Patents

Literature

165results about How to "Reduce the number of defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ni-based alloy oil sleeve and manufacturing method for high-acidity deep well

ActiveCN101613833ALow costImprove high temperature corrosion resistanceDrilling rodsRoll mill control devicesSolution treatmentImpurity

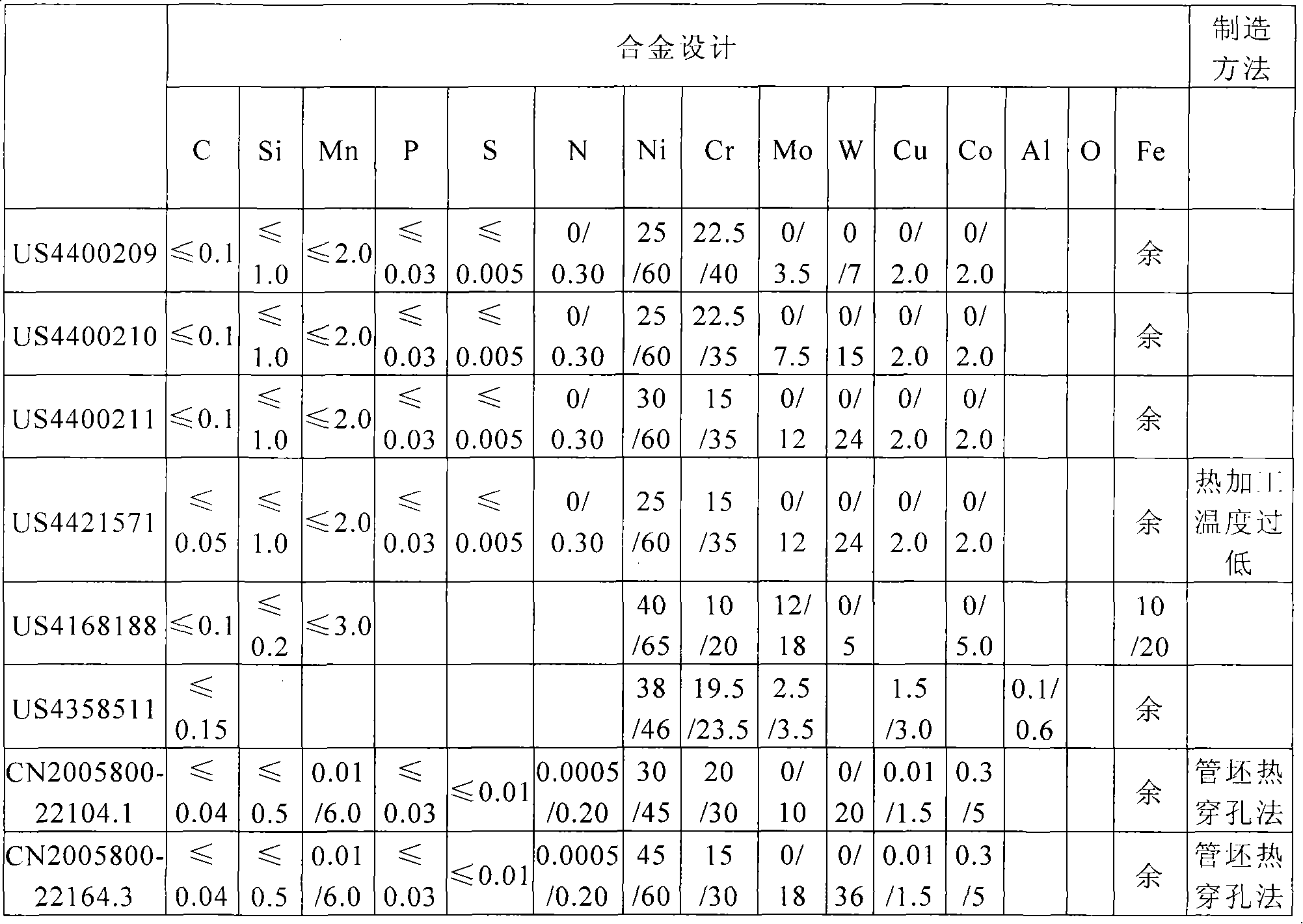

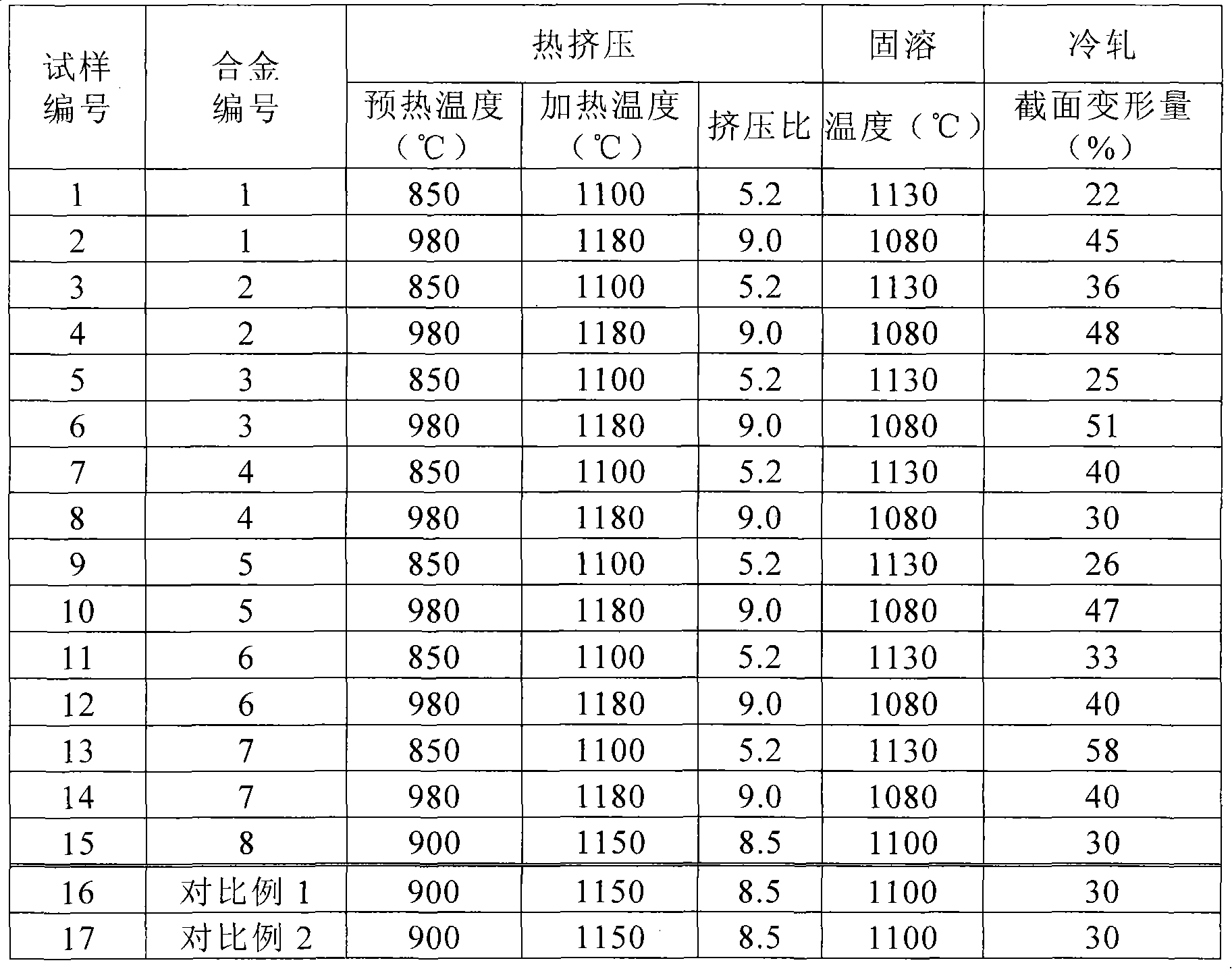

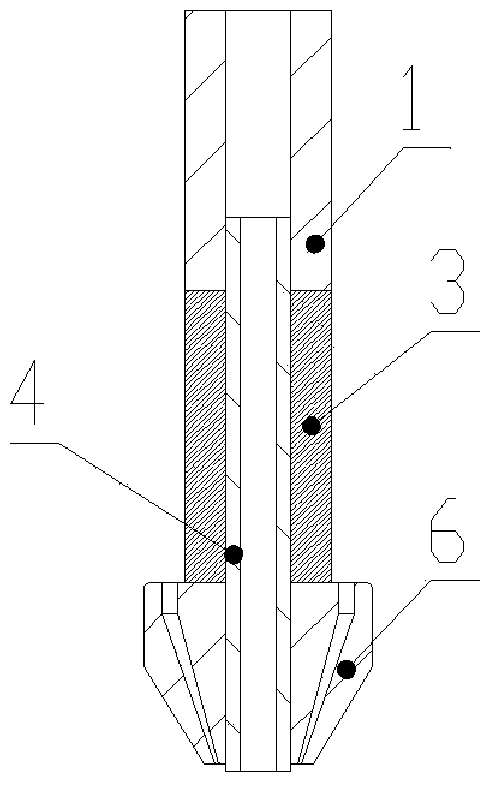

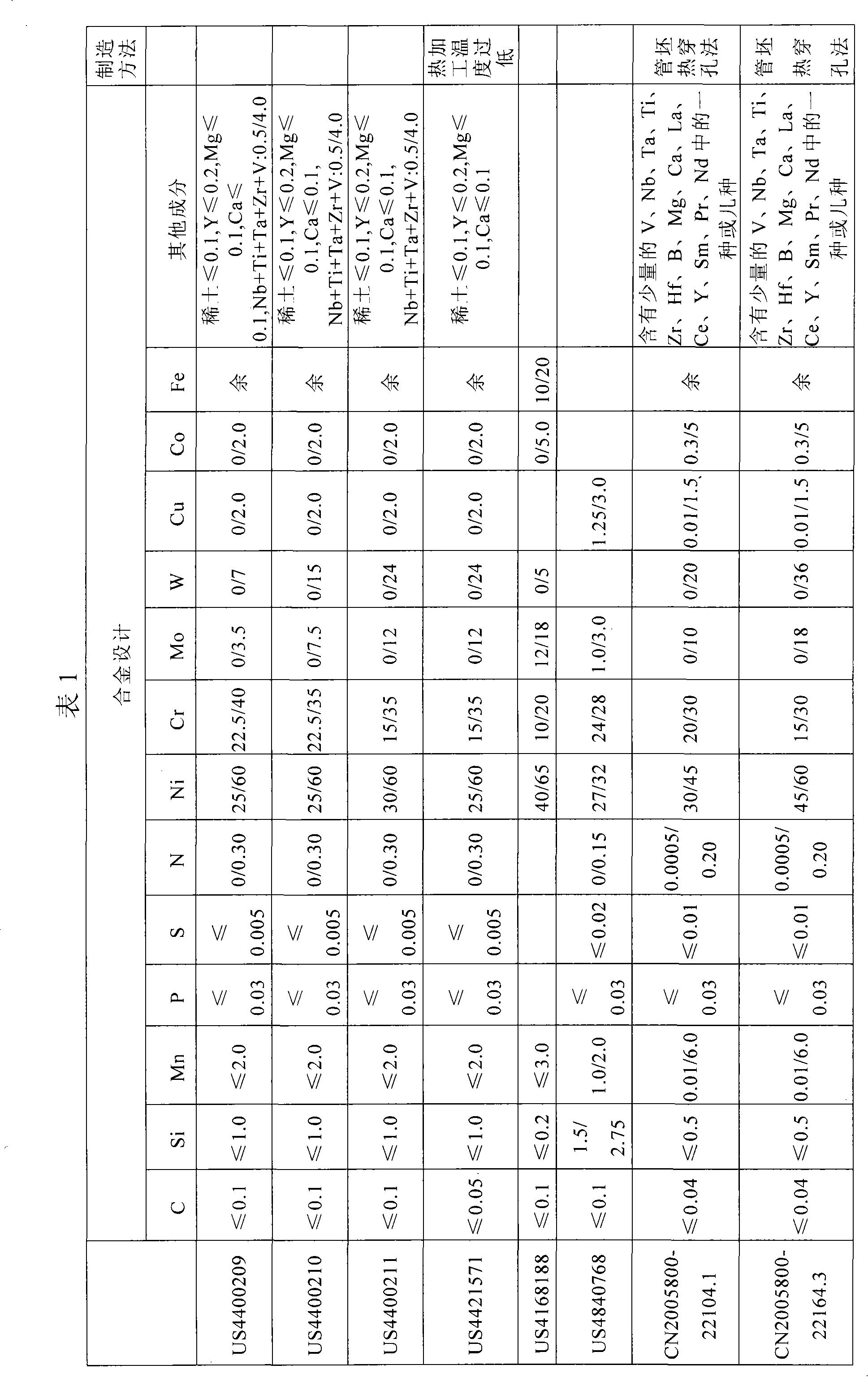

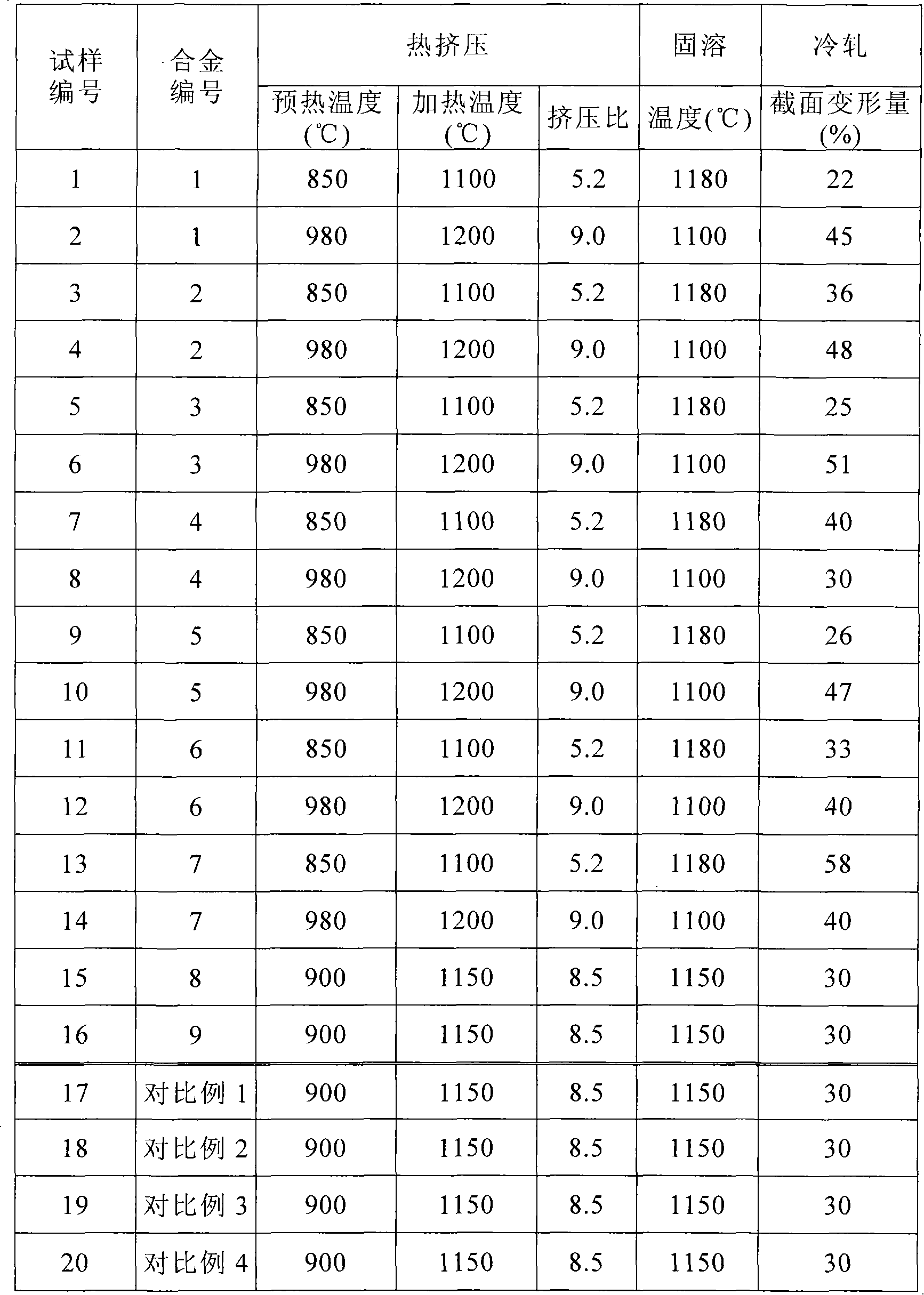

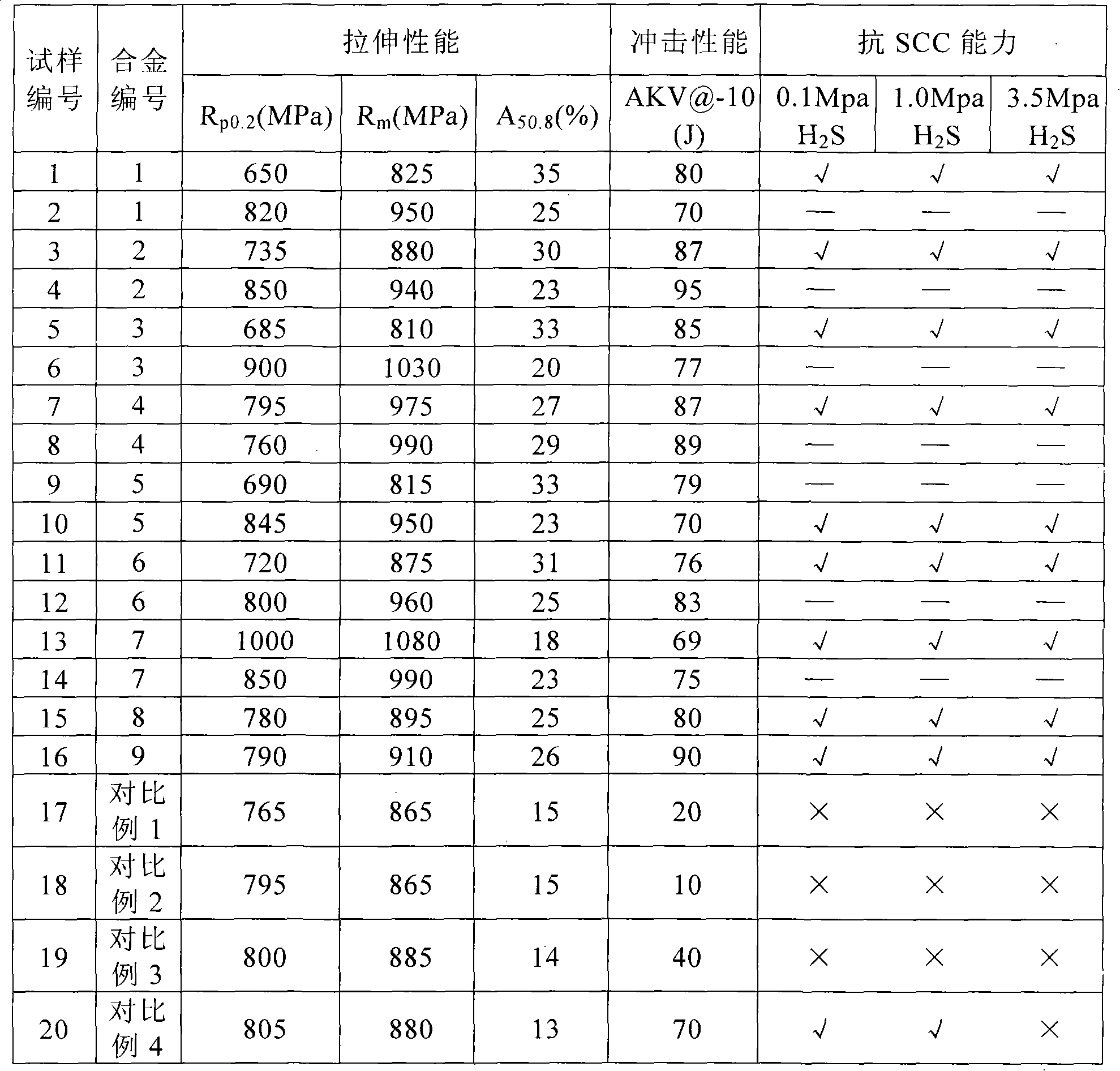

The invention relates to a Ni-based alloy oil sleeve for a high-acidity deep well, which comprises the following components in percentage by mass: less than or equal to 0.02 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, less than or equal to 0.5 percent of Si, less than or equal to 1.0 percent of Mn, 40 to 60 percent of Ni, 20 to 30 percent of Cr, 1 to 10 percent of Mo, 1 to 5 percent of W, 0 to 5 percent of Co, 0.1 to 3.0 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, less than or equal to 1.5 percent of Ti, and the balance of Fe and inevitable impurities. In the invention, the thermal extrusion processing performance and corrosion resisting performance of the alloy are effectively ensured by controlling the contents of the Al and O. The 90 to 140 ksi steel-grade Ni-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,150 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

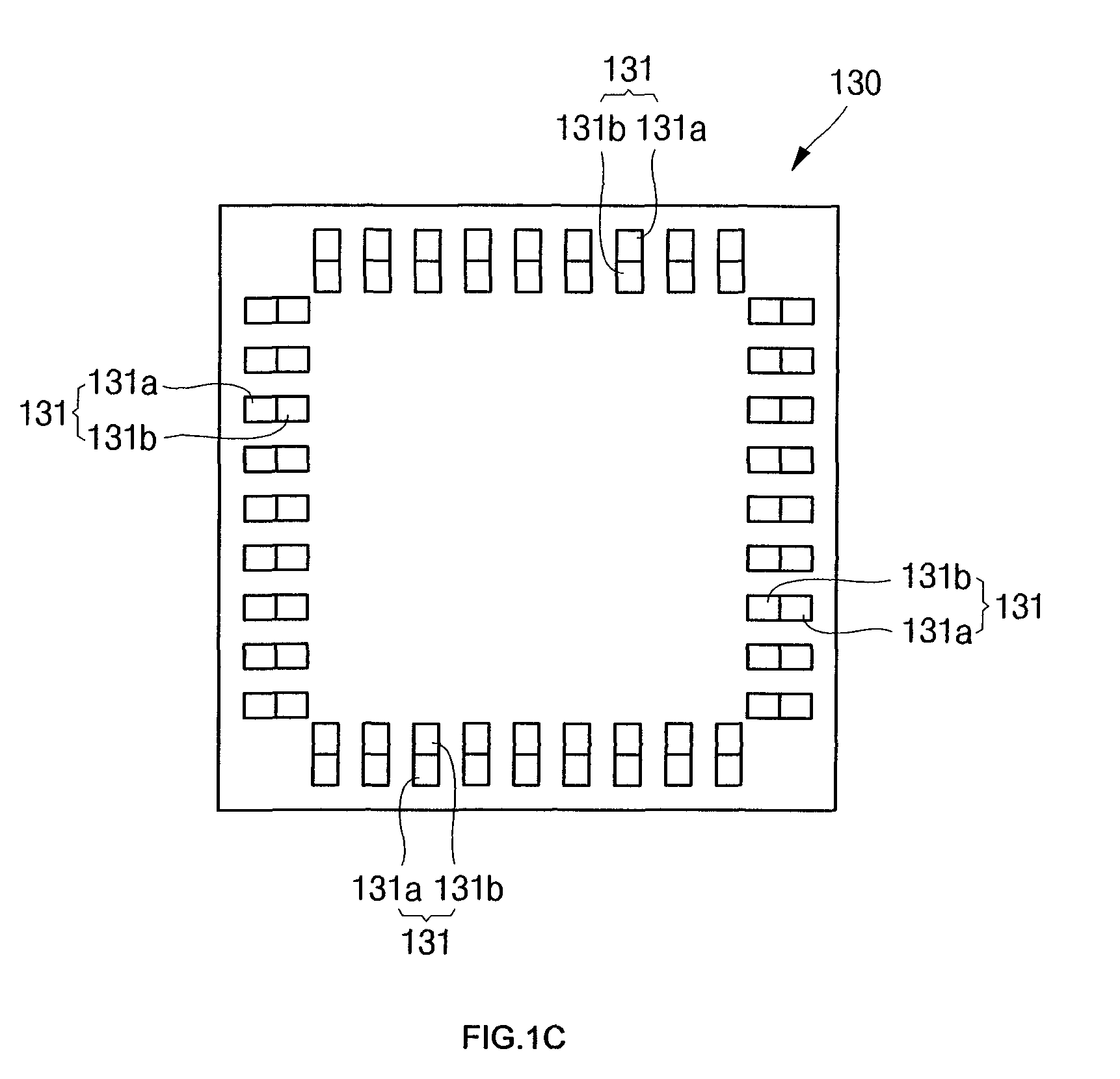

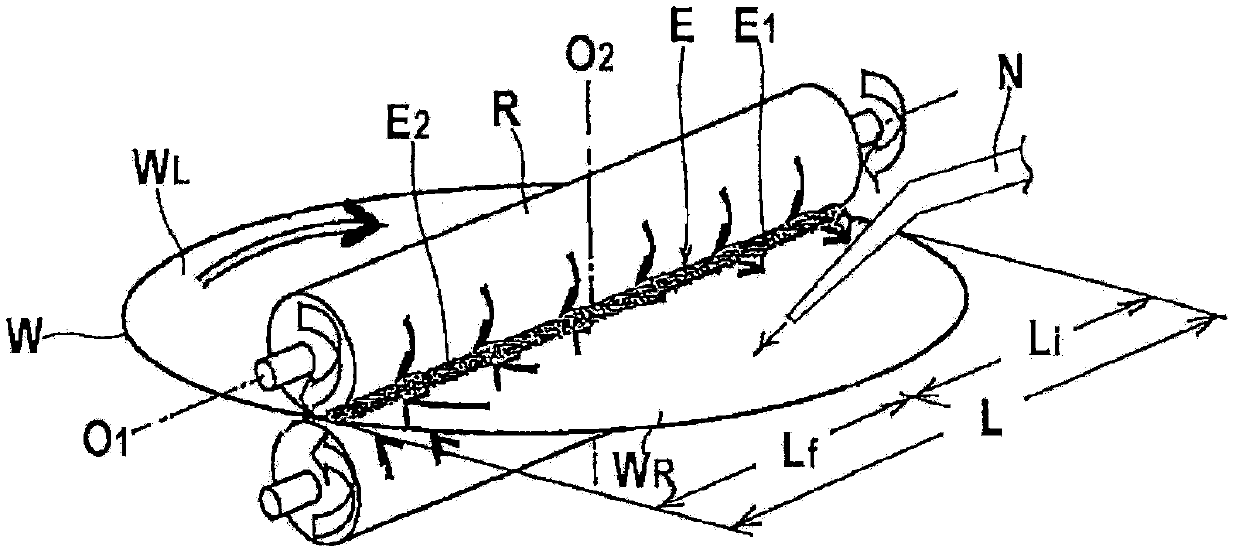

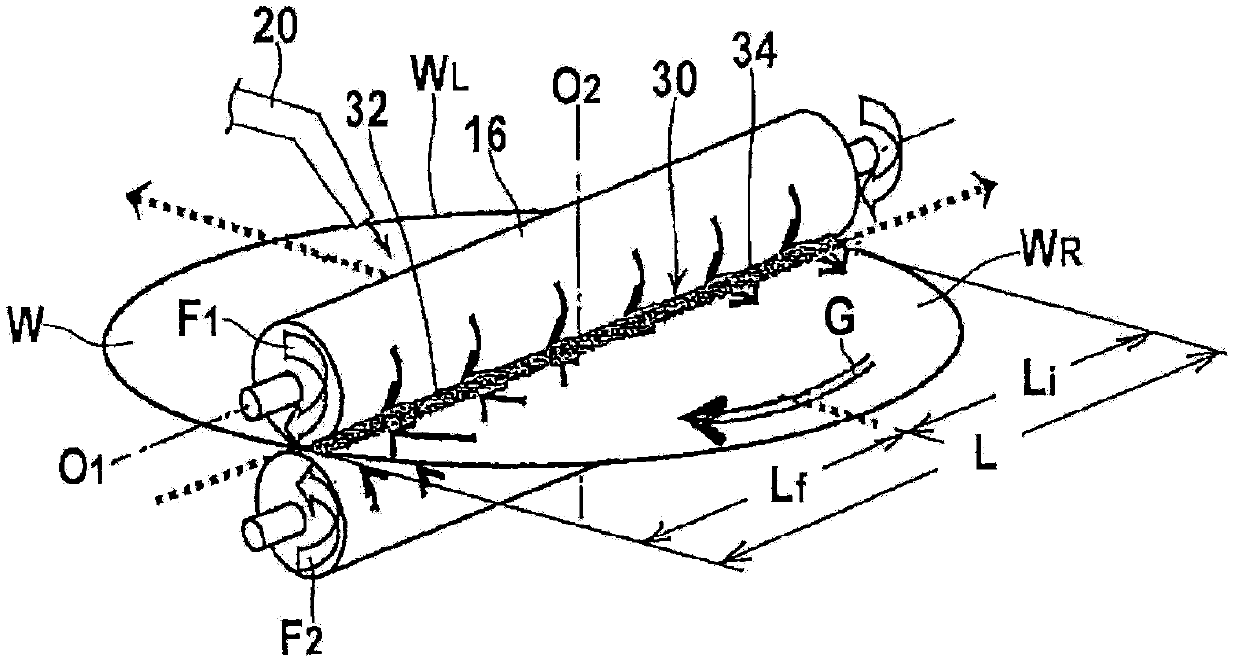

Static magnetic field-laser coaxial composite fusion covering method and device

ActiveCN103741138AWide range of applicationsFlexible regulationMetallic material coating processesSurface shapeElectromagnet

The invention relates to a static magnetic field-laser coaxial composite fusion covering method and a device and belongs to the technical field of laser processing. A static magnetic field is provided by an electromagnet, and the coaxial compositing of the magnetic field and a laser beam is realized through a device. When in magnetic field-laser coaxial fusion covering, the magnetic field generation device moves coaxially and synchronously with the laser beam, the coupling of the magnetic field and a laser-induced molten pool flow field can be completed, the laser fusion covering process is completed through a preset or coaxial powder delivery way, the flowing of the laser-induced molten pool can be inhibited, so that a purpose for controlling the solidification structure, improving the surface shape of the fuse covering layer, optimizing the distribution of the stress and reducing the splashing phenomenon in the fuse covering process can be realized. The coaxial synchronous motion of the magnetic field and the laser can be realized. The static magnetic field-laser coaxial composite fusion covering method and device have the characteristics of good capacity for controlling the fuse covering layer, wide application range, simplicity in structure, convenience in popularization and the like.

Owner:HANGZHOU BOHUA LASER TECH

Fe-based austenite alloy oil sleeve and manufacturing method for high-acidity deep well

InactiveCN101613834ALow head lifeIncrease production costDrilling rodsRoll mill control devicesSolution treatmentChemical composition

The invention relates to a Fe-based austenite alloy oil sleeve, which comprises the following components in percentage by mass: less than or equal to 0.03 percent of C, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 0.01 to 1.0 percent of Si, 0.01 to 3.0 percent of Mn, 25 to 40 percent of Ni, 20 to 35 percent of Cr, 1 to 5 percent of Mo, 0.1 to 1.5 percent of Cu, 0.01 to 0.5 percent of Al, less than or equal to 0.01 percent of O, and the balance of Fe and inevitable impurities. The 90 to 140 ksi steel-grade Fe-based alloy oil sleeve meeting different well depth requirements of high-acidity oil fields and gas fields is manufactured by thermal extrusion, 1,050-1,180 DEG C of solution treatment and cold rolling of the smelted and forged blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

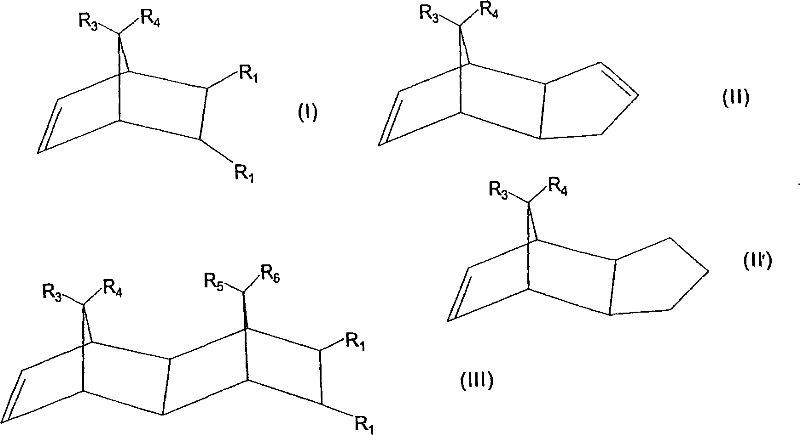

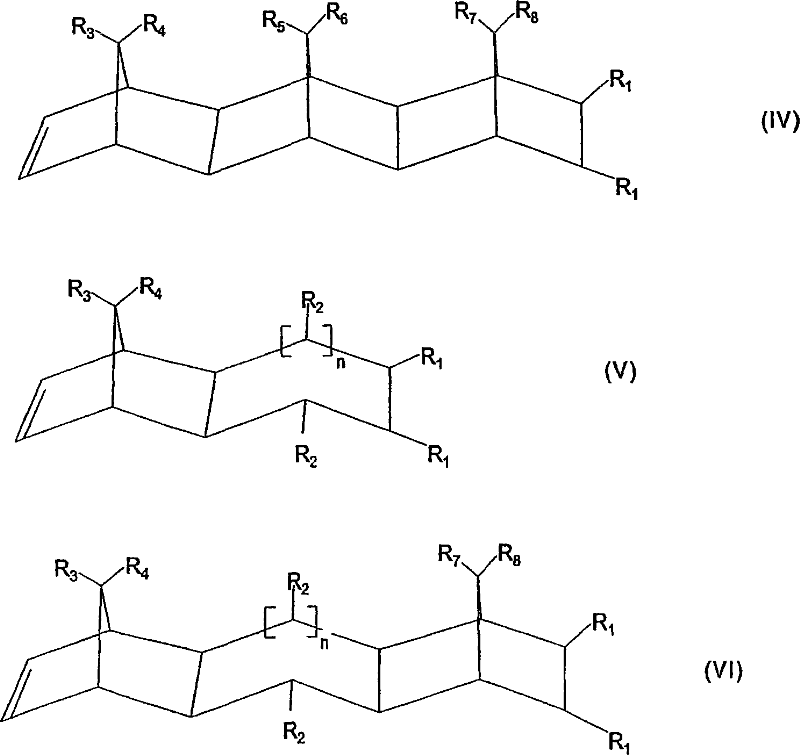

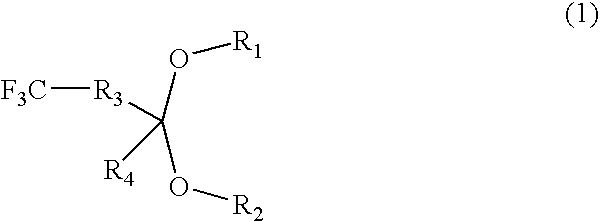

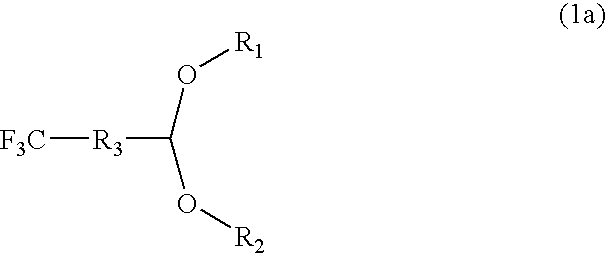

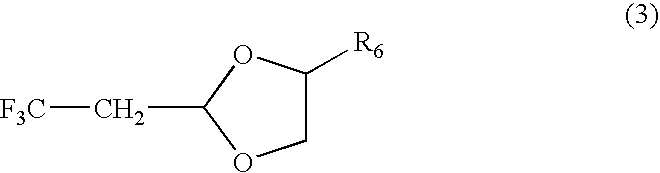

Fluorine-containing polymer coating composition, method for forming fluorine-containing polymer film using coating composition, and method for forming photoresist or lithographic pattern

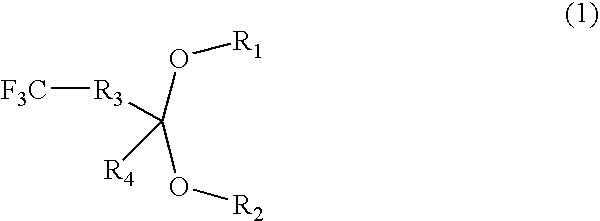

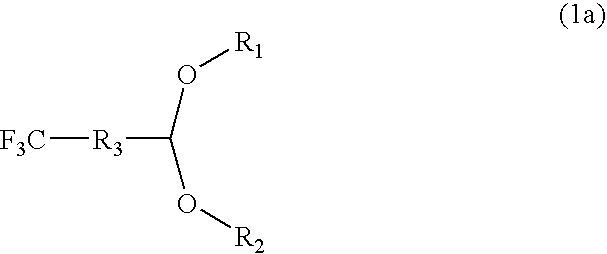

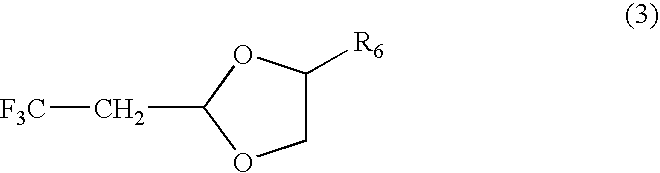

InactiveUS20070105044A1Reduce defectHigh resolutionOrganic chemistryPhotosensitive materialsSolventResist

There is provided a means for forming a protective film of a fluorine-containing polymer composition excellent in smoothness and adhesiveness on a photoresist. Moreover, there is provided a means for removing the protective film without impairing the underlying photoresist. A polymer coating composition obtainable by dissolving a fluorine-containing polymer compound in a solvent comprising a fluorinated acetal having a specific structure is applied on a photoresist and dried to form a protective film. The fluorinated acetal having the specific structure is suitable as a solvent for being brought into contact with a fluorine-containing polymer film, peeling the film, and forming a photoresist or a lithographic pattern.

Owner:CENT GLASS CO LTD

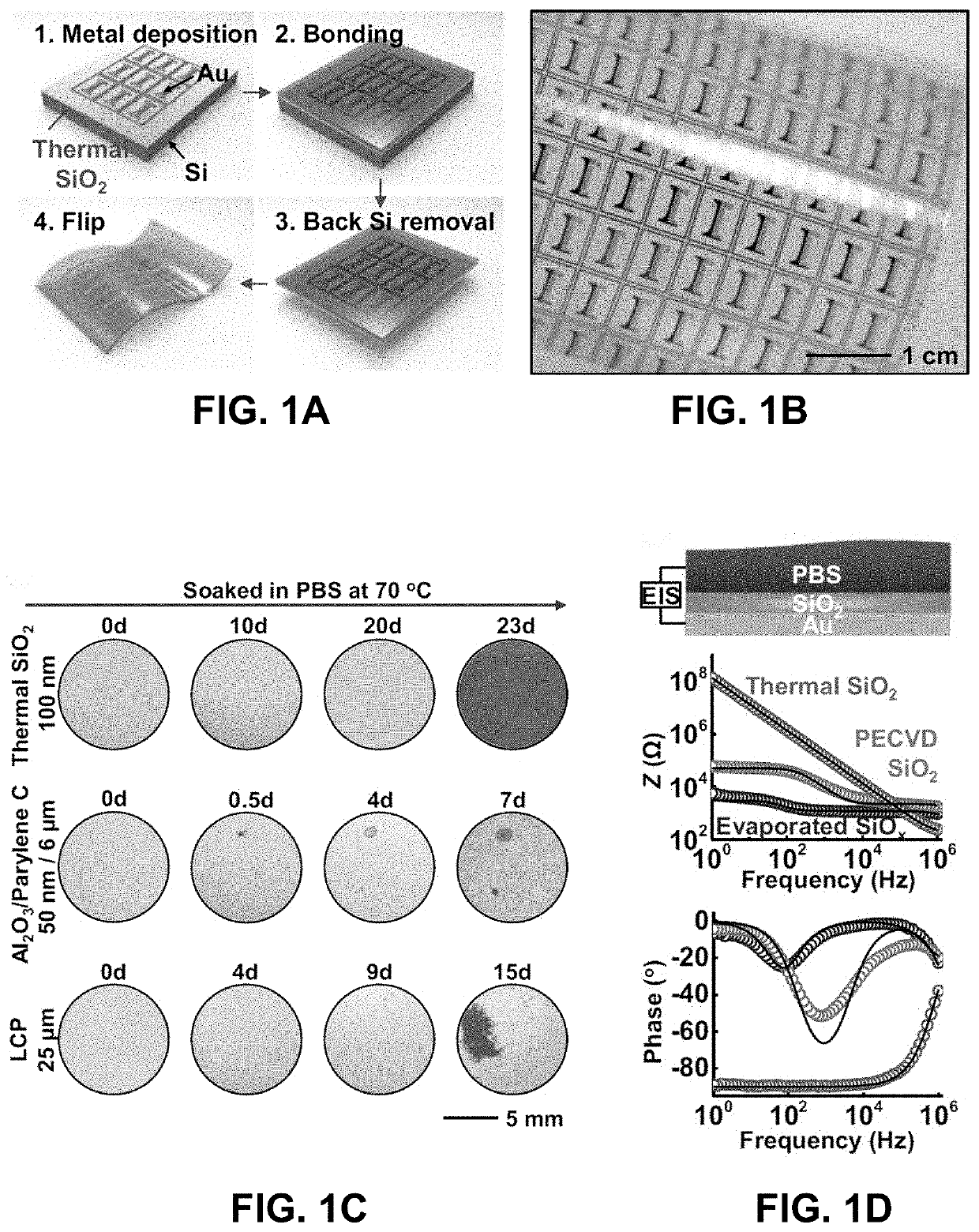

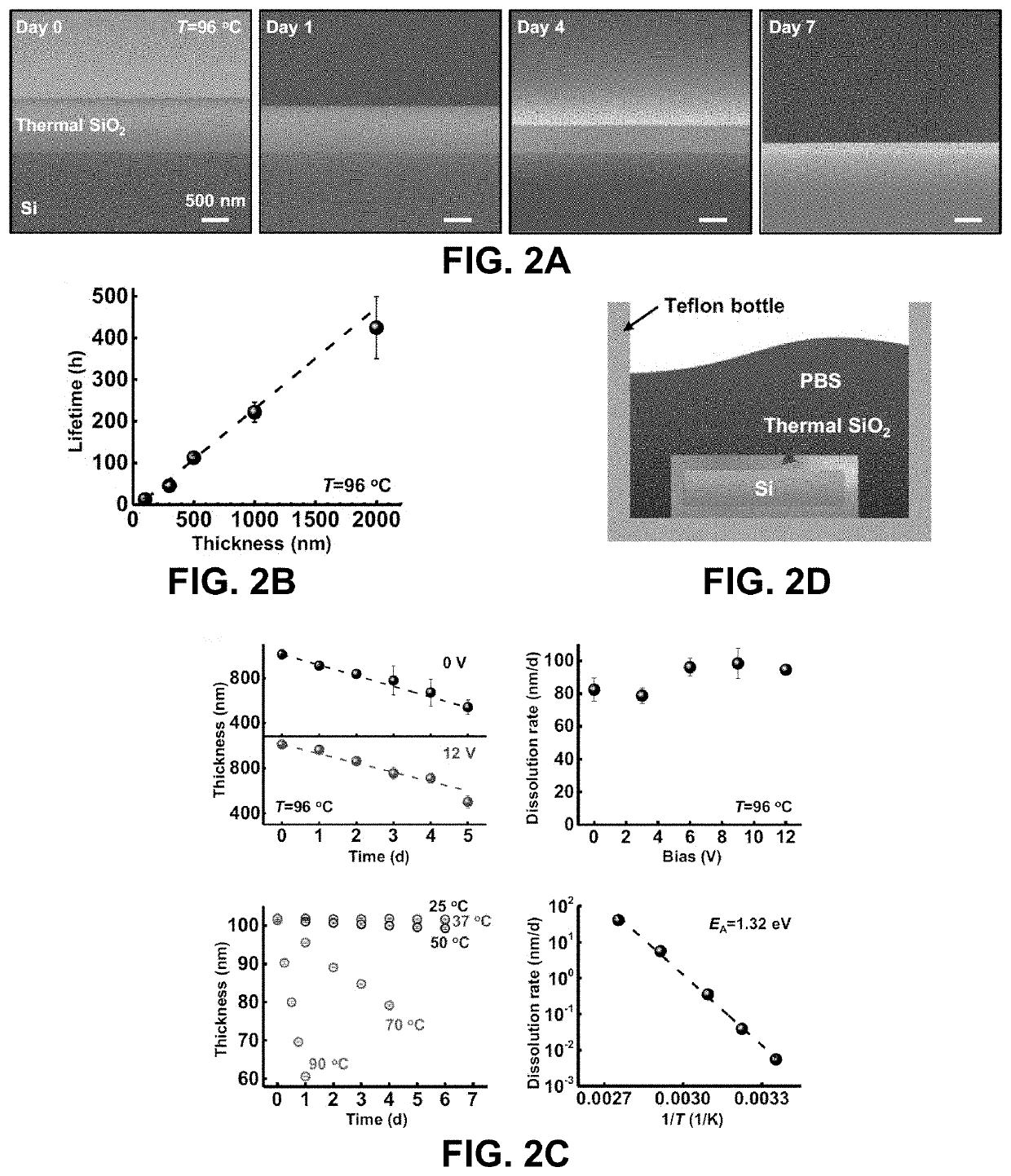

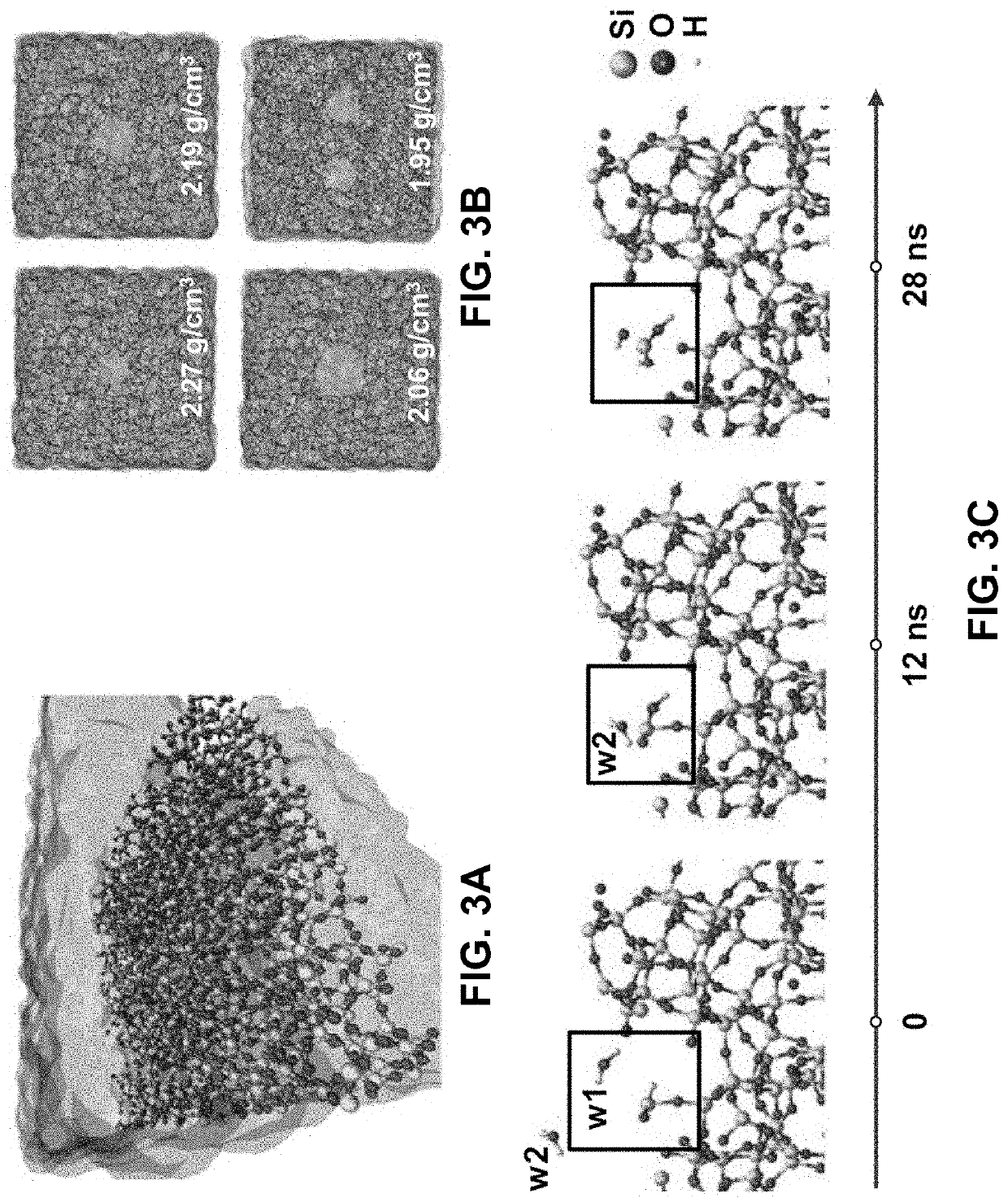

Encapsulated flexible electronics for long-term implantation

ActiveUS20200022601A1Beneficial long-term implantation characteristicImprove featuresElectrocardiographyEpicardial electrodesEngineeringFlexible electronics

Provided are methods of making a long-term implantable electronic device, and related implantable devices, including by providing a substrate having a first encapsulation layer that covers at least a portion of the substrate, the first encapsulation layer having a receiving surface; providing one or more electronic devices on the first encapsulation layer receiving surface; and removing at least a portion of the substrate from the first encapsulation layer; thereby making the long-term implantable electronic device. Further desirable properties, including device lifetime increases during use in environments that are challenging for sensitive electronic device components, are achieved through the use of additional layers such as longevity-extending layers and / or ion-barrier layers in combination with an encapsulation layer.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS +1

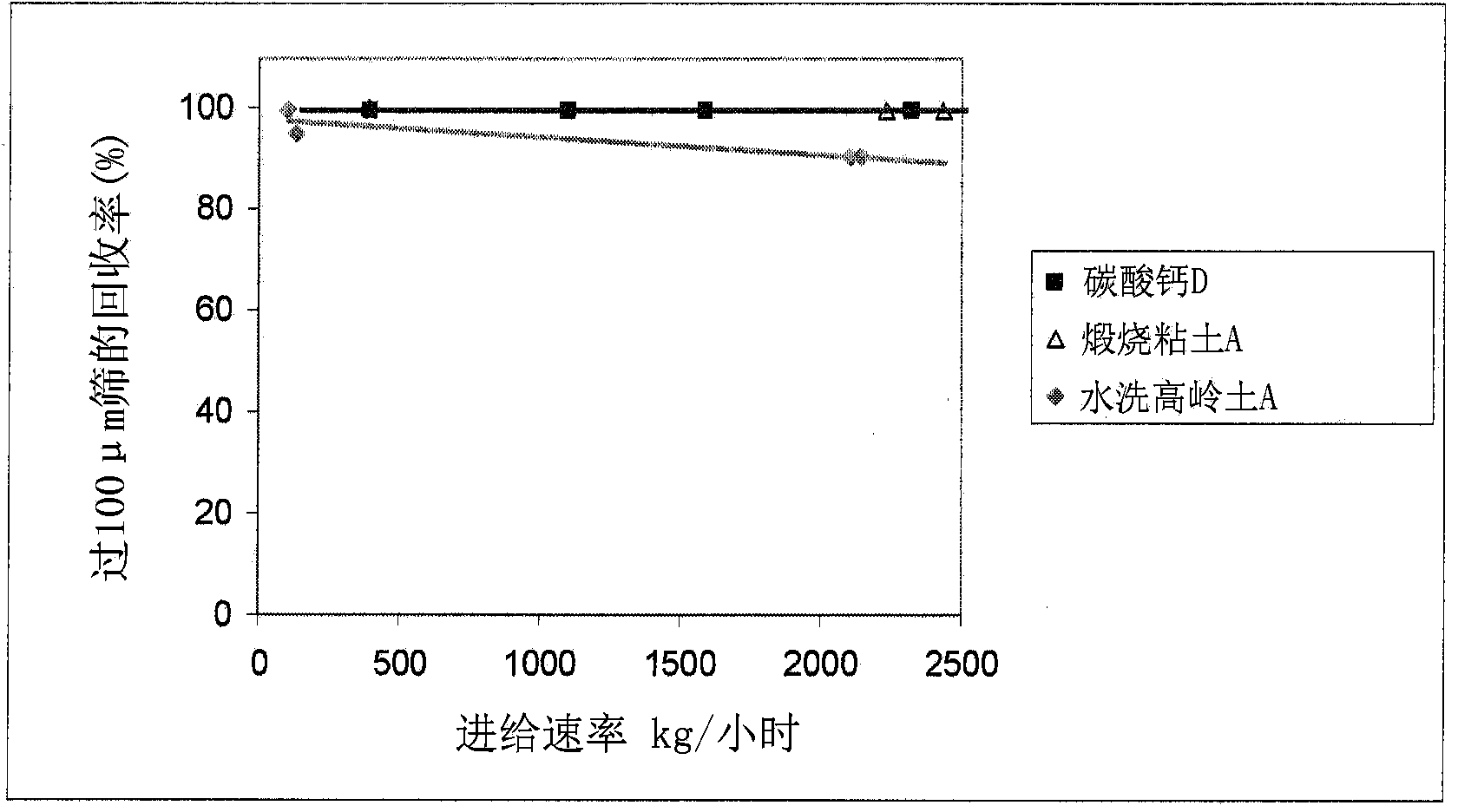

Particulate fillers

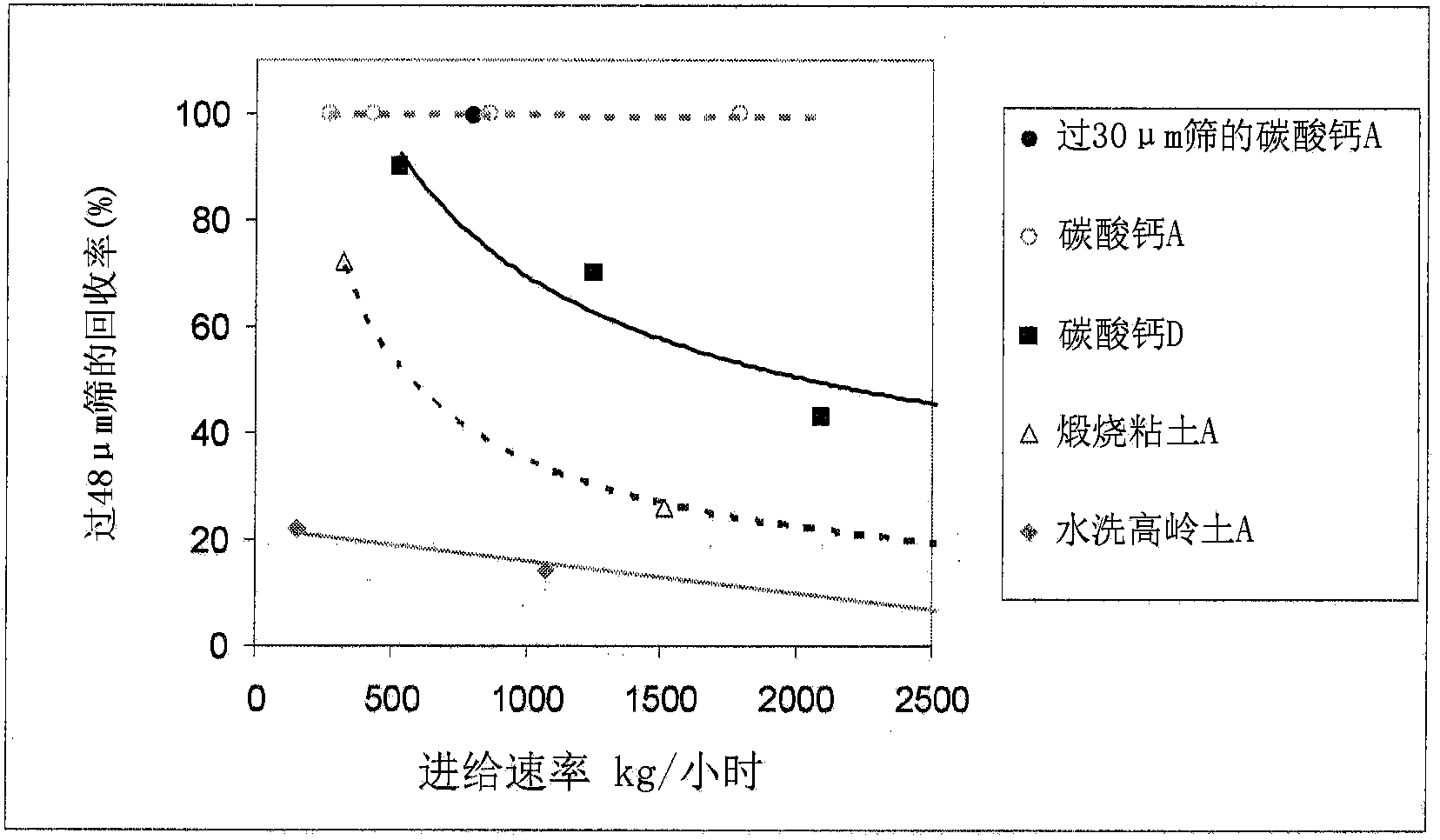

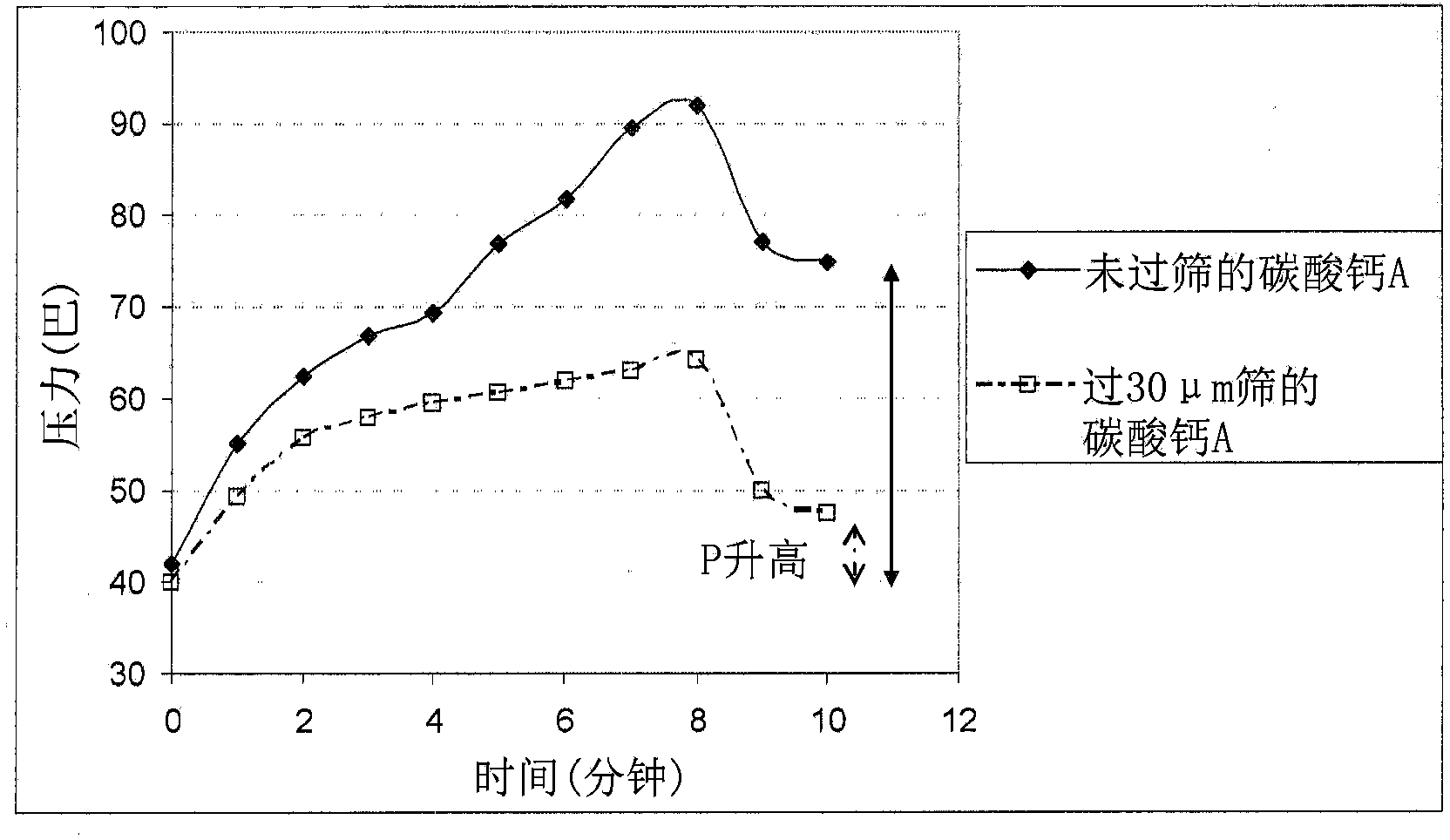

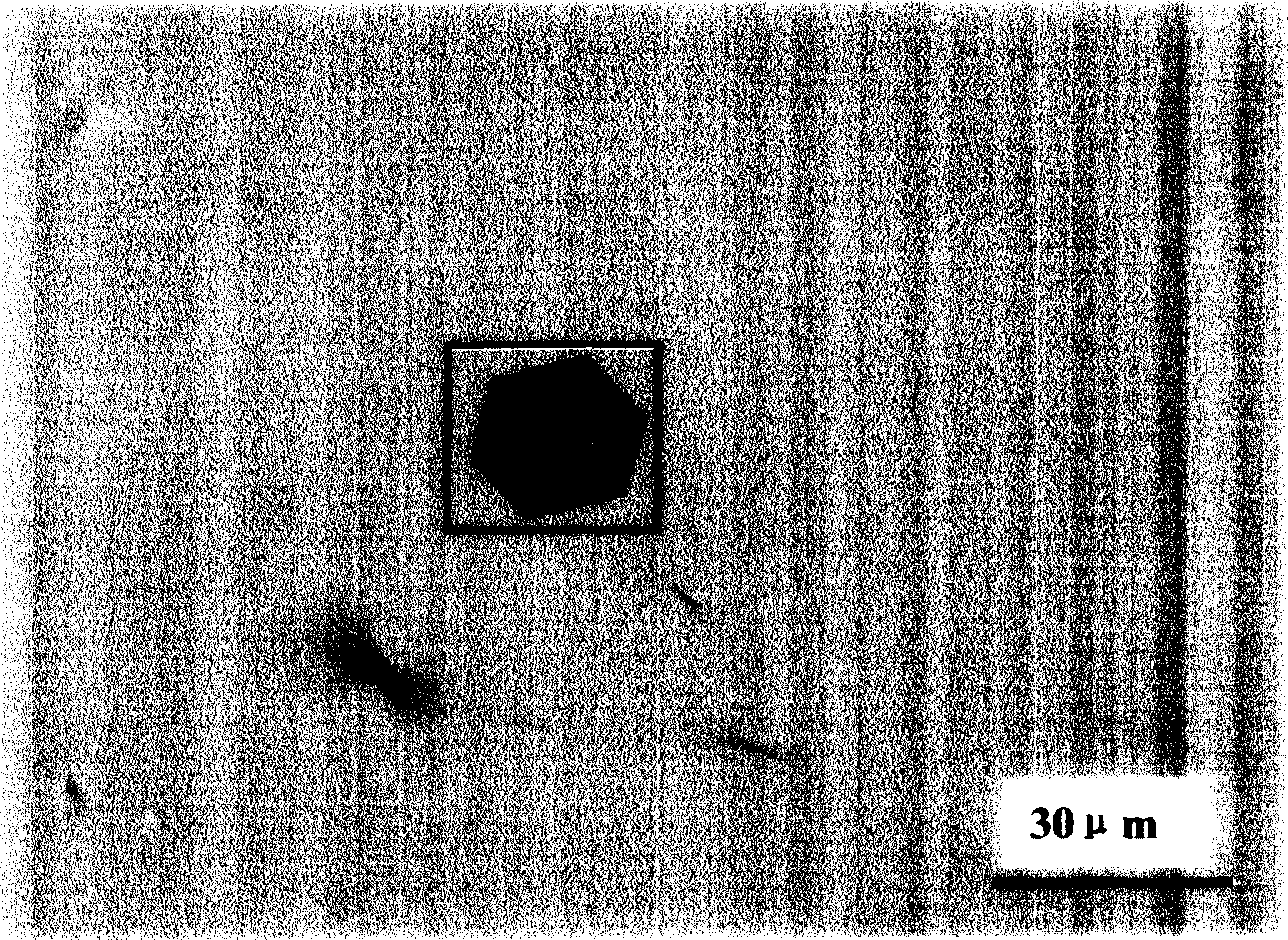

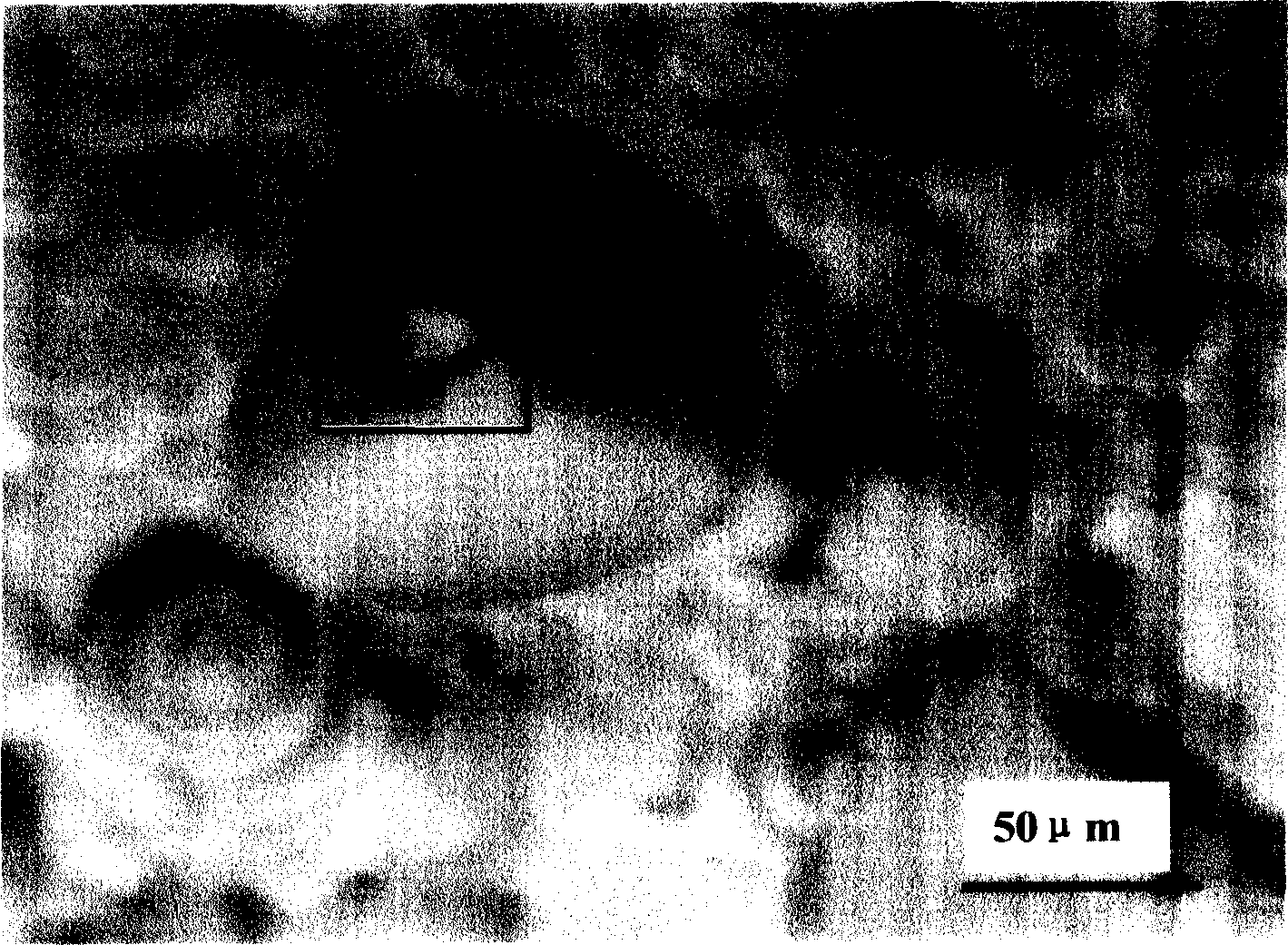

ActiveCN104053728AImprove mechanical propertiesNo or very little cloggingSurgeryAbsorbent padsFiberPolymer science

Particulate fillers possess no, or very low, amounts of coarse particles. The particulate fillers may be included in compositions, such as polymer compositions including polymer film formed from a polymer composition, such as breathable film. The particulate fillers may be included in spunlaid fiber, and the spunlaid fiber may be included in products and non-woven fabric. The particulate filler may be included in staple fibers, which may be included in carpet.

Owner:IMERYS MINERALS

Heat treatment method after silicon carbide monocrystal growth

ActiveCN1884639AQuality improvementReduce in quantityPolycrystalline material growthAfter-treatment detailsCarbon filmCrucible

The invention discloses a heat disposing method of carborundum monocrystalline, which comprises the following steps: placing SiC monocrystalline with carbon film and powder material in the copple; heating argon to preset temperature; keeping temperature for certain time; cooling argon along with furnace; recrystallizing SiC crystal and solid diffusion to eliminate partial micro-pipe and pack defect. The invention reduces defect quantity of micro-pipe and package in the SiC monocrystalline, which improves SiC monocrystalline quality.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD

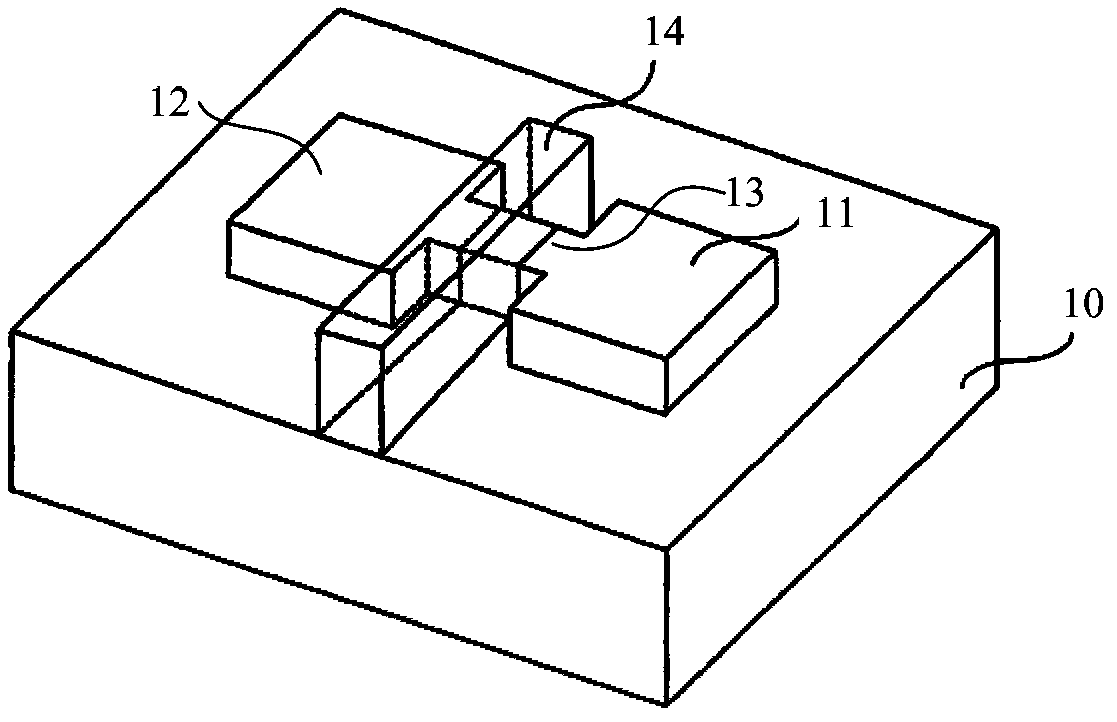

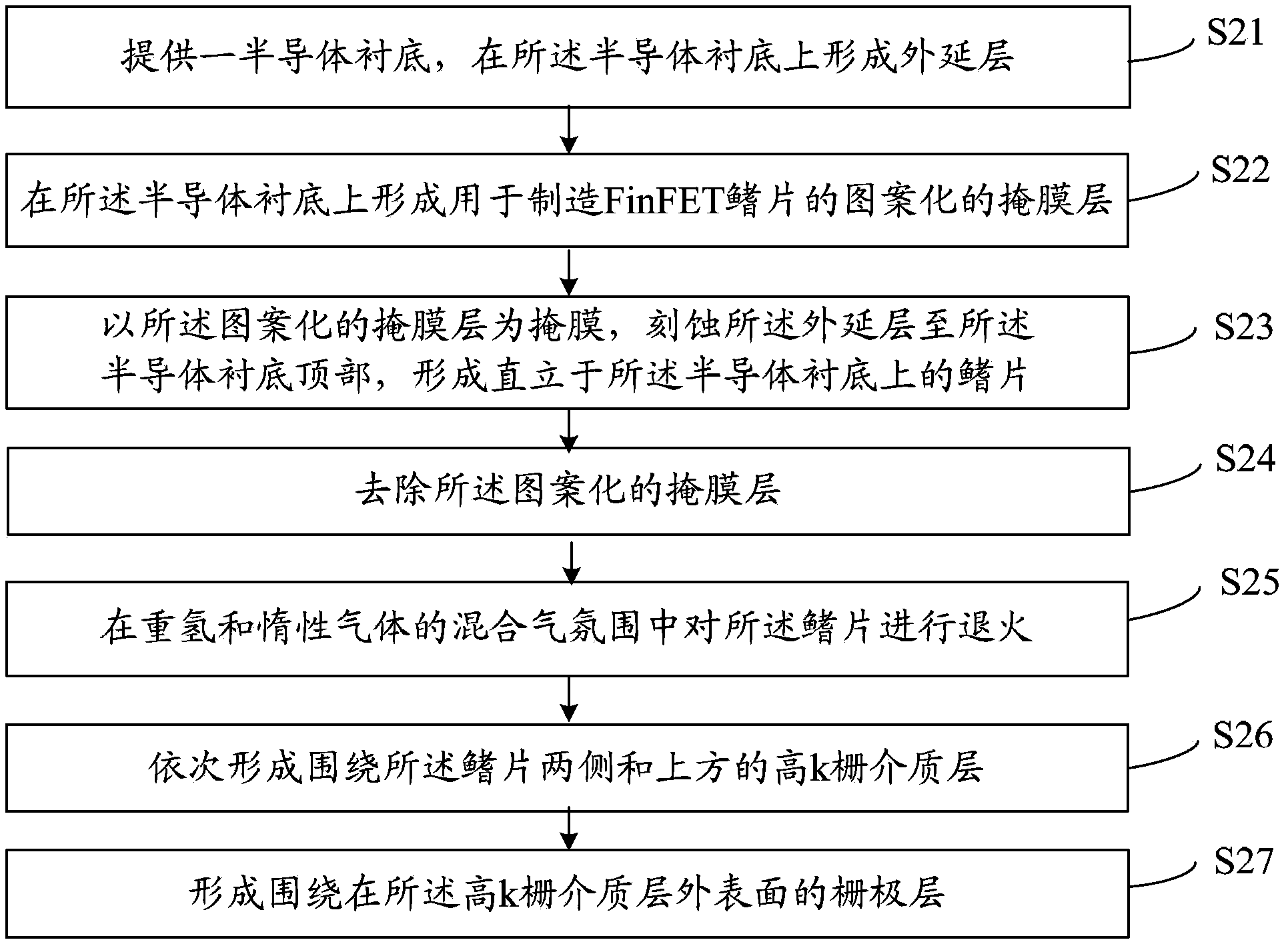

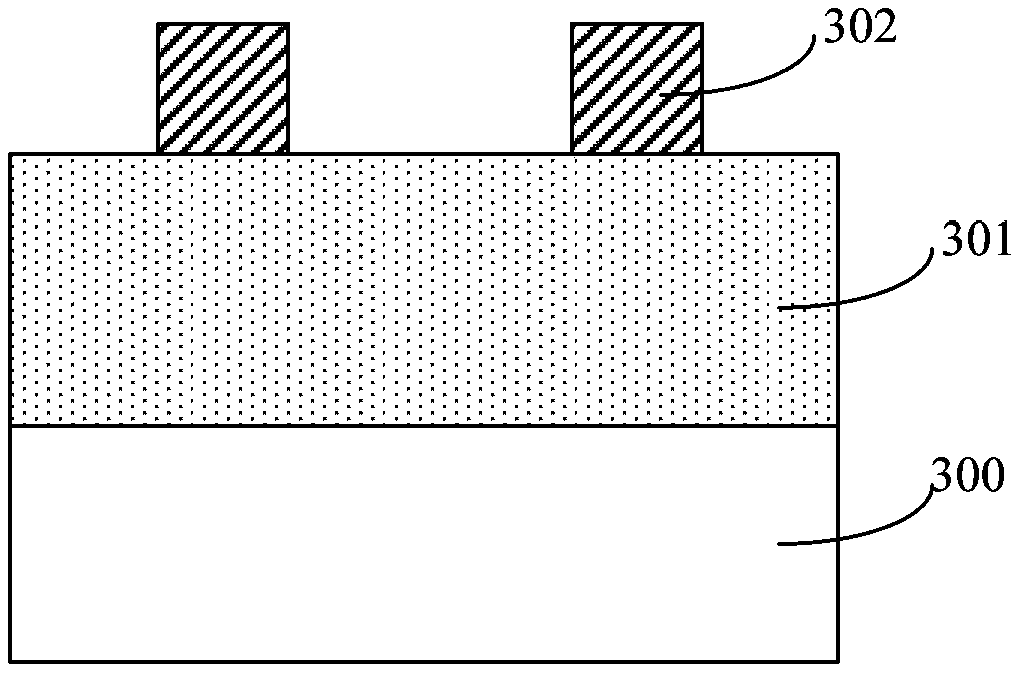

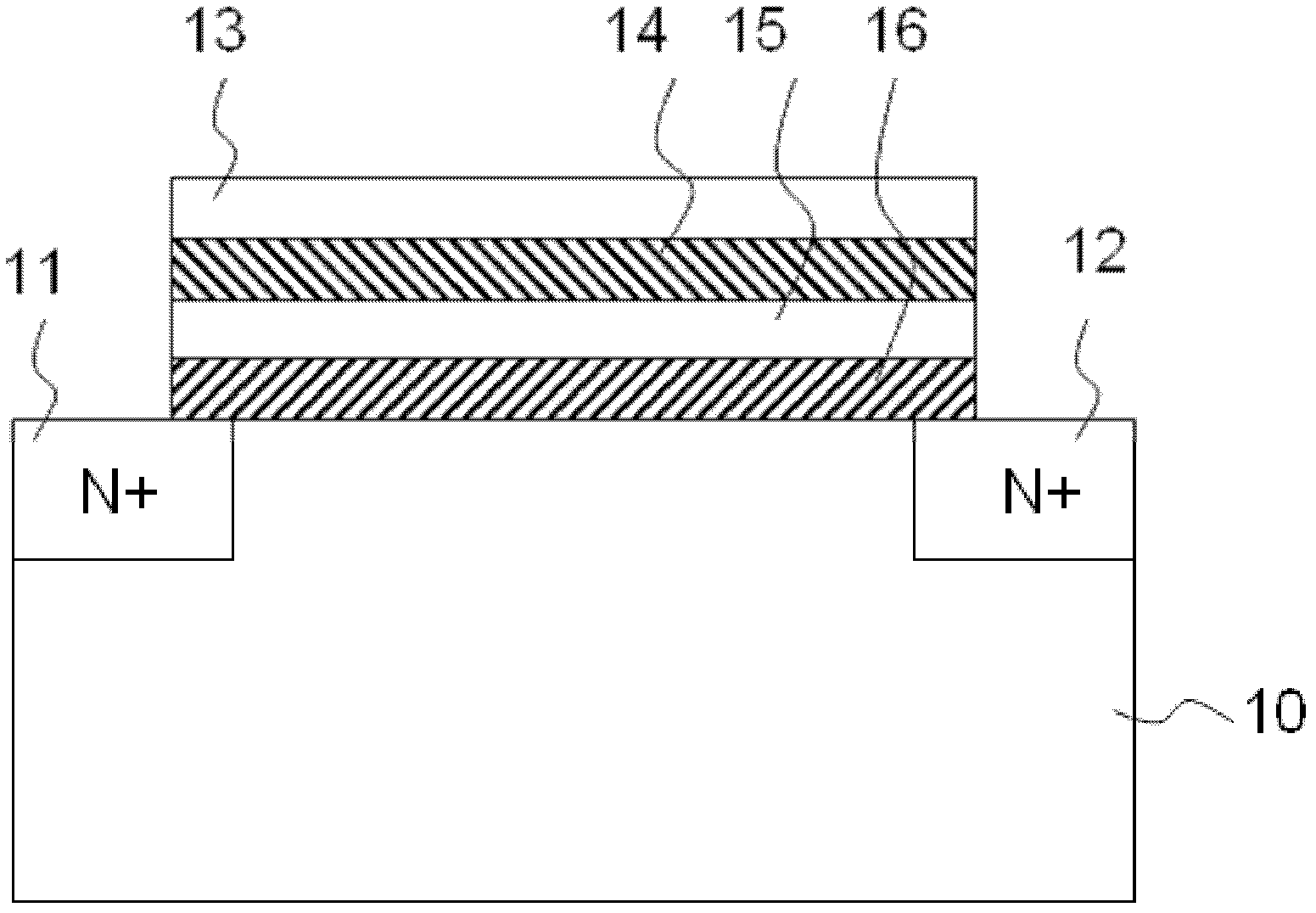

FinFET manufacturing method

InactiveCN103515223AImprove Fermi level pinning problemReduce the number of defectsSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricOxygen vacancy

The invention provides a FinFET manufacturing method. Before or after a step of forming a high-k gate dielectric layer surrounding the two sides and the upper side of a fin, the fin is annealed in a mixed atmosphere of heavy hydrogen and inert gas, dangling bonds of silicon in the fin are eliminated, induced band gap state or oxygen vacancy at a fin interface are reduced, the problem of Fermi energy level pinning in the high-k dielectric layer is improved, and the fin interface is smoothed, thereby reducing the number of defects in the high-k dielectric layer, suppressing the charge trap effect, improving the threshold voltage drift and improving the performance of FinFET devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP

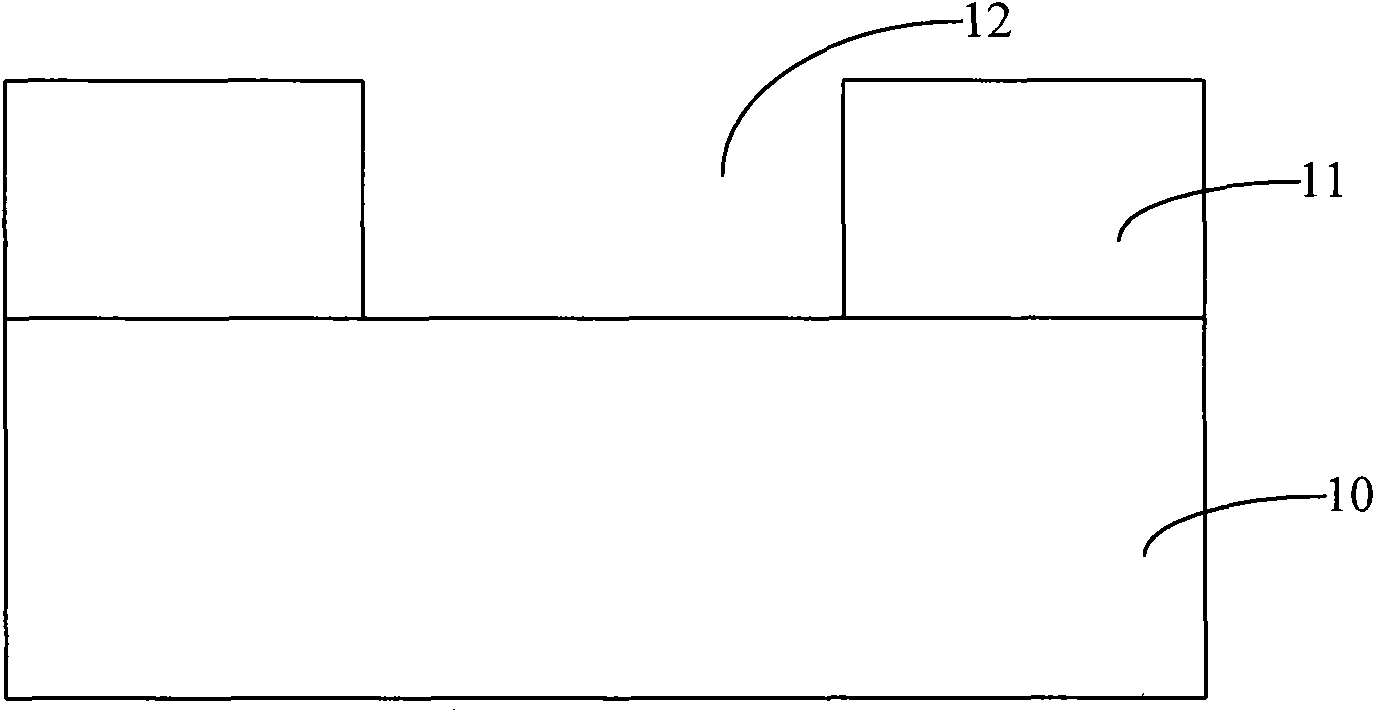

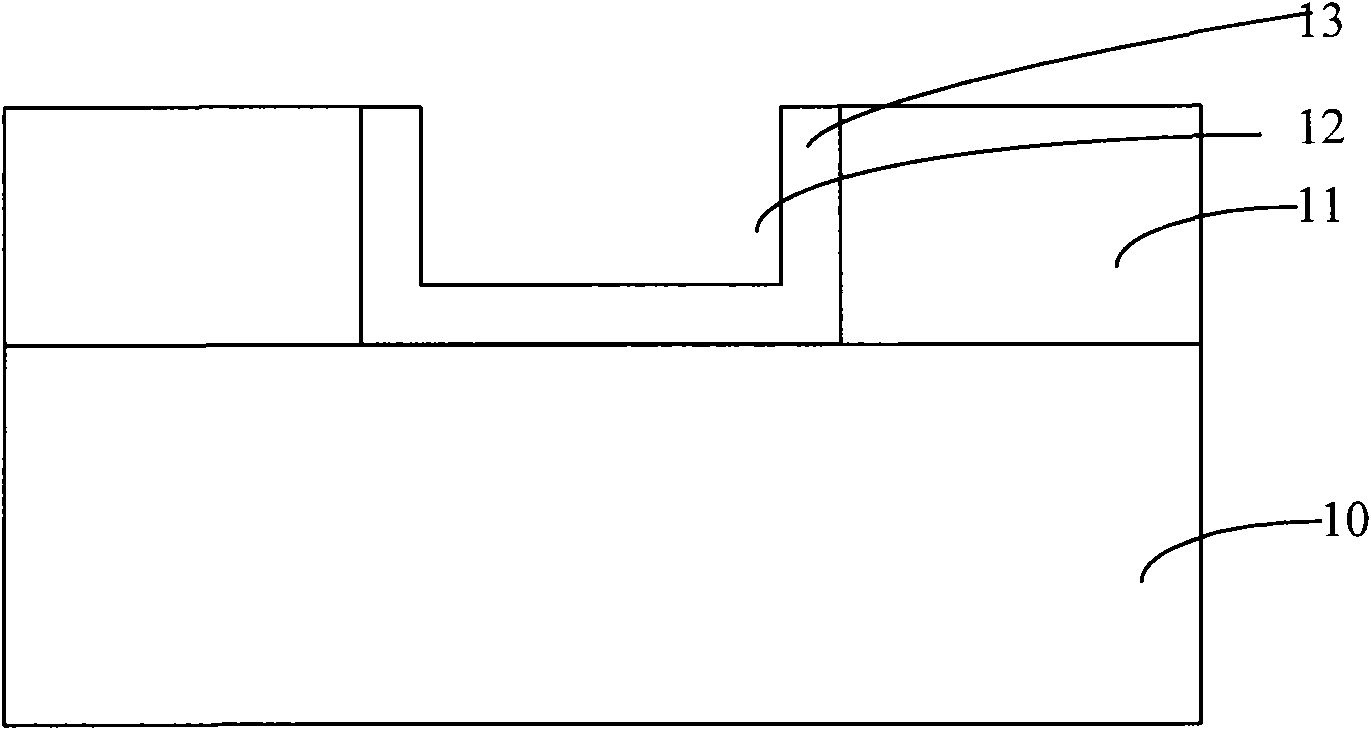

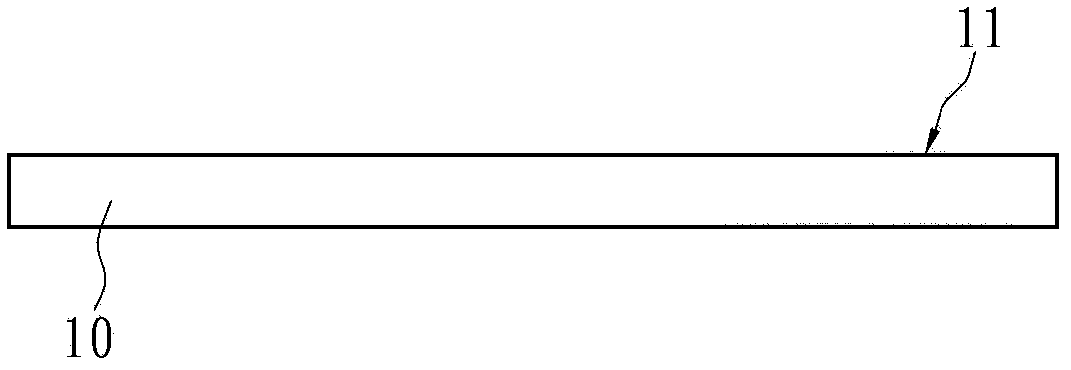

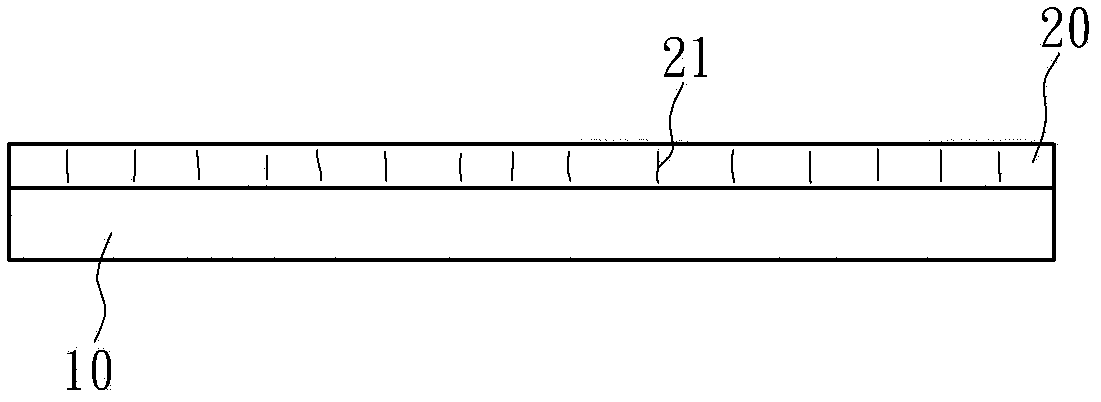

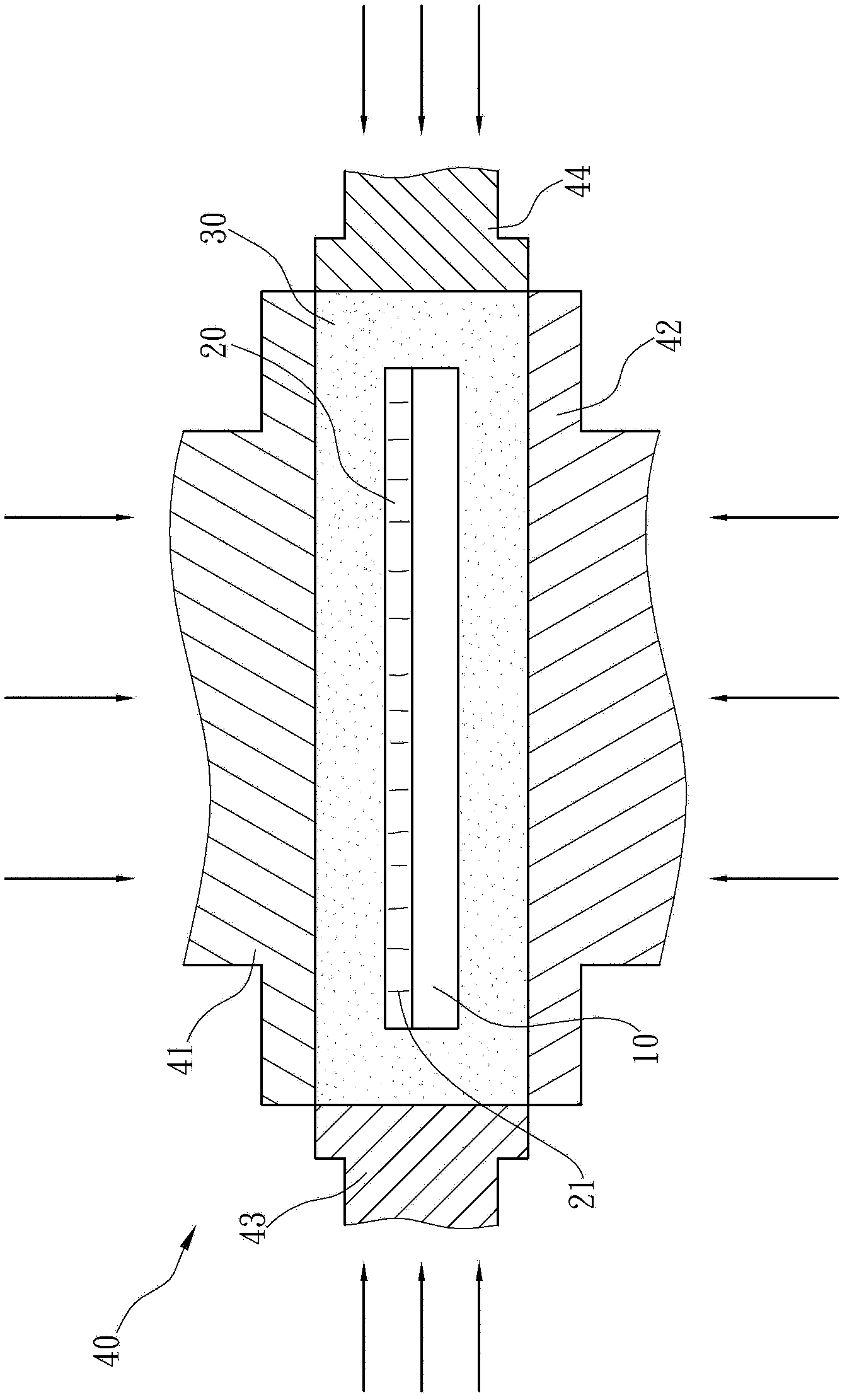

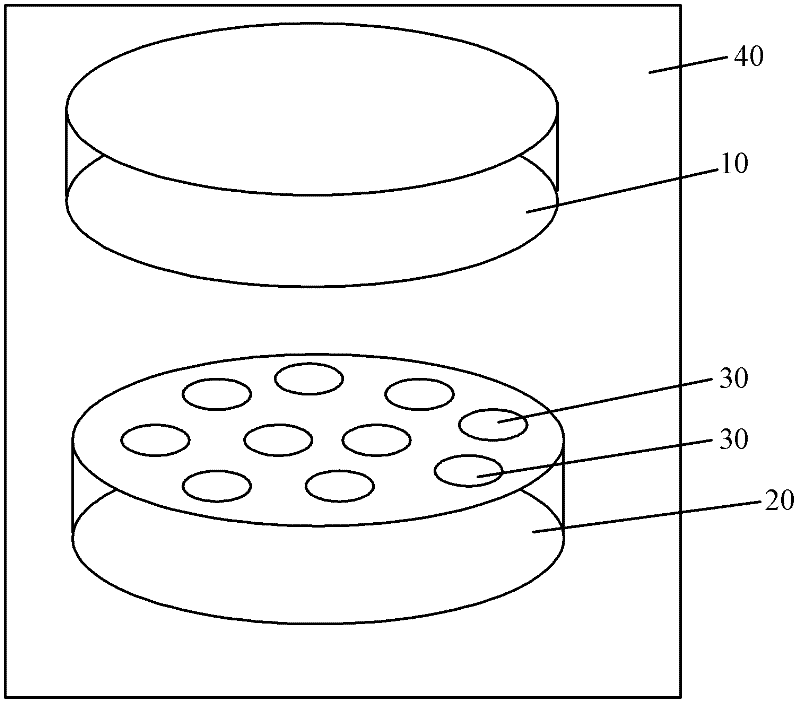

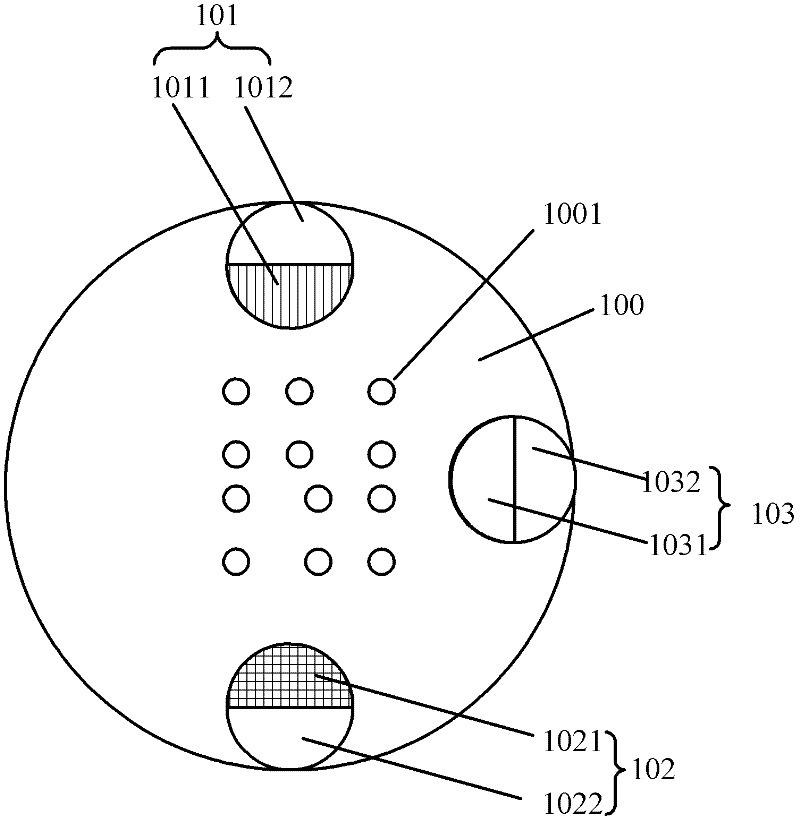

Substrate and manufacturing method thereof

ActiveCN106611739AReduce the number of defectsQuality improvementSemiconductor/solid-state device manufacturingChemical-mechanical planarizationOptoelectronics

The invention provides a substrate and a manufacturing method thereof. The method comprises steps: an auxiliary substrate and a supporting substrate are provided, wherein at least a defect elimination structure, an epitaxial layer above the defect elimination structure and a passivation layer above the epitaxial layer are arranged on the auxiliary substrate, and at least a buried dielectric layer is arranged on the supporting substrate; the auxiliary substrate is bonded on the supporting substrate; the auxiliary substrate is removed; and chemical-mechanical planarization (CMP) is carried out until the epitaxial layer reaches a specified thickness. As defects of the epitaxial layer can be reduced by the defect elimination structure and damages of the epitaxial layer during the bonding process can be effectively reduced by the passivation layer, a large amount of defects can be prevented from being generated in the epitaxial layer, and the performance and the reliability of using the epitaxial layer to manufacture a device can be enhanced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

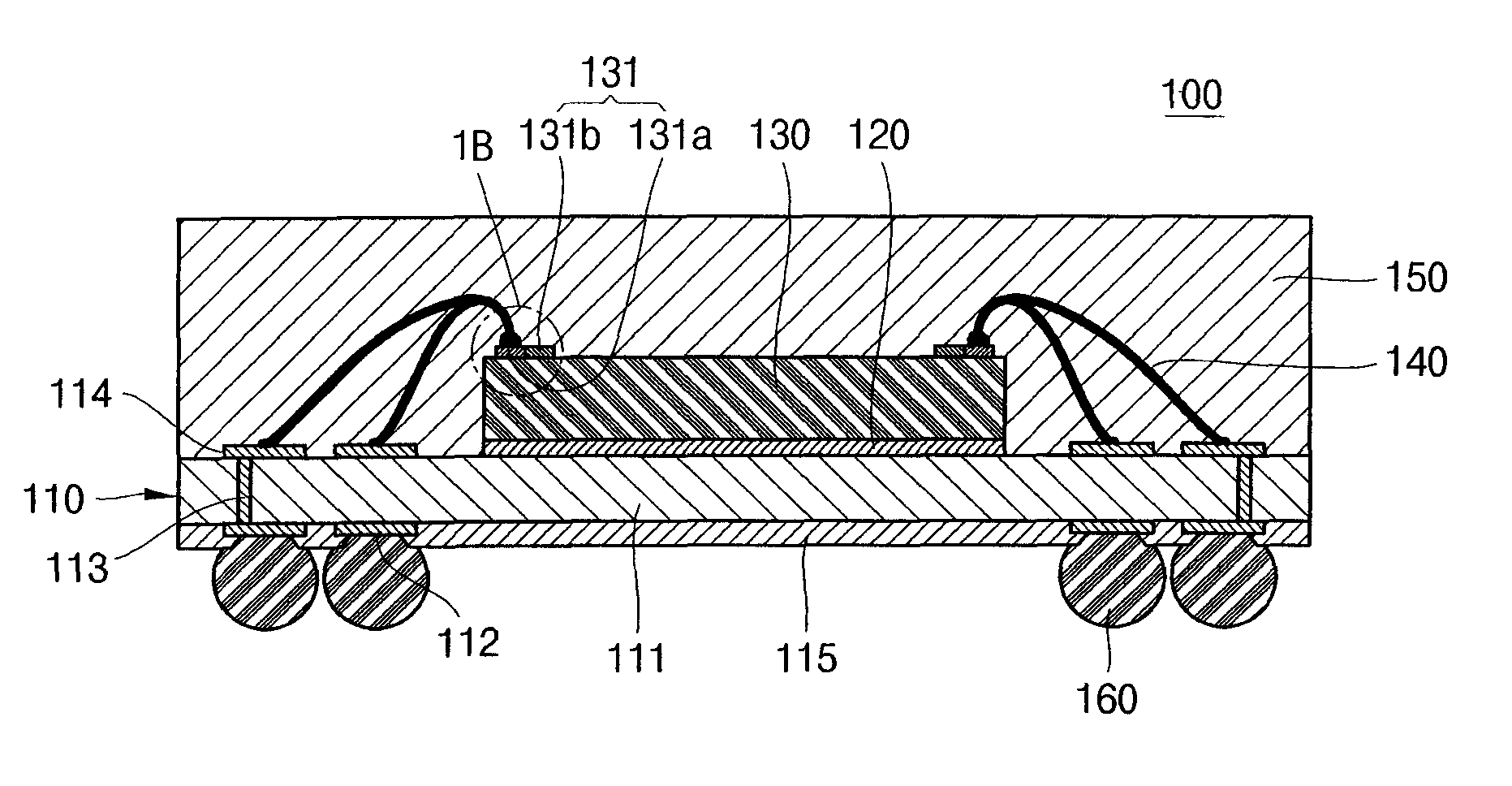

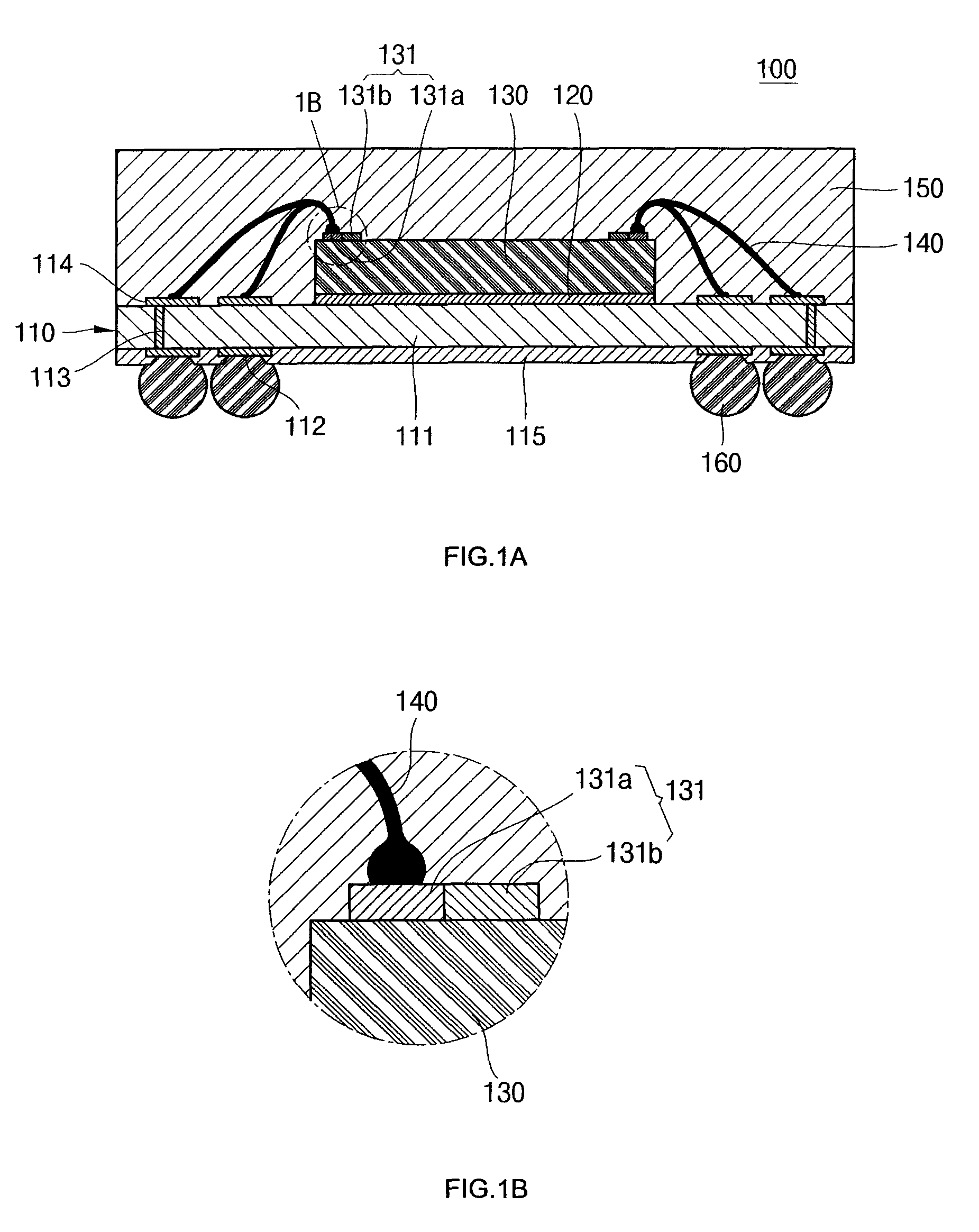

Semiconductor device and fabricating method thereof

ActiveUS8183683B1Reduce the number of defectsAvoid it happening againSemiconductor/solid-state device detailsSolid-state devicesIonizationSemiconductor

A semiconductor device is provided. The semiconductor device comprises a semiconductor die having bond pads, each of which consists of a first bond pad made of a material whose ionization tendency is relatively low and a second bond pad made of a material whose ionization tendency is relatively high. The second bond pads function as sacrificial anodes to prevent the occurrence of galvanic corrosion at the interfaces between the first bond pads and conductive wires. In an embodiment, the upper surfaces of the second bond pads are marked instead of those of the first bond pads, which reduces the number of defects in the first bond pads. A method for fabricating the semiconductor device is also provided.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Substrate cleaning method

InactiveCN103418558AImprove comprehensivenessReduce reverse pollutionSemiconductor/solid-state device manufacturingFlexible article cleaningEnvironmental engineeringMechanical engineering

Owner:EBARA CORP

Method for making gallium nitride crystal

InactiveCN1434482AReduce the number of defectsSimple methodPolycrystalline material growthSemiconductor/solid-state device manufacturingSemiconductor materialsHeat deposition

This invention relates to a process method for semiconductor materials of gallium nitride crystals including the following steps: (1) epitaxial growth of Ga nitride or Al nitride on a substrate (2) heat-deposition of crystal particles of silicon, silicon carbide, silicon nitride or silicon oxide (3) continuation of epitaxial growth of Ga nitride further growing undoped and doped Ga nitride film Dor LED, LD, HEMT etc. photoelectronic and electronic apparatus. The said substraet can be sapphire, SiC SiL GaAs, ZnO, MgO, LiAlO2 or Li GaO2 effectively reducing dislocation, overcoming mismatch of the substrate and epitaxial layer.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for reducing seed crystal growth face defects of silicon carbide crystals

InactiveCN103088426AReduce the number of defectsReduce defectsPolycrystalline material growthFrom condensed vaporsSeed crystalCrystallographic defect

The invention relates to a method for reducing seed crystal growth face defects of silicon carbide crystals. The method comprises the following steps of: tightly pasting the Si faces of two seed crystals together, and putting the tightly pasted Si faces to a corrosive consisting of molten KOH and K2CO3; and heating up the mixture to 400 DEG C and corroding the C faces of the seed crystal growth faces under the constant-temperature condition of 400 DEG C, so that the seed crystal growth face defects of the silicon carbide crystals are reduced by corroding off the defects caused by grinding and polishing. According to the method disclosed by the invention, the defects, which are caused by grinding and polishing, on the C faces of the growth faces are quickly and simply corroded off on the condition of effectively protecting the Si faces on the growth back faces from being not corroded, so that the quantity of the defects on the growth faces is lower than that of the un-corroded defects by about five times, thereby reducing the crystal defects obtained by regeneration, improving the crystal quality and preventing the defects on the Si faces from being reversely sublimated and extended to the growth faces due to expansion.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

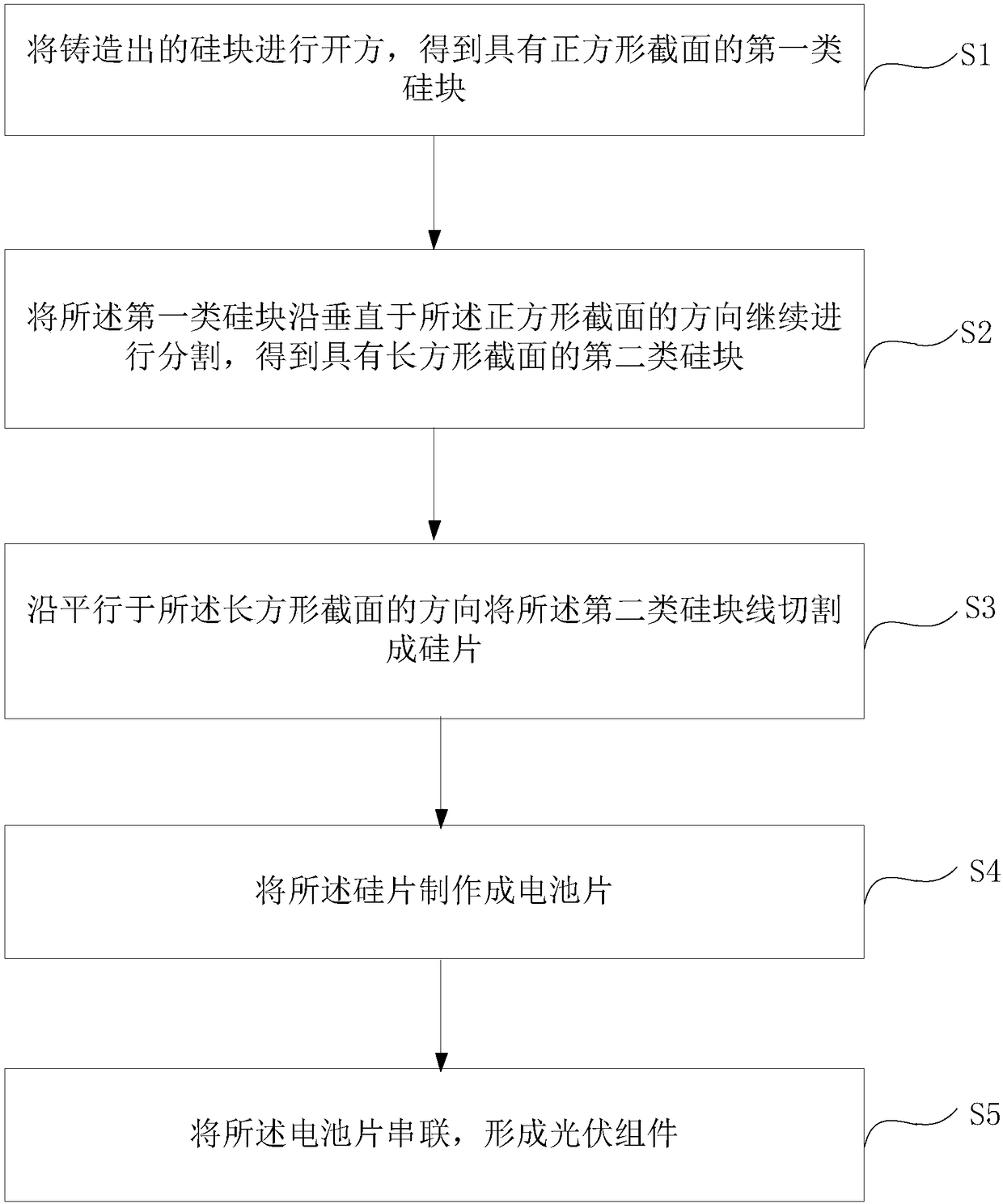

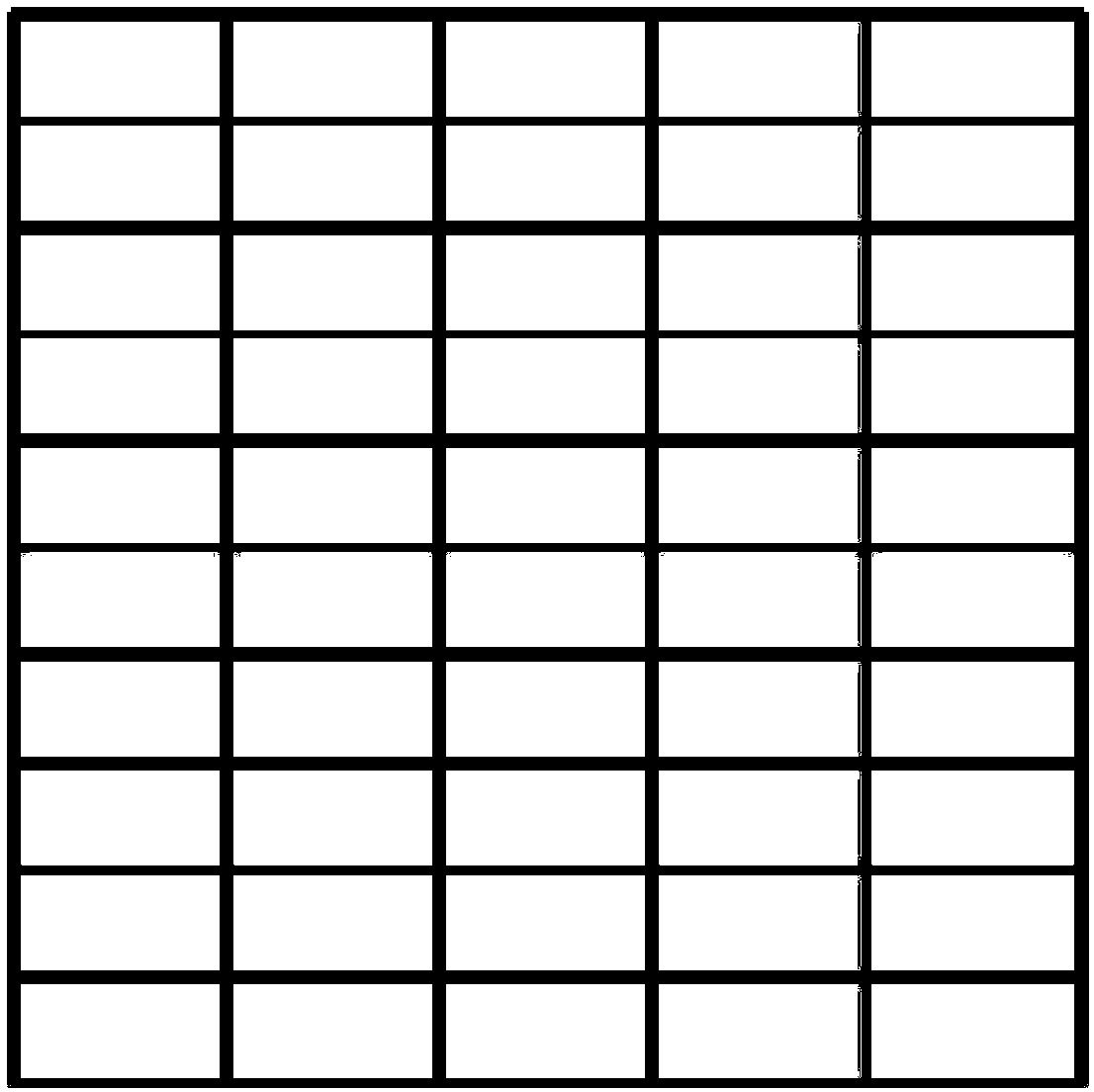

Method for fabricating photovoltaic module

InactiveCN108461577AImprove efficiencyNo reduction in flexural strengthPhotovoltaic energy generationSemiconductor devicesSquare cross sectionSilicon

The application discloses a method for fabricating a photovoltaic module, comprising the following steps of: engraving a cast silicon block to obtain a first type silicon block having a square cross section; continuously dividing the first type silicon block in a direction perpendicular to the square cross section to obtain a second type silicon block having a rectangular cross section; cutting the second type silicon block wire into silicon wafers in a direction parallel to the rectangular cross section; fabricating the silicon wafers into battery sheets; and connecting the battery sheets inseries to form the photovoltaic module. The method for fabricating a photovoltaic module above is capable of passivating the cutting surface, thereby improving the efficiency of the battery sheets andenhancing the bending strength of the battery sheets to better avoid damages.

Owner:ZHEJIANG JINKO SOLAR CO LTD +1

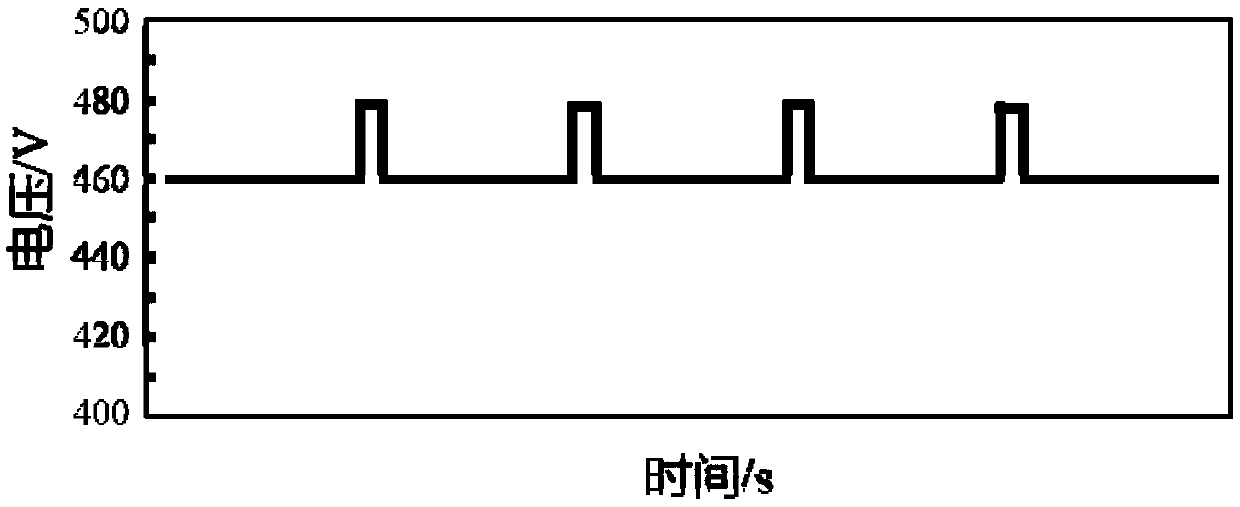

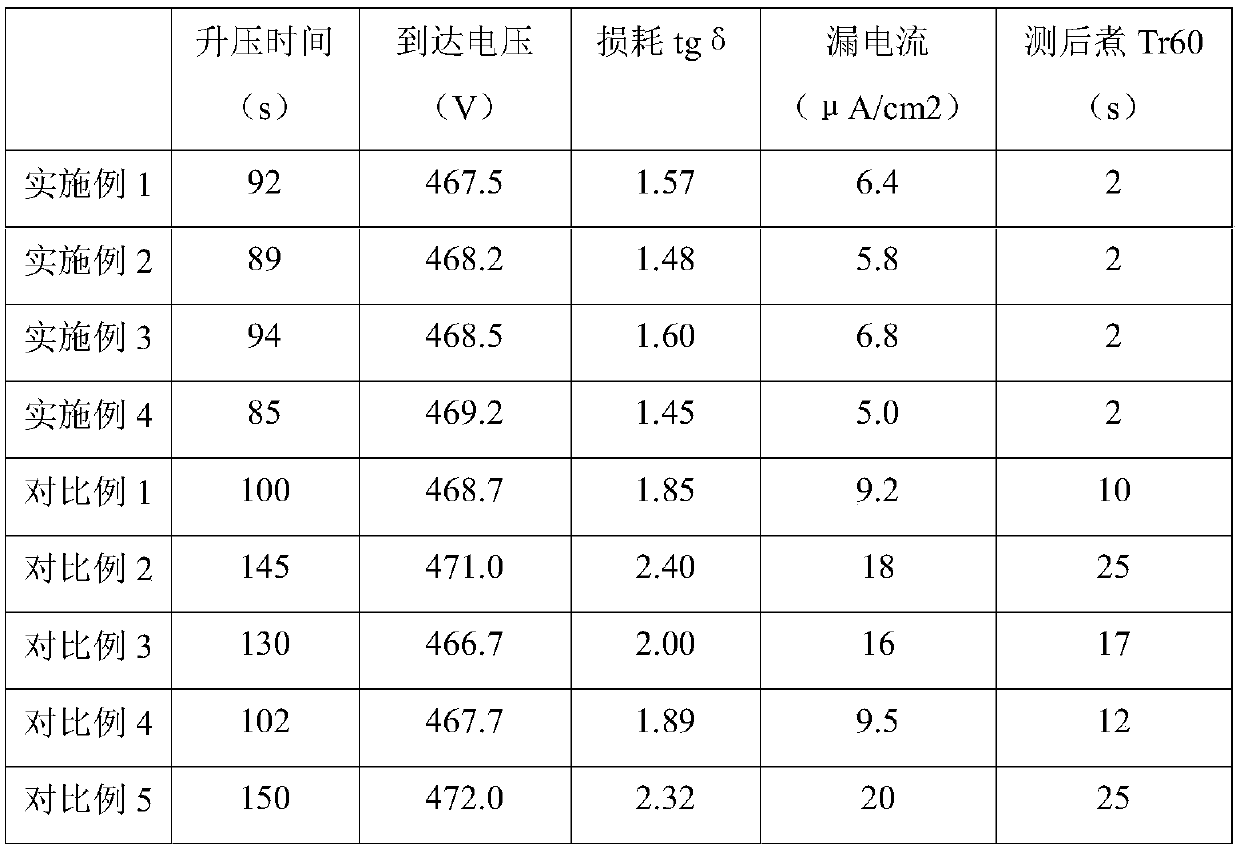

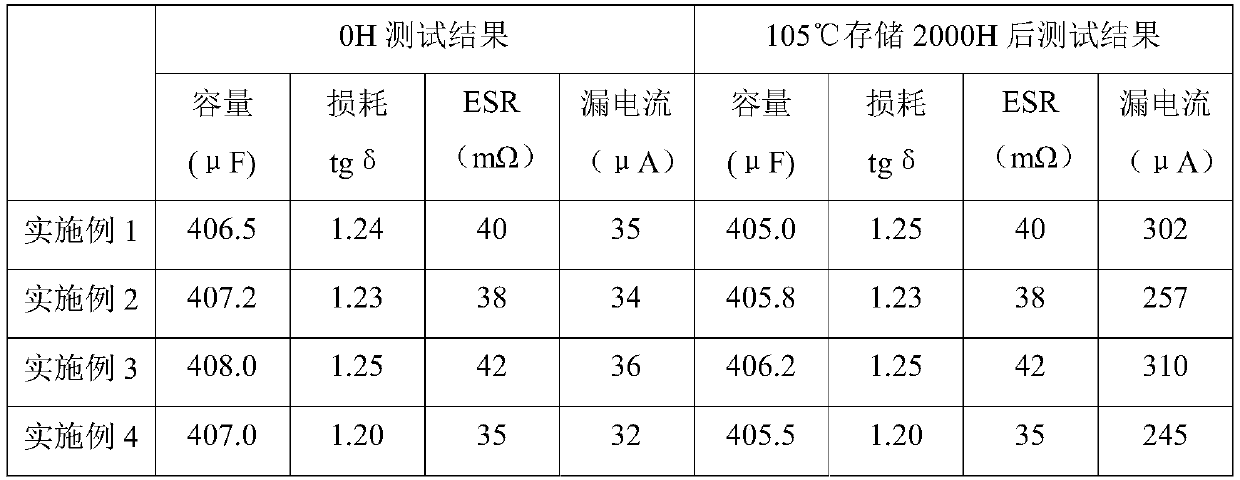

Formation foil, preparation method and application thereof

ActiveCN109609991AAcid controlReduce corrosionAnodisationElectrolytic capacitorsOXALIC ACID DIHYDRATEPhysical chemistry

The embodiment of the invention discloses a method for preparing a formation foil. The method comprises the following steps that the corrosion foil is placed in the treatment liquid for constant-current oxidation treatment; the treatment liquid comprises oxalic acid with the mass concentration of 1-5% and boric acid with the mass concentration of 0.5%-2%; and the second sub-formation comprises thefollowing steps that the aluminum foil subjected to the first phosphating treatment is placed in a mixed solution of boric acid and ammonium borate, and a direct-current superposition pulse power source is used for processing. The corrosion foil is subjected to anodic oxidation treatment by using a mixed solution of the oxalic acid and the boric acid, on one hand, the acidity of the solution is better controlled due to the introduction of boric acid, and the corrosion resistance of the solution to the corrosion foil is reduced; on the other hand, the oxidation film formed in the anodic oxidation process is more compact, so that the formed porous oxide film is more stable in subsequent formation; the direct-current superposition pulse power supply is used for processing, so that the defectis exposed and repaired, the number of defects of the formation foil oxidation film is reduced, and the quality of the formation foil is further improved.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

Method for forming semiconductor device

InactiveCN101996928AReduce the number of defectsAvoid bulgingSemiconductor/solid-state device manufacturingSemiconductorHeat treating

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Low-chromium cast iron grinding ball and casting method thereof

The invention relates to a low-chromium cast iron grinding ball and a casting method thereof. The low-chromium cast iron grinding ball contains carbon, silicon, manganese, chromium, nickel, molybdenum, copper, boron, lithium, sodium, rare-earth elements and essential impurity elements. The casting method comprises the following steps: preparing raw materials and an evaporative mold according to requirements, adding a simple substance sodium into the evaporative mold, and casting molten metal into the evaporative mold; and after the casting is cooled to 300-520 DEG C, taking out the casting, and carrying water quenching to finish the casting. The small-atom lithium and sodium are added, so that the sodium atoms and lithium atoms are diffused and filled in clearances of eutectic carbides or pores in the crystalline phase in the cast iron under high-temperature conditions, thereby greatly lowering the number of internal defects; and the boron powder and rare-earth elements can increase the quantity of the eutectic structures and enhance the dispersivity, so that the lithium atoms and sodium atoms can be filled and distributed in the whole structure, thereby enhancing the overall performance.

Owner:王会智

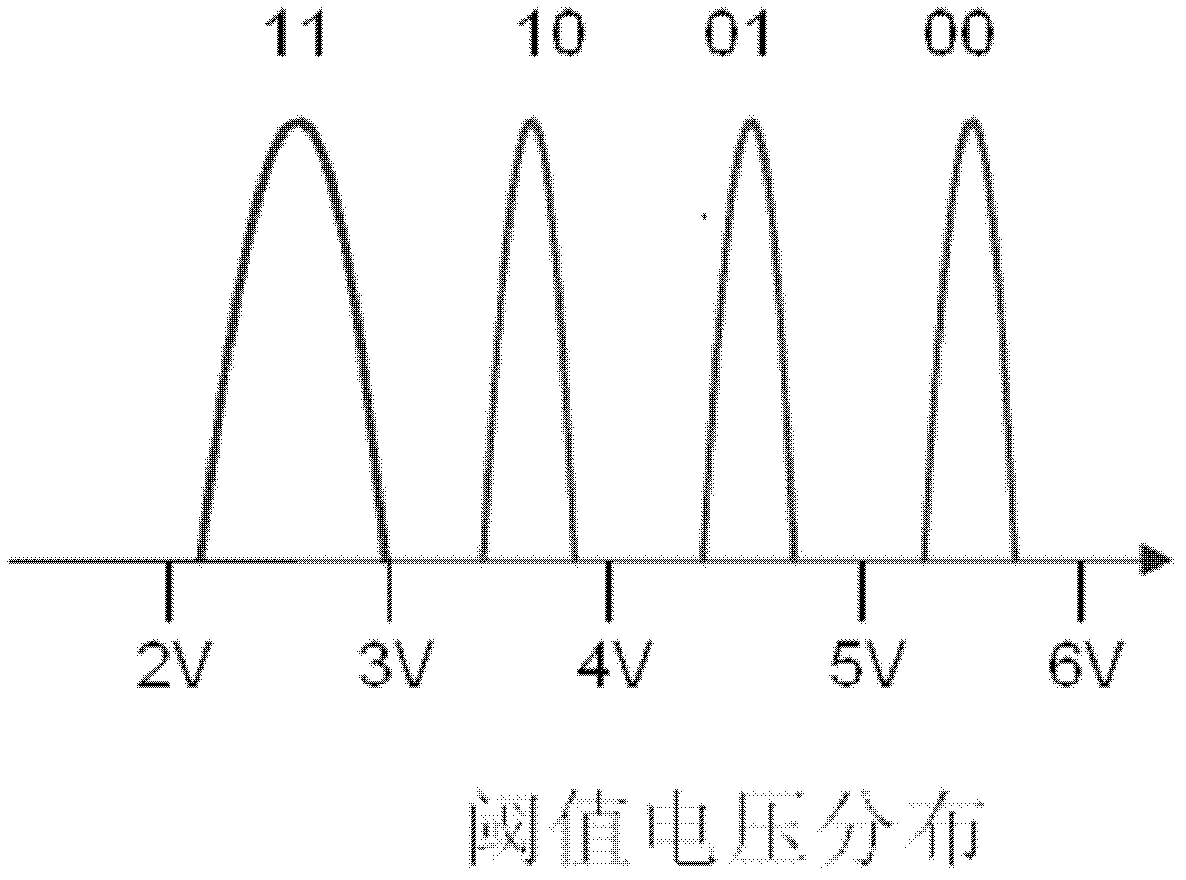

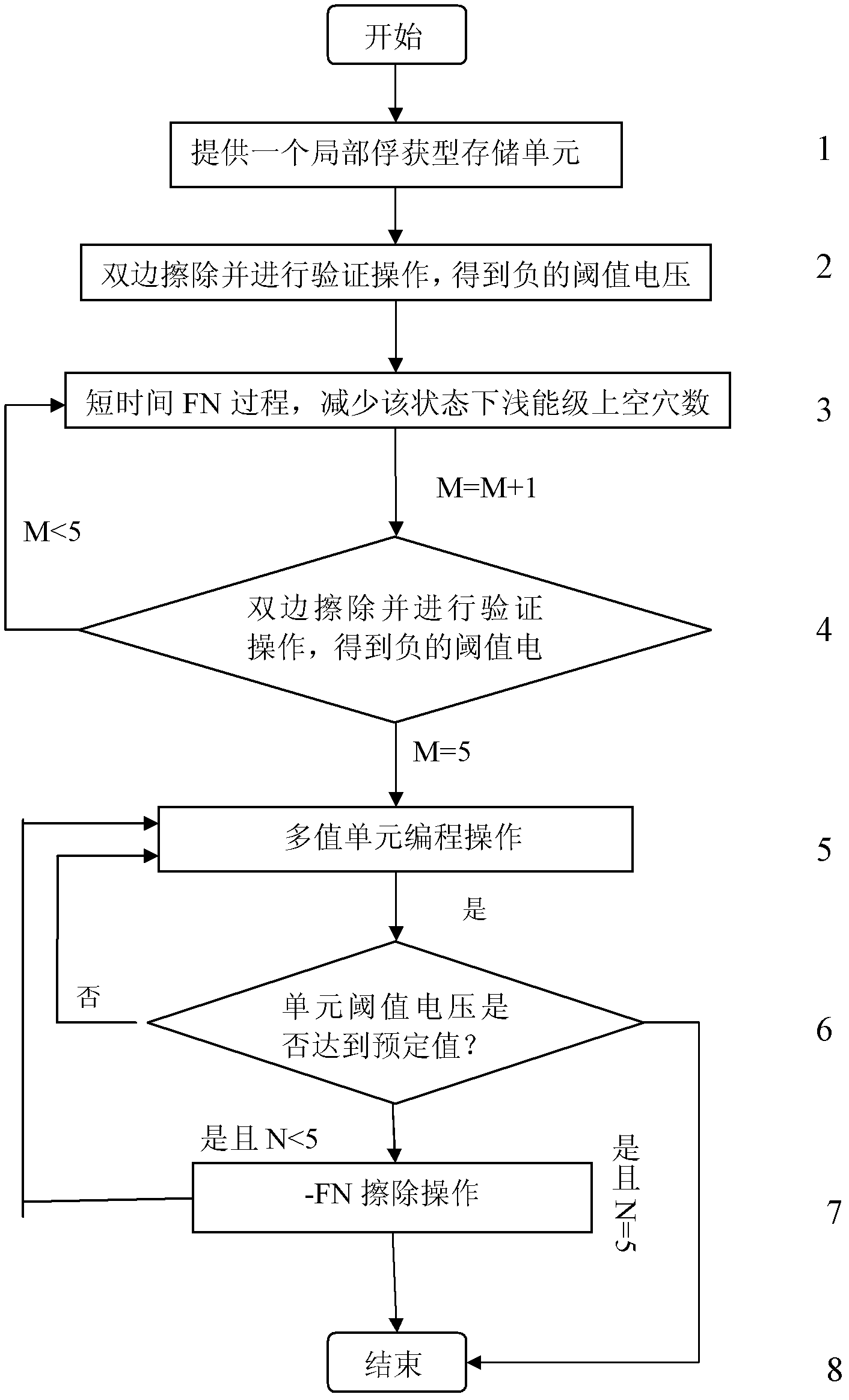

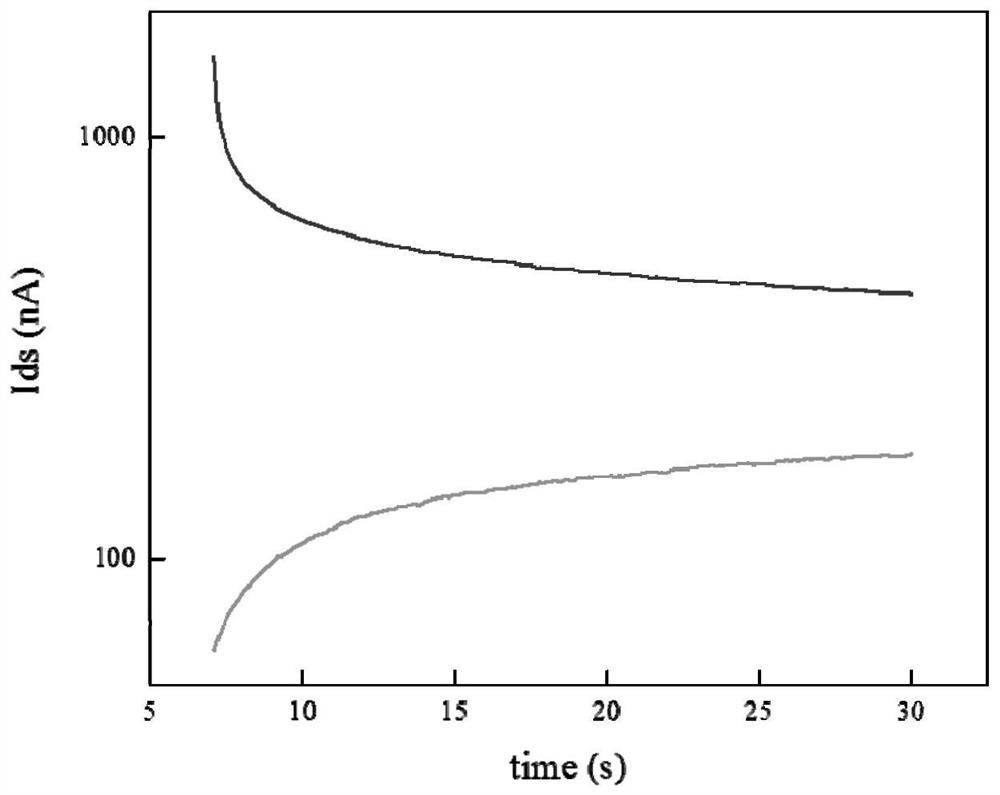

Operation method for increasing high-density storage characteristic of non-volatile flash memory

ActiveCN102509559AIncrease spacingLess likely to overlapRead-only memoriesHigh densityComputer science

The invention relates to an operation method for increasing a high-density multi-valued storage characteristic of a non-volatile flash memory. The operation method comprises the following steps of: (1), adjusting an initial state of a local captured type non-volatile flash storage unit to threshold voltage of minus 2V to minus 1 V at first: adjusting to the threshold voltage by adopting a bilateral belt-belt tunnelling hot hole injection (BBHH) erasing method; and then carrying out a transient FN operation so as to promote charges in a channel to be distributed uniformly; (2), repetitively carrying out the step (1) for many times, wherein the initial state is adjusted to the threshold voltage of minus 2V to minus 1 V through the bilateral BBHH and FN operation steps, and the fact that the threshold voltage in a channel region is same everywhere is finally realized; (3), taking the threshold as the multi-valued storage initial state, and carrying out a multi-valued unitary programming operation on an NOR type local captured storage unit; and (4), carrying out a -FN process for a short time at one time after achieving a programming state. The operation method disclosed by the invention is capable of increasing holding characteristic and tolerance characteristic of a storage device.

Owner:NANJING UNIV

Conductive agent for negative electrode of lithium ion battery and preparation method for battery containing conductive agent

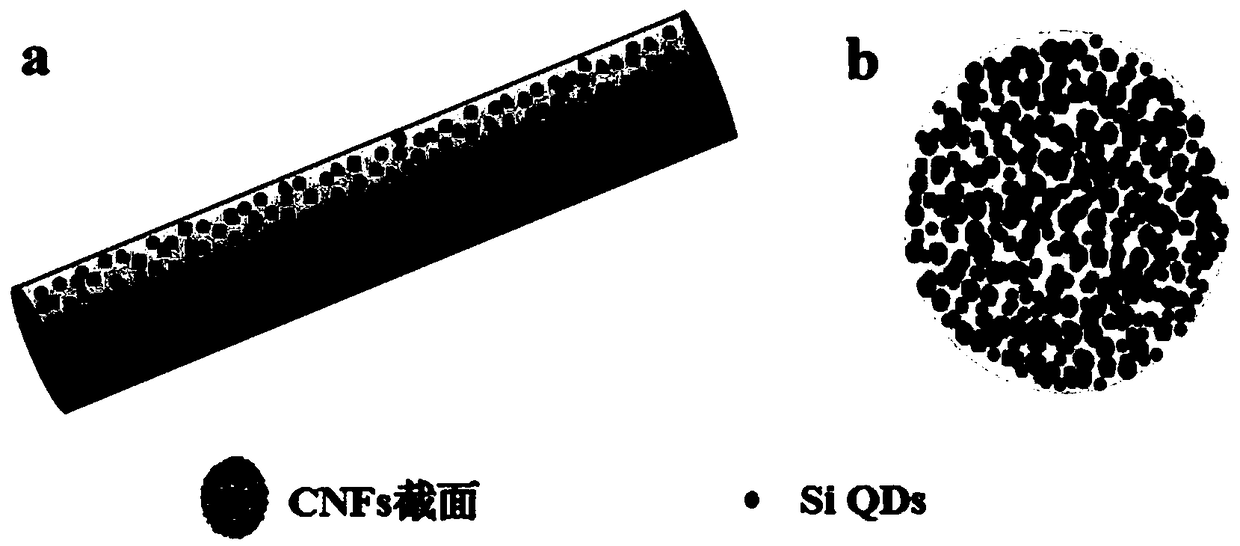

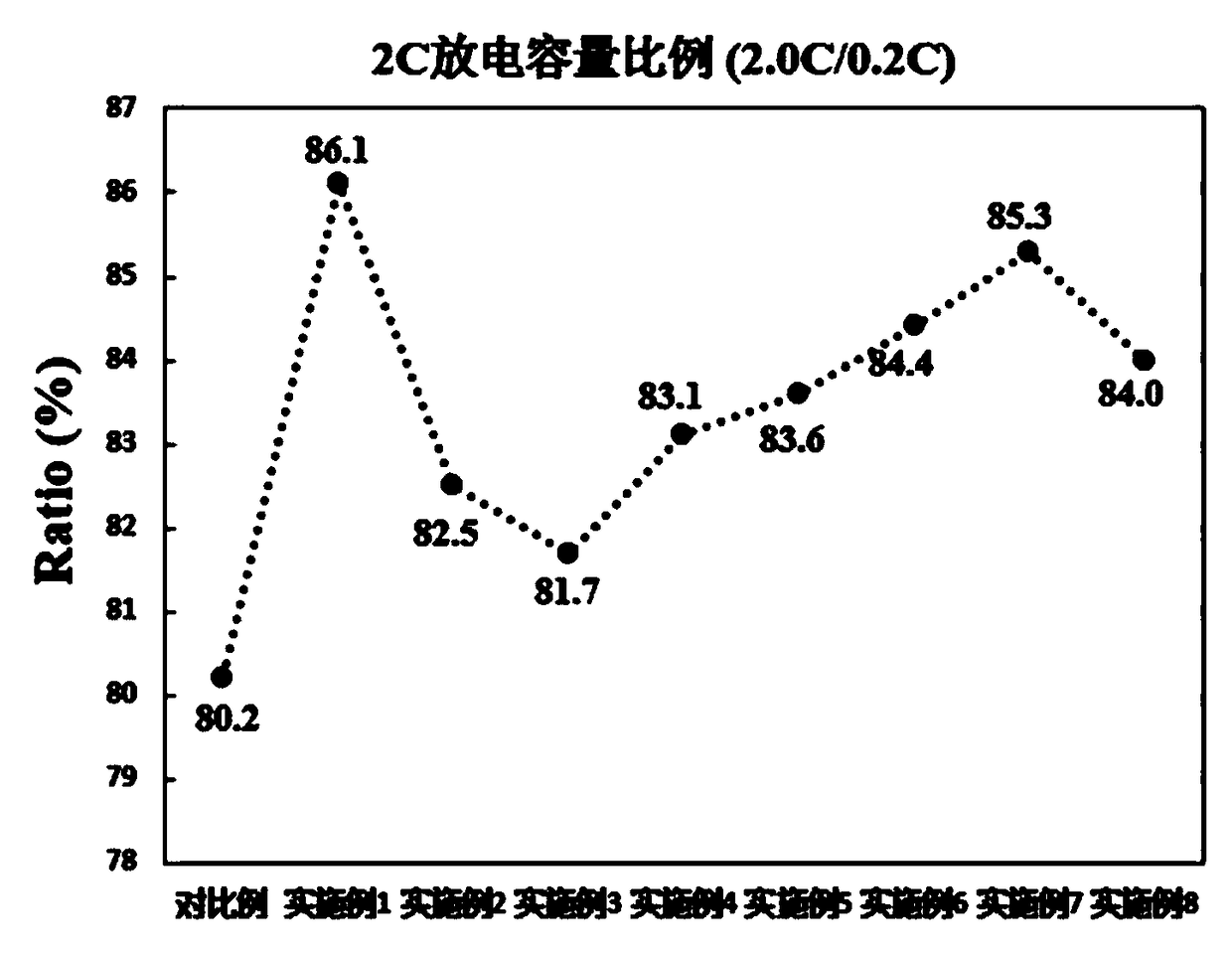

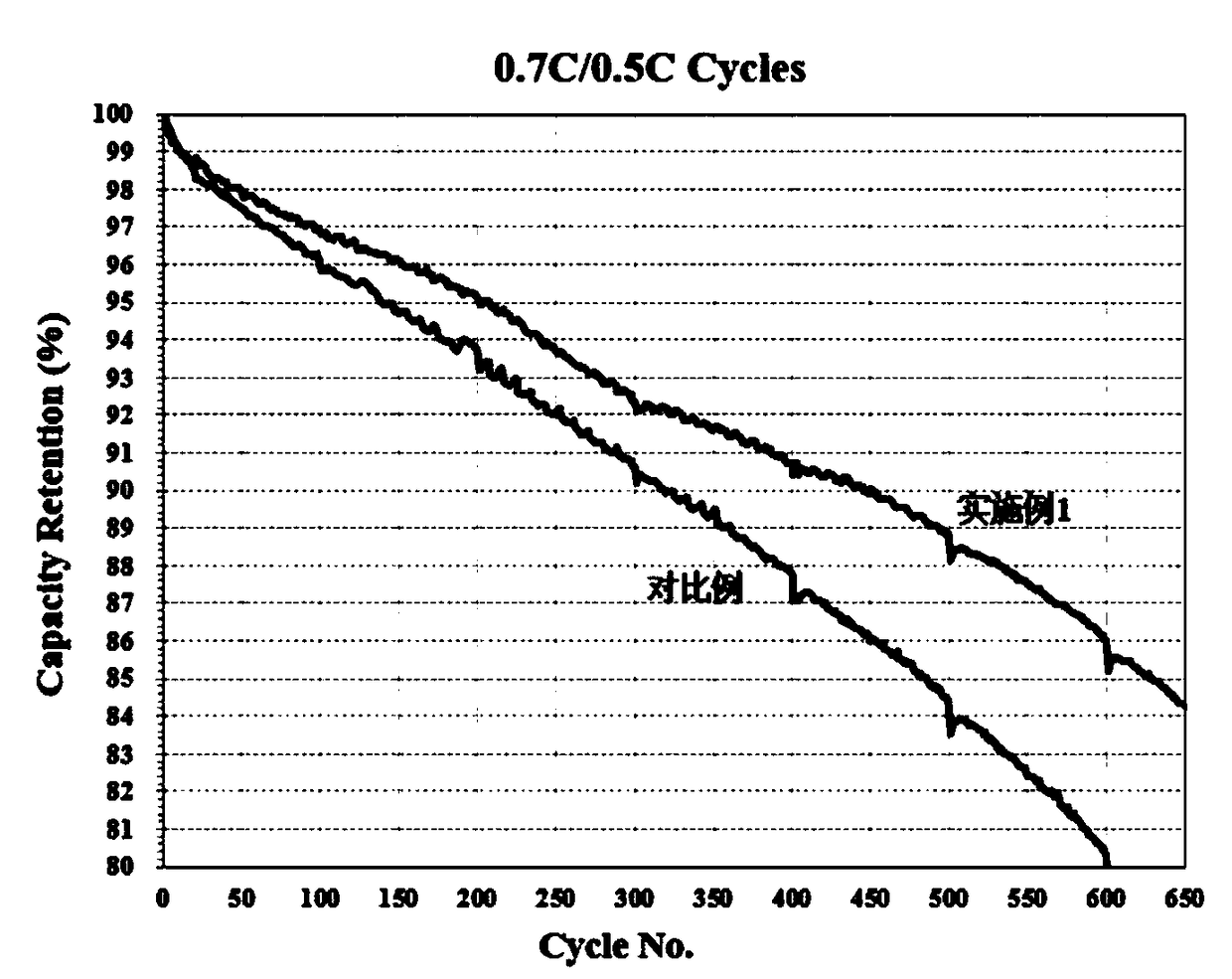

ActiveCN108649207AEvenly dispersedAvoid reunionCell electrodesSecondary cells servicing/maintenanceCyclic processFiber

The invention relates to a conductive agent for a negative electrode of a lithium ion battery and a preparation method for the battery containing the conductive agent. Silicon quantum dots SiQDs are mixed into micropores of carbon nanofibers CNFs by adopting an electrospinning technology, and a compound SiQDs / CNFs of the silicon quantum dots / carbon nanofibers is synthesized, and then the compoundSiQDs / CNFs is used as the conductive agent for the negative electrode of the lithium ion battery. The silicon quantum dots prepared in the method have a very small size, an effect of buffering the volume expansion of silicon particles can be effectively achieved by the micropore structures of the carbon nanofibers in a circulation process, the damage of the volume expansion of silicon in a lithiumintercalation process to an electrode structure is solved, and meanwhile, through the porous structures in the carbon nanofibers, a diffusion path of lithium ions can be greatly shortened, the diffusion speed of the lithium ions is increased, and solid-phase diffusion is improved. The battery designed by the composite conductive agent prepared by the method has a great improvement in the aspectsof the energy density, the power density and the cycling performance.

Owner:安普瑞斯(无锡)有限公司

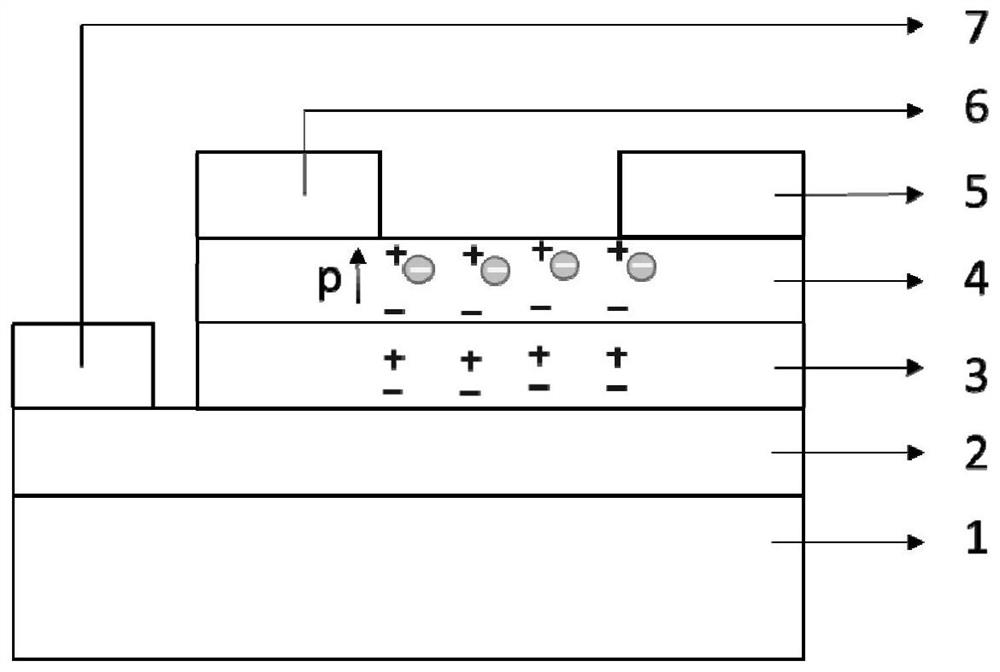

Two-dimensional ferroelectric semiconductor channel ferroelectric dielectric layer field effect transistor and preparation method thereof

ActiveCN112968055AProlong remanent polarizationHigh dielectric constantSemiconductor/solid-state device manufacturingSemiconductor devicesField-effect transistorDielectric layer

The invention discloses a two-dimensional ferroelectric semiconductor channel ferroelectric dielectric layer field effect transistor and a preparation method thereof. The two-dimensional ferroelectric semiconductor channel ferroelectric dielectric layer field effect transistor comprises an insulating substrate, a graphene grid electrode is arranged on the insulating substrate, and a two-dimensional ferroelectric dielectric layer and a metal grid electrode are arranged on the graphene grid electrode; and the two-dimensional ferroelectric dielectric layer is provided with a two-dimensional ferroelectric semiconductor channel, and the two-dimensional ferroelectric semiconductor channel is provided with a metal source electrode and a metal drain electrode which are separated from each other. The invention also comprises the preparation method of the two-dimensional ferroelectric semiconductor channel ferroelectric dielectric layer field effect transistor. According to the invention, the two ferroelectric bodies are combined with each other, and the bound charges of the two ferroelectric bodies at the interface can perform charge shielding on a depolarization field, so that the residual polarization of the ferroelectric bodies can be prolonged, and the problems that stable nonvolatile storage is difficult to realize and a silicon-based semiconductor process cannot be compatible in the prior art are effectively solved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Annealing method to reduce defects of epitaxial films and epitaxial films formed therewith

InactiveCN102969241AReduced annealing methodReduce lattice stressSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGas phaseOptoelectronics

An annealing method to reduce defects of epitaxial films and epitaxial films formed therewith. The annealing method includes features as follows: apply a pressure ranged from 10 MPa to 6,000 MPa to an epitaxial film grown on a substrate through a vapor phase deposition process and heat the epitaxial film at a temperature lower than the melting temperature of the epitaxial film. Through applying pressure to the epitaxial film, the lattice strain of the epitaxial film is alleviated, and therefore the defect density of the epitaxial film also decreases.

Owner:RITEDIA CORPORATION

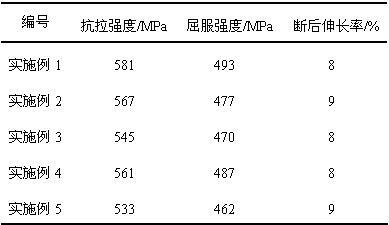

Preparation method of VW93M super-high-strength nano gradient magnesium alloy

InactiveCN108728710AReduced tendency to crackIncrease the dislocation densityMetal-working apparatusRoom temperatureIngot

The invention relates to a preparation method of VW93M super-high-strength nano gradient magnesium alloy. The magnesium alloy is prepared from the following ingredients by mass percent: Mg, 8.0-9.6% of Gd, 1.8-3.2% of Y, 0.3-0.7% of Zr, 0.02-0.5% of Ag and 0.02-0.3% of Er, and the method comprises the following steps of enabling a semicontinuous casting ingot blank to be subjected to homogenization treatment, then squeezing to form a bar, afterwards, carrying out rotary forging deformation, controlling rotary forging temperature at 100-380 DEG C, pass deformation amount to be 5-20%, total deformation amount to be 5-60% and feed rate to be 1-4mm / min, keeping the feed direction unchangeable during deformation to prepare a nano gradient magnesium alloy bar of which the diameter is 3-30mm andthe length is 1,000-2,000mm. From the core of the bar to a side part, the grain sizes gradually increase from 30-100nm to 1-2 mu m, for the alloy which is combined with subsequent thermal treatment, the tensile strength at room temperature is greater than or equal to 530MPa, the yield strength is greater than or equal to 460MPa, and the elongation percentage after fracture is greater than or equalto 8%.

Owner:CENT SOUTH UNIV

Small-pore-diameter narrow-distribution polytetrafluoroethylene microporous membrane and preparation method thereof

InactiveCN109224885AWell packagedImprove wettabilitySemi-permeable membranesPore diameterSurface-active agents

The invention discloses a preparation method of a small-pore-diameter narrow-distribution polytetrafluoroethylene microporous membrane. By mixing of dispersible polytetrafluoroethylene resin, solventoil and a surface active agent and adopting the processes of ageing, blank manufacture, pushing and squeezing, calendaring, oil removal, longitudinal pulling treatment, horizontal pulling treatment, sintering and sizing and the like, the polytetrafluoroethylene microporous membrane with the pore diameter being 10-50nm and the bubble-point pore diameter being less than 80nm is manufactured; the surface active agent is added into a formula, and by the action of the surface active agent, the wettability of the solvent oil is obviously improved, and the wrapping degree of the solvent oil to the polytetrafluoroethylene resin is obviously improved, so that the formation degree of micropores in the drawing and expanding processes is greatly reduced; under the action of same shearing force, the formed micropores are more and smaller, so that the microporous membrane with small pore diameter and narrow distribution is obtained; the preparation method is easy in industrial production, can utilize the existing manure equipment only in need of proper process adjustment, and has strong practicability and wide applicability.

Owner:华设设计集团环境科技有限公司

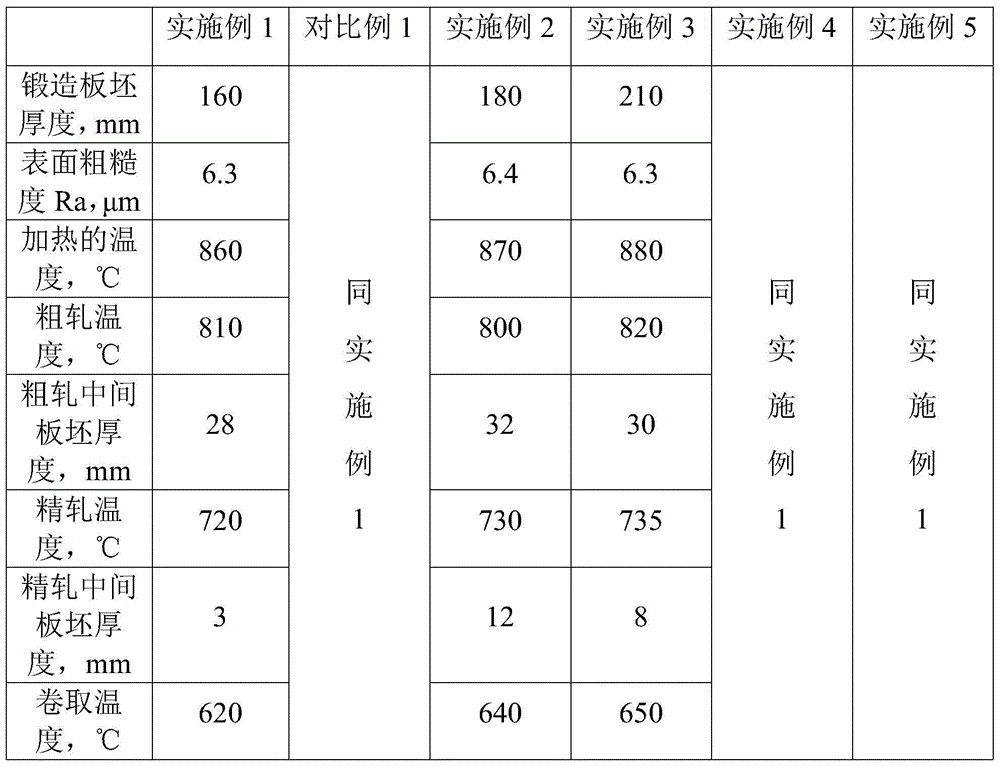

Hot-rolled titanium coil and surface quality control method thereof

InactiveCN105710141AImprove surface qualityReduce the number of defectsWork cleaning devicesProfile control deviceQuality controlTitanium

The invention relates to the field of titanium coil production, and discloses a method for controlling the surface quality of hot-rolled titanium coils. The method includes: sequentially heating, rough rolling, finish rolling and coiling a titanium slab formed by forging, wherein, in the During the finish rolling process, the surface of the titanium slab is purged with water. The surface quality of the hot-rolled titanium coil prepared by the surface quality control method of the present invention is significantly improved, the number of defects is greatly reduced, the types and probability of defects are correspondingly reduced, and the product quality is greatly improved. It is applied to cold rolling When using titanium coil blanks, the amount of grinding is greatly reduced, labor costs are saved, losses are reduced, production efficiency is improved, and the quality of cold-rolled titanium coils is also improved, and the method provided by the invention is low in input cost, simple in operation, and easy to implement .

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Method for reducing impurity element nickel in complex multi-element brass alloy

The invention discloses a method for reducing impurity element nickel in a complex multi-element brass alloy, and belongs to the technical field of metal copper refining and impurity removal. The maintreatment process comprises raw material pretreatment, melting, refining, slag removal and casting treatment. The complex multi-element brass alloy raw material is firstly pretreated by raw materialpretreatment process, impurities unrelated to copper materials are picked out, after being melted in an induction furnace at the temperature of 1100 -1300 DEG c, added the 0.1%-5 % (weight percentage)refining agent elementary substance boron which is coated with the copper foil and the raw material is subjected to heat preservation for 5-20 minutes, and adding a slag remover (the mass ratio of the sodium fluosilicate to the calcium carbonate is 3: 1 ) carrying out heat preservation for 15-30 minutes, and casting into ingots. According to the method for reducing impurity element nickel, the content of nickel in the cast ingot is reduced by 30%-60%, so that the content of the nickel in the brass alloy product produced by the complex raw material waste copper is reasonably controlled, and the competitiveness of the product is improved.

Owner:UNIV OF SCI & TECH BEIJING

Developing device

InactiveCN102566326AImproves the effect of pre-soakingImprove cleaning efficiencyPhotosensitive material processingTemperature controlNozzle

The invention provides a developing device, which comprises a developing cavity, a tray which is arranged in the developing cavity and used for holding a wafer, and a cleaning nozzle and a developing liquid nozzle which are positioned above the tray and can be adjusted, a control module, an atomizing device and an atomized liquid nozzle positioned above the tray, wherein the atomizing device and the atomized liquid nozzle are controlled by the control module; and a temperature control unit is arranged in the atomizing device. Compared with the prior art, the developing device is provided with the atomizing device and the atomized liquid nozzle, so that atomized liquid sprayed by the atomized liquid nozzle can cover the whole wafer once, so that an effect of pre-infiltrating the wafer is improved remarkably, the cleaning efficiency is improved, and the number of defects is reduced.

Owner:CSMC TECH FAB2 CO LTD

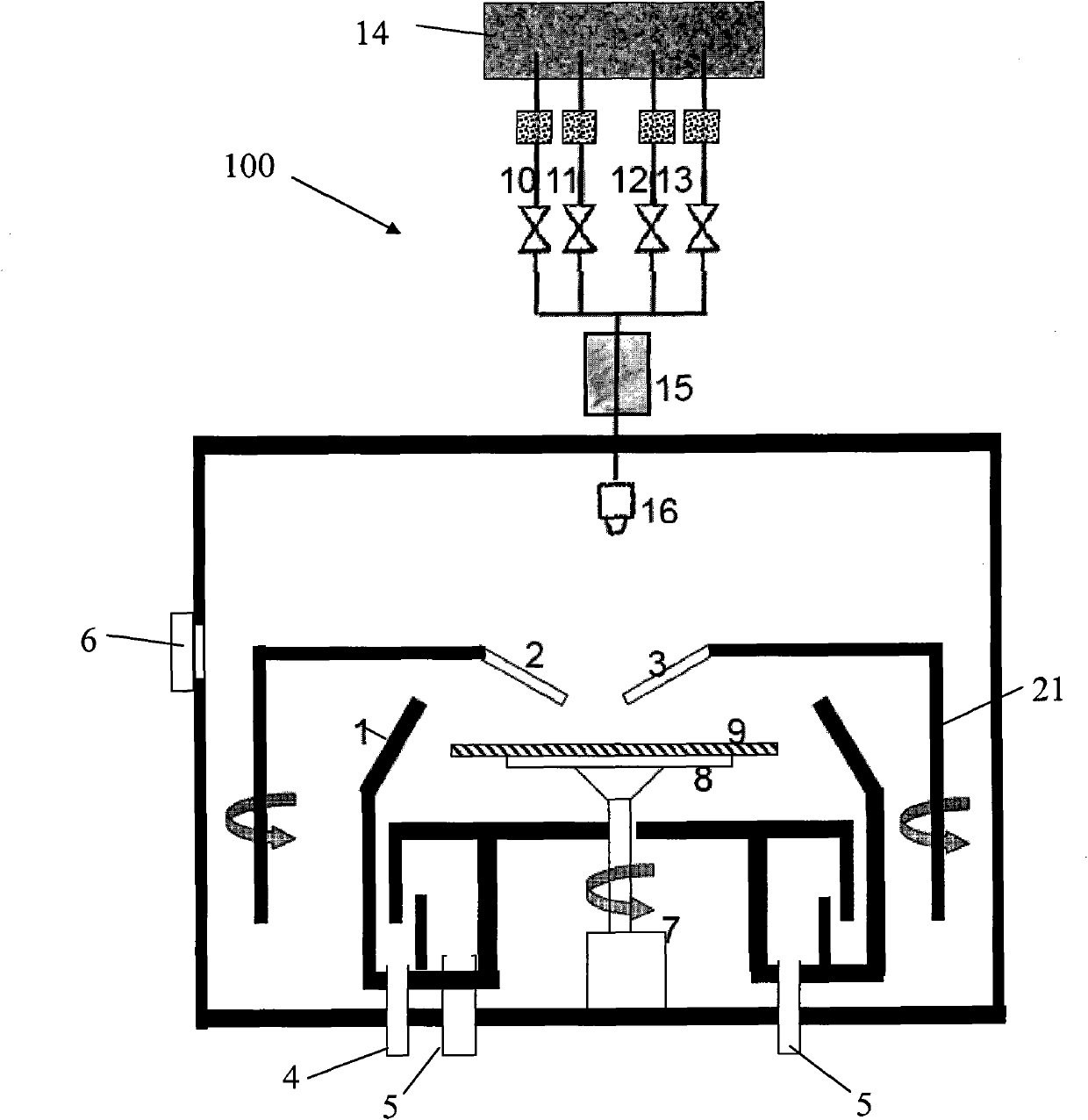

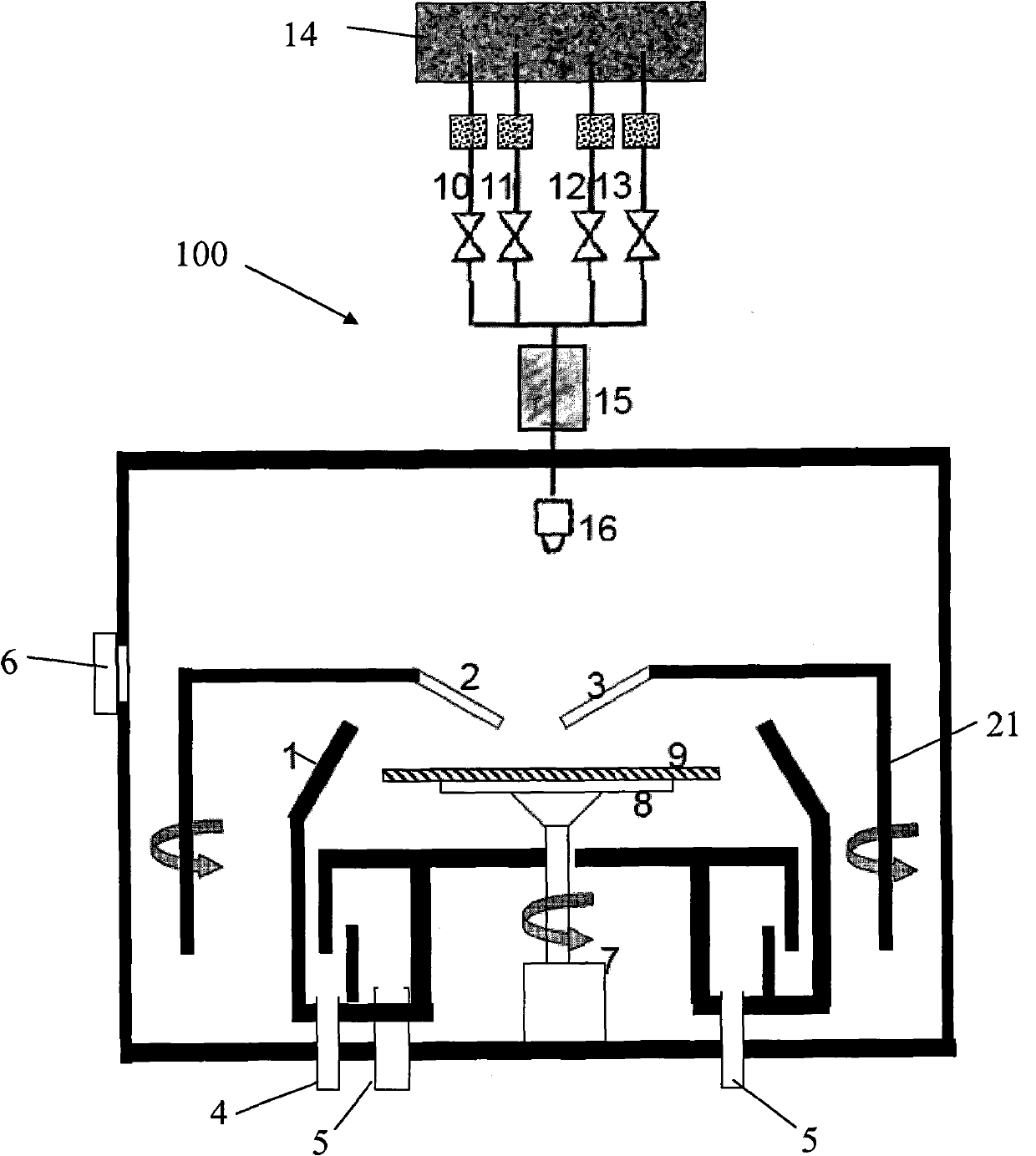

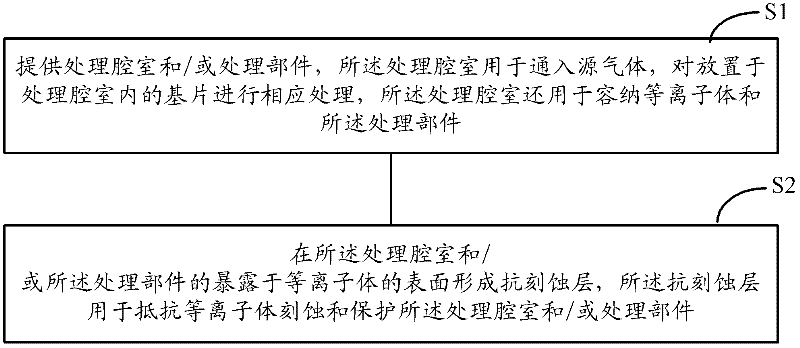

Anti-etching layer, semiconductor processing device and manufacturing method

InactiveCN102260856AReduce surface damageExtended service lifeChemical vapor deposition coatingResistSemiconductor

Embodiments of this invention provide an anti-etching layer, a semiconductor processing device and its fabrication method. The semiconductor processing device comprises a processing chamber configured for the source gas introduction for corresponding to the treatment of substrates placed in the processing chamber. The processing chamber is further configured to receive the plasma and has a plurality of processing parts therein. The semiconductor processing device further comprises: an anti-etching layer covered on the surface of the processing chamber and / or processing parts exposed to the plasma. The anti-etching layer is used to resist the plasma etching and protect the processing chamber and / or processing parts. This invention uses the anti-etching layer to protect the processing chamber and processing parts to prevent them from being damaged by the plasma and increase their service lives.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

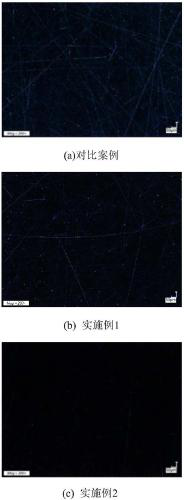

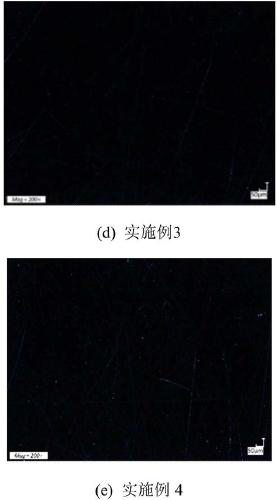

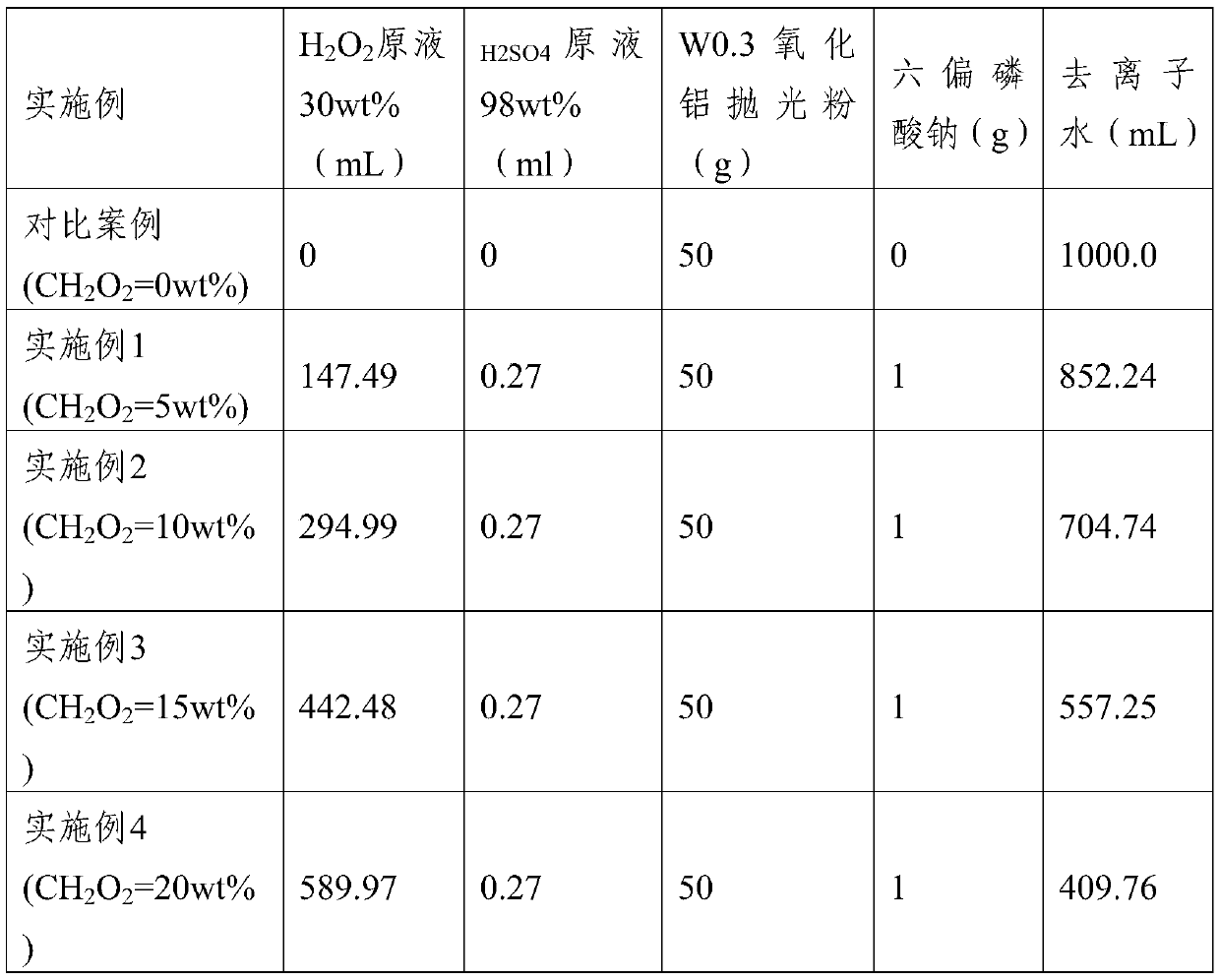

Chemical mechanical polishing solution for processing optical surface of Ge-As-Se chalcogenide glass

InactiveCN111040639AReduce the number of defectsDecrease the surface roughness valuePolishing compositions with abrasivesSodium bicarbonatePhosphate

The invention discloses a chemical mechanical polishing solution for processing an optical surface of Ge-As-Se chalcogenide glass. The chemical mechanical polishing solution comprises polishing powder, a chemical corrosion reagent, a pH reagent, a dispersing agent and deionized water, the polishing powder is selected from aluminum oxide, diamond powder and cerium oxide, the chemical corrosion reagent is an alkaline reagent or an oxidizing agent, the alkaline reagent is sodium hydroxide, sodium carbonate, sodium bicarbonate, cyclohexylamine, triethylamine or ethylenediamine, the oxidizing agentis one of hydrogen peroxide, potassium permanganate, ferric chloride and potassium ferrate, the pH reagent is used for ensuring the stable acid-base property of the polishing solution, the acid is selected from sulfuric acid, hydrochloric acid, oxalic acid, acetic acid and citric acid, the alkali is selected from sodium hydroxide, sodium carbonate, sodium bicarbonate, cyclohexylamine, triethylamine and ethylenediamine, and polyphosphate is selected as the dispersing agent and used for improving the dispersity of the polishing powder in turbid liquid. For chalcogenide glass with different components, only the concentration of the chemical corrosion reagent needs to be adjusted in a targeted mode, and universality is achieved.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Fluorine-containing polymer coating composition, method for forming fluorine-containing polymer film using coating composition, and method for forming photoresist or lithographic pattern

InactiveUS8211612B2Reduce the number of defectsEasy to useOrganic chemistryPhotosensitive materialsTectorial membraneResist

A method for forming a protective film of a fluorine-containing polymer composition excellent in smoothness and adhesiveness on a photoresist. Moreover, there is provided a means for removing the protective film without impairing the underlying photoresist. A polymer coating composition obtainable by dissolving a fluorine-containing polymer compound in a solvent comprising a fluorinated acetal having a specific structure is applied on a photoresist and dried to form a protective film. A fluorinated acetal having the specific structure is suitable as a solvent for being brought into contact with a fluorine-containing polymer film, peeling the film, and forming a photoresist or a lithographic pattern.

Owner:CENT GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com