Preparation method of permanent magnet material

A permanent magnet material, rare earth permanent magnet technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of inability to achieve magnet orientation, acceleration of densification process, decrease of coercive force, etc., to increase the comprehensive permanent magnet performance , high performance cost, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of two main alloys R M32 Fe 63 Zr 3 Al 0.9 B 1.1 and (Pr 0.4 Nd 0.6 ) 30 Fe 67 Al 2 B 1 , the total mass of the two main alloys is 2.5Kg, respectively prepared into quick-setting sheets with a thickness of 0.3mm.

[0028] (2) The above two main alloys are subjected to hydrogen crushing respectively to obtain particles with a particle size distribution of about 1-3 mm, and then respectively jet milled to obtain particles with an average particle size of about 2 μm.

[0029] (3) According to mass ratio R M32 Fe 63 Zr 3 Al 0.9 B 1.1 :(Pr 0.4 Nd 0.6 ) 30 Fe 67 Al 2 B 1 Mix the above jet-milled powder in a ratio of 30:70, weigh 10g of it, seal it, put it into an argon-protected magnetic field orientation mold, and perform orientation molding under a magnetic field of 1.5T (the pressure is about 20MPa).

[0030] (4) Put the molded magnet into a hot isostatic press under an isostatic pressure of 120MPa and a temperature of 900°C for 0.5 hou...

Embodiment 2

[0042] (1) Preparation (Nd 0.6 PR 0.4 ) 31 Fe 66 Cu 0.6 Zr 1 Ga 0.4 B 1 Alloy 2.5Kg, and made into 0.3mm quick-setting sheet.

[0043] (2) The above alloy is subjected to hydrogen crushing to obtain jet mill powder with a particle size of 1.5 μm.

[0044] (3) Weigh 10 g of it, seal it, put it into an argon-protected magnetic field orientation mold, and perform orientation molding under a magnetic field of 2T (the pressure is about 20 MPa).

[0045] (4) Put the molded magnet into a hot isostatic press under an isostatic pressure of 200MPa and a temperature of 800°C for 0.5 hours, and then quickly cool it through a built-in cooler (introducing Ar gas).

[0046] The magnet prepared above was processed into a small cylinder of Φ10mm×10mm and tested in a B-H loop instrument. The test results are also listed in Table 1.

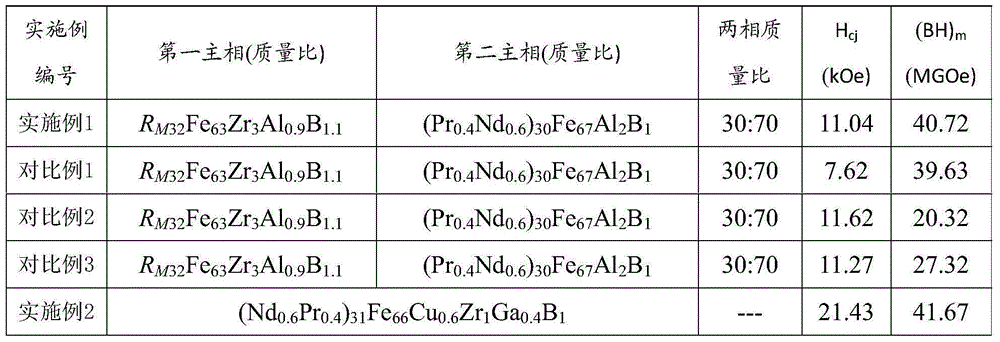

[0047] It can be seen from the data in Table 1 that the rare earth permanent magnet prepared by the hot isostatic pressing technology of the present inven...

Embodiment 3

[0051] (1) Prepare R by mass ratio M28 Fe 67 Zr 3 al 1 B 1 and Pr 15 Nd 14 Fe 68 mn 1 co 1 B 1 The two main phase alloys have a total mass of 2.5Kg respectively. Jetmill particles of 1.4 μm and 2 μm were prepared as described in Example 1, respectively.

[0052] (2) Preparation of auxiliary alloy Ga 90 sn 10 : Ga and Sn are weighed according to the mass ratio, but they are not smelted. Instead, the two simple substances are mixed and ball milled directly to prepare particles with an average particle size of about 5 μm.

[0053] (3) two kinds of main phase alloys prepared by step (1) and the auxiliary alloy elemental ball mill particles obtained by step (2) according to R M28 Fe 67 Zr 3 al 1 B 1 : Pr 15 Nd 14 Fe 68 mn 1 co 1 B 1 : Ga 90 sn 10 Mix evenly in a mass ratio of 40:56:4. 10 g of it was weighed, sealed and put into an argon-protected magnetic field orientation mold for orientation molding under a magnetic field of 2T (pressure about 20 MPa). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com