Polymer blends for producing films with a reduced number of defects

一种聚合物、共混物的技术,应用在制备膜片领域,能够解决膜片高缺陷数等问题

Active Publication Date: 2007-09-19

TOPAS ADVANCED POLYMERS

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But membranes made from this blend have high defect counts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 10

[0105] Example 10 8.33kg 3.2% Exceed 1018CA solution

Embodiment 11

[0106] Example 11 8.33kg 2.7% Dowlex NG5066E solution

Embodiment 12

[0107] Example 12 16.66kg 3.0% Dowlex NG5066E solution

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

Description

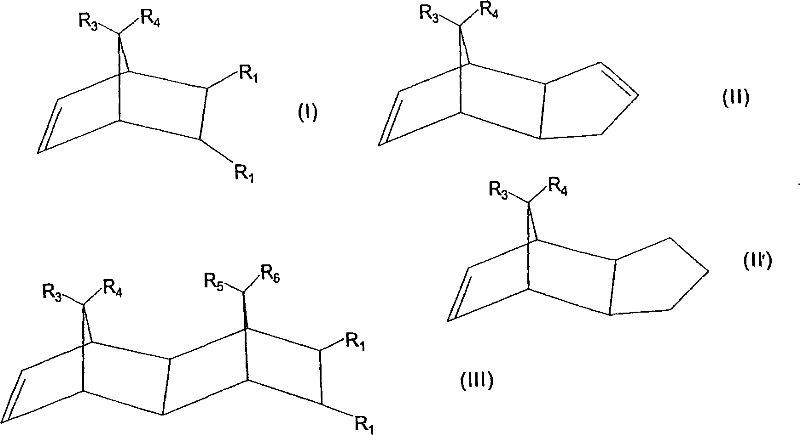

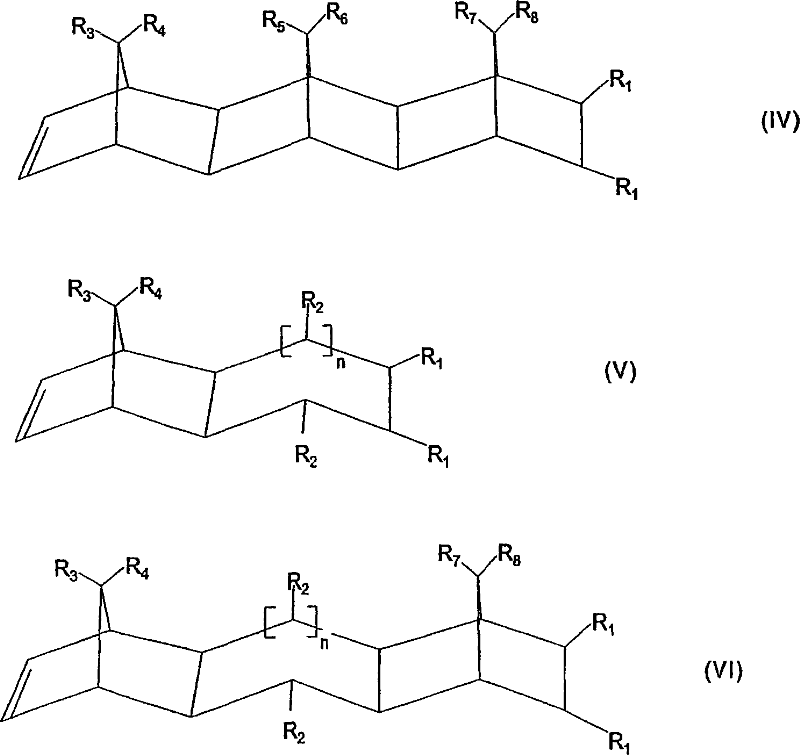

technical field [0001] The present invention relates to selected polymer blends that can be used to make membranes with reduced defect counts; and also to processes for making the polymer blends. Furthermore, the use of the polymer blends according to the invention for producing membranes is claimed. Background of the invention [0002] Films and moldings made of cyclic olefin copolymers (COC) feature low density, high transparency, low birefringence, extremely low water absorption, and high rigidity, strength, and hardness. [0003] The production of sheets or films from COCs on conventional industrial extrusion equipment such as slotted extruders or smooth-bore extruders often leads to an increased number of defect sites in the sheet, such as so-called gel / fish eyes. These increased defects limit the material's application in certain industrial fields. Other polymers that can be processed into membranes that may have a lower number of defects do not have the good propert...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L45/00

CPCY10T428/31913C08L23/0823Y10T428/24661Y10T428/31909Y10T428/1345C08L23/0815Y10T428/2495C08L45/00C08L2666/06C08L23/06

Inventor W·格利茨A-M·绍温霍尔德

Owner TOPAS ADVANCED POLYMERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com