Field application of polymer-based electrical insulation

a polymer-based, electrical insulation technology, applied in the direction of insulation, liquid/solution decomposition chemical coating, borehole/well accessories, etc., can solve the problems of increasing the cost of oil, affecting the effect of use, and the pattern may be problematic by itself.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

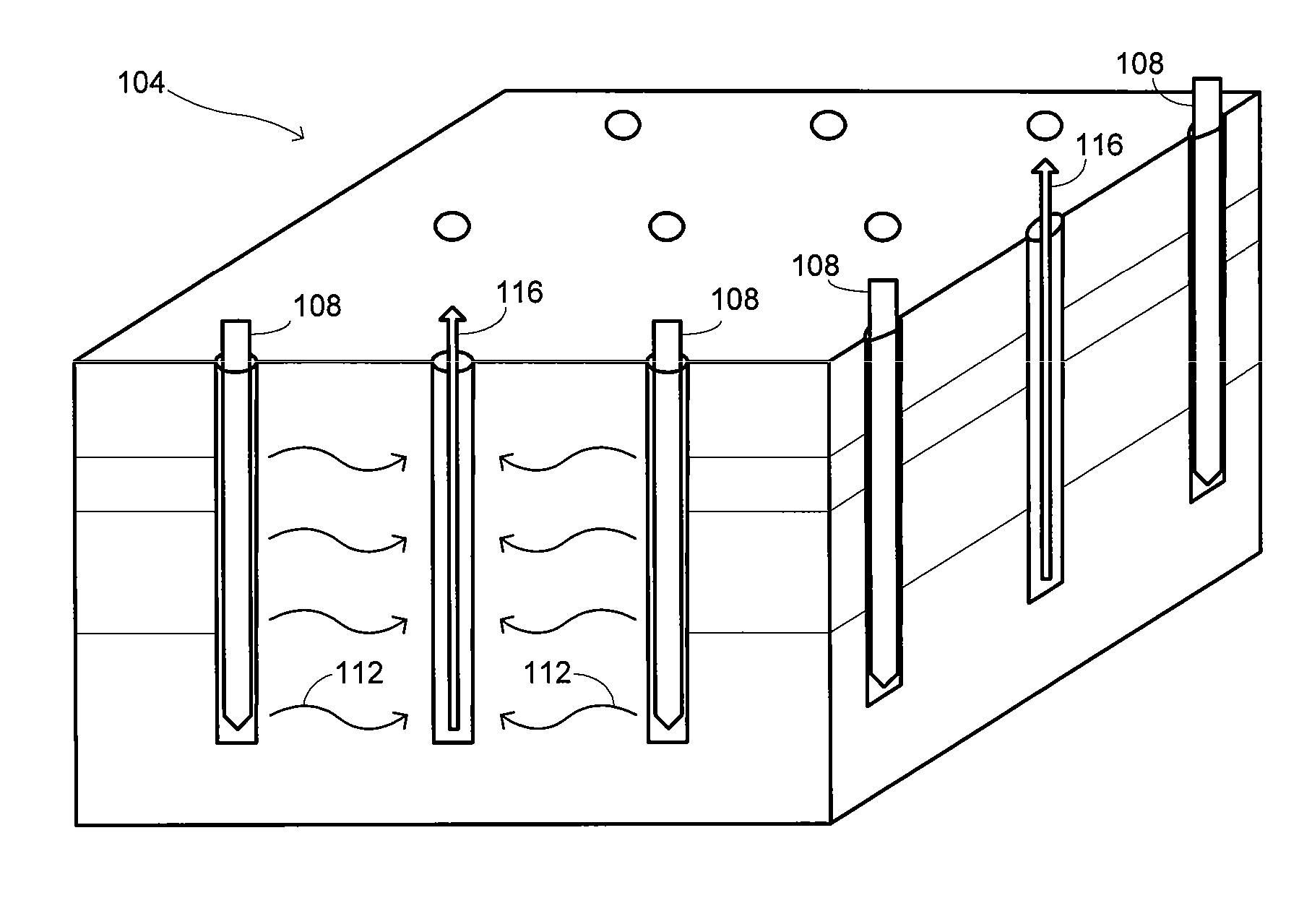

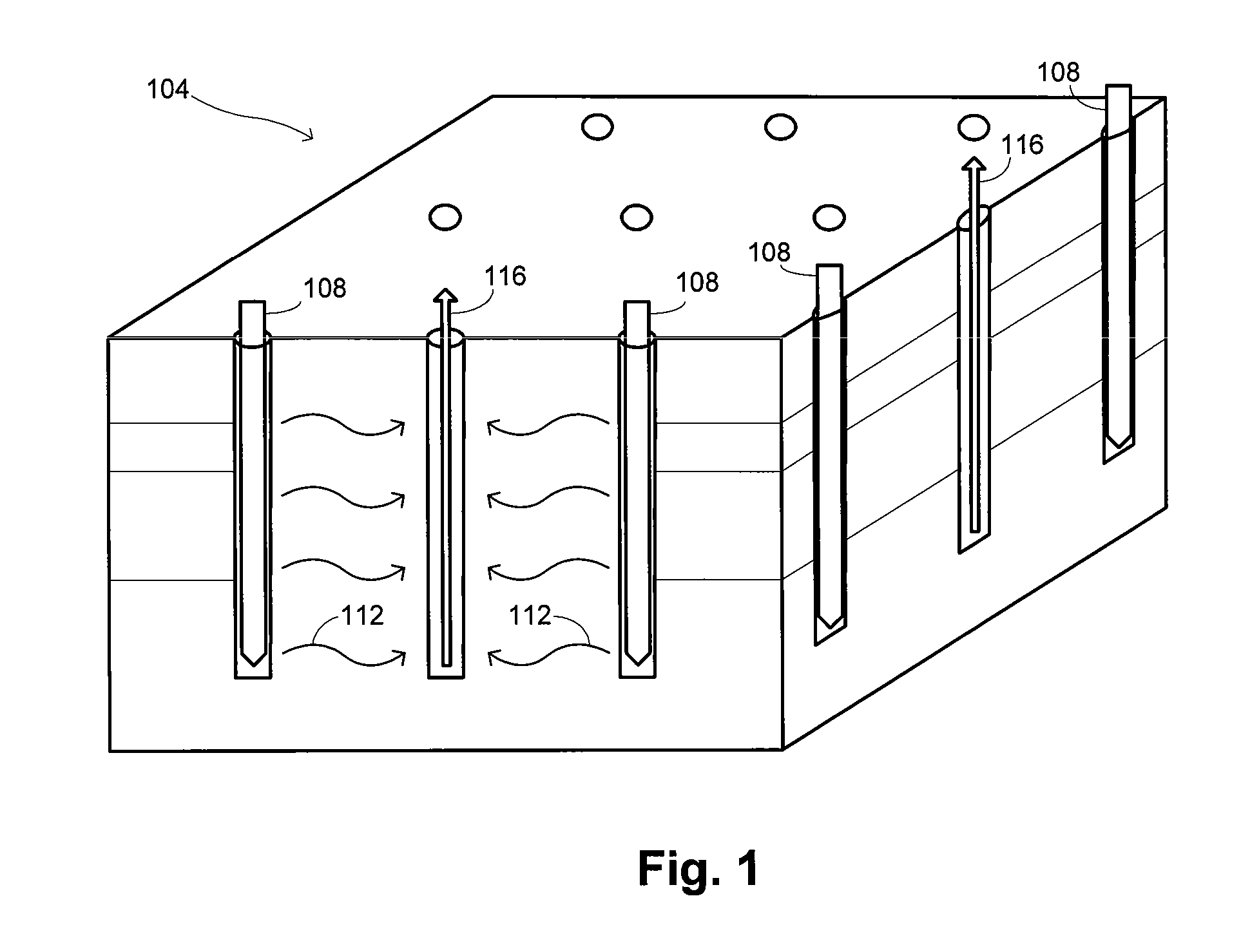

[0031] Embodiments of the invention are directed generally at in situ processing of high-temperature electrical insulation. While much of the discussion that follows illustrates such processing with deployment of heater cables in certain oil-recovery environments, such illustrations are intended to be exemplary rather than limiting. As is noted below, embodiments of the invention find utility in a wide range of applications outside of oil-recovery techniques.

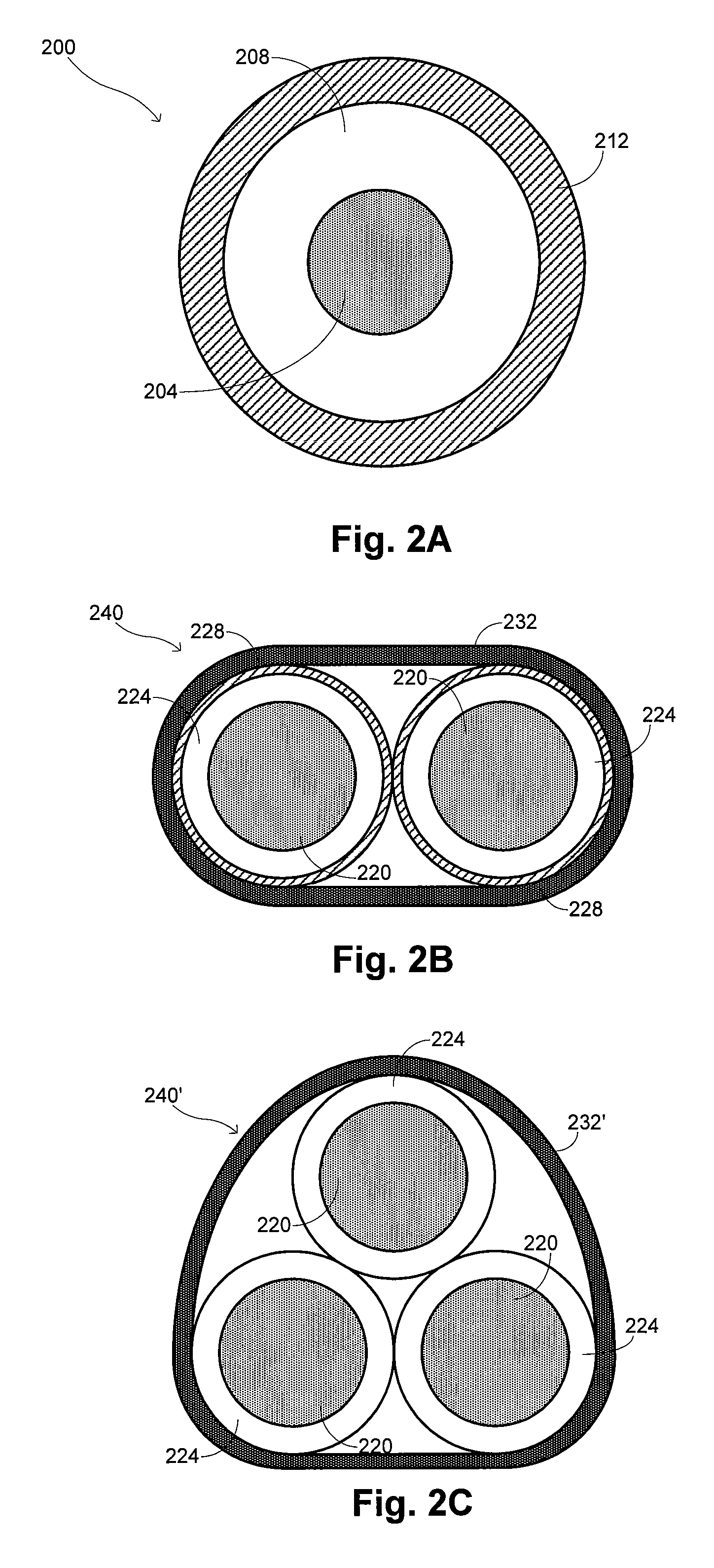

[0032] Those embodiments where the in situ processing is used to aid oil-recovery processes generally make use of certain thermal processes. In particular, these thermal processes rely on the deployment of heater cables that provide the thermal energy used in oil recovery. Such heater cables have a structure in which an electrical conductor is sheathed, with an electrical insulator being disposed to insulate the conductor from the sheath. Embodiments of the invention permit the heater cables to be deployed with a precursor to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com