Anti-etching layer, semiconductor processing device and manufacturing method

A processing device and manufacturing method technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problem of increasing user cost, damage to MOCVD equipment chamber, and reducing the use of MOCVD equipment chamber and processing components Life and other issues, to achieve the effect of improving service life, reducing surface damage, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

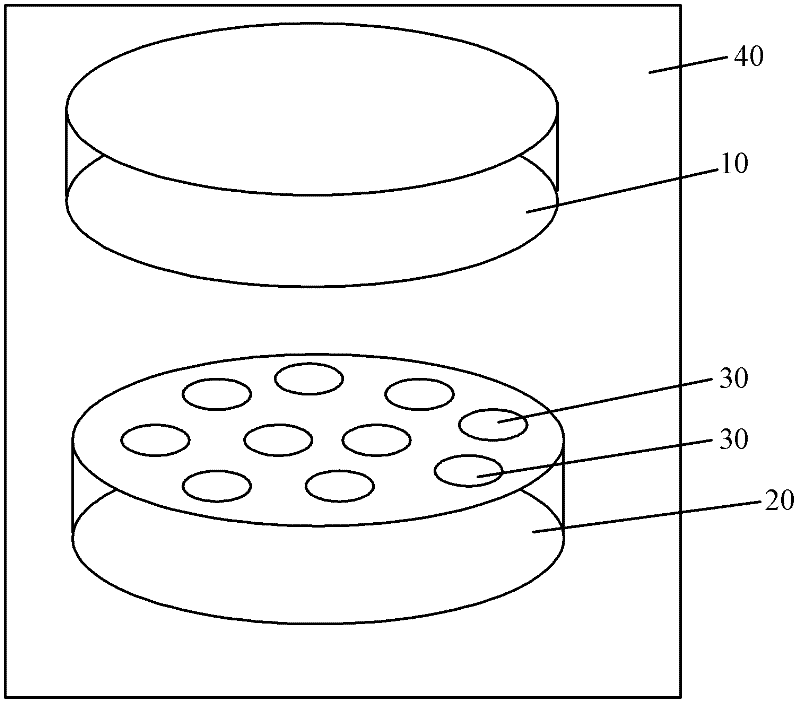

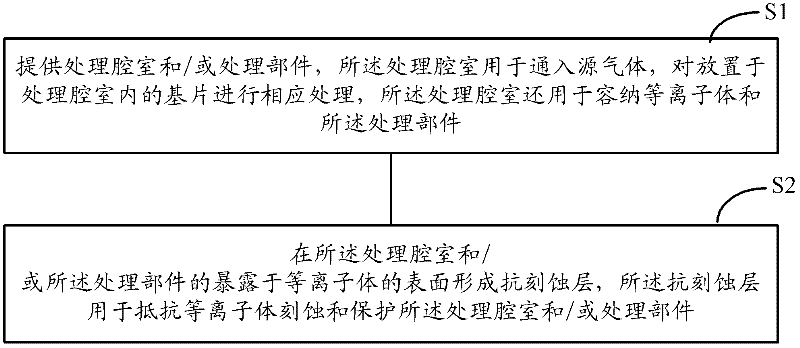

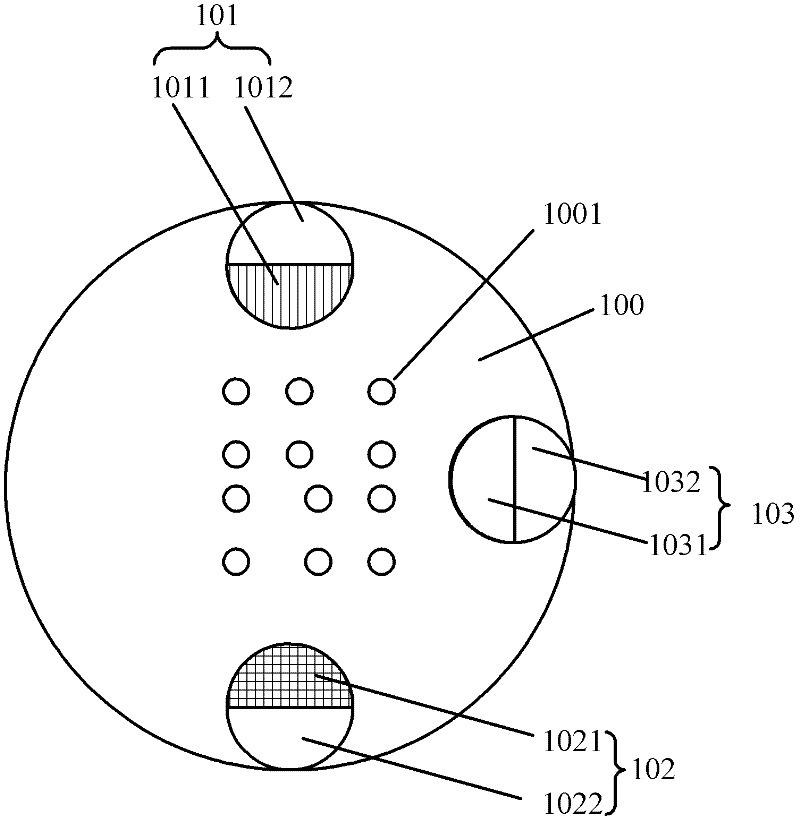

[0035] For equipment that uses plasma for process treatment, such as plasma etching equipment, plasma enhanced chemical vapor deposition equipment, MOCVD (using plasma to clean processing chambers and processing components), its processing chambers and processing components are vulnerable to plasma body etching damage, an embodiment of the present invention proposes a semiconductor processing device, including:

[0036] A processing chamber, the processing chamber is used to feed the source gas to perform corresponding processing on the substrate placed in the processing chamber, and the processing chamber is also used to accommodate plasma, and there are multiple processing chambers in the chamber components, the semiconductor processing apparatus further comprising:

[0037]Anti-etching layer covering the surface of the processing chamber and / or processing components exposed to plasma, the anti-etching layer is used to resist plasma etching and protect the processing chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com