Composite binder and method for preparing soft magnetic composite material by using same

A soft magnetic composite material and binder technology, which is applied in the fields of inorganic material magnetism, metal processing equipment, inductor/transformer/magnet manufacturing, etc. problems, to achieve the effect of reducing the number of defects, optimizing the mechanical strength, and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

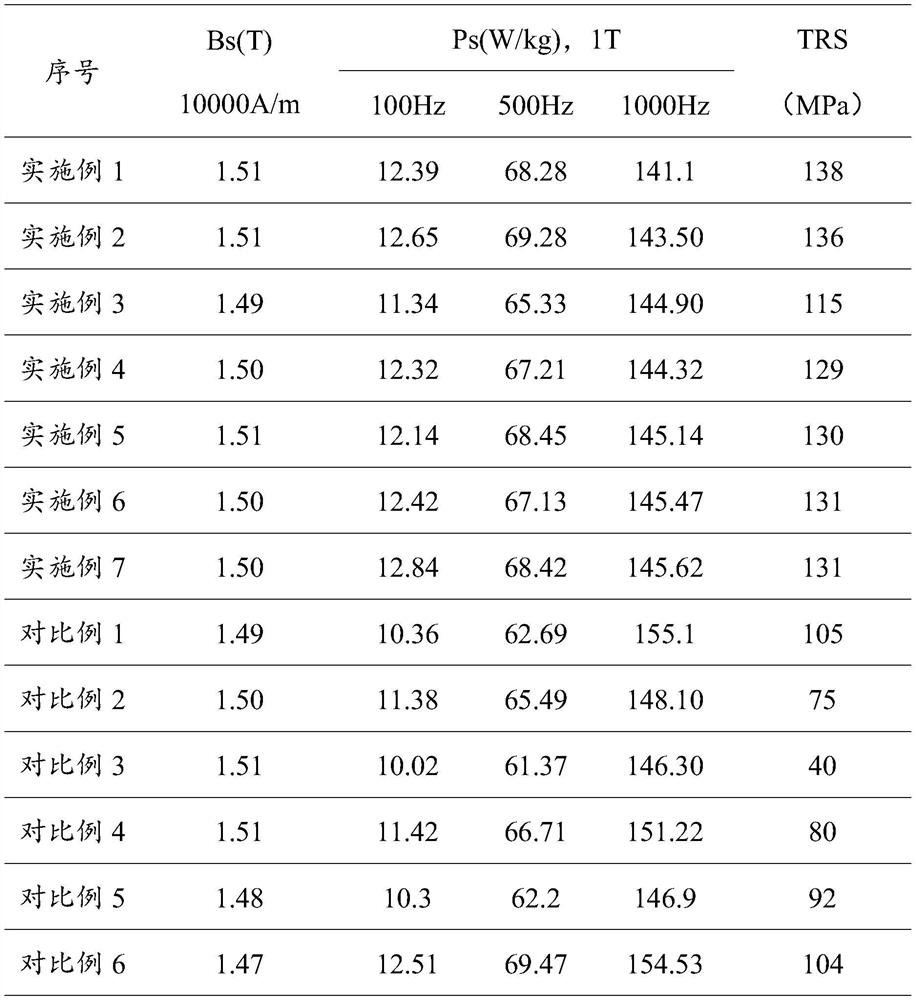

Embodiment 1

[0034] A method for preparing a soft magnetic composite material, comprising:

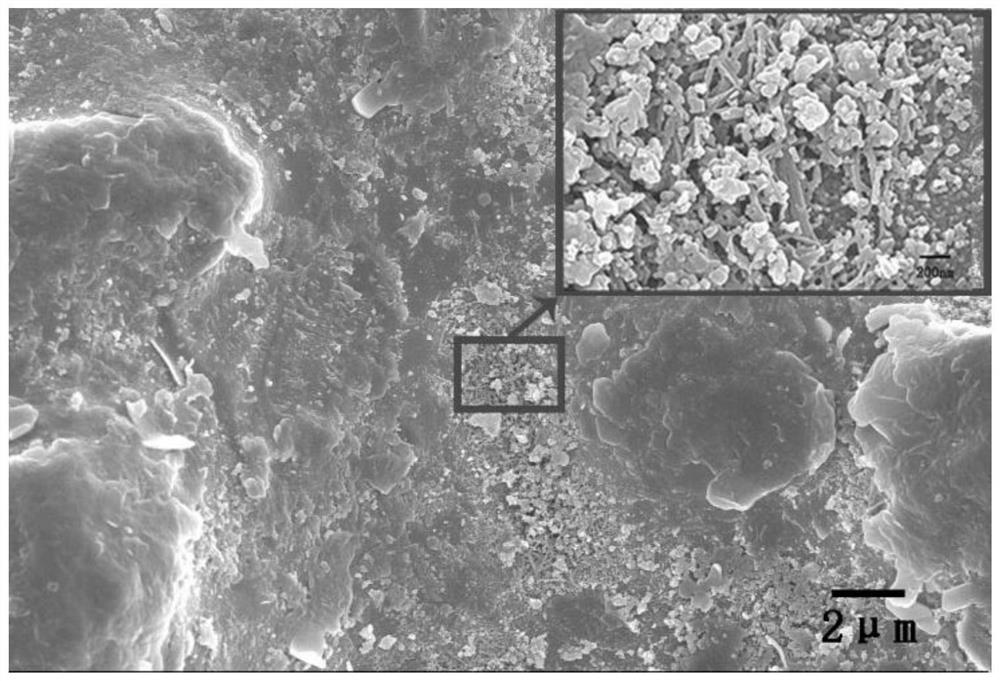

[0035] Step 1: Preparation of composite binder: make a 1:10 solution of silicone resin and acetone, mix the two evenly by ultrasonic vibration treatment, and then put 2wt% carbon nanotubes of silicone resin, in which carbon The length of the nanotubes is 200nm-1μm; the diameter is 10-50nm; ultrasonic shock treatment for 1 hour, stirring at room temperature for 2 hours to disperse the carbon nanotubes evenly in the solution to obtain a composite binder;

[0036] Step 2: Iron powder pretreatment: water atomized iron powder, purity requirement > 99.9%, iron powder particle size 180-250μm; mechanical ball milling pretreatment and ultrasonic cleaning on iron powder to improve the surface of iron powder to coating agent Absorptivity; the parameters of ball milling are: the speed of ball mill is 300-600 rpm, the ratio of ball to material is 2:1-6:1, and the pretreatment time is 5-10 minutes; after that, a...

Embodiment 2

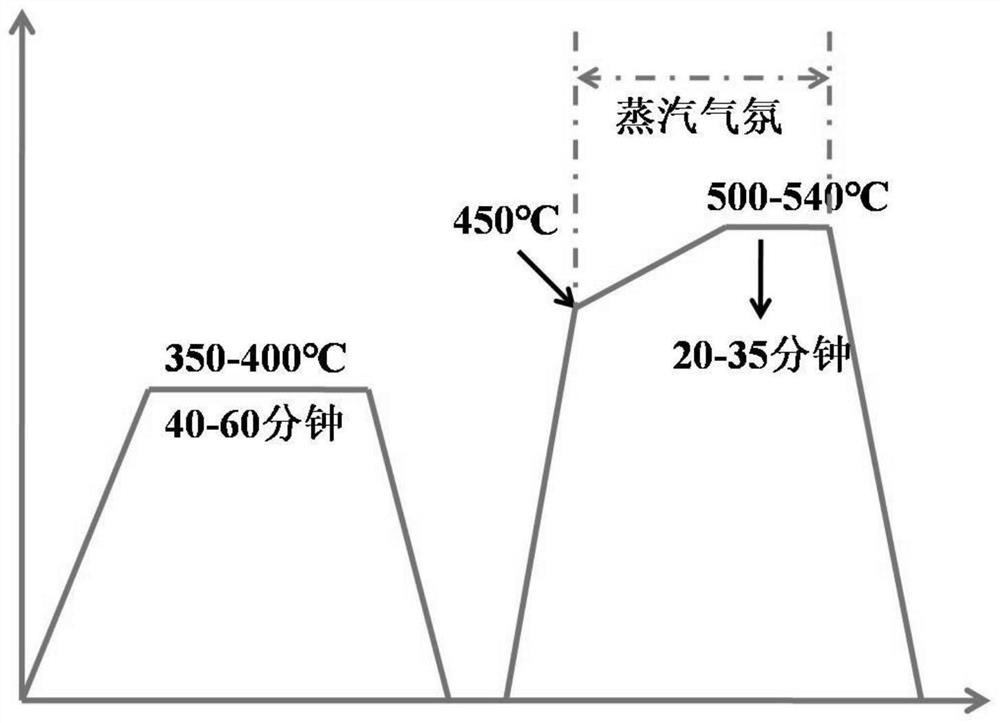

[0041] A method for preparing a soft magnetic composite material, wherein step 5 specifically includes: placing the pressed blank block in an annealing furnace, vacuumizing the furnace chamber and then filling it with nitrogen to stabilize it to 0.04MPa, and increasing the temperature at a rate of 15°C / min. Heat at a rate of 380°C for 60 minutes, then cool to room temperature; then heat up to 450°C at a rate of 15°C / min after feeding nitrogen gas, then pass in water vapor, and reduce the temperature rise rate to 5°C / min The temperature was raised to 520° C., and after 35 minutes of heat preservation, nitrogen gas was introduced to start cooling down. After the furnace temperature was cooled to room temperature, the sample was taken out; other conditions were the same as in Example 1.

Embodiment 3

[0043] A method for preparing a soft magnetic composite material, wherein step 5 specifically includes: placing the pressed blank block in an annealing furnace, vacuumizing the furnace chamber and then filling it with nitrogen to stabilize it to 0.04MPa, and increasing the temperature at a rate of 15°C / min. Heat at a rate of 400°C and hold for 60 minutes; then carry out a second temperature rise, heating to 450°C at a rate of 15°C / min, then start to feed water vapor, reduce the rate of temperature rise to 5°C / min and raise to 520°C, hold for 35 minutes Feed into nitrogen to start cooling afterward, and take out sample after furnace temperature is cooled to room temperature; All the other conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com