Mechanical-type chip clamping-pressing device for vacuum plasma technology

A plasma and mechanical technology, applied in the field of plasma technology, can solve the problems of wafer substrate surface damage, large brittleness, cracking, etc., and achieve the effect of eliminating instantaneous impact force, improving production efficiency, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

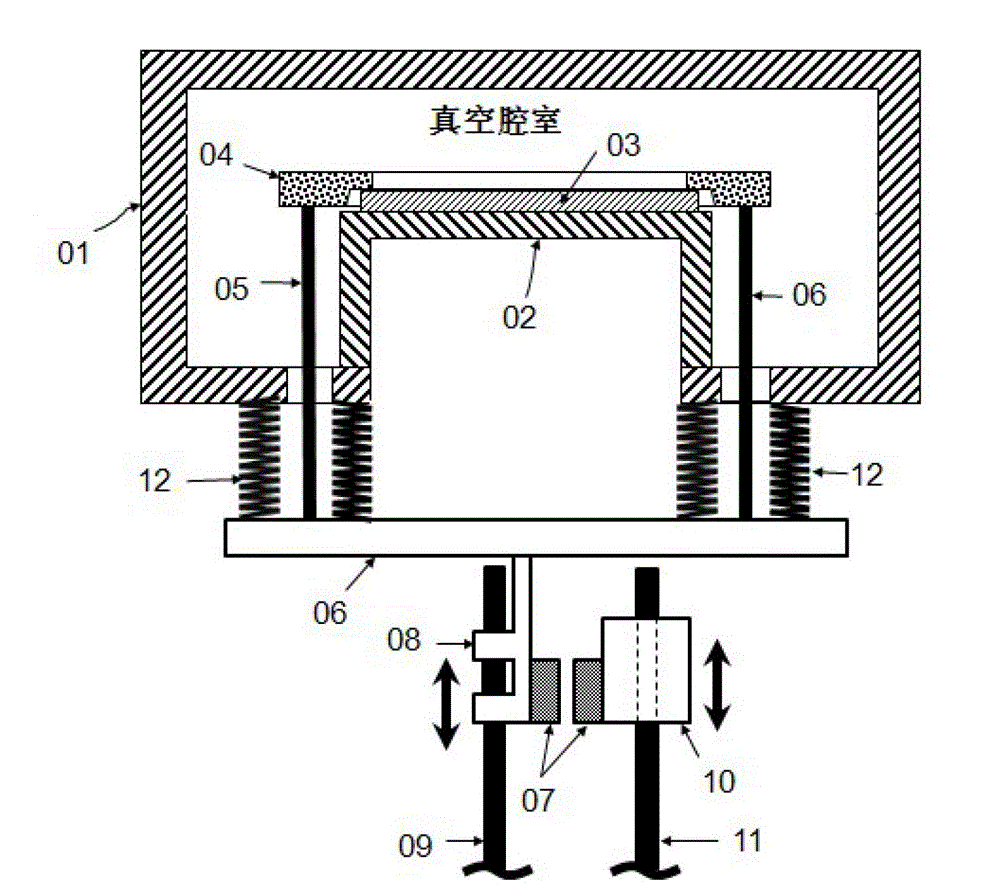

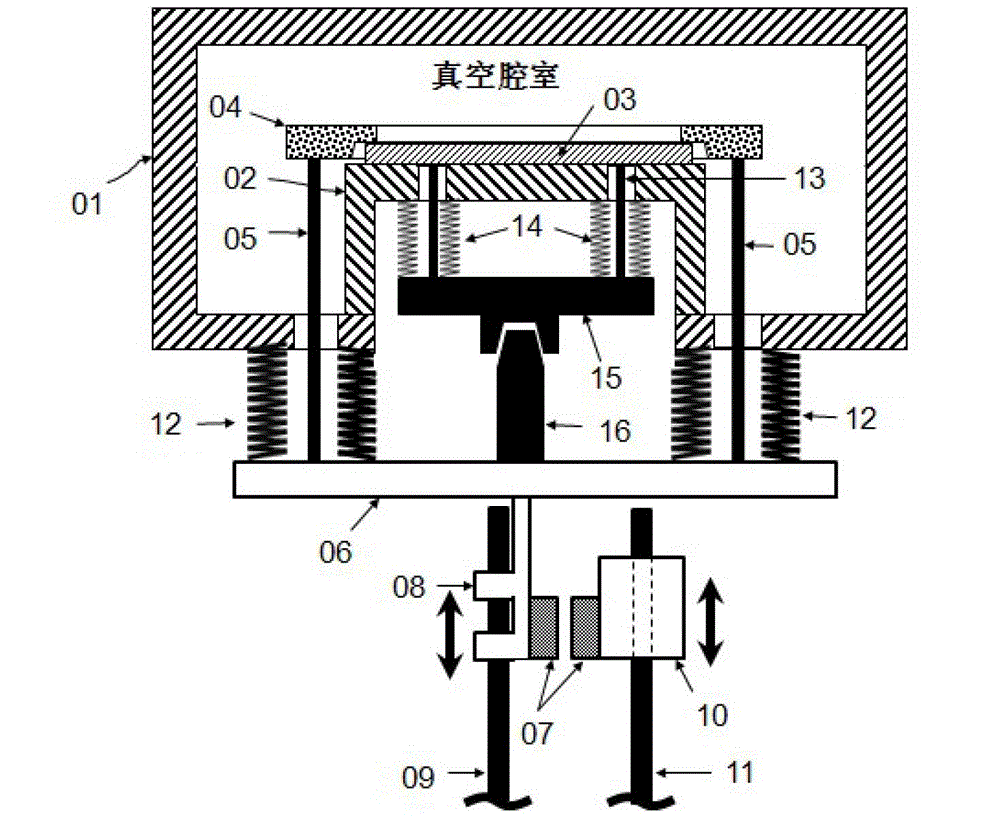

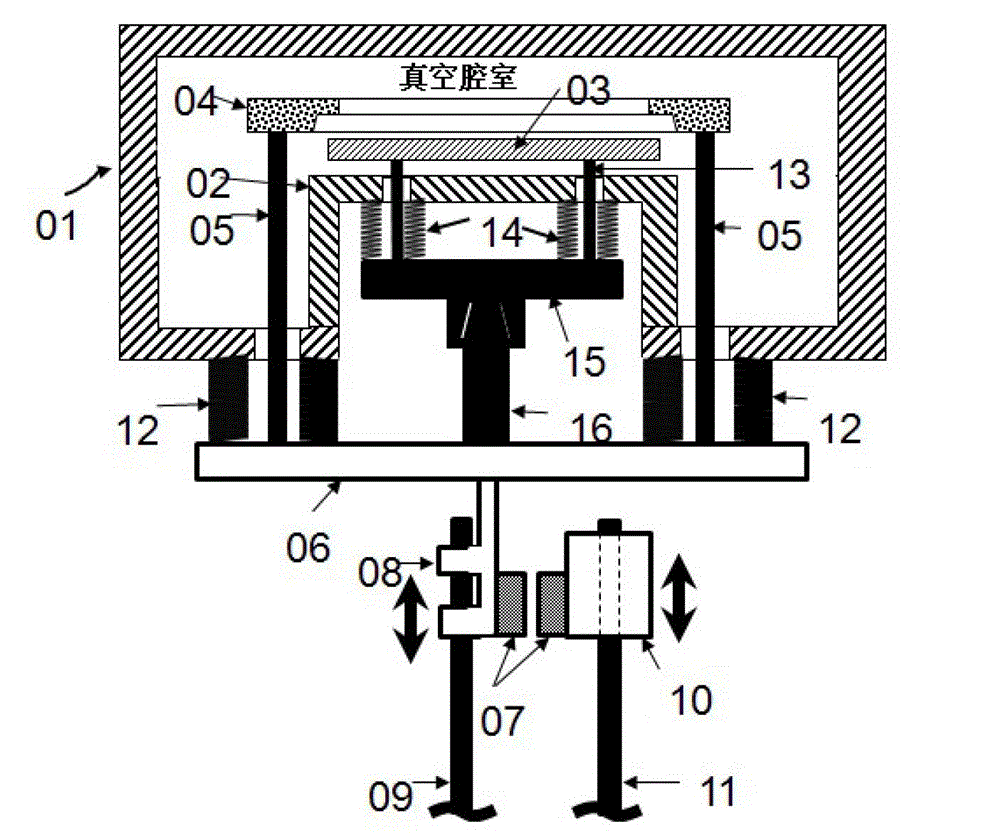

[0030] Such as figure 1 As shown, a mechanical wafer clamping device for a vacuum plasma process includes an electrode 02, a wafer substrate 03, a ceramic pressure ring 04, a pressure ring connecting rod 05, a connecting rod bracket 06, a permanent magnet pair 07, Drive motor 10, and motor support 11; The wafer substrate 03 is placed on the electrode 02, and the ceramic pressure ring 04 is arranged above the wafer substrate 03, and is connected with the linkage bracket 06 through the pressure ring connecting rod 05; The permanent magnet group pair 07 includes two corresponding first group permanent magnets and second group permanent magnets that are magnetically coupled to each other; the first group of permanent magnets is fixedly connected with the link bracket 06, and the second group of permanent magnets It is fixed on the driving motor 10, and the driving motor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com