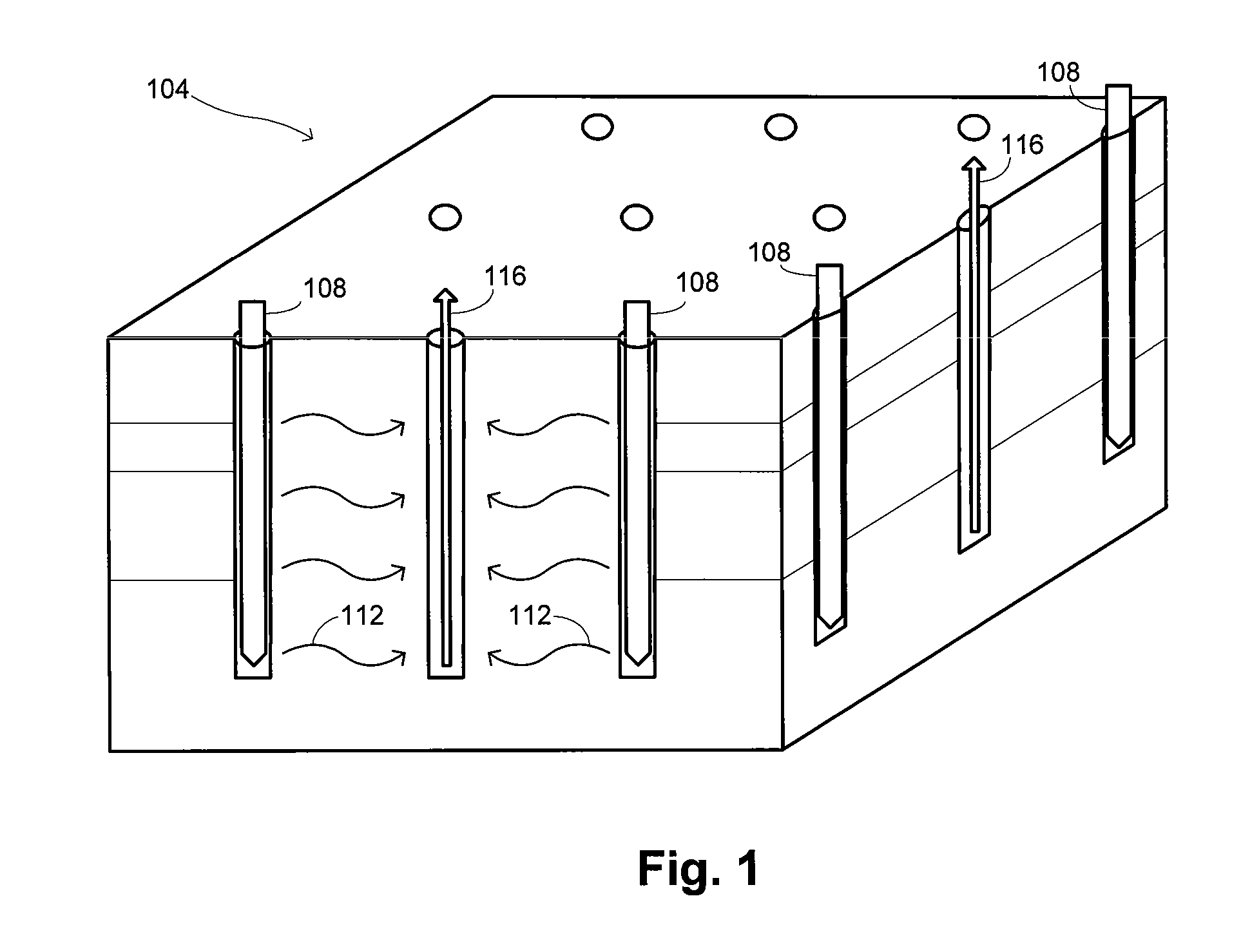

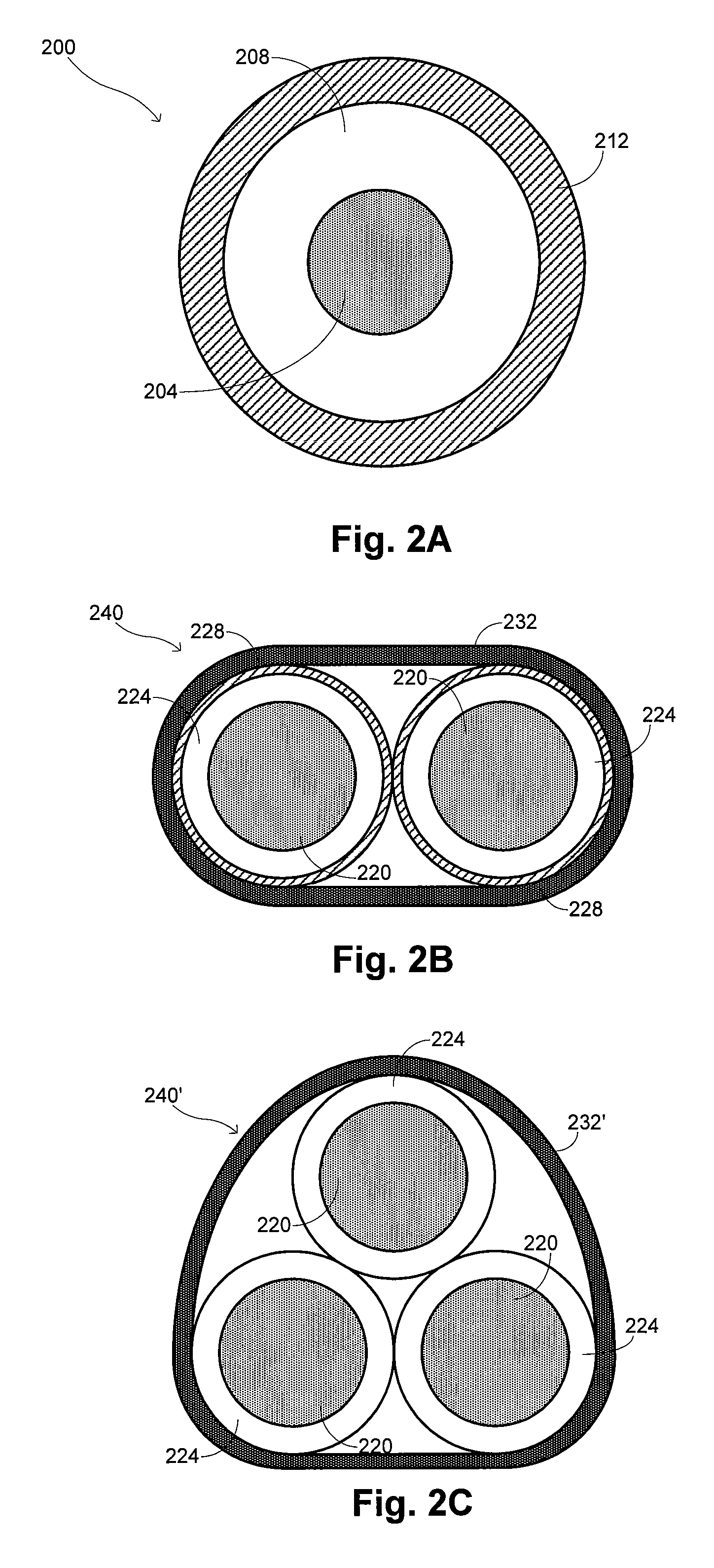

Network scheduler for selectively supporting work conserving mode and network scheduling method thereof

InactiveUS20090154351A1Effective bandwidthImprove efficiencyError preventionFrequency-division multiplex detailsDistributed computingGreen state

Provided are a network scheduler and a network scheduling method capable of effectively managing network bandwidths by selectively supporting a work conserving mode to network entities by using an improved token bucket scheme. The network scheduler selectively supports a work conserving mode to network scheduling units (NSUs) serving as network entities by using a token bucket scheme, such that the network scheduler ensures an allocated network bandwidth or enables the NSUs to use a remaining bandwidth. The network scheduler manages the NSUs by classifying the NSUs into a green state, a red state, a yellow state, and a black state according to a token value, a selection / non-selection of the work conserving mode, and an existence / non-existence of the packet request to be processed.

Owner:ELECTRONICS & TELECOMM RES INST

Single layer capacitor

InactiveUS6885539B1Improve structural strengthEasy and inexpensive to manufactureFixed capacitor electrodesFixed capacitor dielectricCapacitanceDielectric

A monolithic or essentially monolithic single layer capacitor with high structural strength and capacitance, a printed circuit board having the capacitor mounted thereon, and a method of making. Sheets of green-state ceramic dielectric material and glass / metal composite material are laminated together, diced into individual chips, and fired to sinter the glass and the ceramic together. The composite material contains an amount of metal sufficient to render the composite conductive whereby the composite may be used for one or both electrodes and for mounting the capacitor to the printed circuit board. Vertically-oriented surface mountable capacitors and hybrid capacitors are provided.

Owner:PRESIDIO COMPONENTS

Shaped composite ply layups and methods for shaping composite ply layups

Ply layups and methods for forming composite components are provided. For example, a method for forming a composite component comprises laying up a plurality of composite plies to form a composite plylayup; partially processing the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing thegreen state layup and the one or more sub-assemblies to form the composite component. In an exemplary embodiment, the composite component is a turbine nozzle airfoil. Another exemplary method comprises laying up a plurality of composite plies to form a composite ply layup; compacting the composite ply layup to form a green state layup; machining the green state layup; assembling the green state layup with one or more sub-assemblies; and processing the green state layup and the one or more sub-assemblies to form the composite component.

Owner:GENERAL ELECTRIC CO

Fuel injector nozzle manufacturing method

InactiveUS20070000128A1Increase manufacturing costSimple methodValve arrangementsInternal combustion piston enginesInjector nozzleEngineering

A method of manufacturing a fuel injector nozzle where a nozzle seat and a nozzle insert are made using a metal injection molding process. The nozzle seat and the nozzle insert are assembled and bonded together while in their green state. The resulting nozzle assembly is then debinded and sintered to obtain the desired fuel injector nozzle.

Owner:BRP US

Field application of polymer-based electrical insulation

Methods are disclosed for producing an insulated electrical conductor. Electrically uninsulated portions of respective electrical conductors are connected. A joint between the electrically uninsulated portions is coated with a preceramic resin, which is heated to cure the preceramic resin into a green-state insulator that substantially covers the joint.

Owner:COMPOSITE TECH DEV

Post-curing method and stereolithography method

InactiveUS20180141243A1Improve accuracyAdditive manufacturing apparatus3D object support structuresComputer visionComputer science

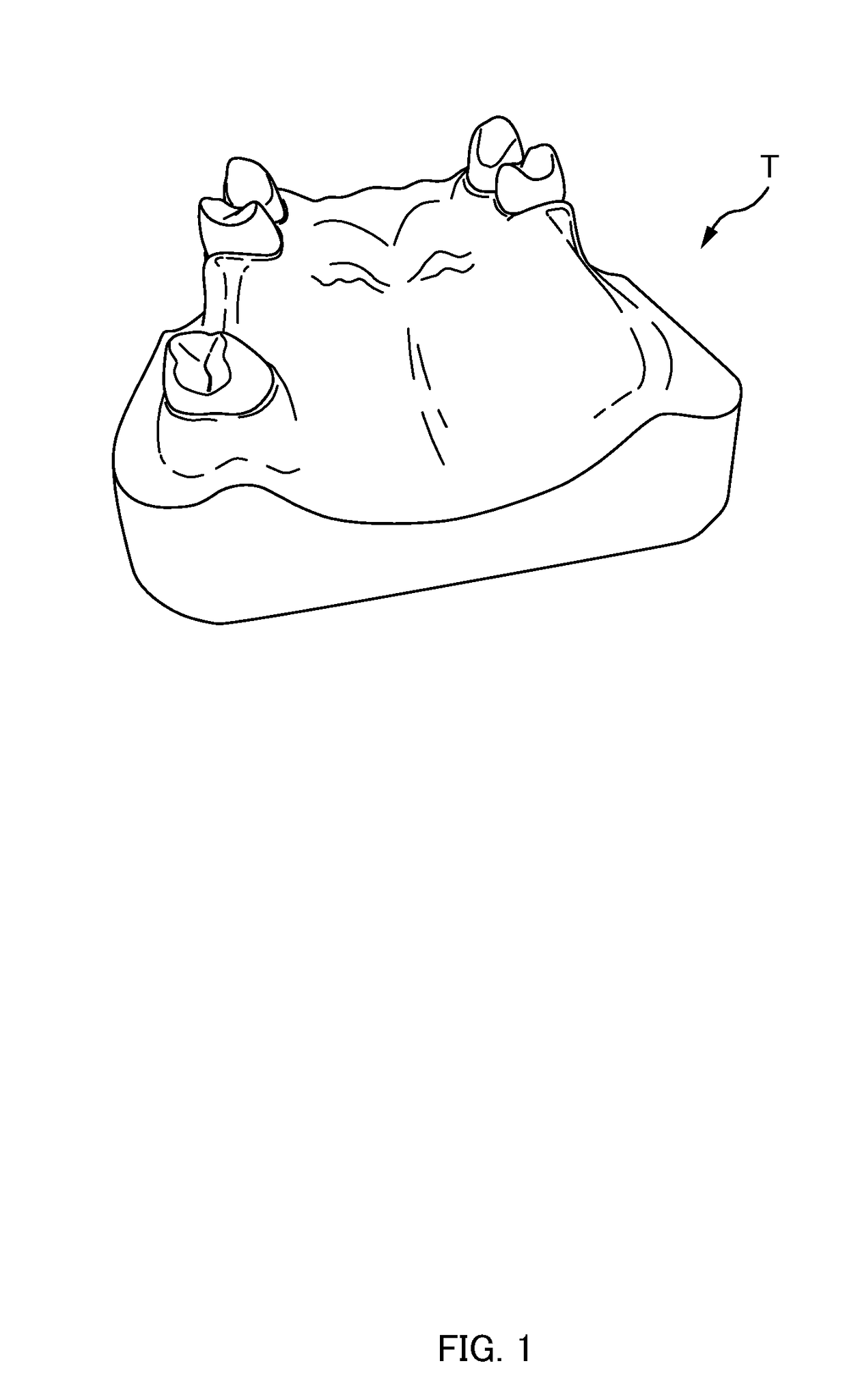

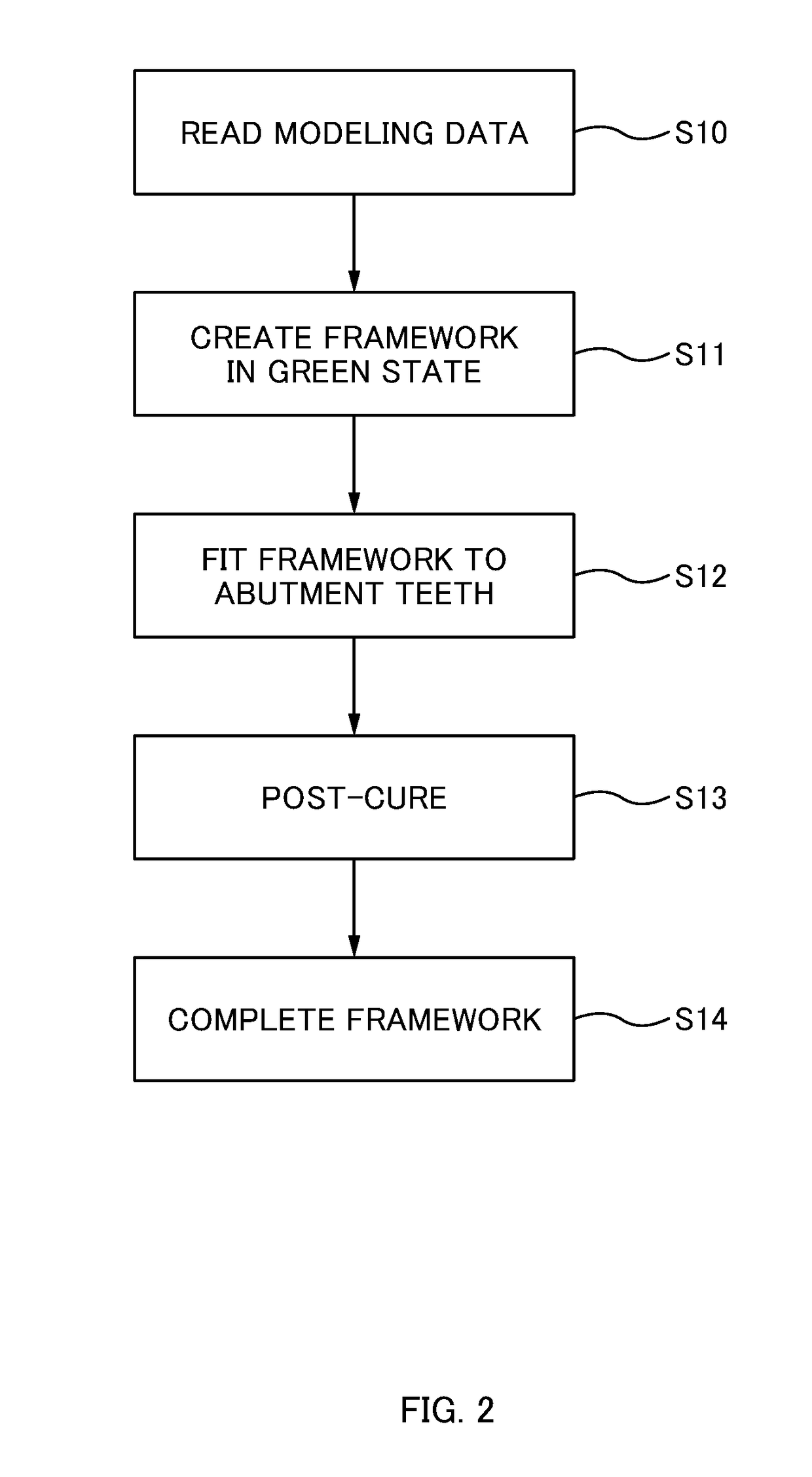

A method of post-curing a modeled object in a green state based on modeling data generated according to a working model includes a curing step of exposing the modeled object to light while the modeled object is fitted to the working model to secondary-cure the modeled object.

Owner:ROLAND DG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com