Preparation method of high-performance neodymium-iron-boron permanent magnet

A NdFeB, permanent magnet technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of easy falling off, poor performance, and poor coating adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

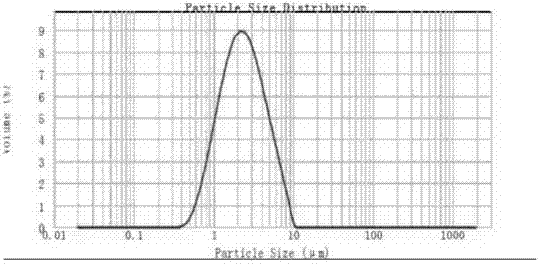

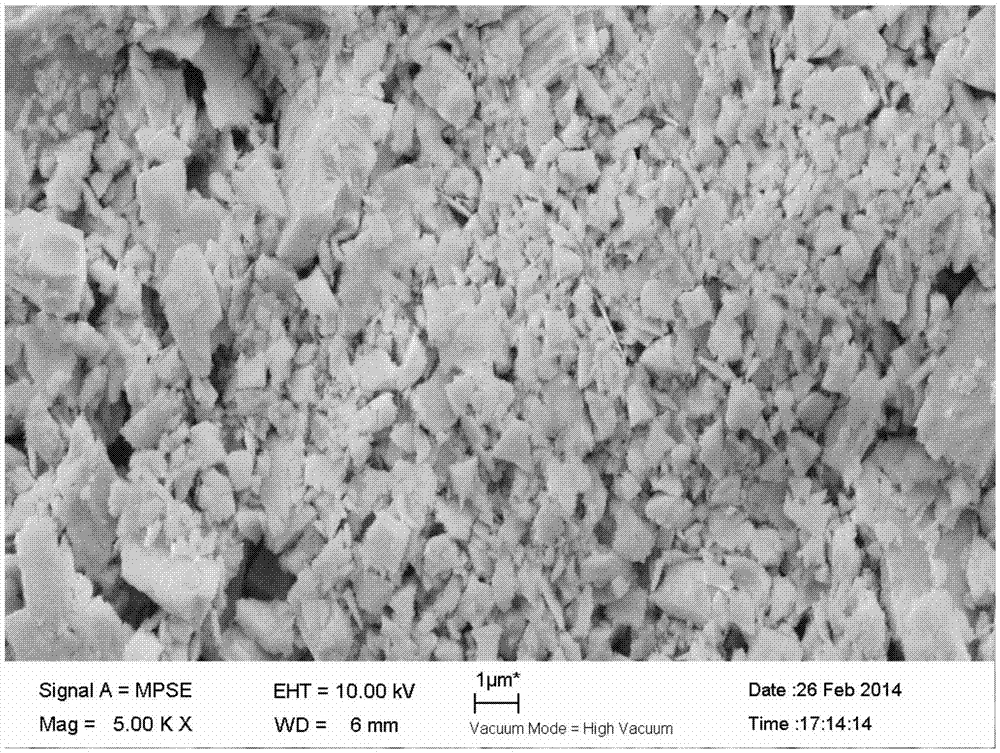

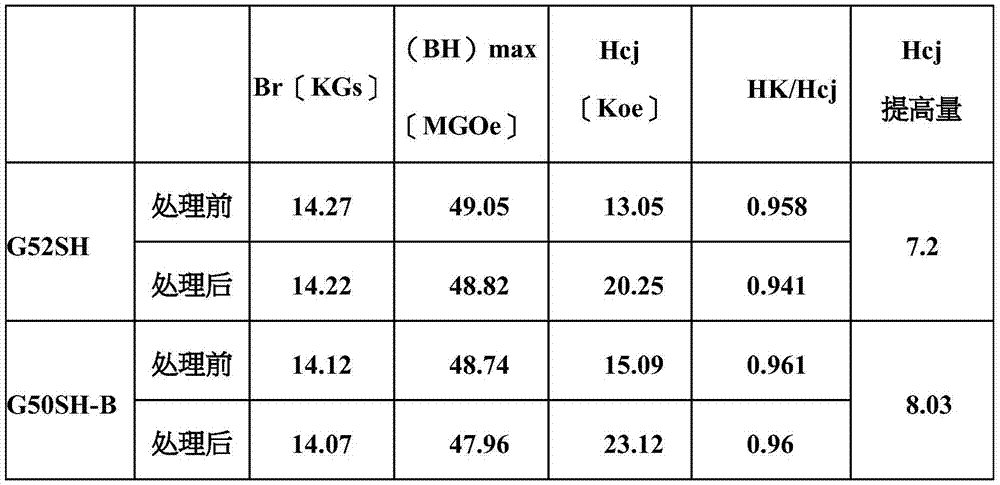

[0019] Firstly, D50 900μm terbium powder and absolute ethanol are mixed according to the weight ratio of 1:5, and rod milling is carried out according to the conventional rod milling process. Filtration is carried out using a 15-micron sieve, and the filtration pressure is lower than 0.2MPA. Then the particle size is tested, and the particle size testing equipment uses Malvern 2000 wet particle size tester. Its D50 is 2.12 microns, see figure 2 , and its microstructure is shown in figure 1 , The powder is distributed in flake form. Get 1wt.% dispersant Sima Chemical CE64, add 1wt.% acrylic resin and absolute ethanol to it and mix, then add the D50 prepared above to be 2.12 micron terbium powder, after mixing by the disperser speed 2000 rev / min, under pressure Spray the sample with a specification of 35*5.2*2 under the air pressure of 0.15-0.4MPA, let it dry naturally, and the thickness of the sprayed layer is 10 microns. Then spray the other side. Among them, the samples ...

Embodiment 2

[0025] First mix D50 in 1000 micron dysprosium powder and anhydrous methanol according to the weight ratio of 1:10, and carry out rod milling according to the conventional rod milling process. Filtration is carried out using a 20-micron sieve, and the filtration pressure is lower than 0.2MPA. Then the particle size is tested, and the particle size test equipment uses Malvern 2000 wet particle size tester. Its D50 is 5.12 microns, and it is flaky. Get 15wt.% dispersant citric acid and anti-settling agent glycerin, add 1wt.% epoxy resin and anhydrous methanol to it and mix, then add D50 to be 6.2 microns terbium Powder, mixed by a disperser at a speed of 2000 rpm, sprayed on a sample with a specification of 35*5.2*2 at a pressure of 0.15-0.4MPA, dried naturally, and the thickness of the sprayed layer was 10 microns. Then spray the other side. Among them, the samples were subjected to conventional chemical degreasing and pickling and rust removal before spraying, and the sprayin...

Embodiment 3

[0031] First mix D50 dysprosium powder of 900 microns and anhydrous isopropanol according to the weight ratio of 1:8, and then carry out rod milling according to the conventional rod milling process, the speed of rod milling is 300 rpm, and then pass through a 300 mesh screen , and then filter, using a 5-micron sieve for filtration, and the filter pressure is lower than 0.2MPA. Then test the particle size, and the particle size test equipment uses Malvern 2000 wet particle size tester. Its D50 is 1.3 microns, and it is flake. Get 0.8wt.% dispersant polyethylene glycol and anti-sedimentation agent hydroxymethyl cellulose, add 0.8wt.% epoxy resin and anhydrous methanol to it and mix, Then add terbium powder with a D50 of 6.2 microns, mix through a disperser at a speed of 2000 rpm, spray a sample with a specification of 35*5.2*2 under a pressure of 0.15-0.4MPA, and let it dry naturally. The thickness of the sprayed layer is 20 microns. Then spray the other side. Among them, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com