Manufacturing method for ferrite type magnets

a technology of ferrite and manufacturing method, applied in the field of permanent magnets, can solve the problems of high cost of substitution elements la and co, high cost of la and co, and high cost of lanthanum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples of embodiments

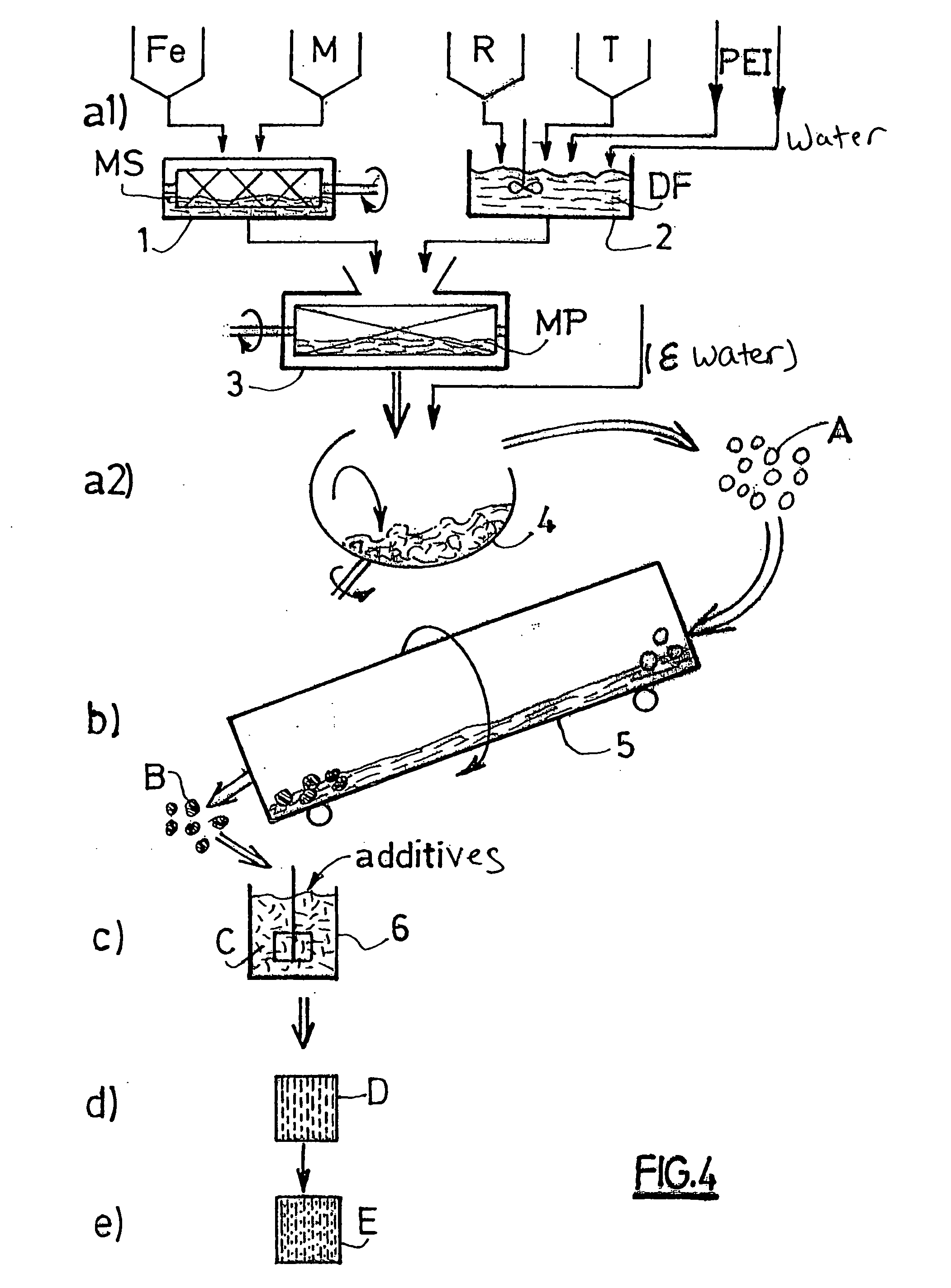

[0107] General Description of Tests

[0108] Six series of tests were carried out (tests numbered 1a, 1b, 1c to 6a, 6b and 6c) as well as 4 complementary tests (tests numbered 7 to 10), which differ by the chemical composition or the calcination temperature.

[0109] For each series of tests, one started with the same raw materials providing the elements Fe, M, R and T, and manufactured 3 mixtures of the same chemical composition:

[0110] one according to all or part of the method according to the invention: tests 1c, 3c and 5c according to the invention and tests 2c, 4c and 6c according to a part of the invention,

[0111] one according to the wet process of the state of the art: tests 1a to 6a,

[0112] and one according to the dry process of the state of the art: tests 1b to 6b.

[0113] For a same test series, one formed, at stage b), clinkers B under the same conditions, in particular with the same calcination temperature.

[0114] The method according to the invention is basically described, in i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com