Patents

Literature

106results about How to "Reduce the momentary impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

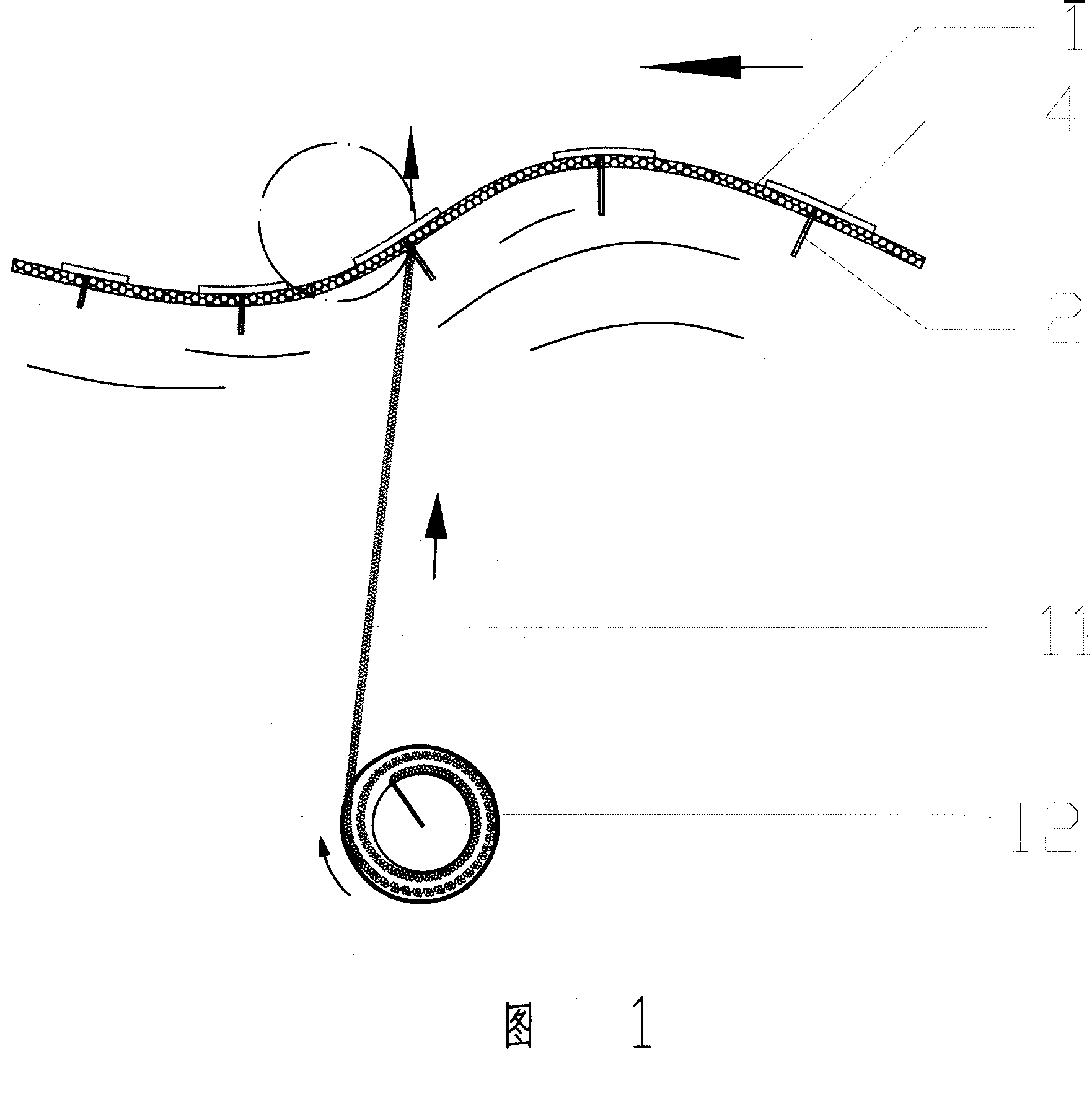

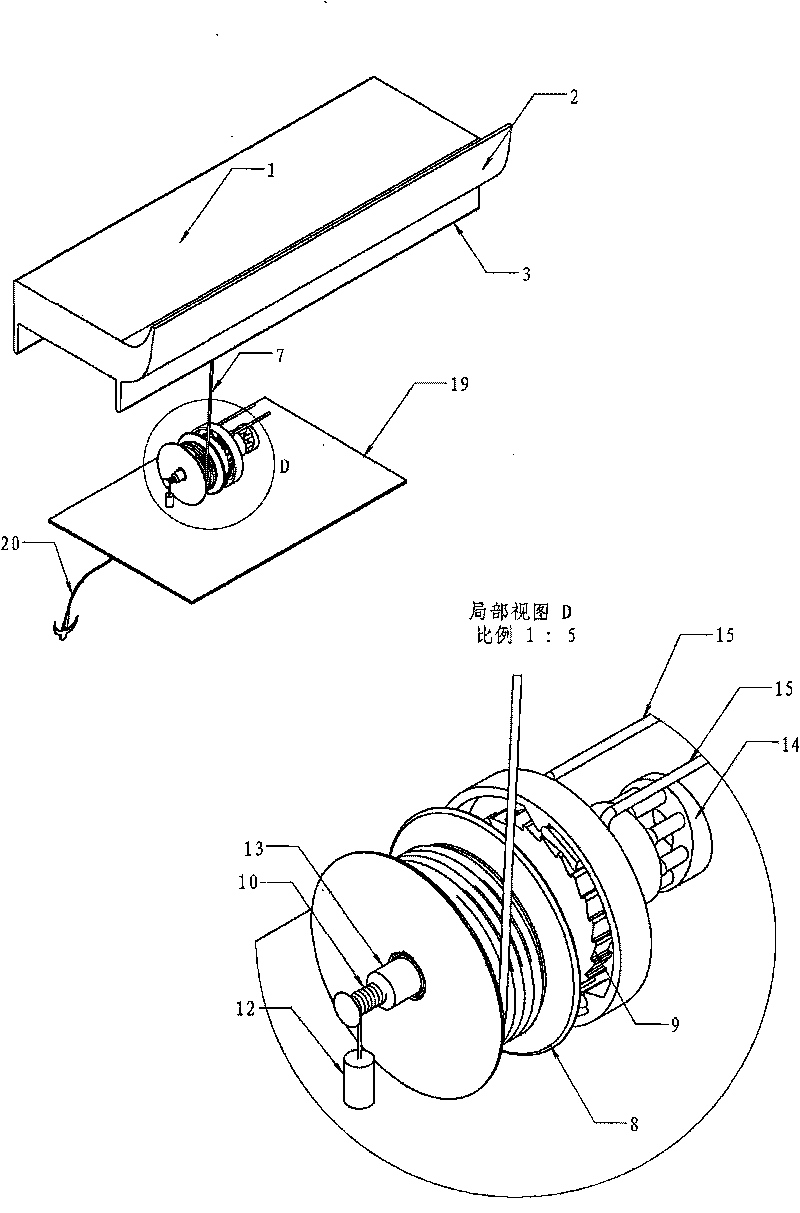

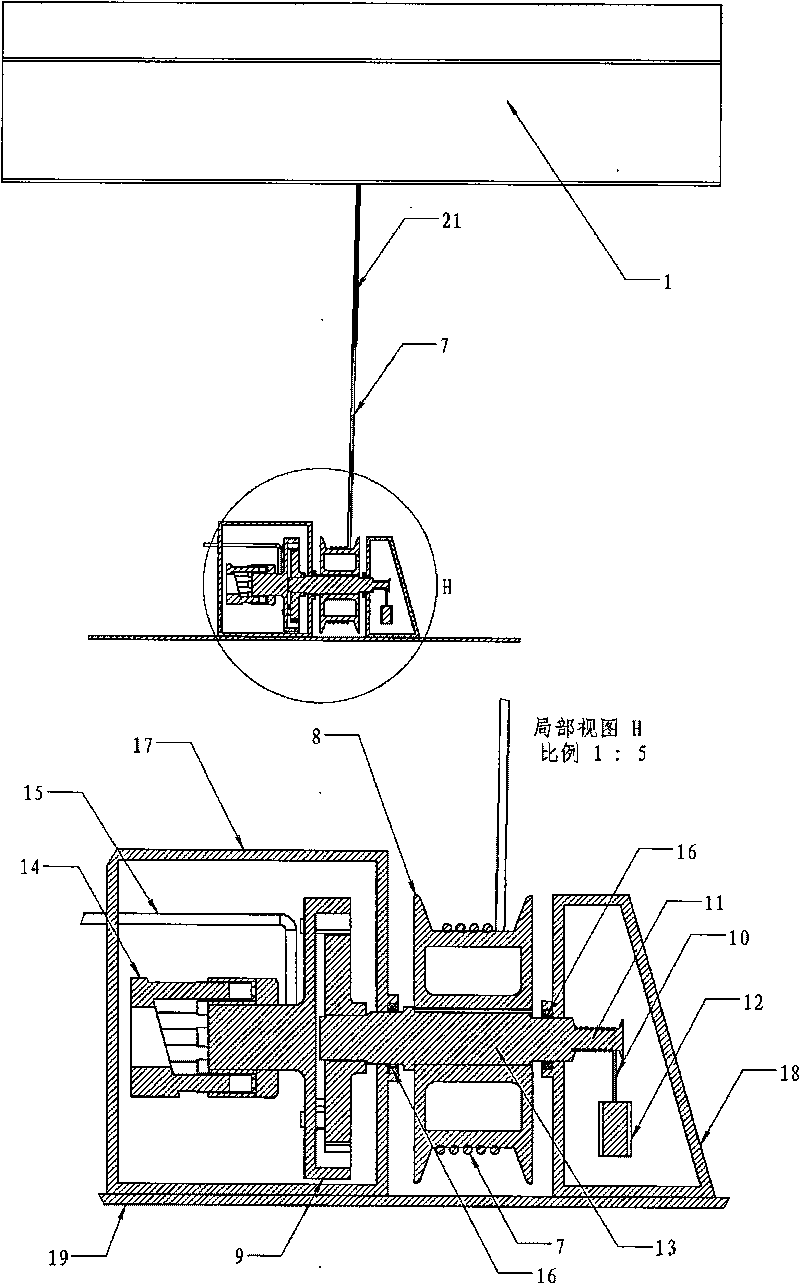

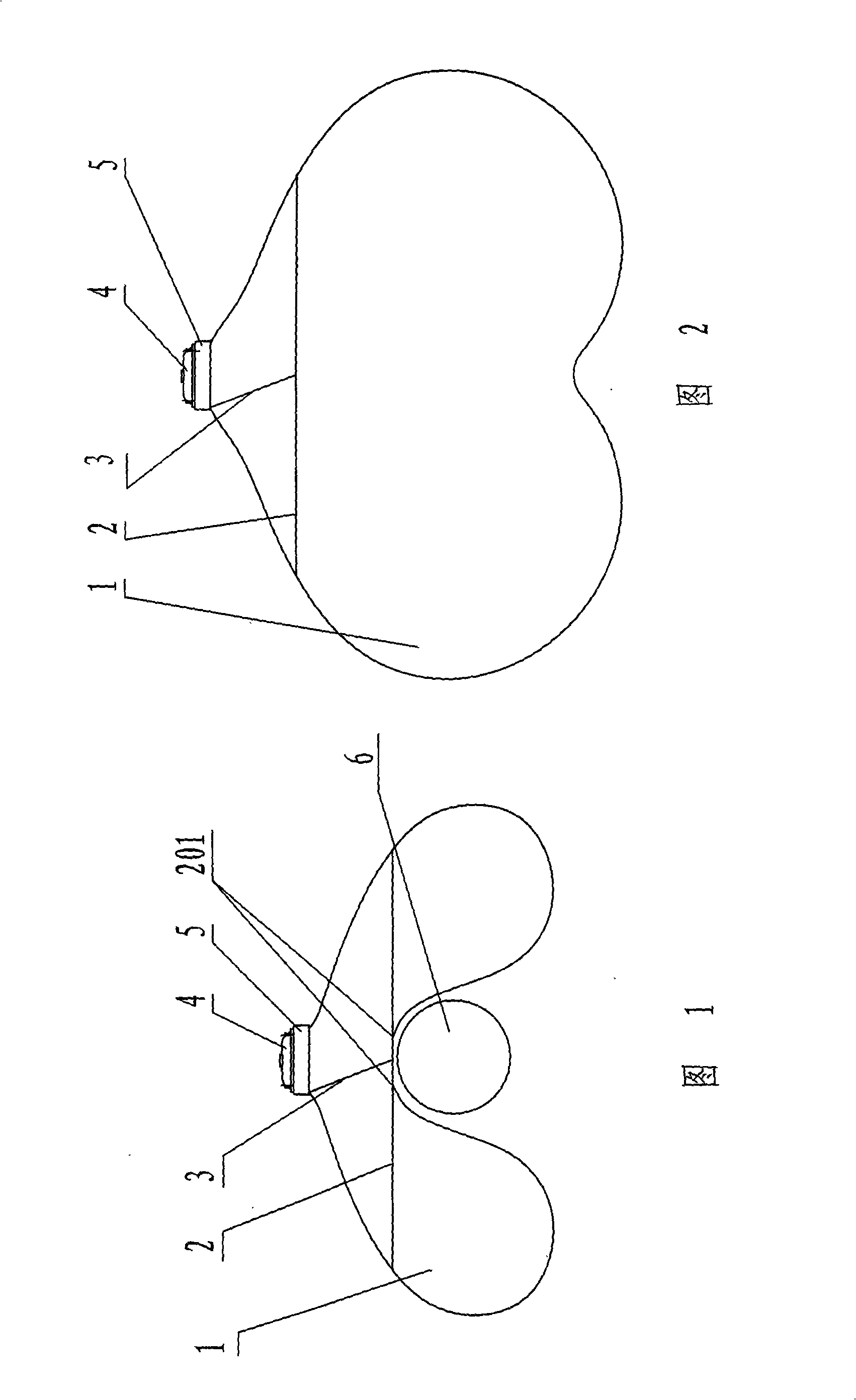

Curved rope wheel wave energy conversion and power generating system

InactiveCN101021199AIncrease the absorption areaAvoid churnMachines/enginesSafety/regulatory devicesWave shapeMechanical energy

The present invention relates to a wave energy conversion and power generation system. Said invention is characterized by that it utilizes a flexible surface which can be flexibly bent and fluctuated with wave to receive drive of wave, and utilizes a rope whose one end is tied on the described flexible surface and another end is winded round a rotating wheel to pull said rotating wheel, so that said rotating wheel can be used for converting wave energy into mechanical energy, then utilizes a hydraulic system and a power generator unit to convert the mechanical energy into electric energy.

Owner:曲言明

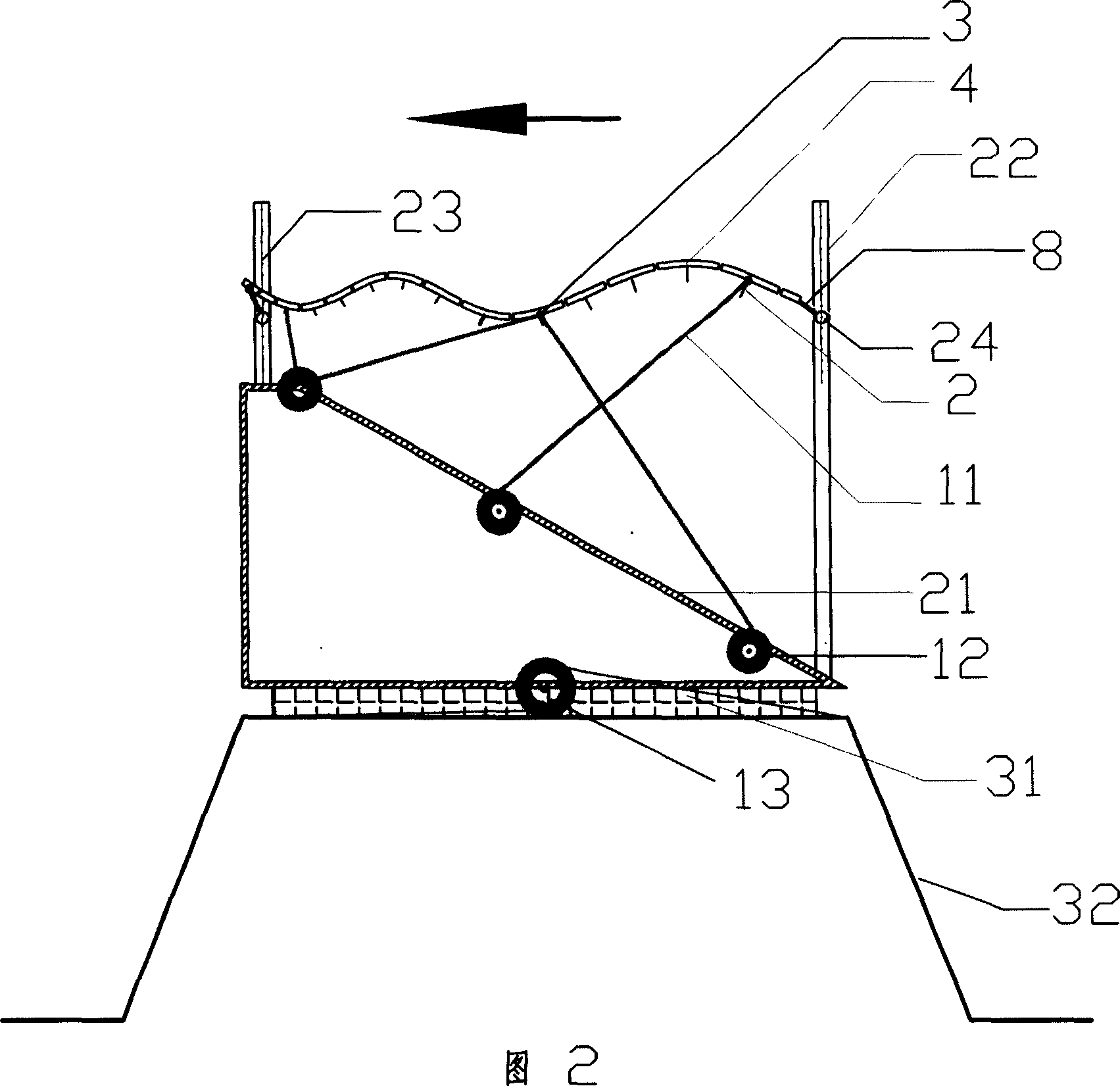

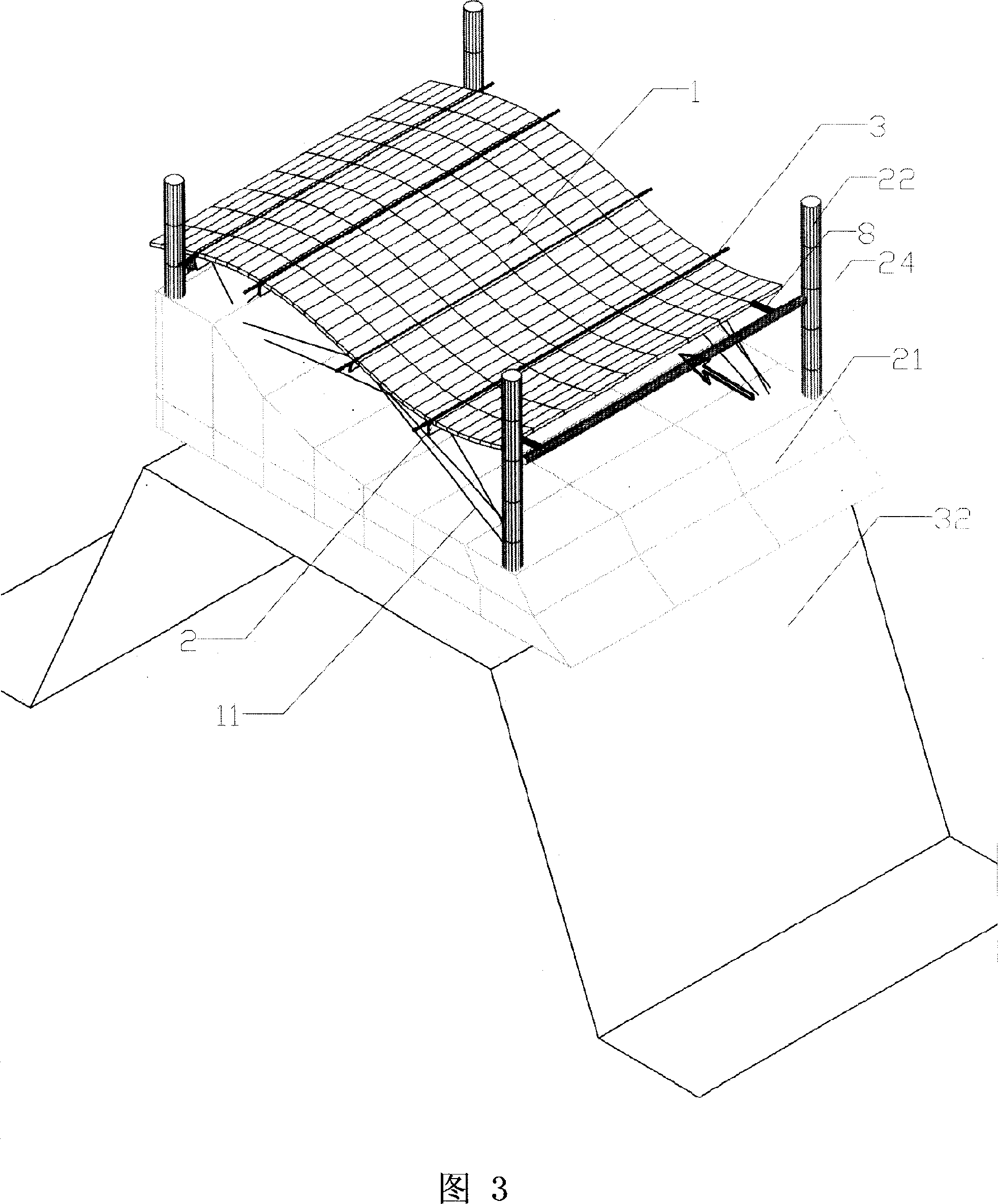

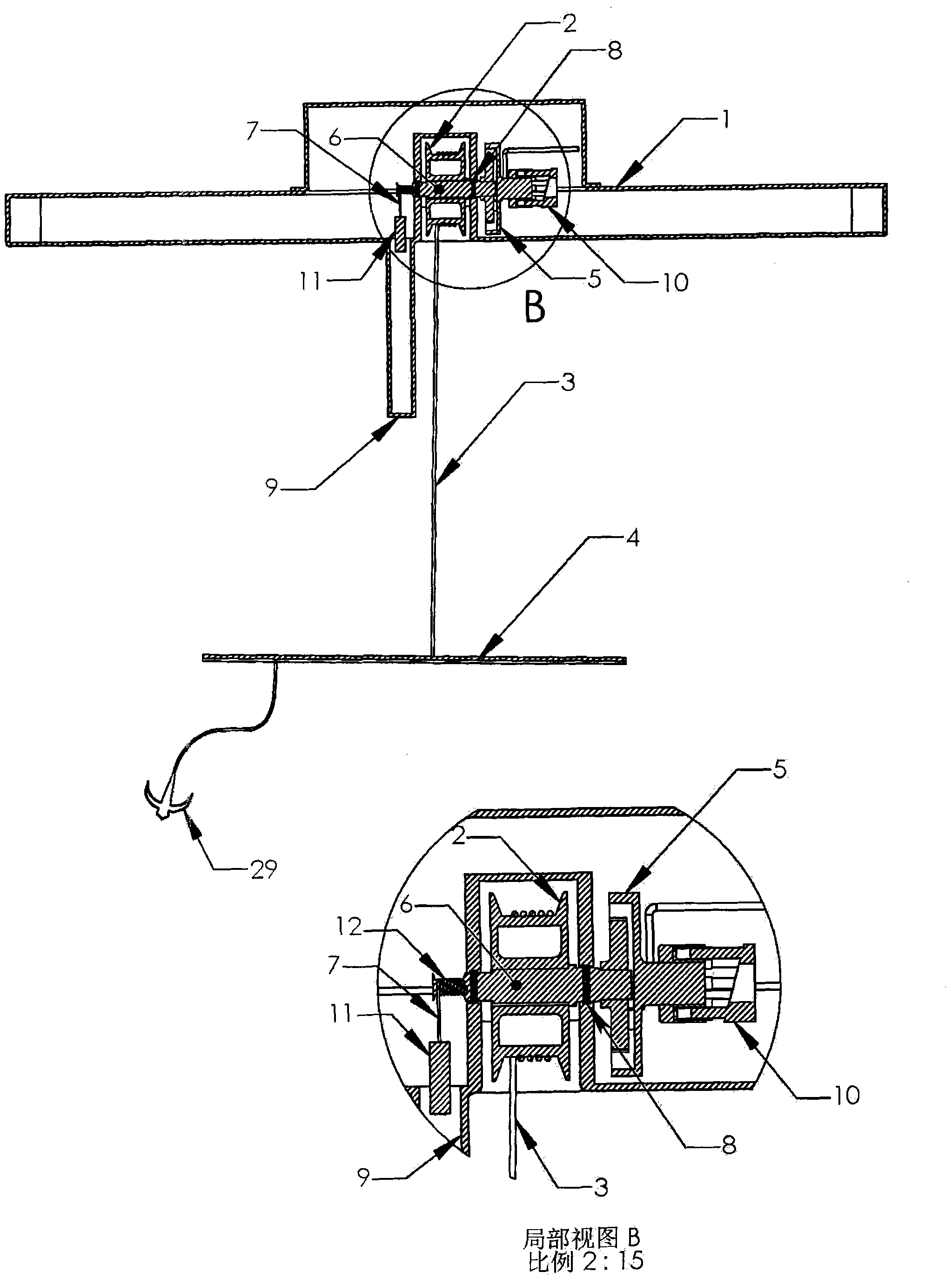

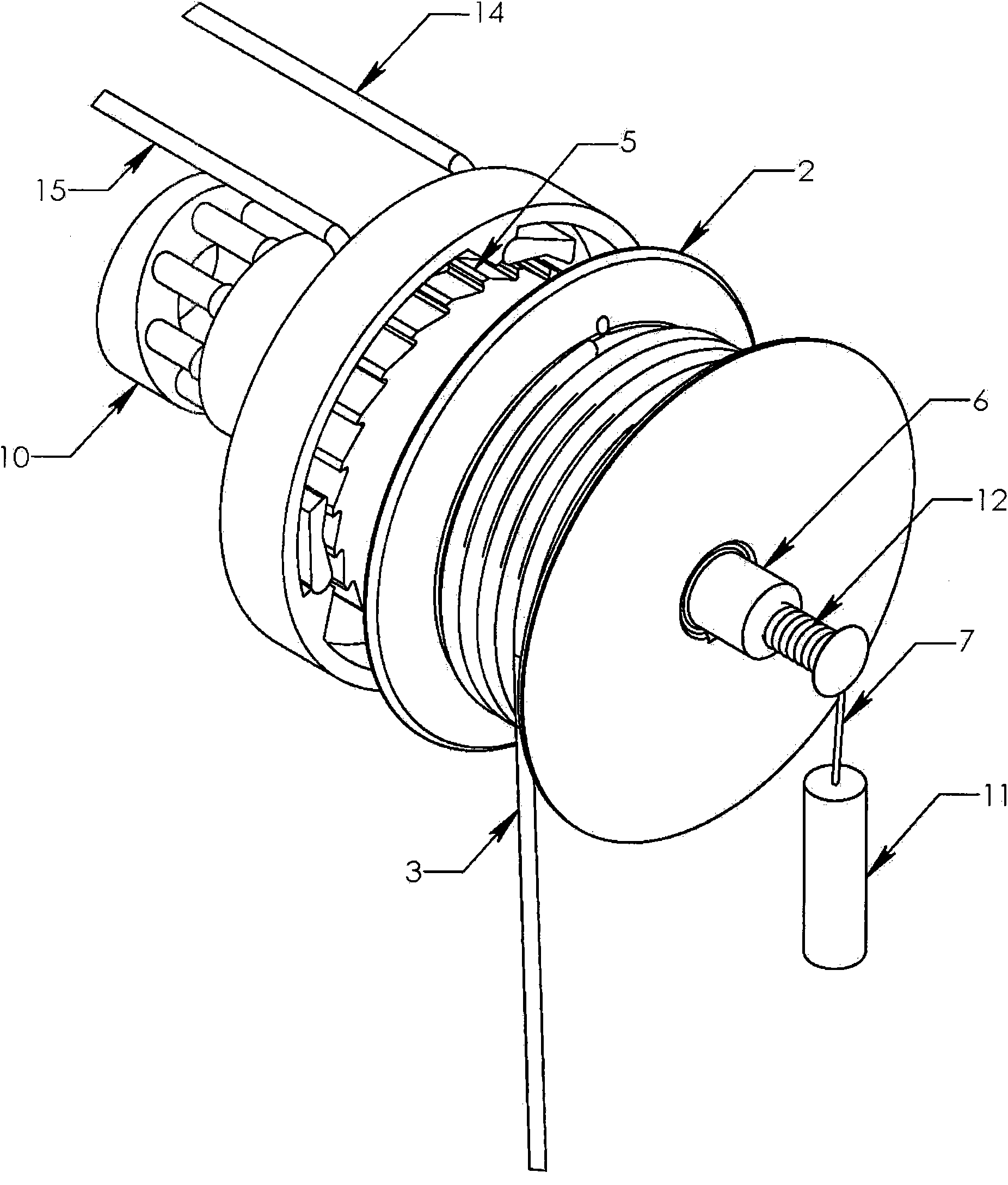

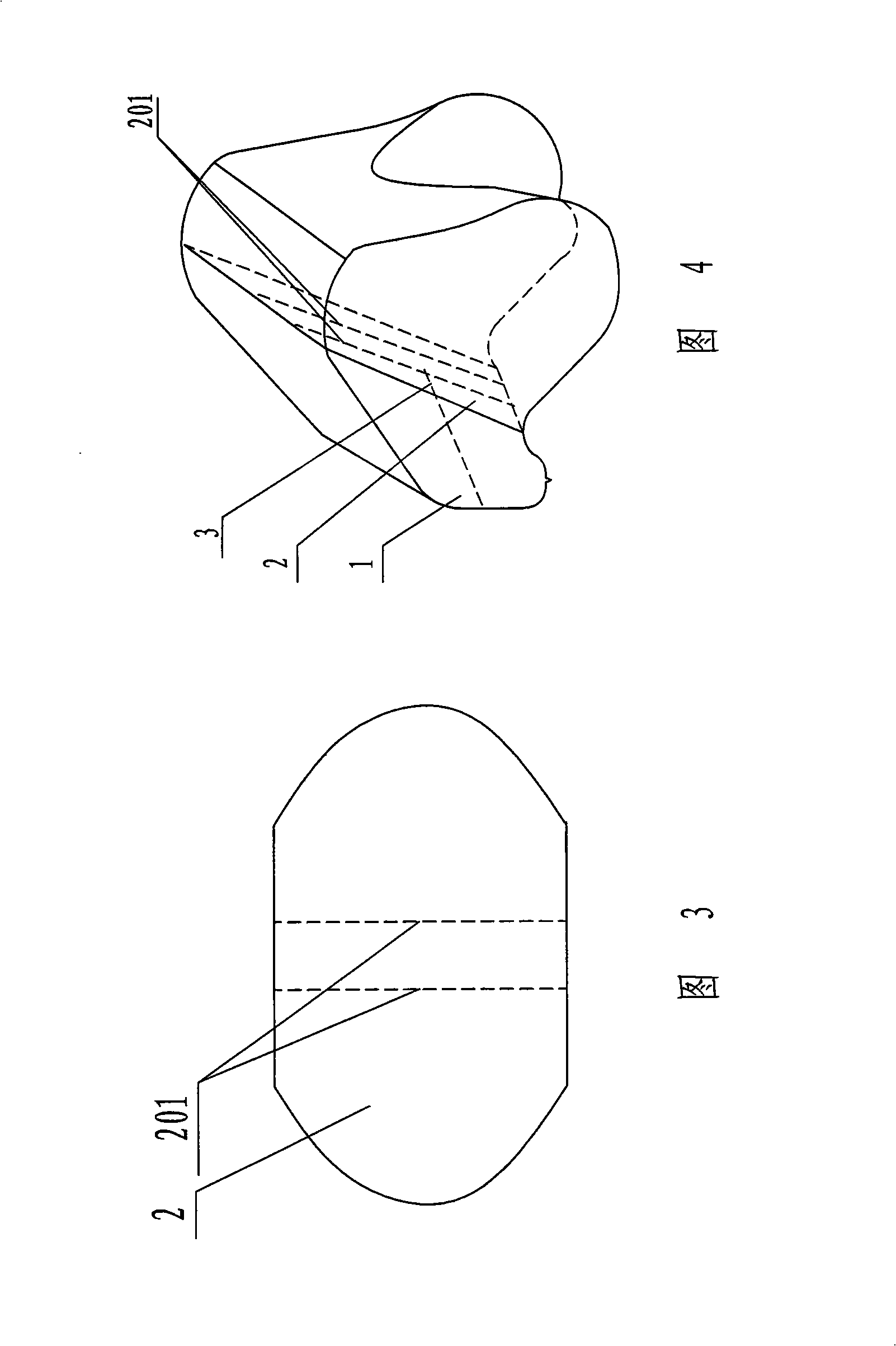

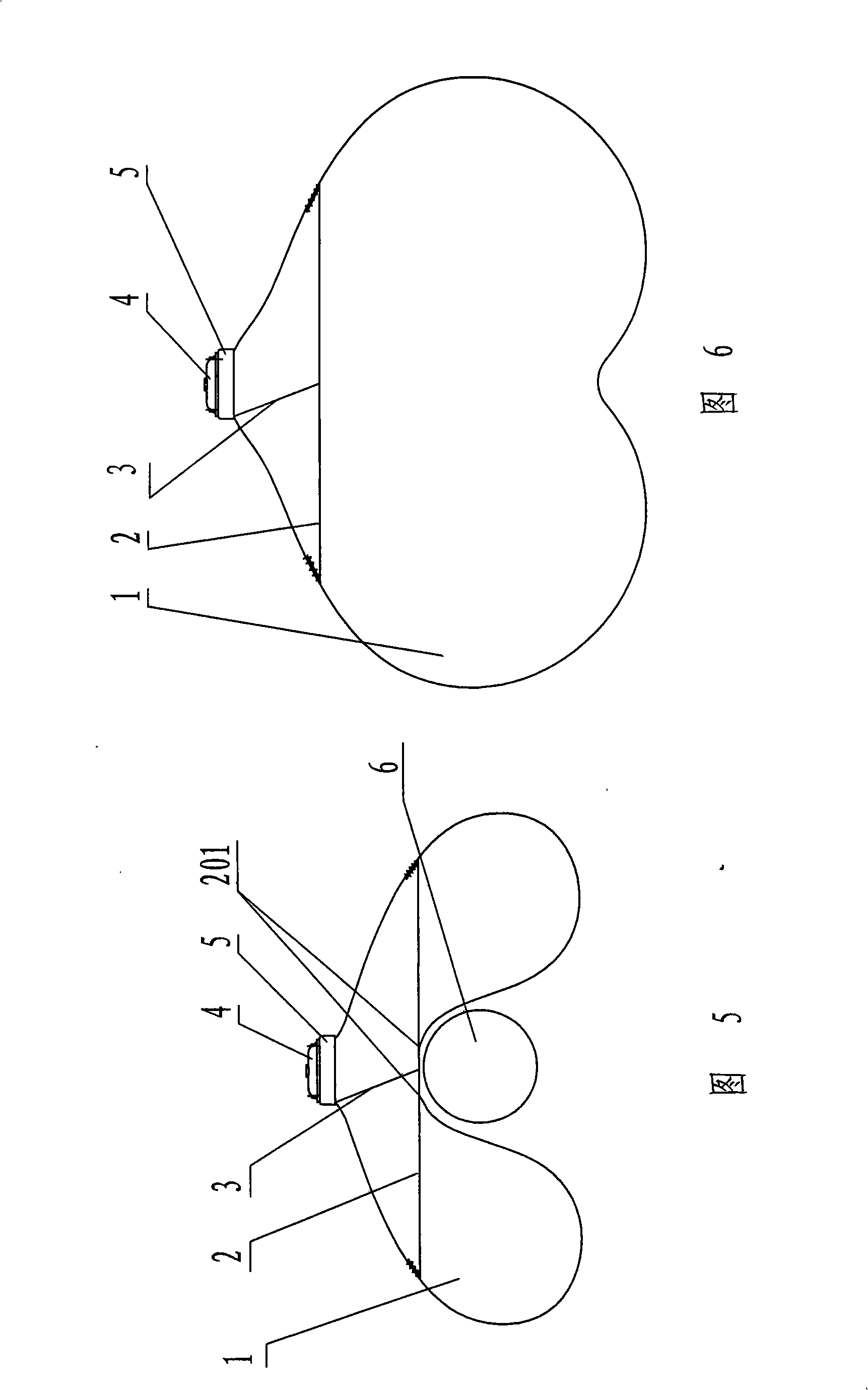

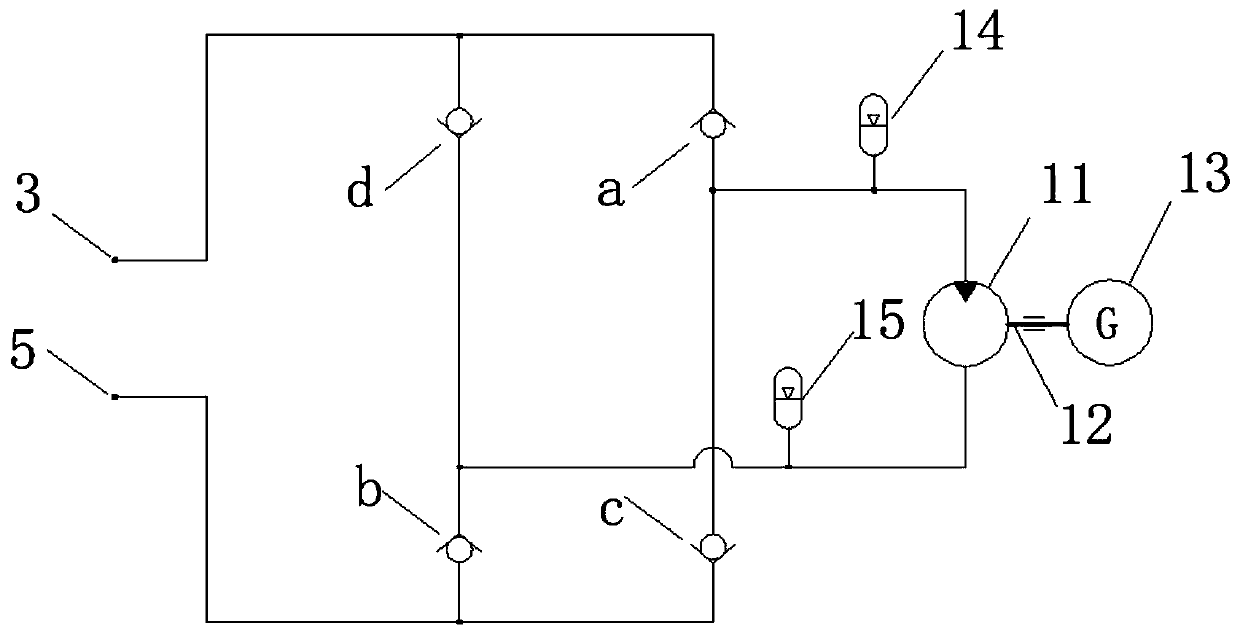

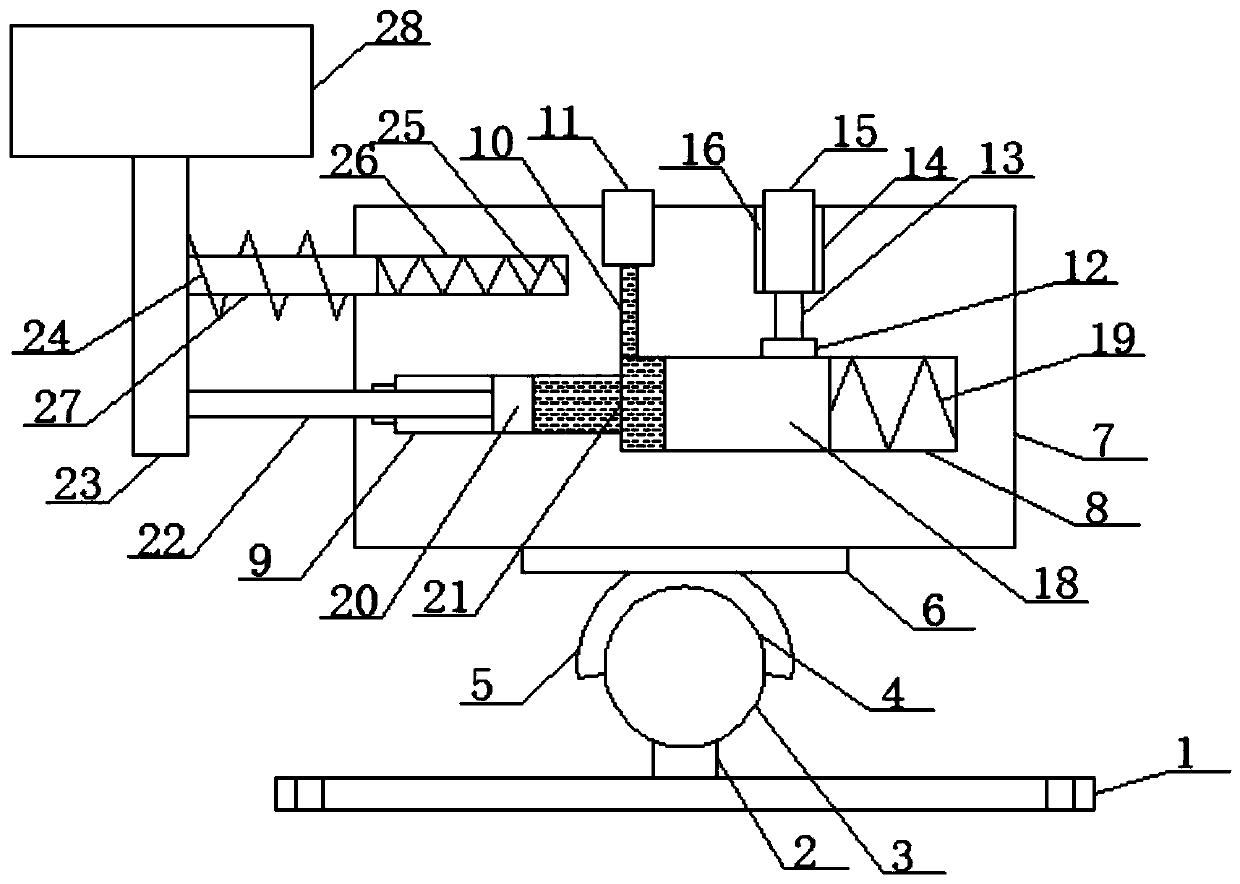

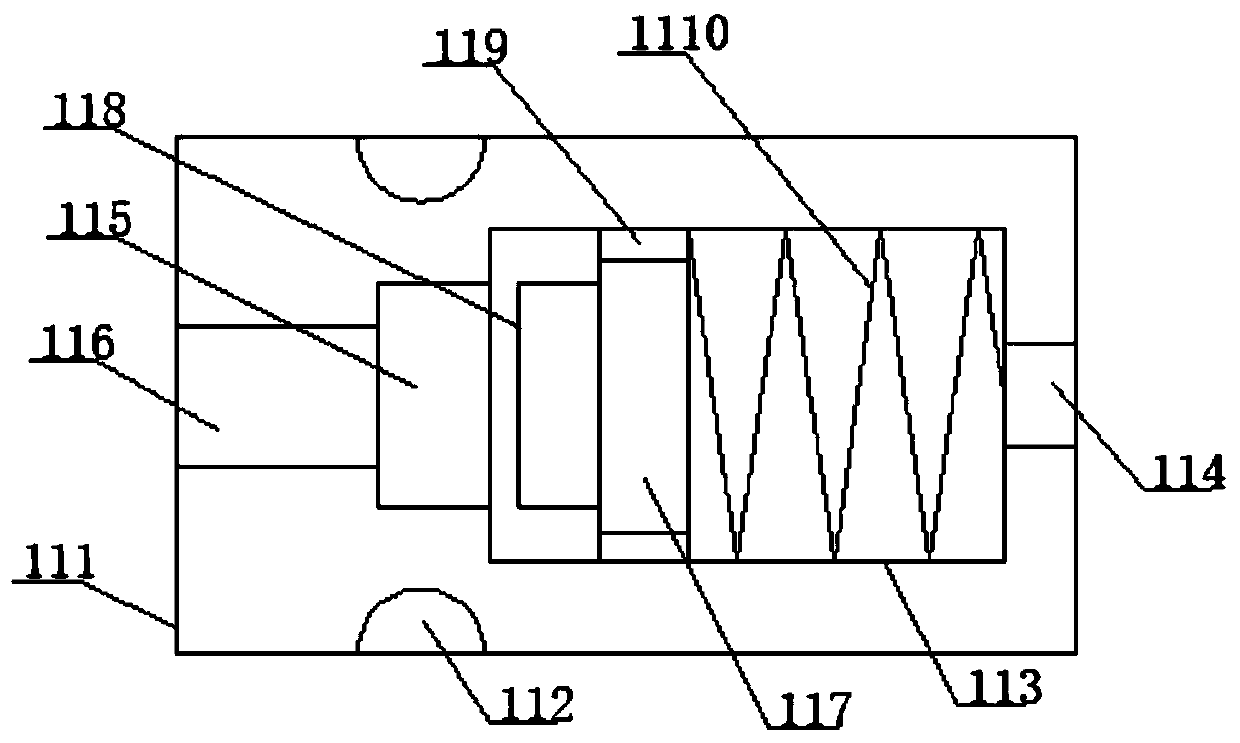

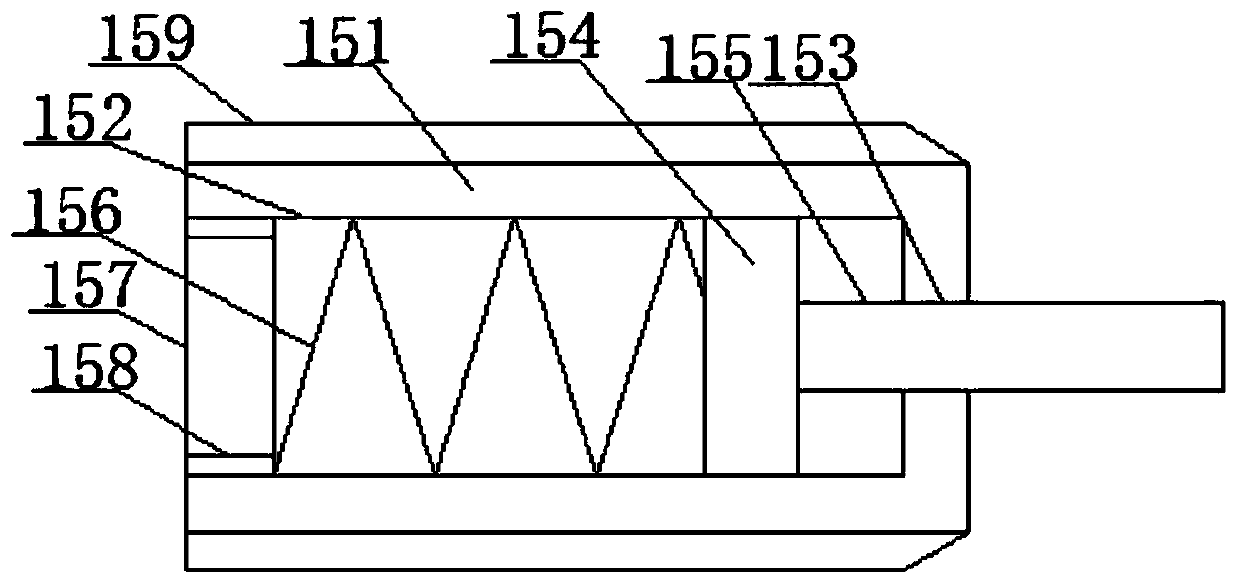

Wave power generating system with floating-body-based rope pulley

InactiveCN101963125AStrong wind and wave resistanceDoes not affect workEngine fuctionsMachines/enginesMechanical energyEngineering

The invention provides a wave power generating system with a floating-body-based rope pulley, relating to a wave energy power generating system and comprising a wave energy collecting part, a power generator and a base, wherein the wave energy collecting part has the mechanism of: pushing a floating body by waves, tightening a rope, further driving a rotating wheel arranged on the floating body to apply work, and outputting mechanical energy to realize the collection of wave energy; and in a wave dropping step, reversely rotating the rotating wheel by using small force, withdrawing the rope, pulling and withdrawing in the way, and continuously circulating. The wave energy collecting part is used for supplying power to the power generator to generate power. The wave power generating system can adapt to most shapes of waves and has the advantages of strong wind and wave resistance, low cost and easy maintenance.

Owner:曲言明

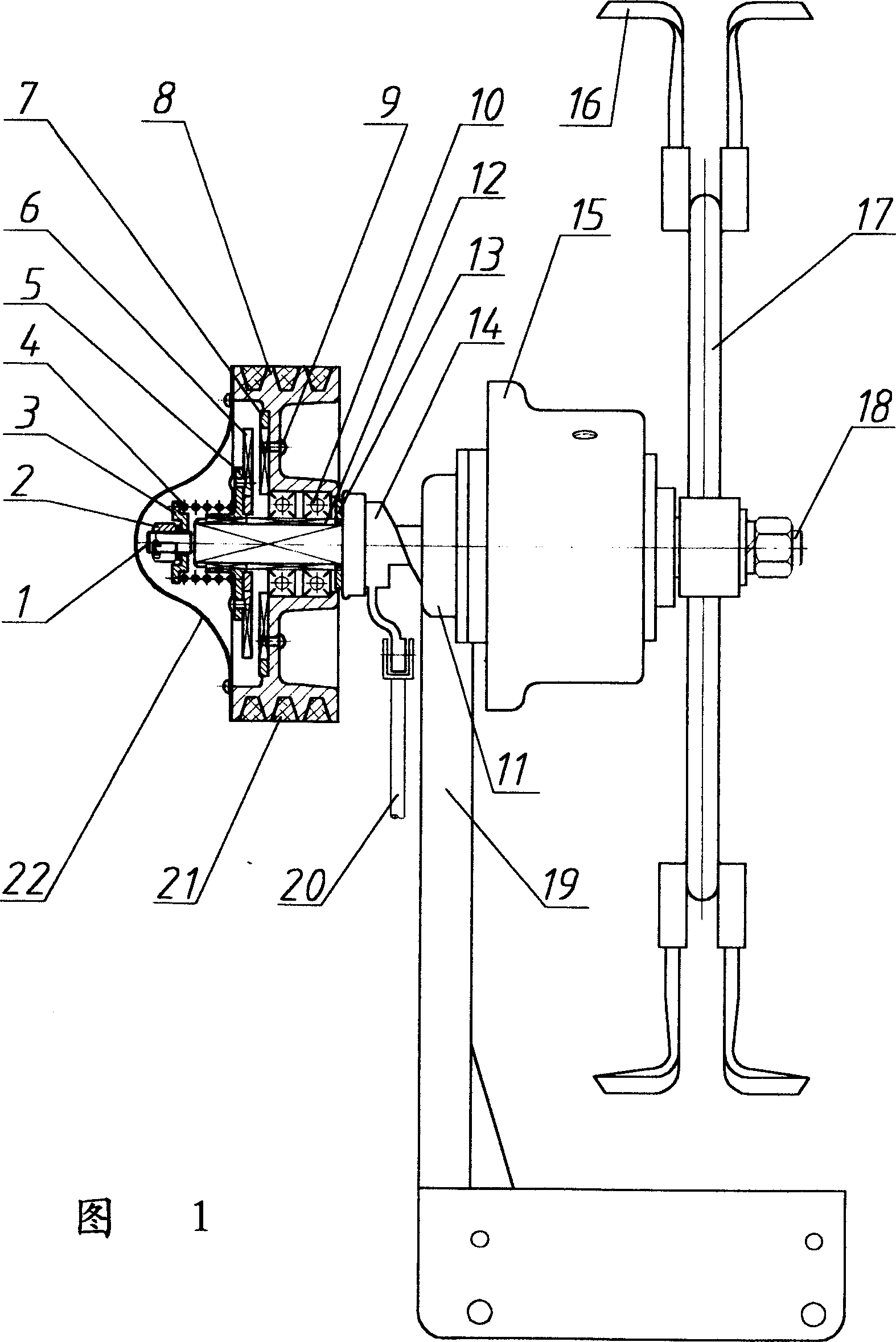

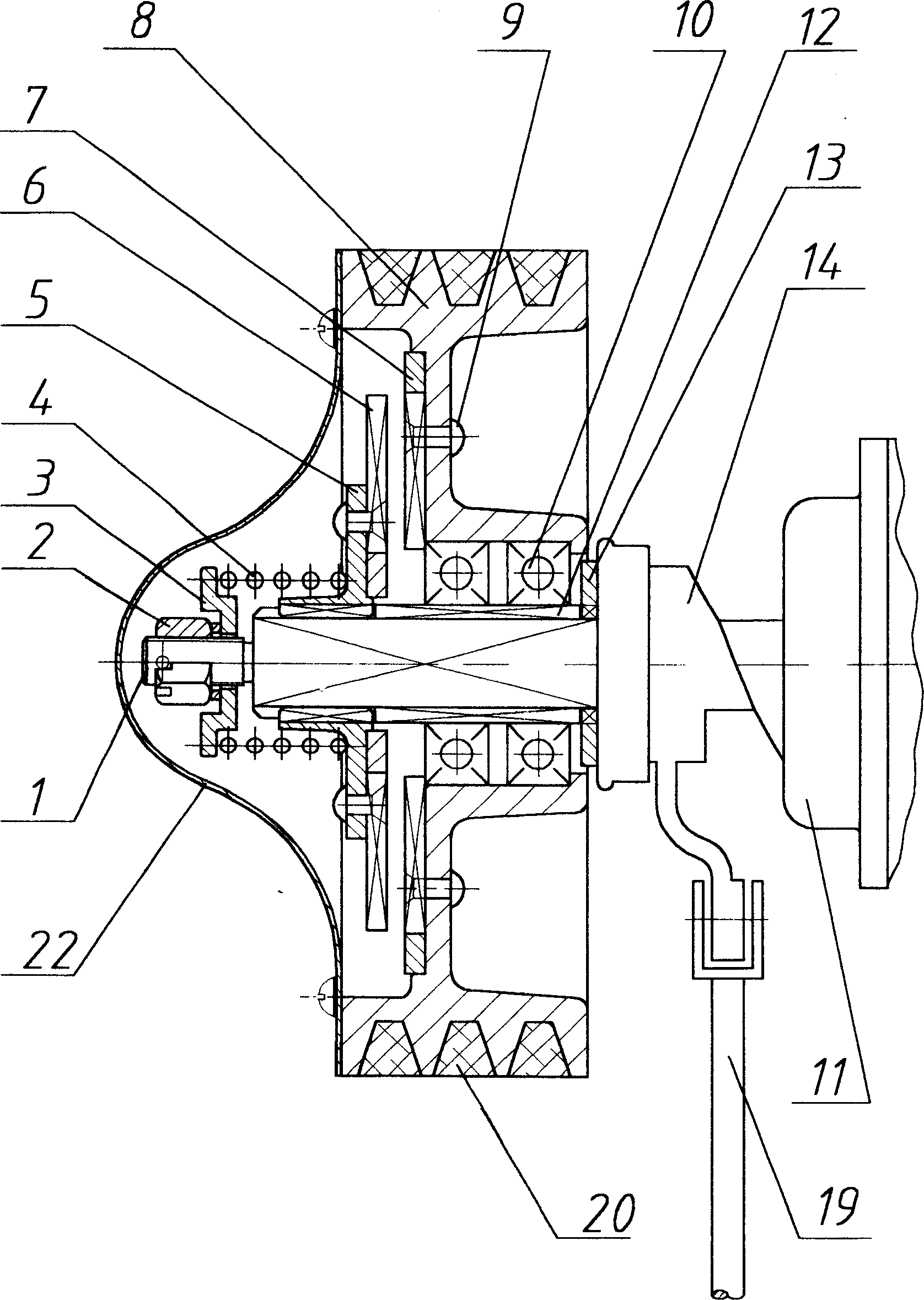

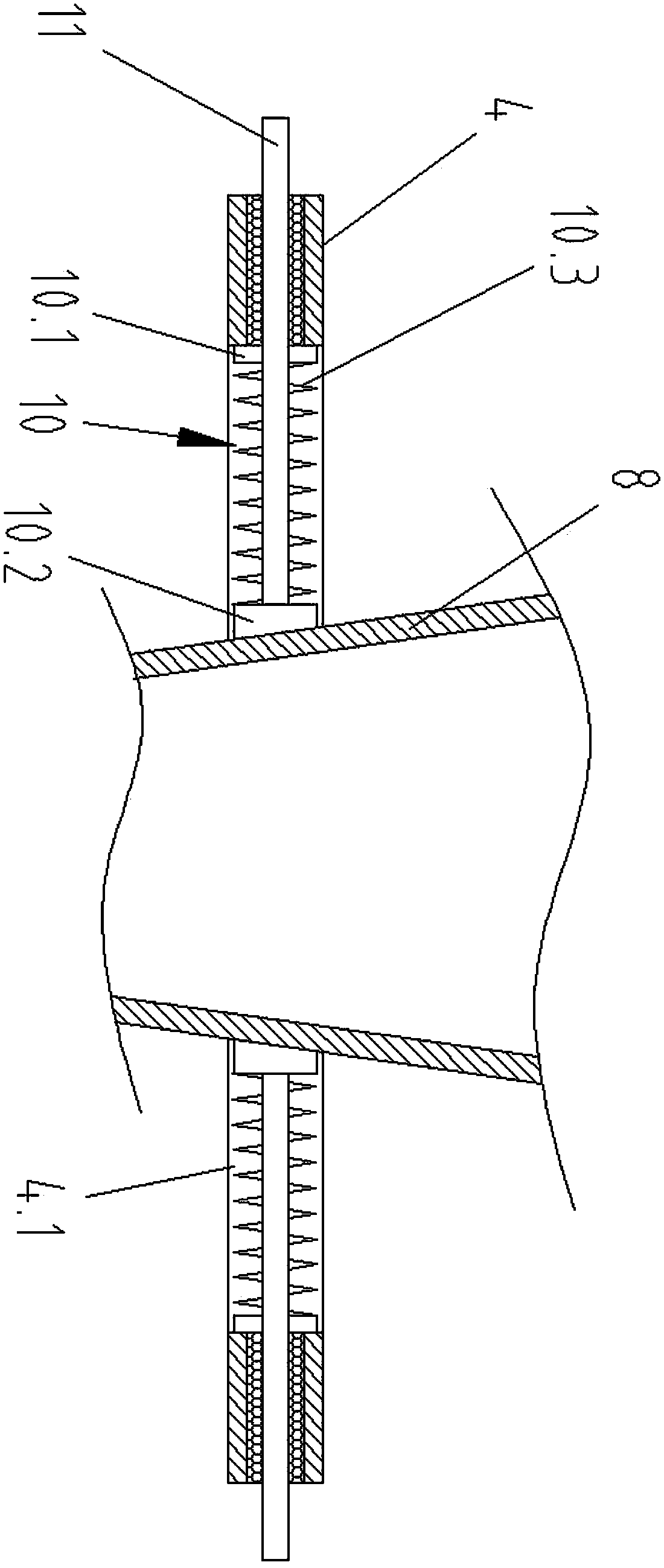

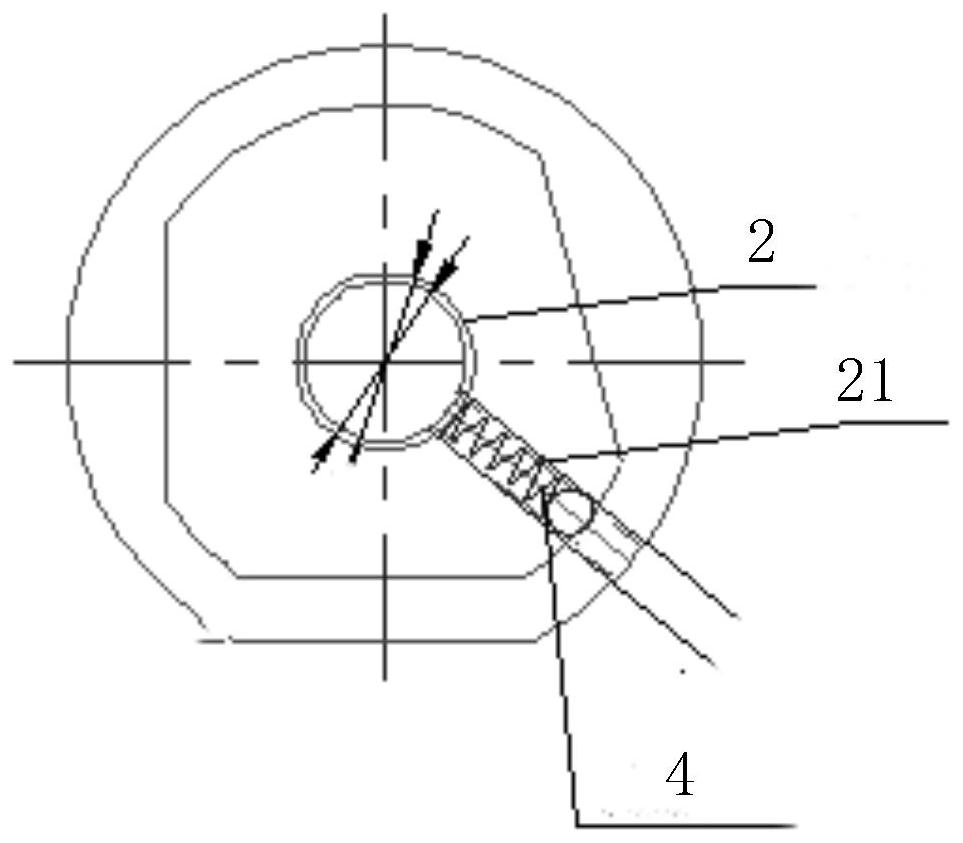

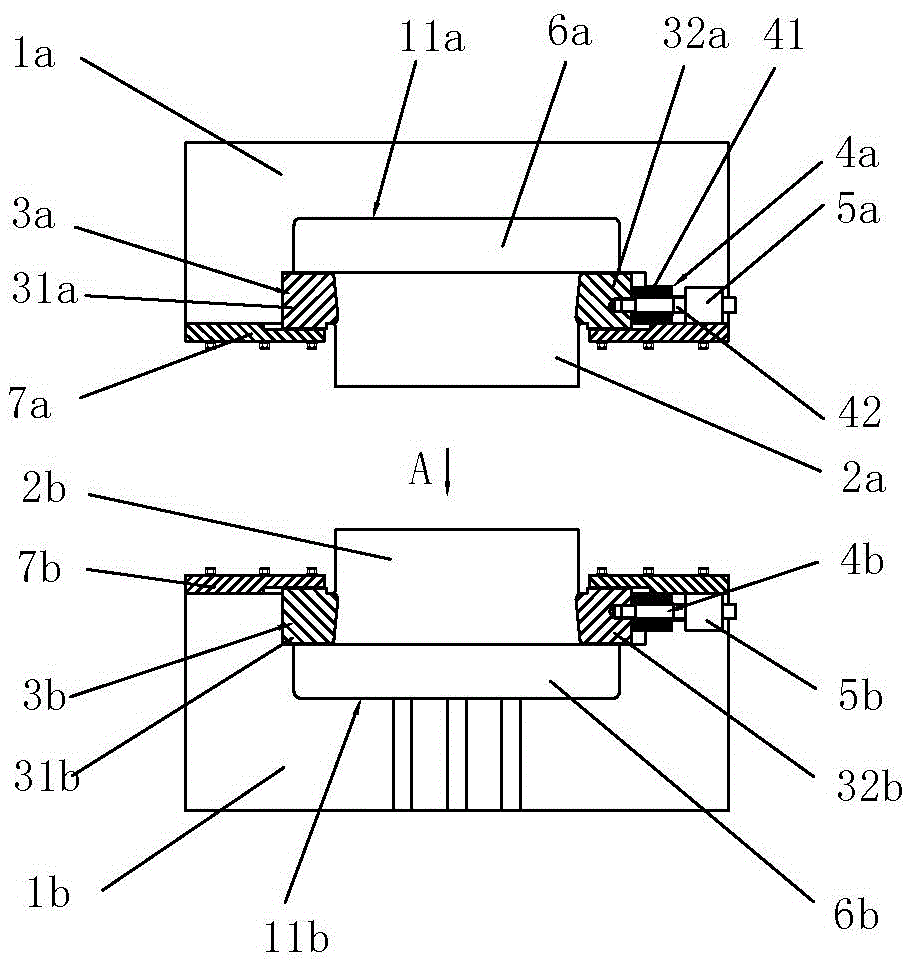

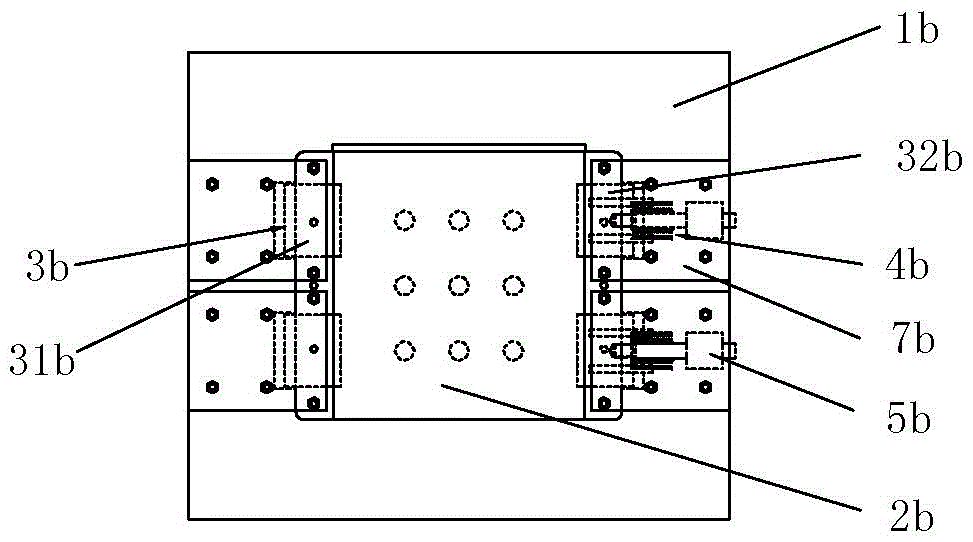

Dual-rope type float body rope wheel sea wave power generation system

InactiveCN101749169AStrong wind and wave resistanceIncrease buffer distanceMachines/enginesEngine componentsWave shapeSea waves

The invention relates to a dual-rope type float body rope wheel sea wave power generation system, belonging to a wave energy generation system. In the invention, wave is pushed by a float body or an oscillating plate; one rope of which one end is tied thereon and the other end is wound on a rotating wheel to pull the rotating wheel to convert the obtained irregular wave push power into rotating power; during the wave fall-back period, another rope drives the rotating wheel to invert by the gravity of a heavy object to take back the rope; the rotating wheel realizes energy transmission and collection by a ratchet wheel mechanism and a hydraulic system so as to realize power generation via a generator. As for large-scale wave energy generation, the float body can form an array surface. The system can be adapted to waves with most waveforms, can efficiently absorb wave energy, has strong wind wave resistance and low cost and does not rely on shore-based operation.

Owner:曲言明

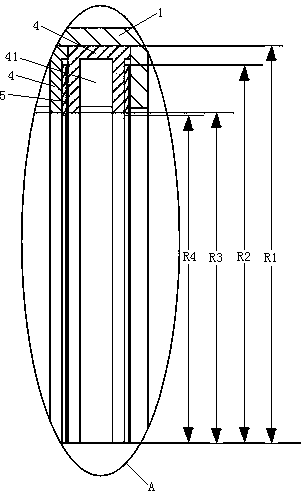

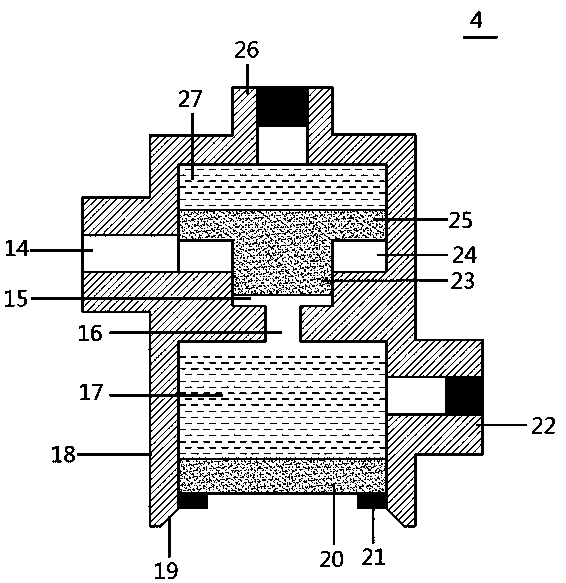

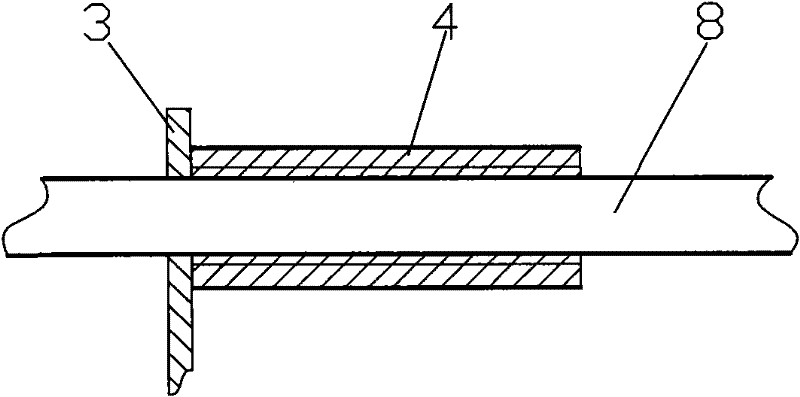

Sealing structure for rotary shaft of flue gas valve

ActiveCN104110496AReduce the momentary impactLower requirementSpindle sealingsEngine sealsFlue gasGraphite

The invention relates to a flue gas valve, and discloses a sealing structure for a rotary shaft of a flue gas valve. The sealing structure comprises a packing pipe. A pressing ring, first buffering rings, a compression spring, a graphite sealing ring and second buffering rings which are sequentially butted to one another are arranged in the packing pipe, an inner rib is arranged at one end of the packing pipe, an outer rib is arranged at the other end of the packing pipe, an outer flange is arranged at the end, which is far away from the first buffering rings, of the pressing ring and is connected with the outer rib by assembling bolts, an adjusting gap is reserved between the outer flange and the outer rib, the second buffering rings are butted to the inner rib, the outer peripheral surface of the graphite sealing ring is hermetically connected with the inner peripheral surface of the packing pipe, the flue gas valve comprises the rotary shaft, the rotary shaft is penetratingly arranged in the graphite sealing ring and is hermetically butted to the graphite sealing ring, matching surfaces of the rotary shaft and the graphite sealing ring are conical surfaces, and small-diameter ends of the conical surfaces are close to the inner rib. The sealing structure for the rotary shaft of the flue gas valve has the advantages that a shaft end of the rotary shaft of the flue gas valve can be sealed by the sealing structure, and sealing effects can be adjusted; the problem of leakage at a shaft end of an existing flue gas valve can be solved by the aid of the sealing structure.

Owner:江苏明江阀业有限公司

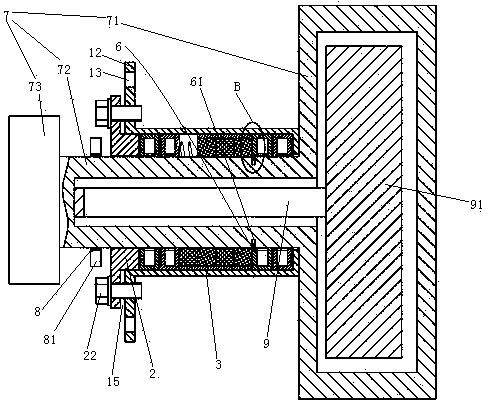

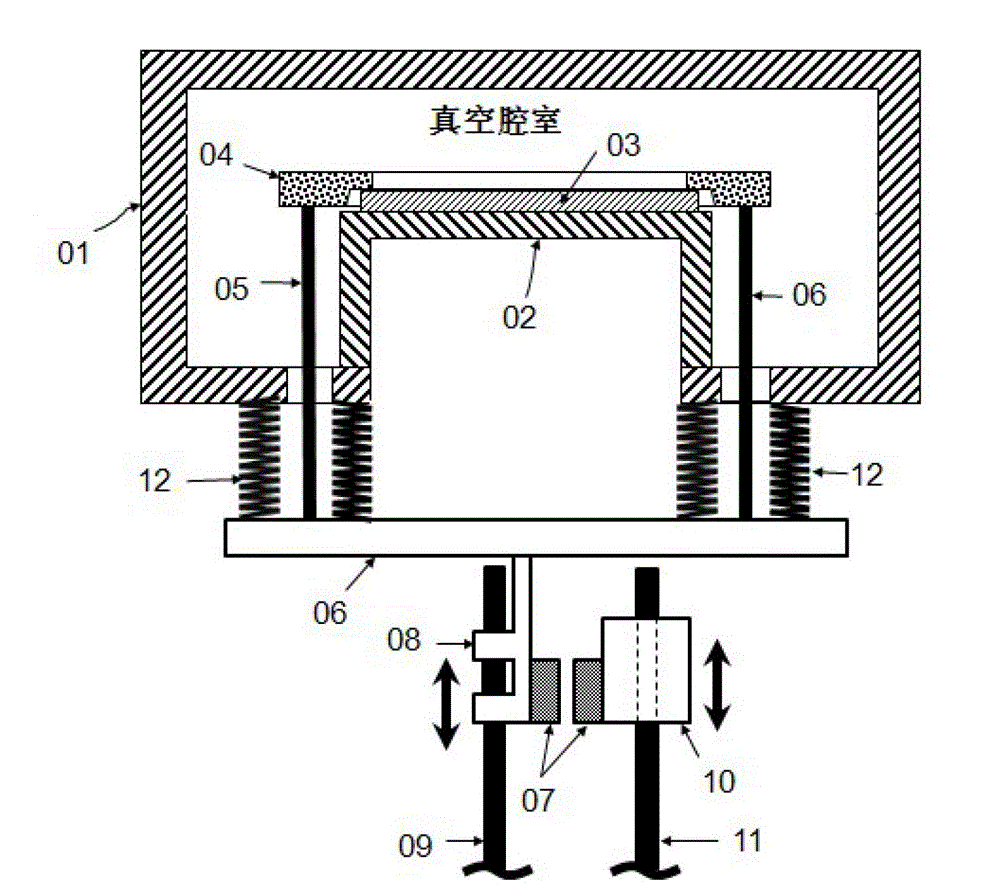

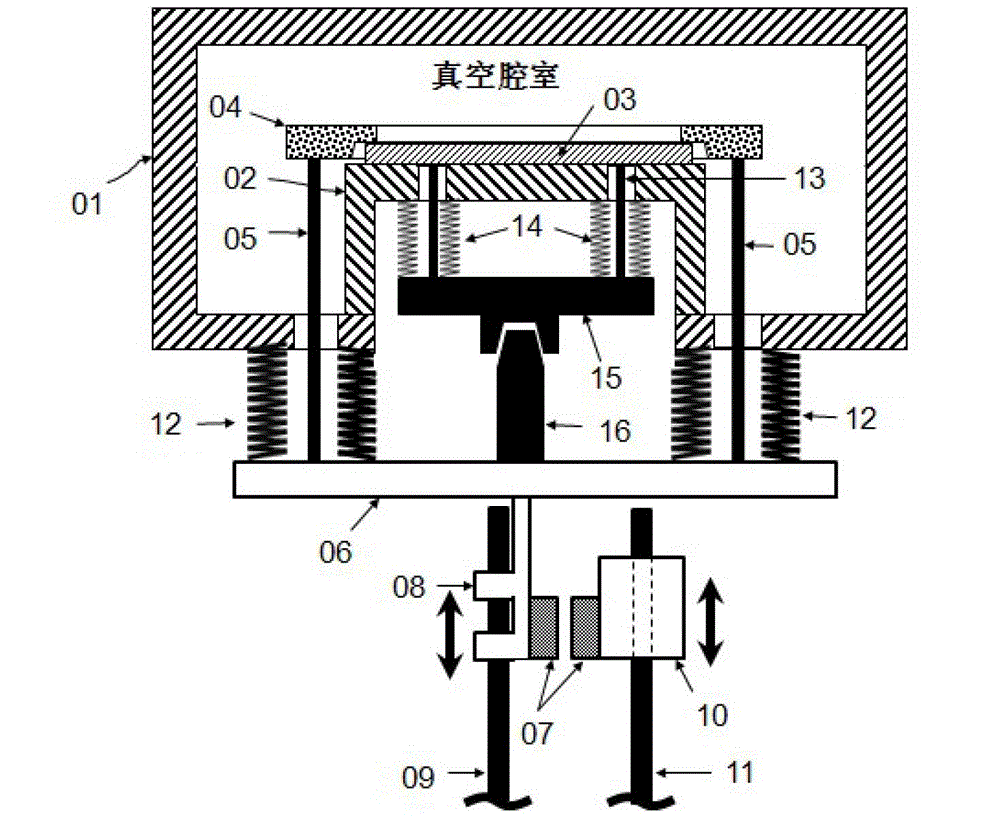

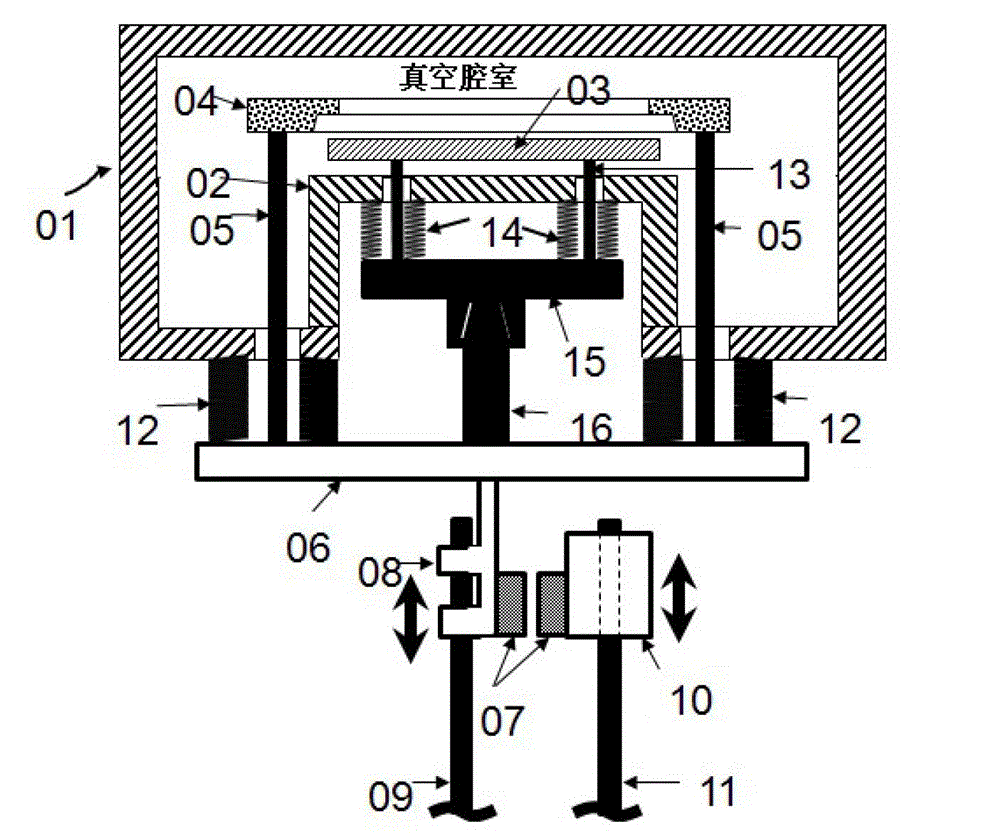

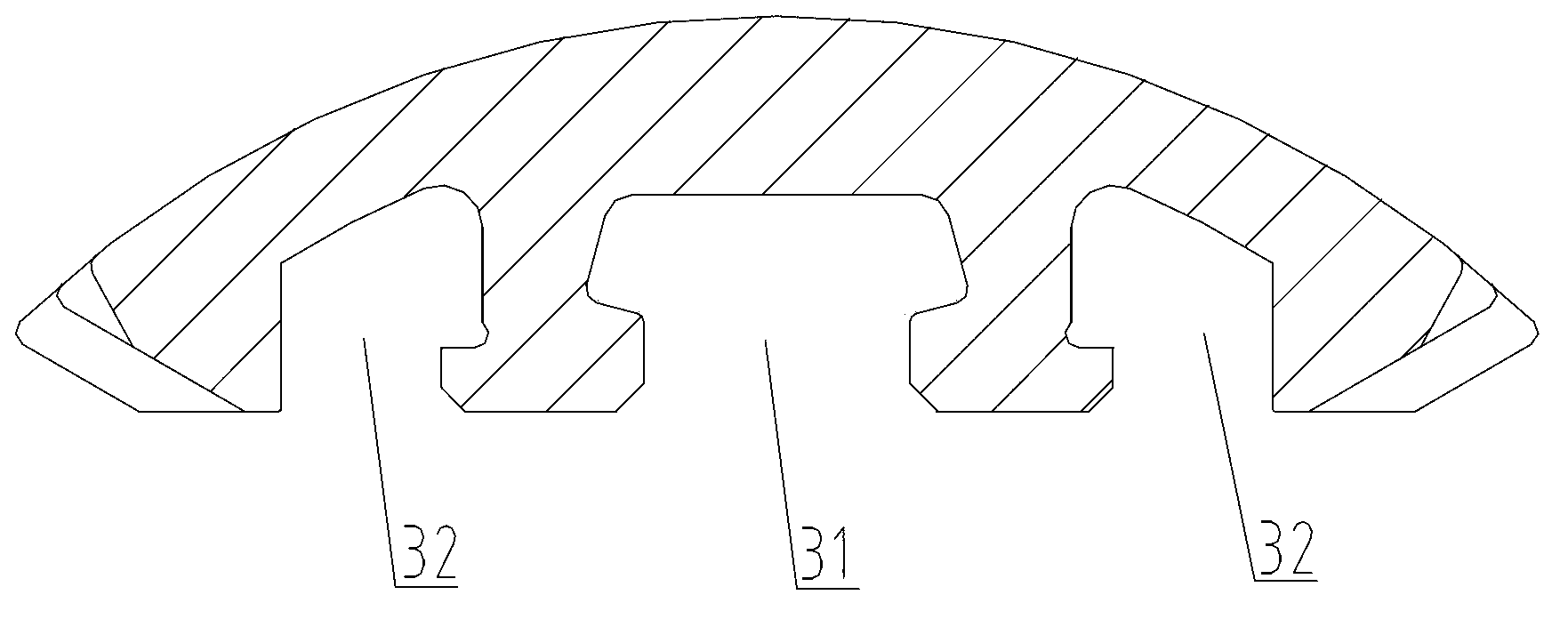

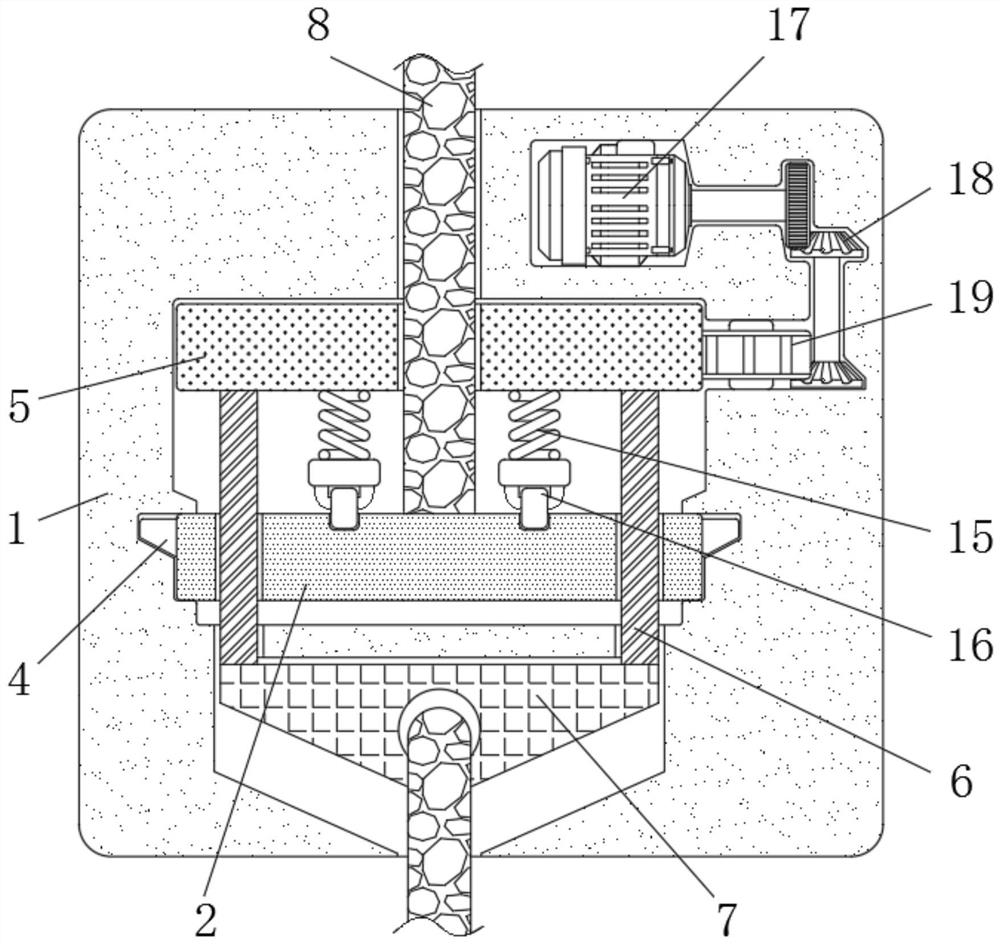

Mechanical-type chip clamping-pressing device for vacuum plasma technology

InactiveCN103066003AImprove use reliabilityReduce surface damageSemiconductor/solid-state device manufacturingMagnetic tension forceCoupling

The invention discloses a mechanical-type chip clamping-pressing device for vacuum plasma technology. The mechanical-type chip clamping-pressing device for the vacuum plasma technology comprises a chip substrate, an electrode, ceramic pressure rings, pressure ring connecting rods, a connecting rod support, a permanent magnet group, a drive motor and a motor support, wherein the chip substrate is positioned on the electrode, the ceramic pressure rings are arranged above the chip substrate and are connected with the connecting rod support through the pressure ring connecting rods, the permanent magnet group comprises a first group of permanent magnets and a second group of permanent magnets, wherein the first group of permanent magnets and the second group of permanent magnets are arranged in a corresponding mode are in magnetic coupling with each other, the first group of permanent magnets is fixedly connected with the connecting rod support, and the second group of permanent magnets is fixed on the drive motor which is movably connected with the motor support. The mechanical-type chip clamping-pressing device for the vacuum plasma technology can overcome the technical defect that an mechanical-type chip clamping-pressing device in the prior art can not be compatible with chip substrates with different thicknesses and surface evenness, is reliable in using, can reduce and eliminate instantaneous impact force generated by the ceramic pressure rings to the chip substrate when the ceramic pressure rings are contacted with the surface of the chip substrate, reduces the probability that the surface of the chip substrate is damaged or cracked, and improves production efficiency.

Owner:赖守亮

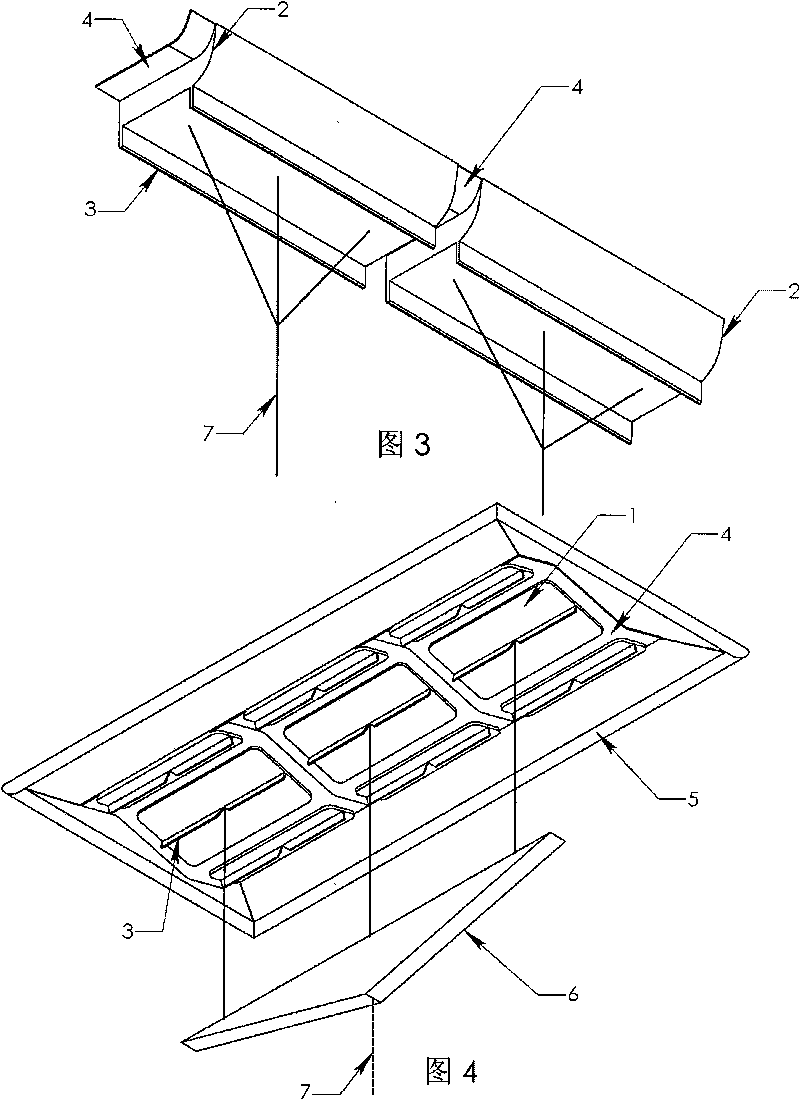

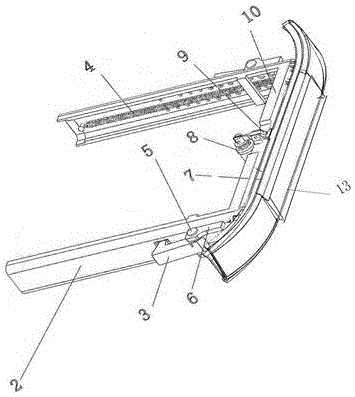

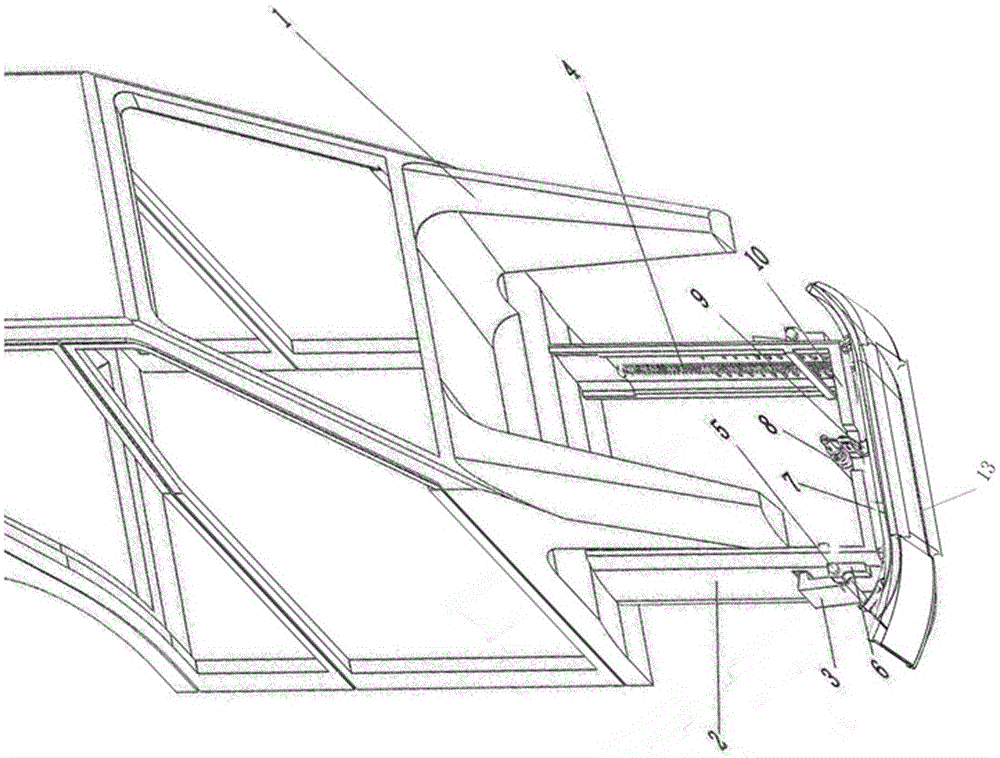

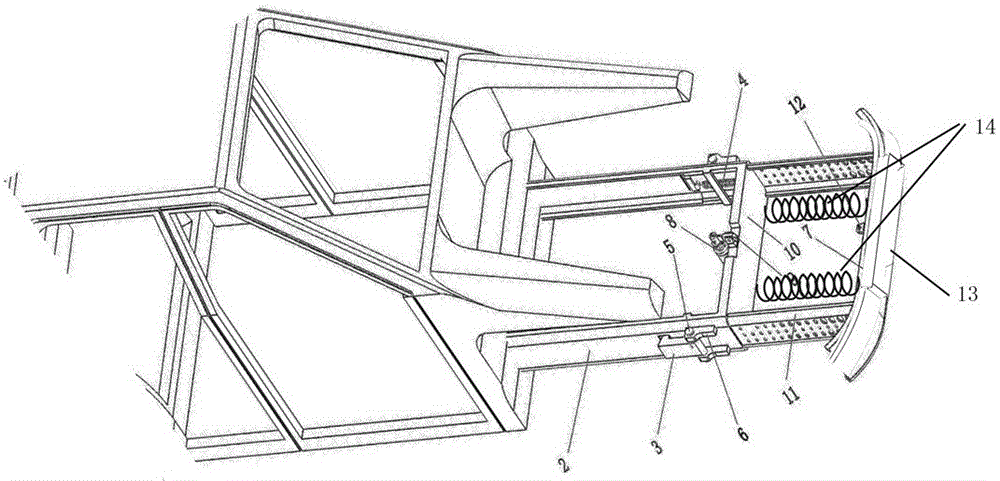

Active protection device

Provided is an active protection device, pertaining to the technical field of car safety.The active protection device is characterized in that an anti-collision beam is divided into a fixed beam and a movable beam; the movable beam is installed on the fixed beam and can perform horizontal movement by stretching and retracting relative to the fixed beam; a retractable locking device of the movable beam is arranged on the fixed beam and can be used for locking the retraction state of the movable beam; a stretching driving unit of the movable beam is arranged on the fixed beam and used for driving the movable beam to stretch outwardly; a stretching locking device of the movable beam is arranged on the fixed beam; a spring buffer device is arranged between the fixed beam and the movable beam; the movable beam is capable of outwardly stretching and locking to receive collision; a spring protection device is opened to buffer collision; and a distance measurement device is arranged on a car and connected with a computer which is also connected with retractable locking device of the movable beam.The active protection device has following advantages: without increasing total length of the car and buffering impact force, larger physical collision space is obtained.

Owner:张文超

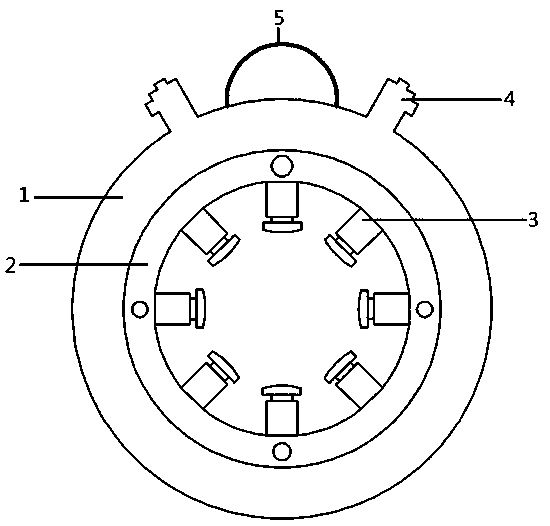

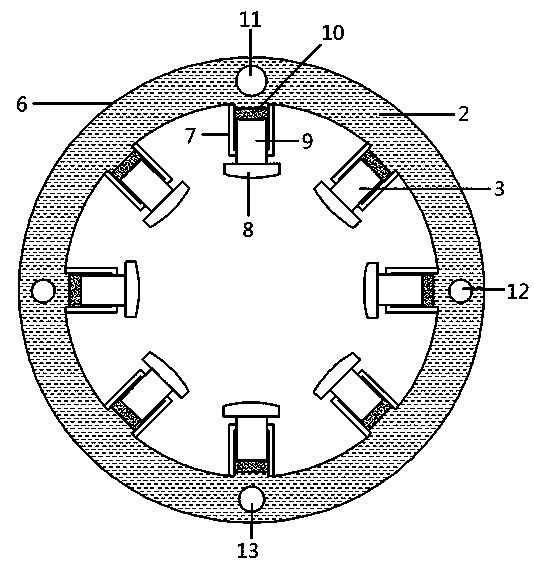

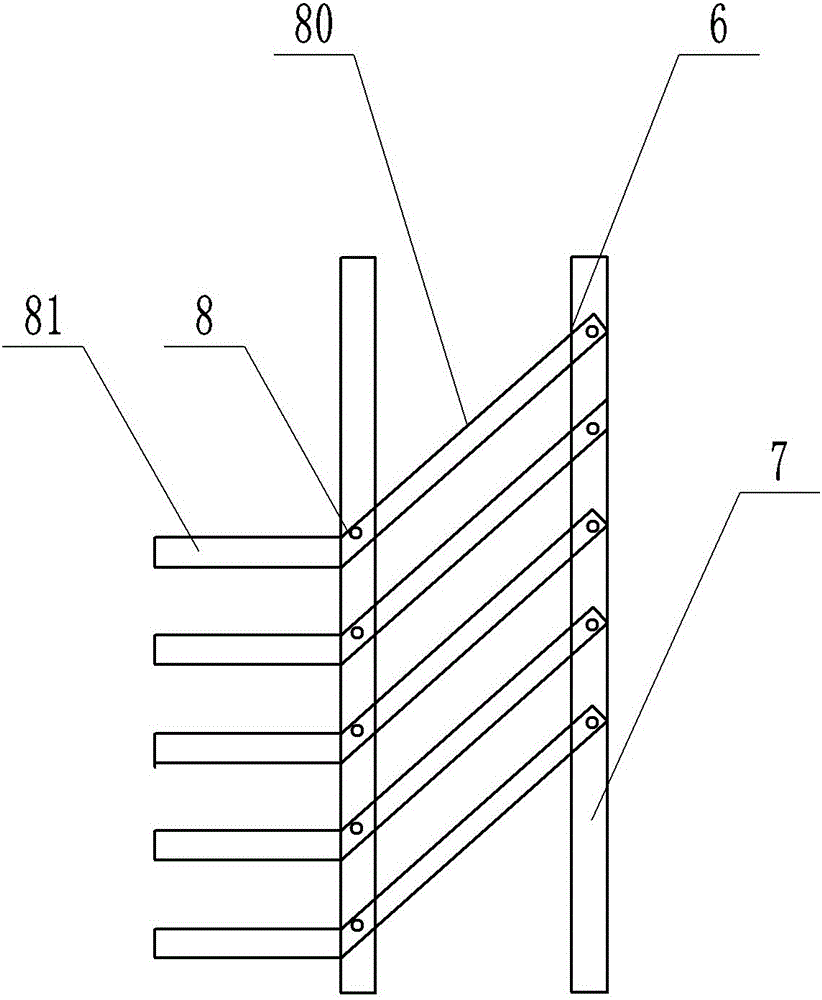

Irregular concrete column carrying device

The invention discloses an irregular concrete column carrying device. The irregular concrete column carrying device comprises an inner ring and an outer ring; the outer ring is fixedly installed on the periphery of the inner ring; a pressure relief device and a lifting ring are fixedly installed on the outer ring; an even number of hold-down devices are fixedly arranged at the inner side of the inner ring; and furthermore, the multiple hold-down devices are uniformly distributed in the same vertical plane at the inner side of the inner ring along the circumference. When the irregular concretecolumn carrying device in the invention is used, the multiple hold-down devices work synchronously by utilization of the same hydraulic pump; depending on change of hydraulic pressure, connecting rodsin the multiple hold-down devices stretch out in different lengths; furthermore, concrete columns having irregular section shapes are clamped tightly; furthermore, by utilization of the pressure relief device on the outer ring, instantaneous impact force can be effectively buffered when the concrete columns are unloaded or drop inadvertently; and thus, the purpose of protecting the hold-down devices and the concrete columns is achieved.

Owner:威海畅享海天新材料科技股份有限公司

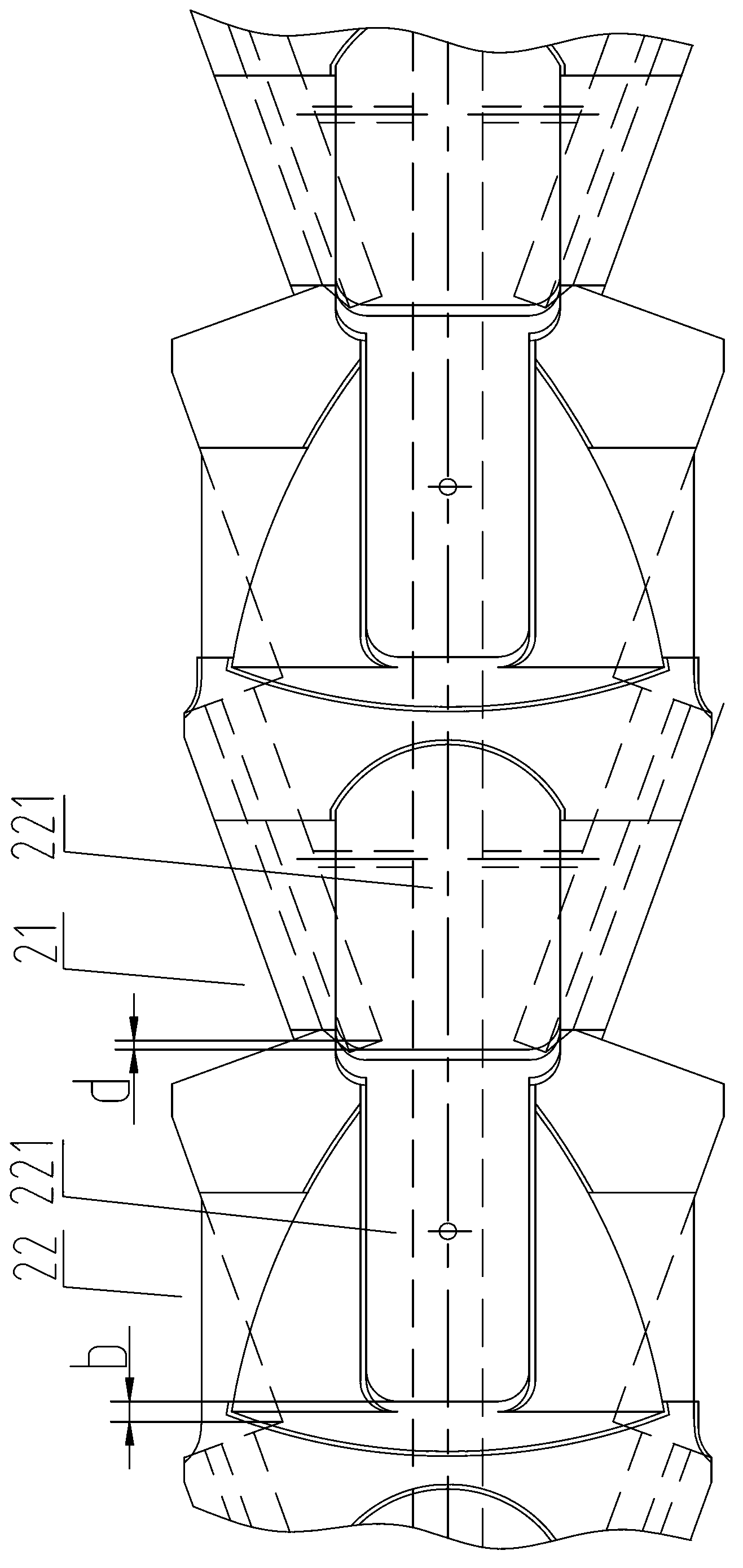

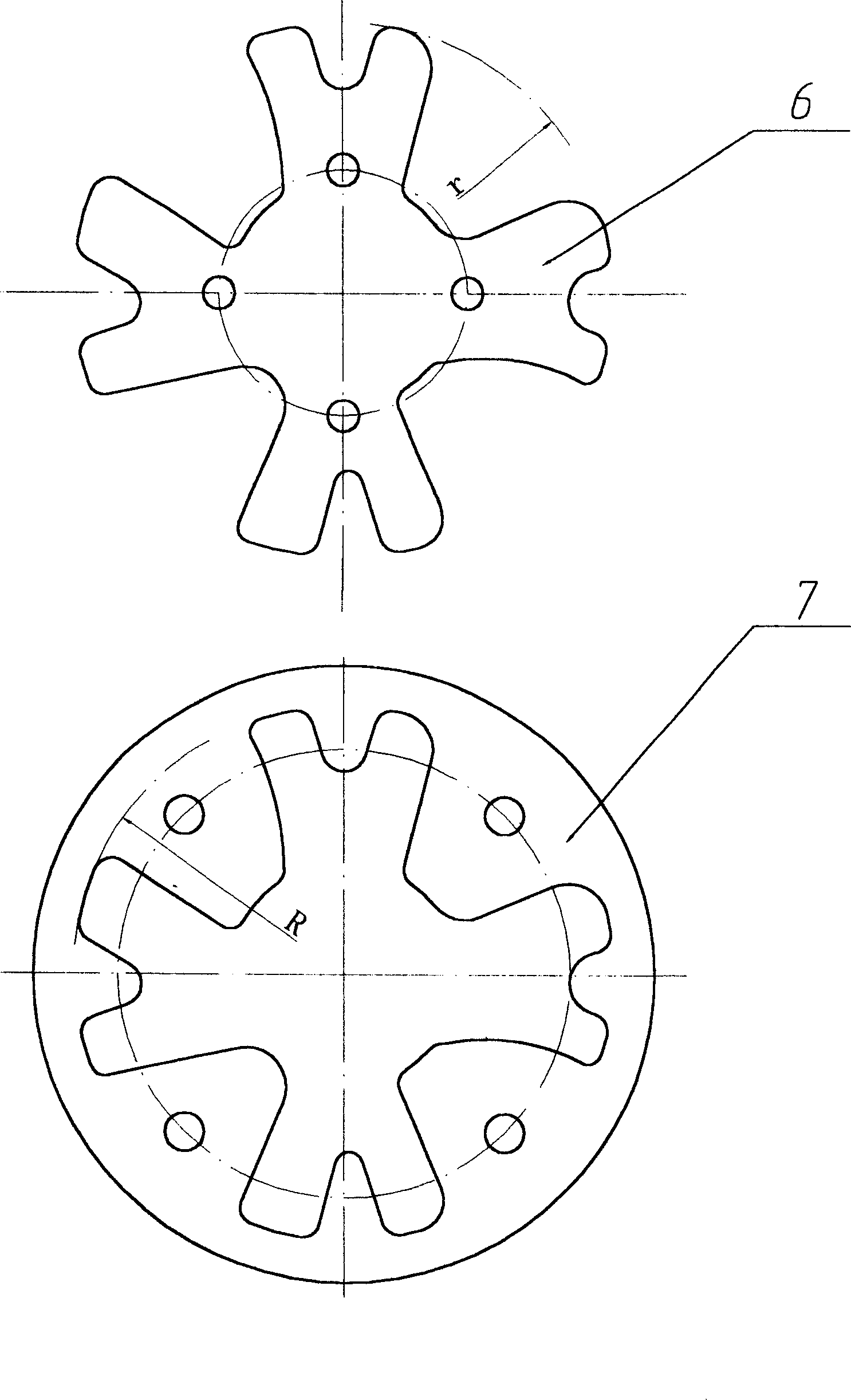

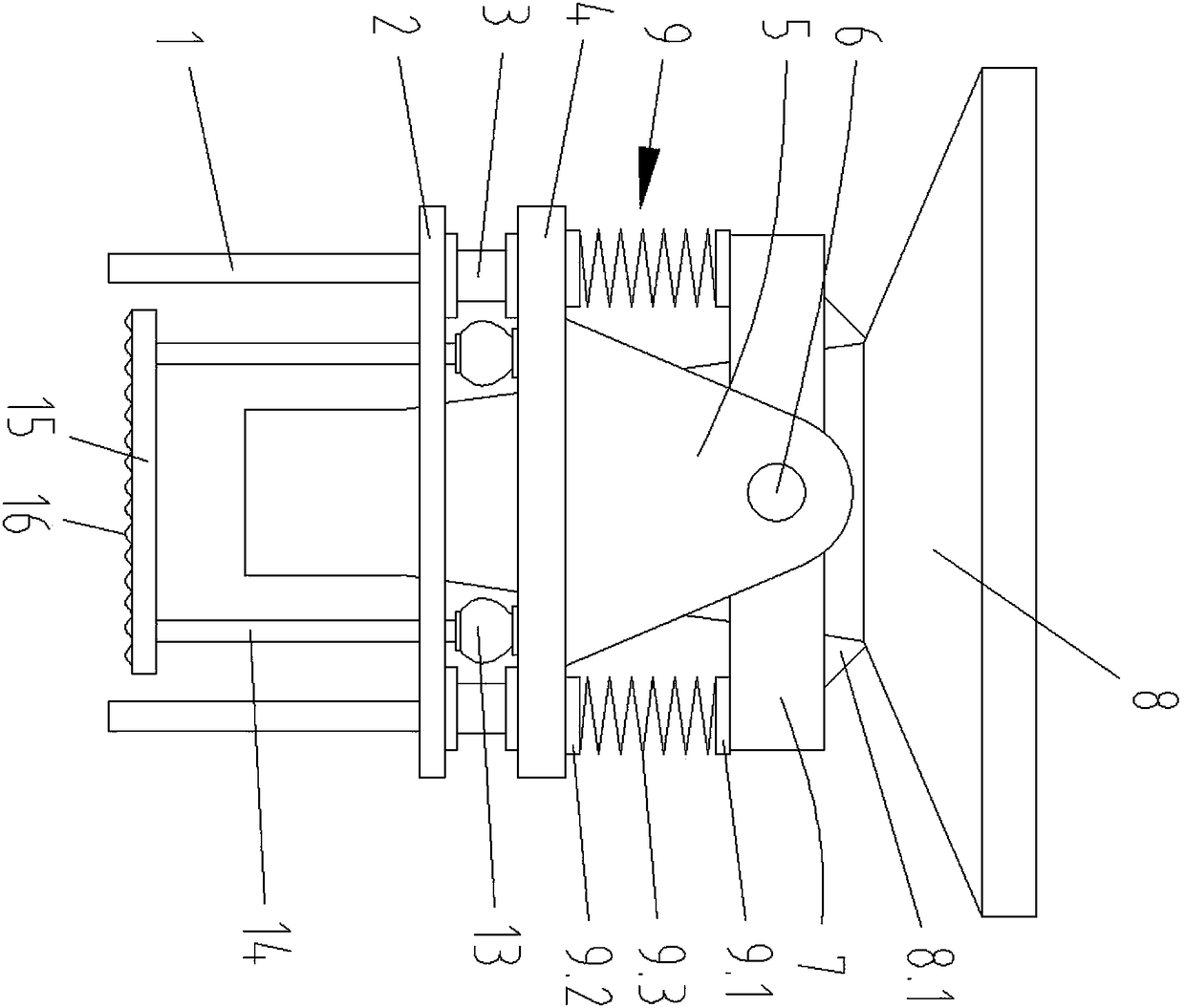

Plunger type coiler mandrel

The invention relates to a plunger type coiler mandrel, which is used for solving the technical problem in the prior art that the plunger type mandrel is short in service life. According to the plunger type coiler mandrel disclosed by the invention, a blind hole is formed in the center of the top of a first plunger body, the blind hole is internally provided with an elastic mechanism, the top surface of the elastic mechanism is a certain distance higher than the top surface of the first plunger body under the condition that only the deadweight of a sector-shaped plate is born, and the elastic mechanism is in contact with the bottom surface of the sector-shaped plate; and a second plunger body is further arranged between the sector-shaped plate and a pull rod, a first key which is arranged in a first flat groove of the sector-shaped plate and has a T-shaped cross section is arranged at the top of the second plunger body, a second key which is arranged inside an inclined groove of a second wedge convex block, can slide along the bottom surface of the inclined groove and has a T-shaped cross section is arranged at the bottom of the second plunger body, and a certain distance is formed between the top surface of the first key and the bottom surface of the first flat groove of the sector-shaped plate. The abrasion and deformation of the first plunger body and the newly and additionally arranged second plunger body are little, so that the service life of the plunger type coiler mandrel is prolonged.

Owner:JINYANG ELECTROMECHANICAL EQUIP MFG HUNAN

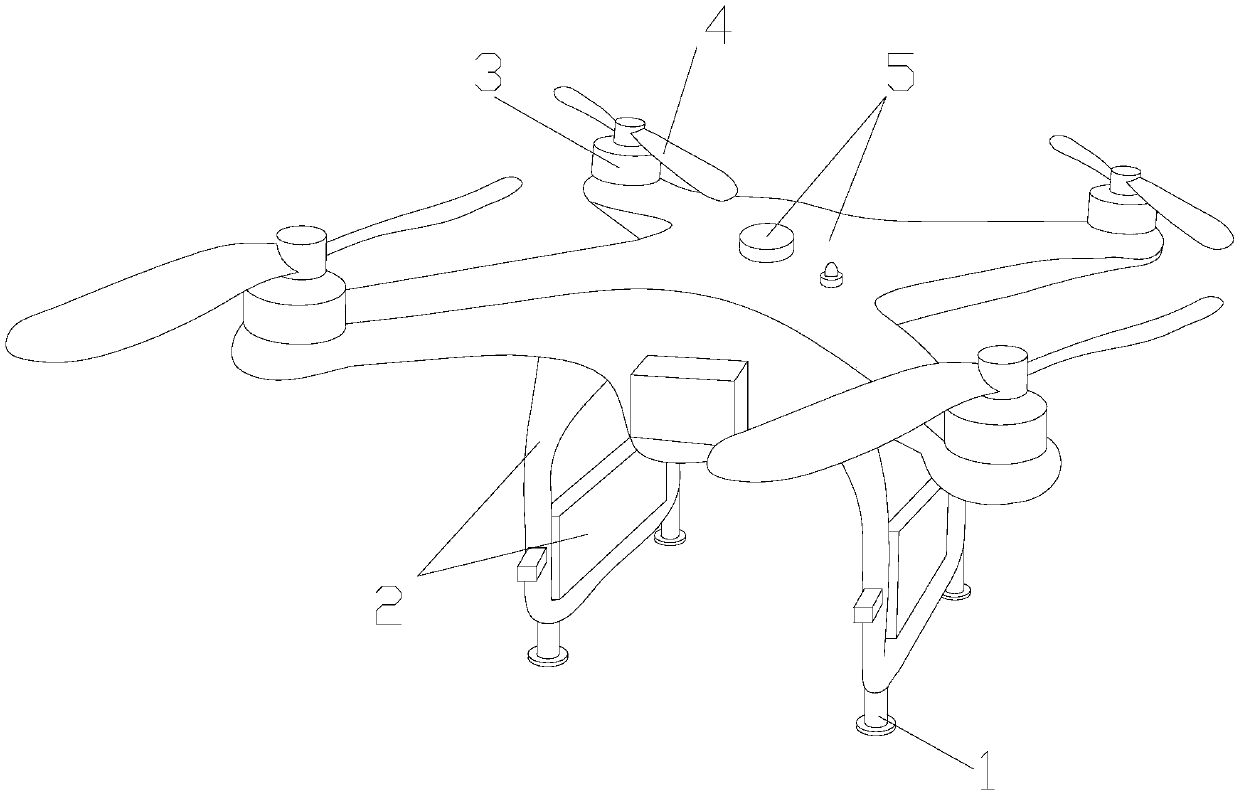

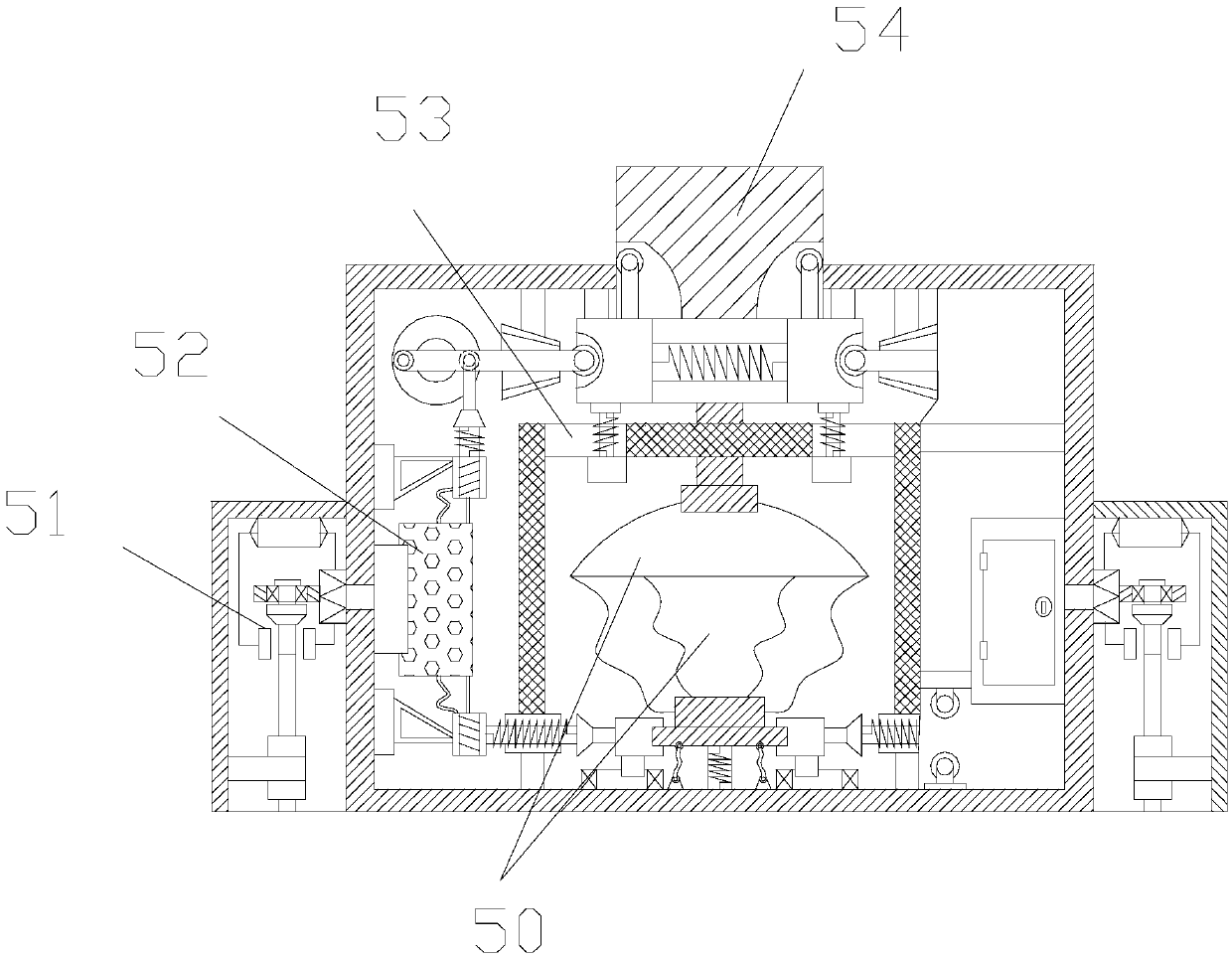

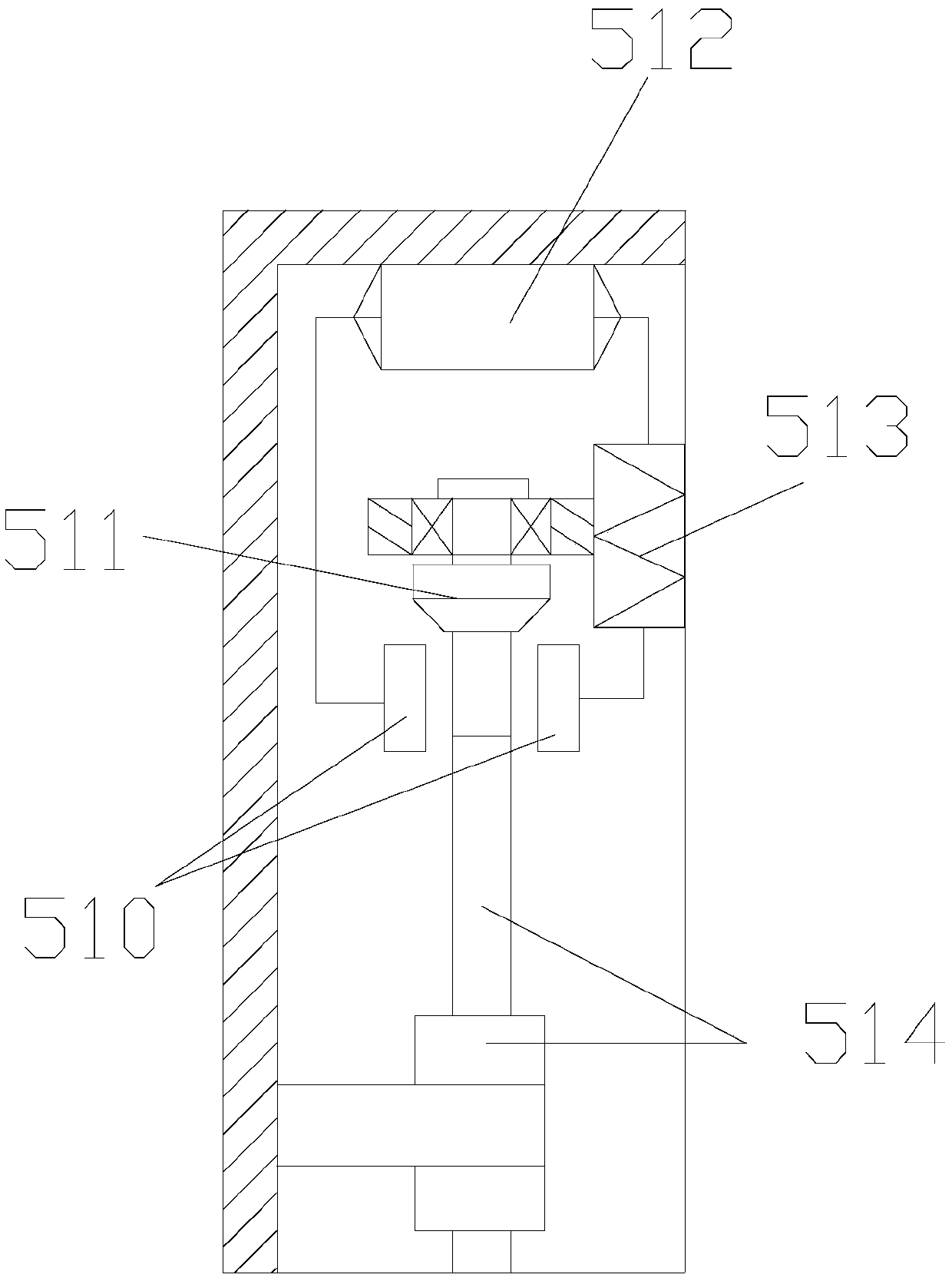

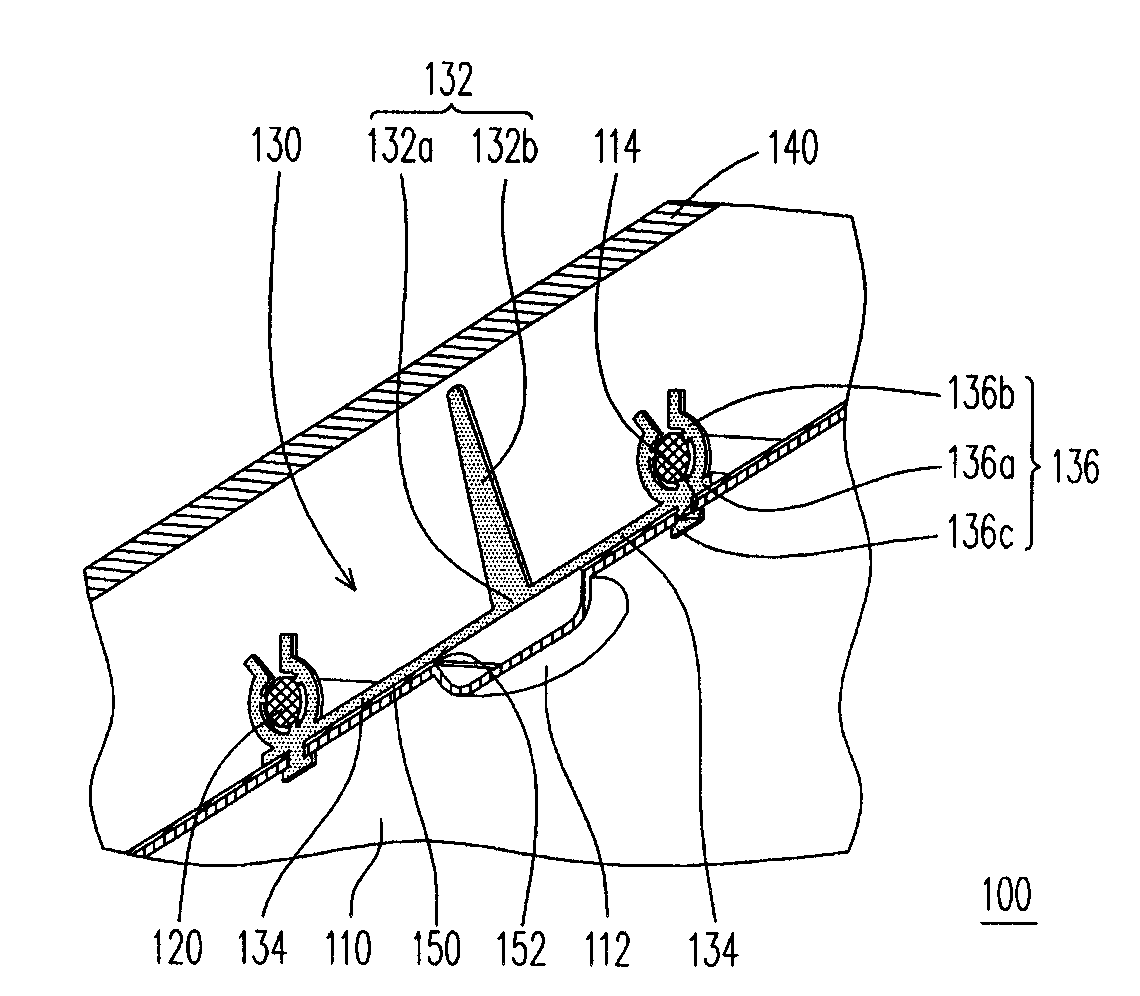

Anti-falling device for high-altitude robot based on rotation in cooperation with gravity sensing

InactiveCN109649663APrevent movementAvoid Adding Appearance BulkParachutesElectric power transmissionGear wheel

The invention discloses an anti-falling device for a high-altitude robot based on rotation in cooperation with gravity sensing. The anti-falling device structurally comprises an anti-skid foot stool,a support, a bearing connecting seat, a rotating blade and a sensitive anti-falling device. The rotating blade stops rotating together with a gear connecting rod, a rotating movable ring descends andis connected with an electric power transmission ring; meanwhile, an unmanned aerial vehicle starts to fall freely at high altitude, and a gravity sensor senses gravitational potential energy at the moment; and then a power transmission block can start a control power supply only by simultaneously triggering the unmanned aerial vehicle and the gravity sensor. The control power supply simultaneously starts an extrusion switch device and a loosening switch device, the unmanned aerial vehicle is prevented from moving up and down in high-altitude operation to trigger a single switch, and the appearance size is prevented from being increased, so that the starting of the anti-falling device is safer and more accurate; a parachute is ejected upwards together with a limit elastic block, by a parachute mode, it is sufficient to cope with vertical height differences, the gravitational potential energy is directly reduced by reducing the descent speed, and the protection effect of the unmanned aerial vehicle is fundamentally improved.

Owner:厦门慕婷服饰有限公司

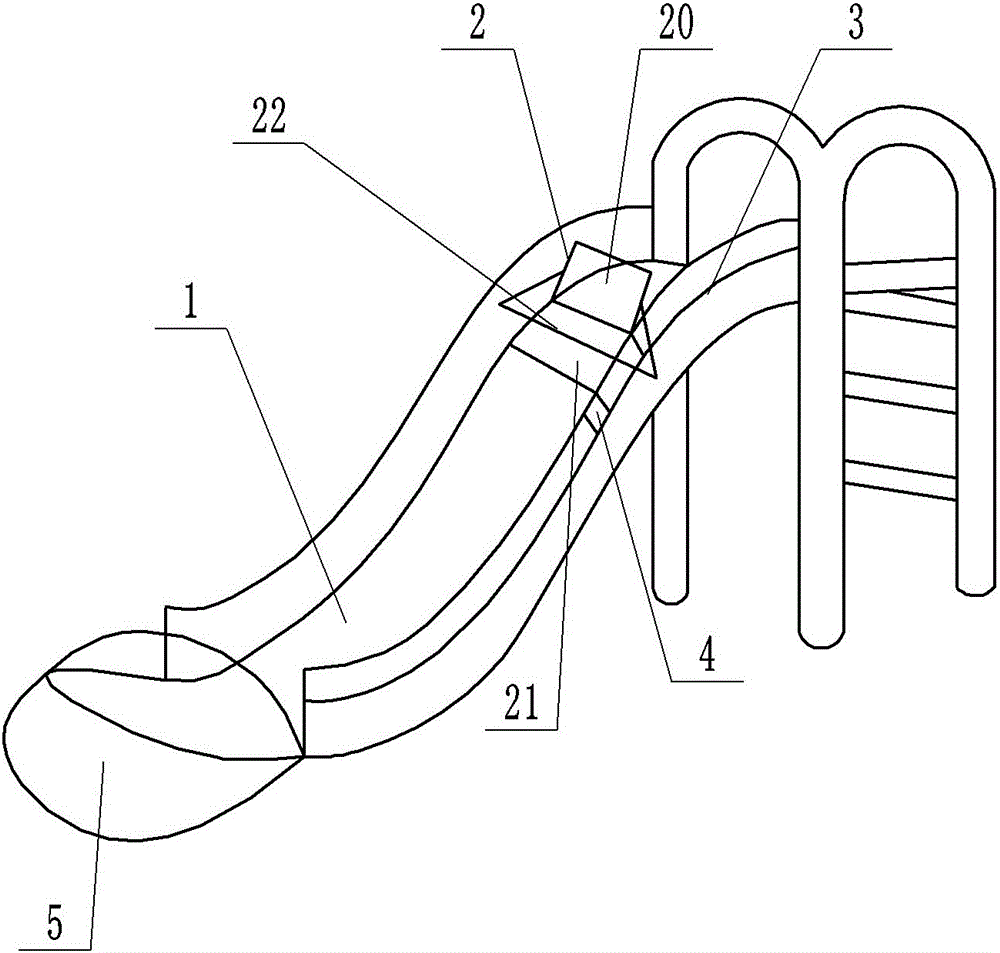

Water slide recreational equipment

ActiveCN106039719AReduce the momentary impactIncrease entertainmentHelter-skeltersWater slidingBed boards

The invention discloses water slide recreational equipment. The water slide recreational equipment comprises a slide bed board, a seat, a sliding block and a water sac, wherein guide rails are arranged on the two sides of the slide bed board in the length direction, and two strip-shaped grooves are formed in each guide rail in the length direction; the seat comprises a seat board and a backup plate, a protection rod is connected to the backup plate in a rotary mode, two lugs are arranged on the bottom portions of the two sides of the seat plate and in sliding fit with the guide rails, and the seat board is connected to the guide rails in a sliding mode; the sliding block in sliding fit with the guide rails is arranged on the side, close to the lower ends of the guide rails, of the seat, and the water sac is arranged at the lower ends of the guide rail.

Owner:来安县永阳知识产权运营有限公司

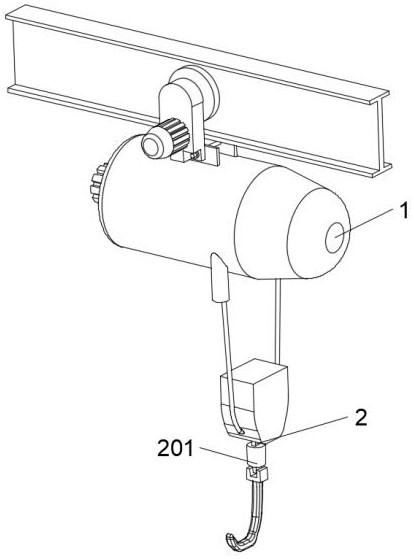

Electric hoist with low-friction spherical hinge

InactiveCN114394527AImprove securityReduce wearNon-rotating vibration suppressionWinding mechanismsClassical mechanicsStructural engineering

The invention discloses an electric hoist with a low-friction type spherical hinge, and belongs to the field of electric equipment.The electric hoist with the low-friction type spherical hinge comprises an electric hoist body, the lower end of the electric hoist body is connected with a spherical hinge connecting shaft, and the outer end of the spherical hinge connecting shaft is wrapped with a hard protective shell barrel; the flexible buffer hemispheres are symmetrically and fixedly mounted in the spherical hinge connecting shaft, and through cooperative use of the flexible buffer hemispheres and the flexible anti-friction blocks, instantaneous traction force generated when the electric hoist is started is decomposed and offset, and damage caused by instantaneous impact force to the spherical hinge connecting shaft and the flexible buffer hemispheres is reduced; when the flexible buffer hemisphere deforms due to traction, the surface of the flexible anti-friction block is lubricated, abrasion of the surface of the flexible buffer hemisphere and aging of rubber are reduced, the service life of the device is effectively prolonged, the damping effect of the spherical hinge connecting shaft during instantaneous traction is improved, and then the use safety of the electric hoist body is effectively improved.

Owner:南通鼎城船舶技术有限公司

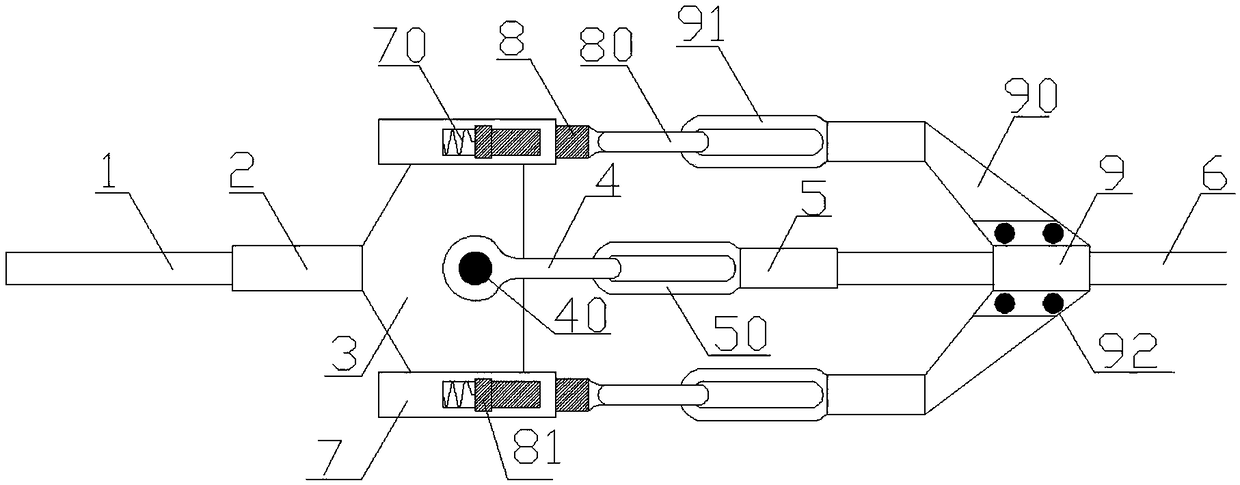

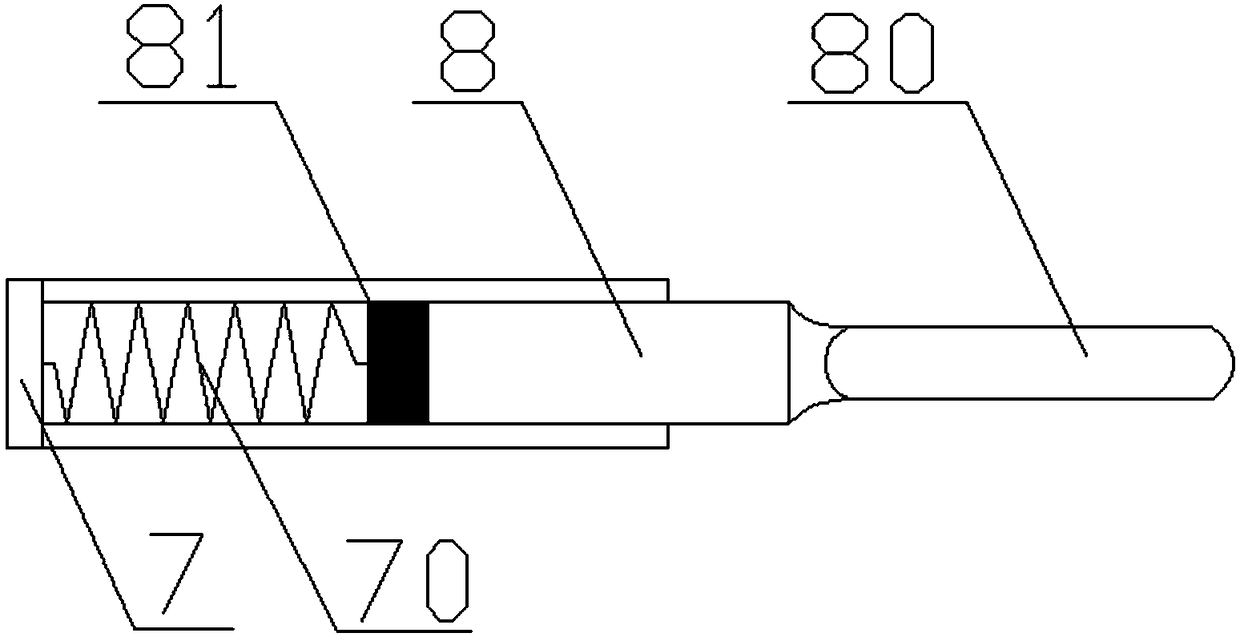

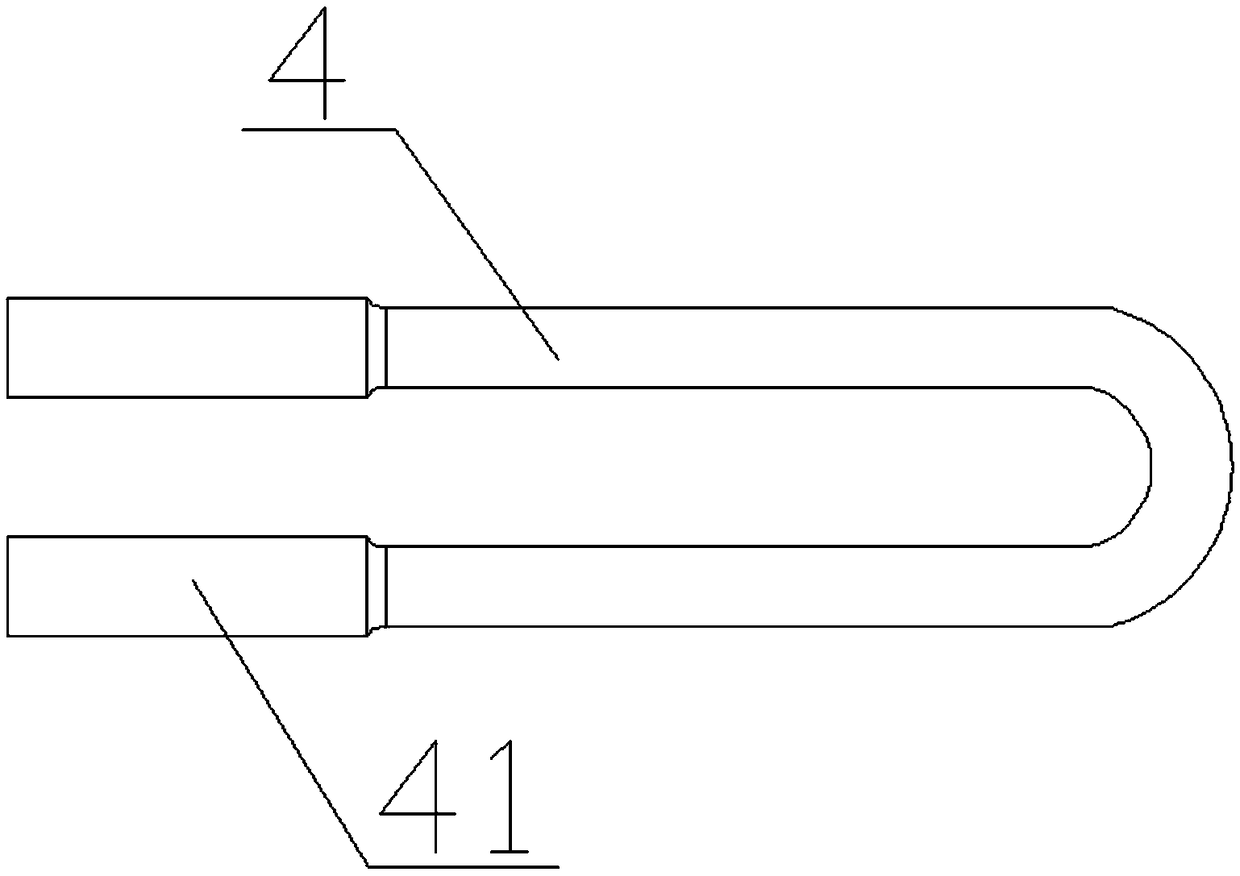

A double-protection connection device with buffer overhead ground wire

InactiveCN109066553AReduce the momentary impactPlay the role of load-bearing connectionAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesEngineeringMechanical engineering

A double-protection connection device with a buffer overhead ground wire includes a connecting rod, a Fixture, a triangular connection plate, a main load-bearing terminal ring, a main load-bearing wire clamp, a spare connecting guide, a Backup connection pillar and standby wire clip, By setting a spare connecting guide, A standby connection guide post and a standby wire clamp form a standby connection piece, so that the main load-bearing terminal ring or the main load-bearing wire clamp can play a load-bearing connection role after the main load-bearing wire clamp is damaged, At the same time,a cushion spring is arranged between the standby connection guide sleeve and the standby connection guide post, As a result, after the main load-bearing terminal ring or the main load-bearing wire clamp is broken, the spare connector is shifted from being slightly stressed to undertaking all the tensile forces of the overhead wire, and the instantaneous impact force is buffered to protect the spare connector. The invention provides double protection for the overhead ground wire connection and reduces the instantaneous impact force with its own buffer.

Owner:ANHUI HUAXI ELECTRIC POWER TECH CO LTD

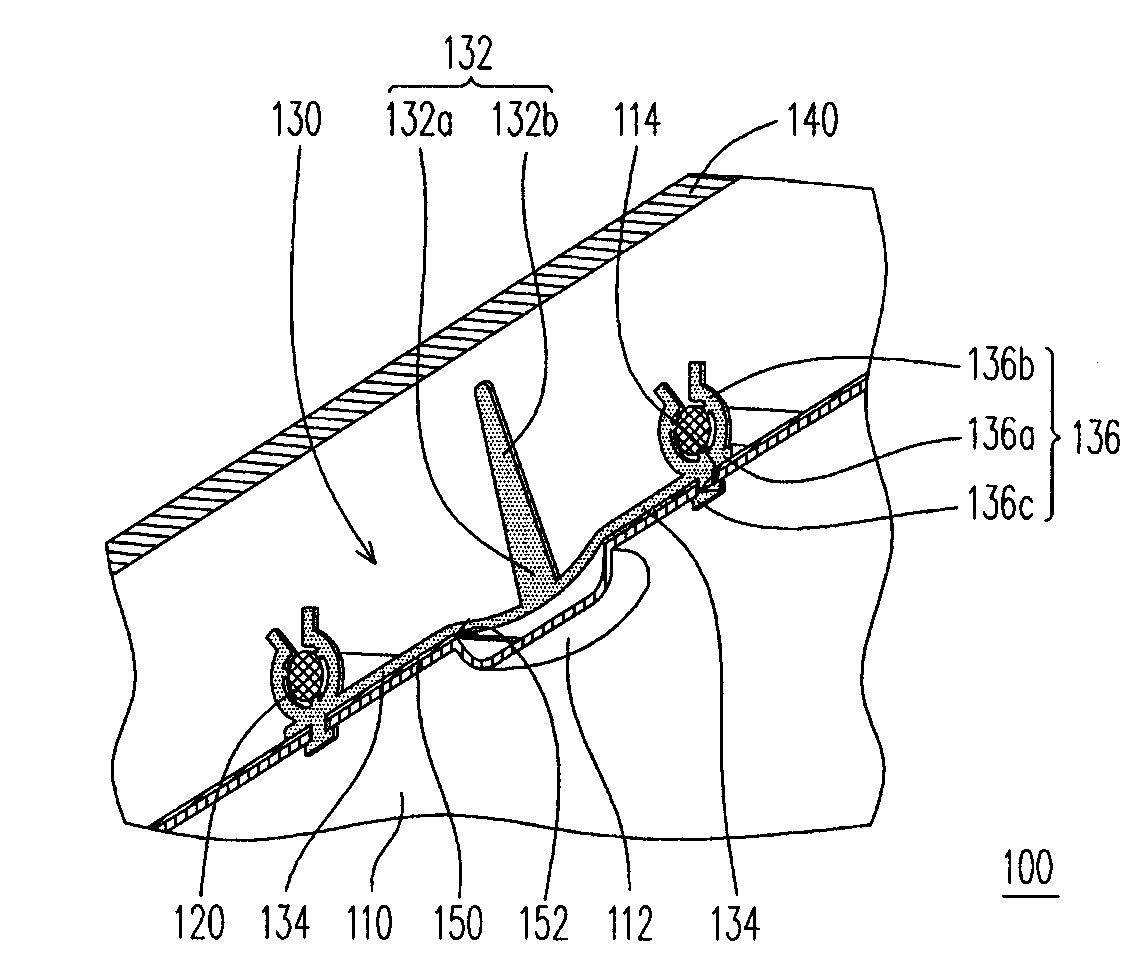

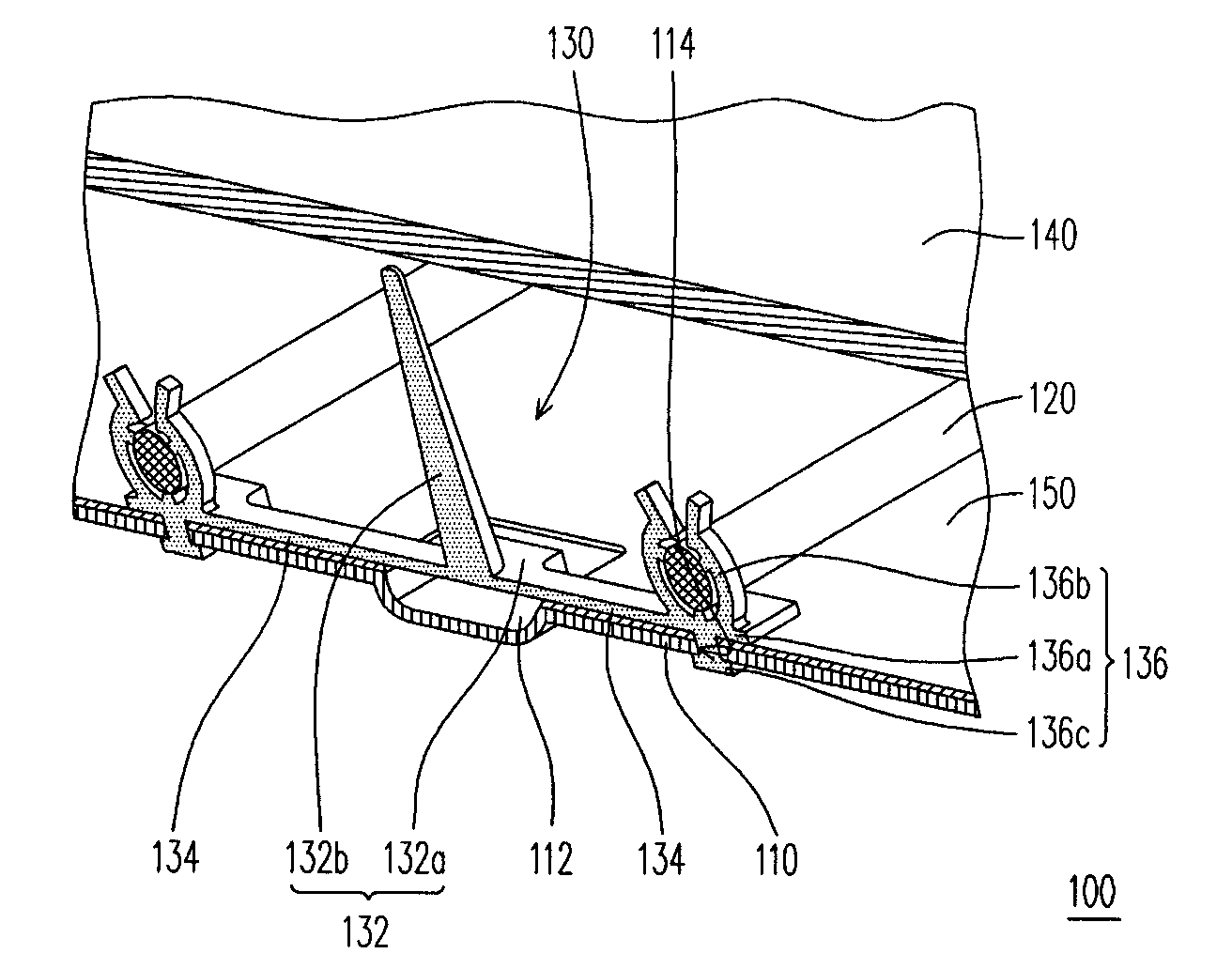

Backlight module

ActiveCN101788119AReduce the momentary impactAvoid damageNon-linear opticsLight fasteningsVertical projectionEngineering

The embodiment of the invention provides a backlight module which comprises a back plate, a plurality of lamp tubes, a lamp tube fixing seat and a diffusion plate, wherein the back plate is provided with a depression; the lamp tubes are arranged on the back plate; the lamp tube fixing seat is arranged on the back plate and used for fixing the lamp tubes; the lamp tube fixing seat is provided with a support part which extends towards a direction away from the back plate; a vertical projection of the support part on the back plate is positioned in the depression; and the diffusion plate is arranged above the back plate, and the support part is used for supporting the diffusion plate. By the embodiment, the force that the support part acts on the diffusion plate can be buffered and the instant impact force suffered from the diffusion plate and the damaged probability of the diffusion plate due to the impact of the support plate are reduced.

Owner:AU OPTRONICS CORP

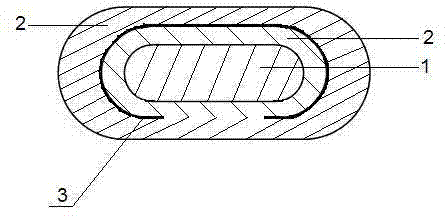

Quake-proof anchor rope

InactiveCN101666093BReduce the momentary impactPrevent overloadExcavationsAnchoring boltsEngineeringImpact energy

The invention discloses a quake-proof anchor rope which comprises a free section and an anchoring section, wherein the anchoring section is provided with a quake-proof anchoring device; the quake-proof anchoring device comprises a bearing plate, a quake-proof anchorage device and a permanent anchorage device; a anchor rope passes through the bearing plate and sequentially passes through the quake-proof anchorage device and the permanent anchorage device; the quake-proof anchorage device has a slidable extruding sleeve structure for setting the maximum anchoring force; the quake-proof anchorage device is pressed tightly at the inner side of the bearing plate; the permanent anchorage device is a standard extruding sleeve; a certain distance is arranged between the permanent anchorage and the quake-proof anchorage device; when earthquake occurs, huge impact energy is generated instantly so as to lead the stress of the anchor rope to be increased dramatically; in the invention, when the instant impact force born by the anchor rope exceeds the largest static frictional force between the quake-proof anchorage device and the anchor rope, the anchor rope slides relatively to the quake-proof anchor rope, thus buffering the instant impact force of the earthquake; and simultaneously, the absolute length of the free section of the anchor rope is lengthened, thus further reducing the instant impact force born by the anchor rope, preventing the anchoring system from overloading or the rope body from being snapped, and achieving the purpose of quake proof.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

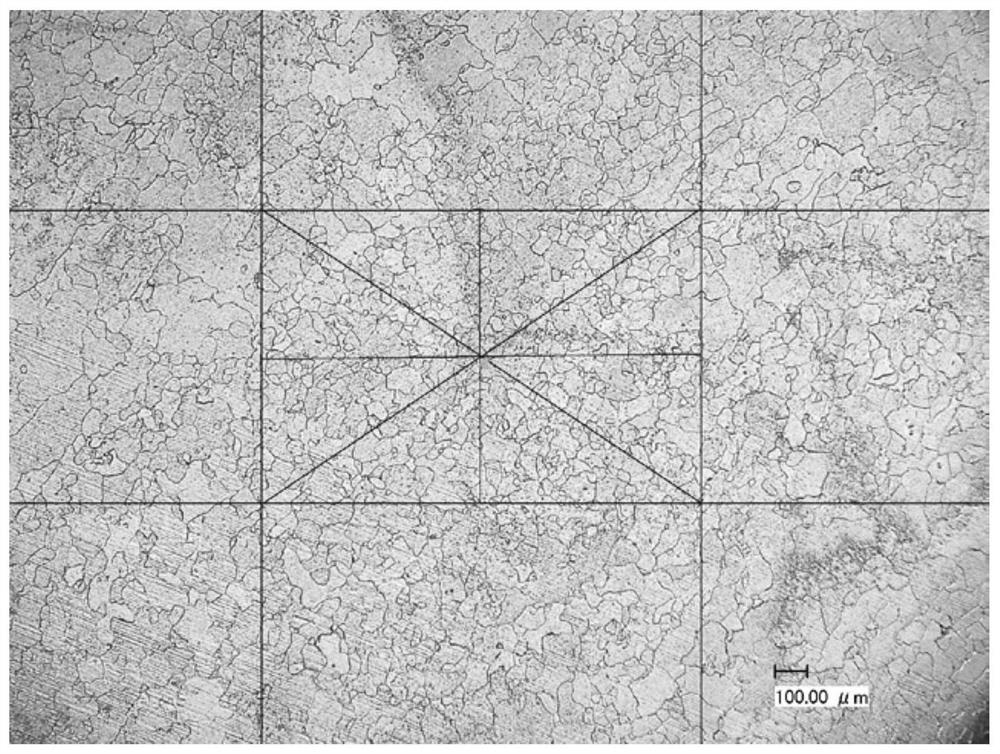

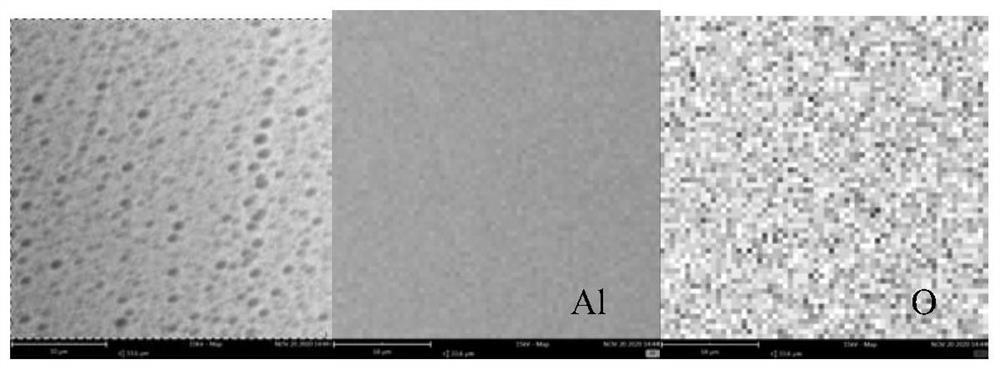

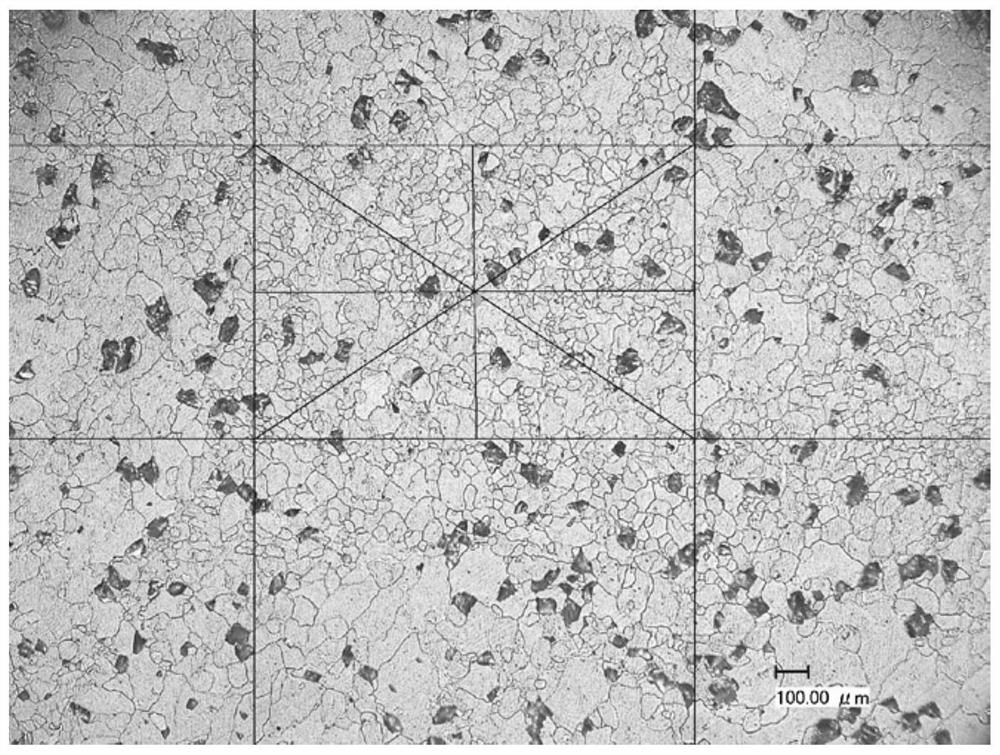

Method for manufacturing aluminum-silicon target material

ActiveCN112538598AGuaranteed mechanical propertiesGuaranteed film qualityVacuum evaporation coatingSputtering coatingIngot castingHeat conservation

The invention relates to a method for manufacturing an aluminum-silicon target material. The method comprises the following steps of: providing an AlSi ingot casting step, a drawing step, a primary upsetting step, an intermediate heat treatment step, a secondary upsetting step, a preheating treatment step, a calendaring step and an annealing heat treatment process step, wherein cold drawing operation is used in the drawing step, and a forging ratio X1 in the cold drawing operation is gerater than or equal to 1 and less than 2; in the primary upsetting step, a forging ratio X2 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for primary upsetting; in the intermediate heat treatment step: a product is kept within a first preset temperature range, and is quickly put into cold water after being subjected to heat preservation for first preset time; in the secondary upsetting step, a forging ratio X3 is greater than or equal to 2 and smaller than 3, and cold heading operation is used for secondary upsetting; in the calendaring step: multi-pass calendaring is performed on the product, and reducing rolling reduction along with increase of calendaring passes; and in the annealing heat treatment process step: in an annealing temperature range, heat preservation is performed for third time, and water cooling treatment is performed to form a final targetproduct. According to the method, the forging ratio is reasonably controlled, water cooling is adopted for cooling, so that Si element precipitation is reduced, and therefore the microstructure and the machining performance of the target material are guaranteed.

Owner:爱发科电子材料(苏州)有限公司

Airflow direction controllable air bag apparatus

InactiveCN101353037AReduce the momentary impactAvoid harmPedestrian/occupant safety arrangementEngineeringAirbag

The invention relates to an air cell device that can control airflow direction, comprising a module bracket that is provided with an air generator and an air bag, the air bag is provided with a drawstring, a piece of cloth is arranged in the air bag along the vertical direction, one end of the drawstring is connected with the cloth, the other end is fixed on the root of the air bag, the middle of the front of the air bag is connected with the cloth by lacerable sewing thread or adhesive tape. The air cell device has the advantages as follows: the device has simple structure and can realize that two sides of the air bag are expanded firstly, and then the middle part is expanded, thus controlling the expanding speed of the middle in the front of the air bag, reducing momentary impact on a passenger in the expanding process of the air bag and avoiding the damage to the passenger in the initial stage of expanding; the device can provide protection for the passenger of normal sitting posture after complete expansion, the vehicle structure does not need to be changed, the device is compatible with the current safety air cell system, high protection property can be realized only by the current igniting circuit, and the device can satisfy higher and higher demands of consumers on passive safety .

Owner:JINZHOU JINHENG AUTOMOTIVE SAFETY SYST

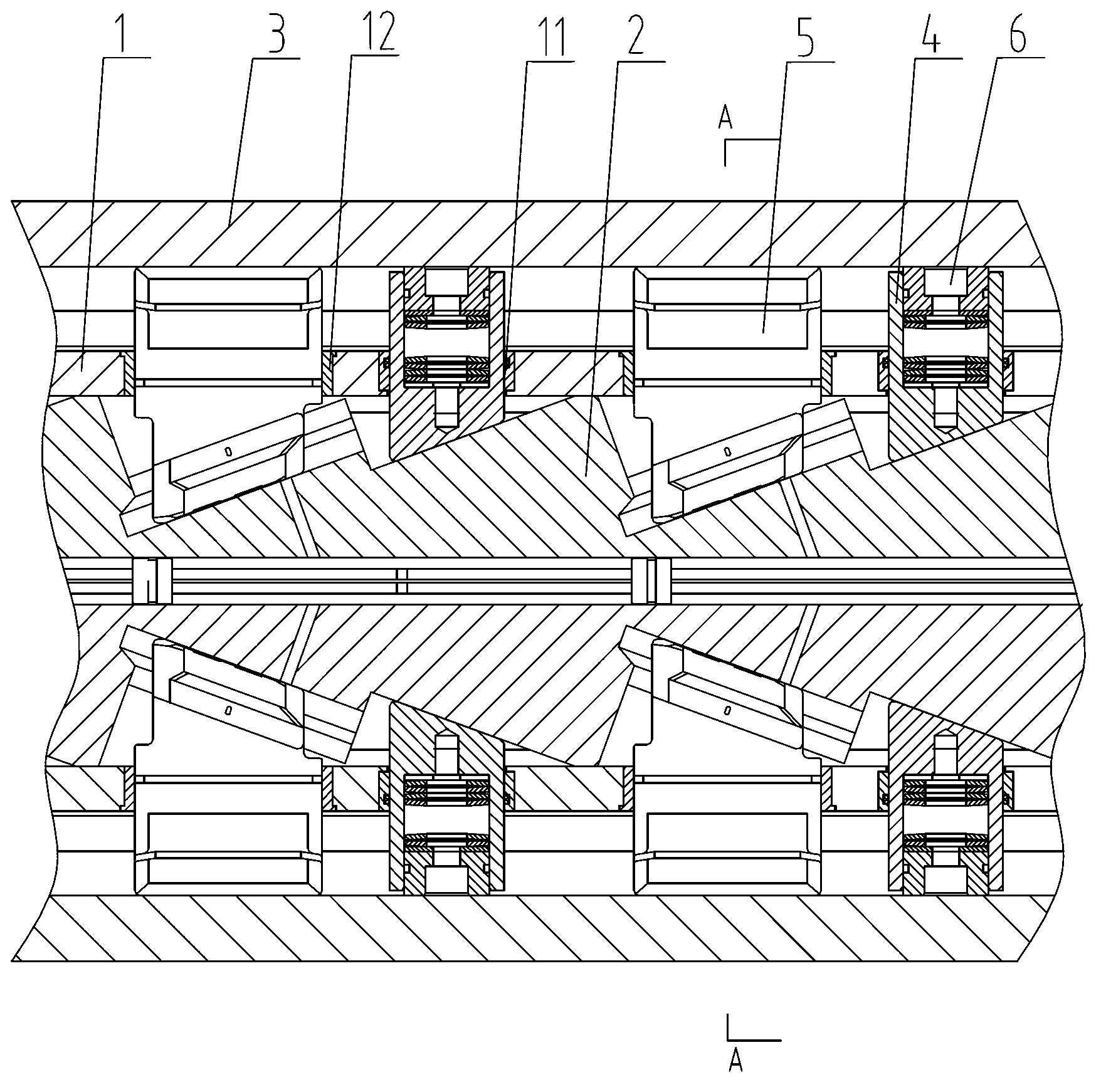

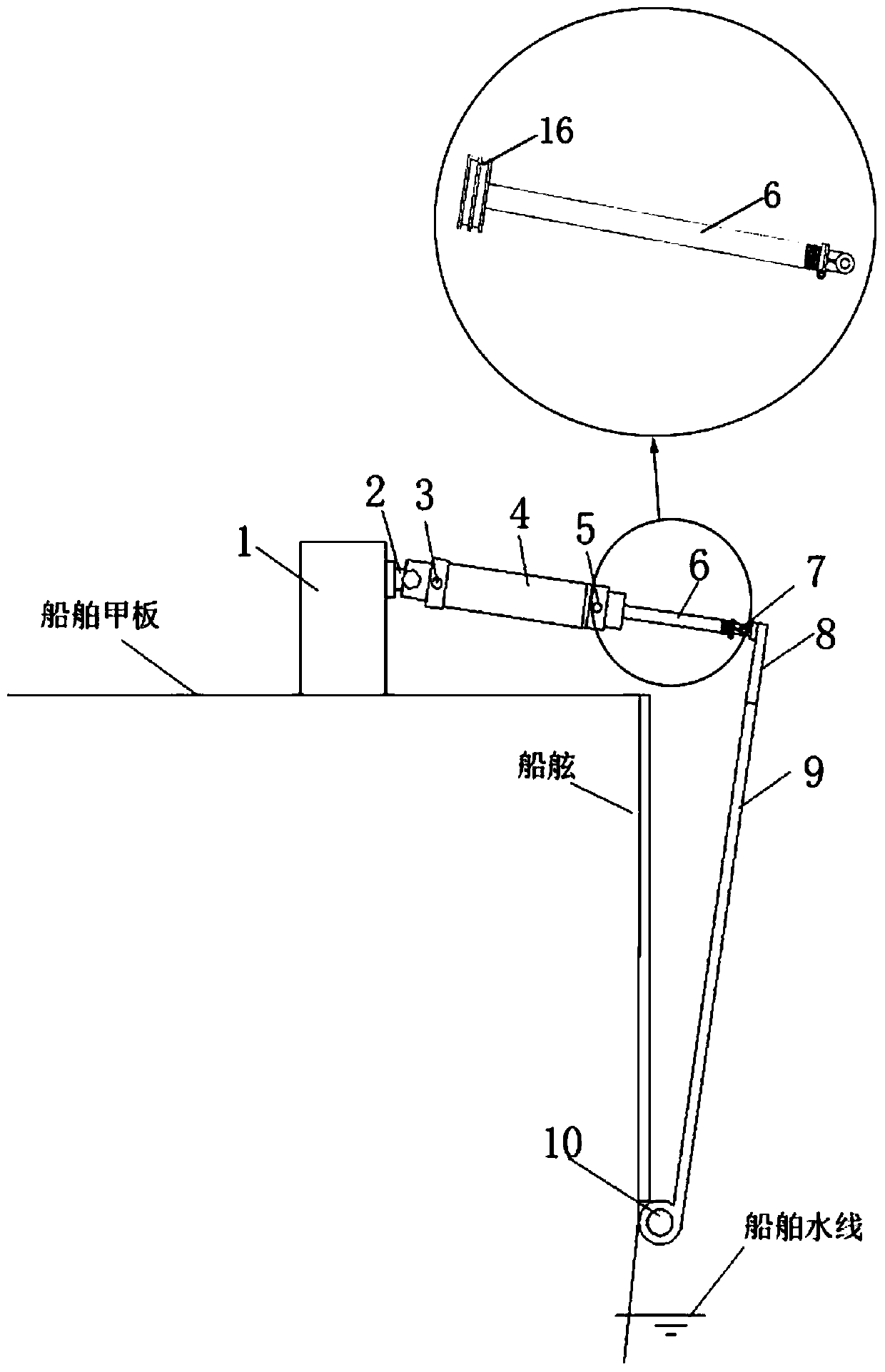

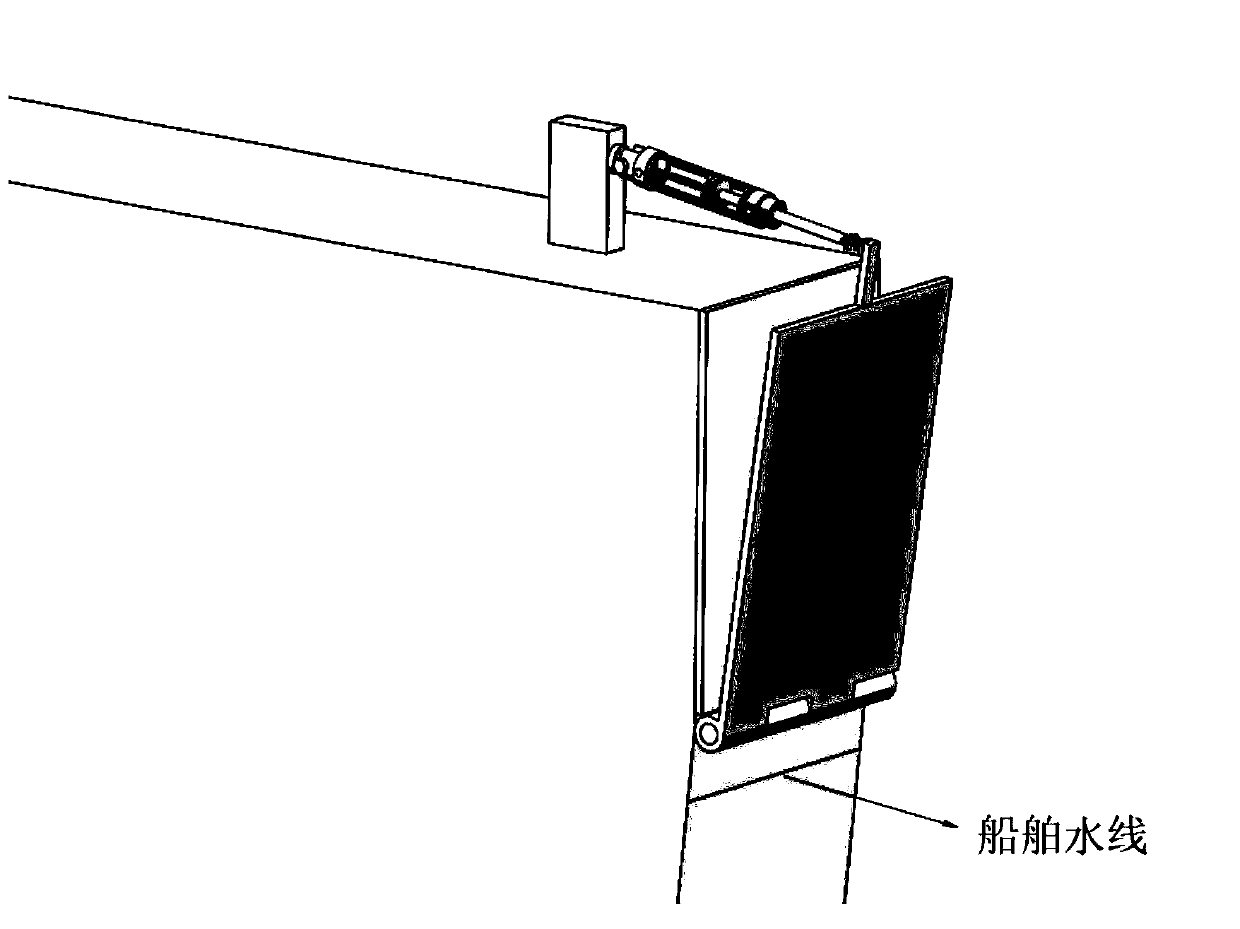

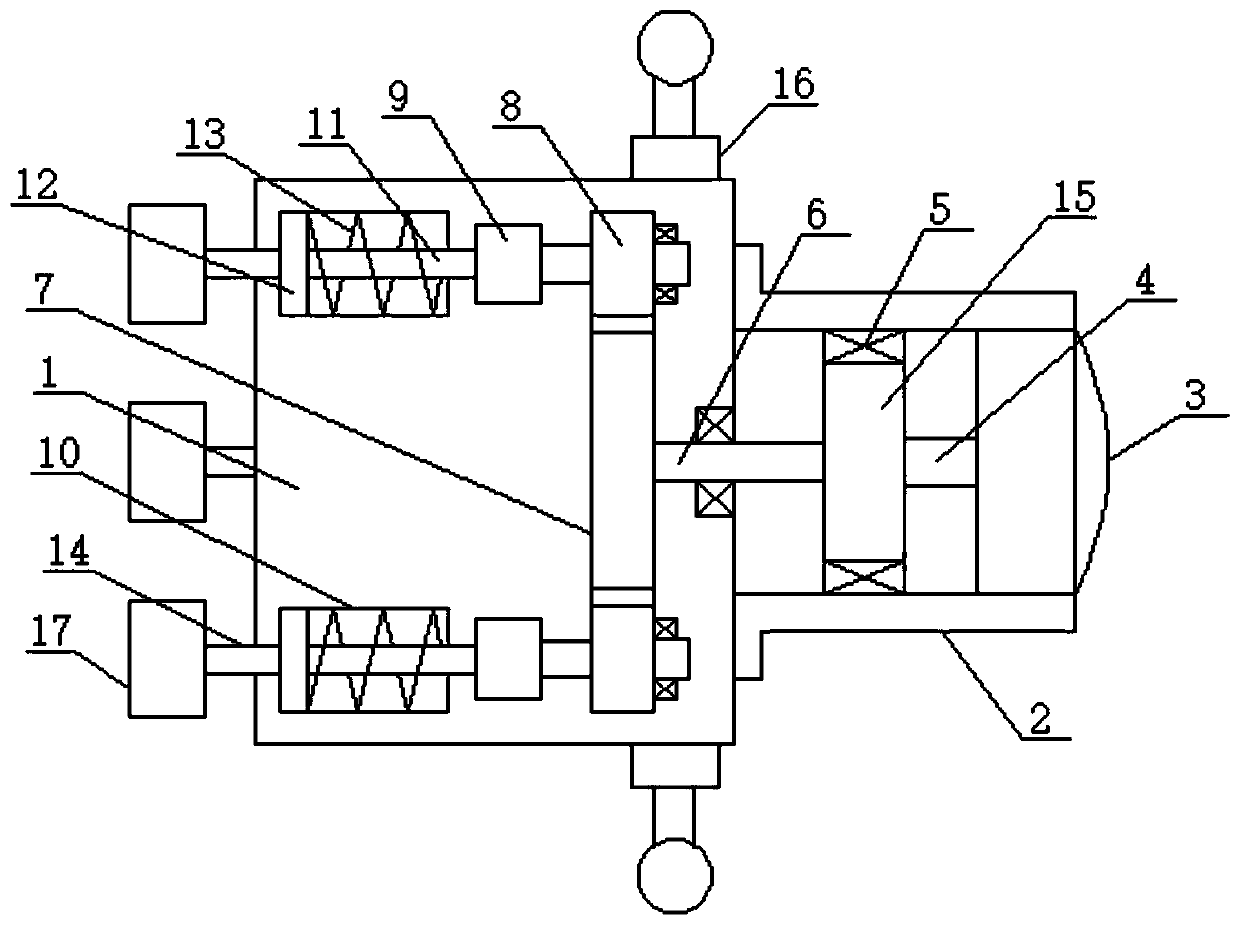

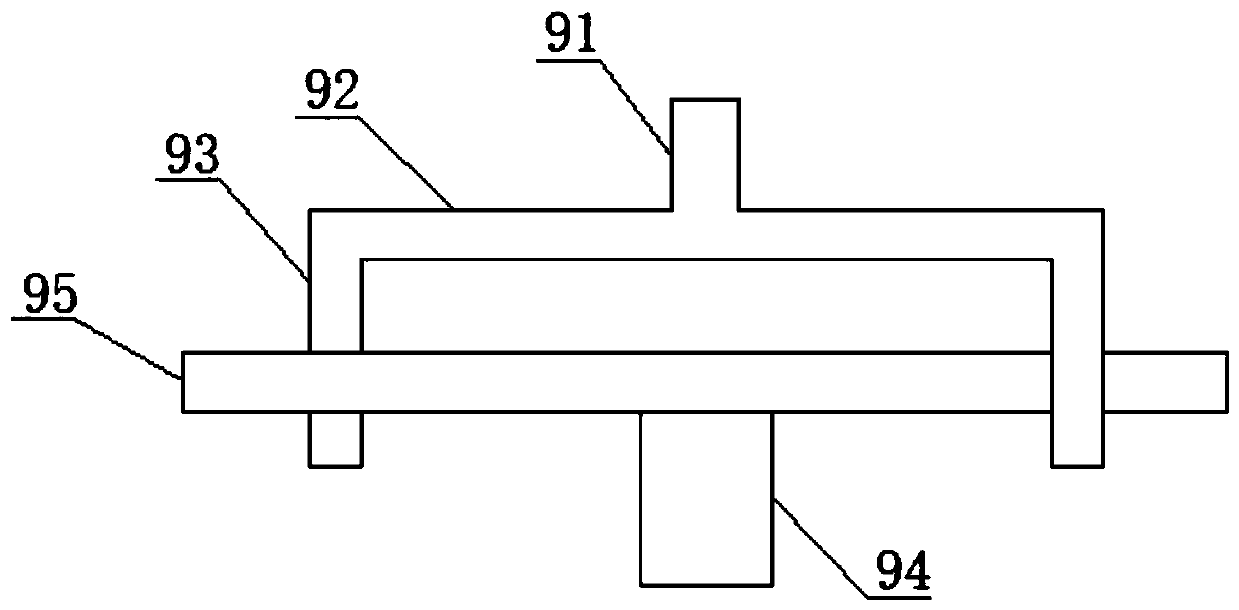

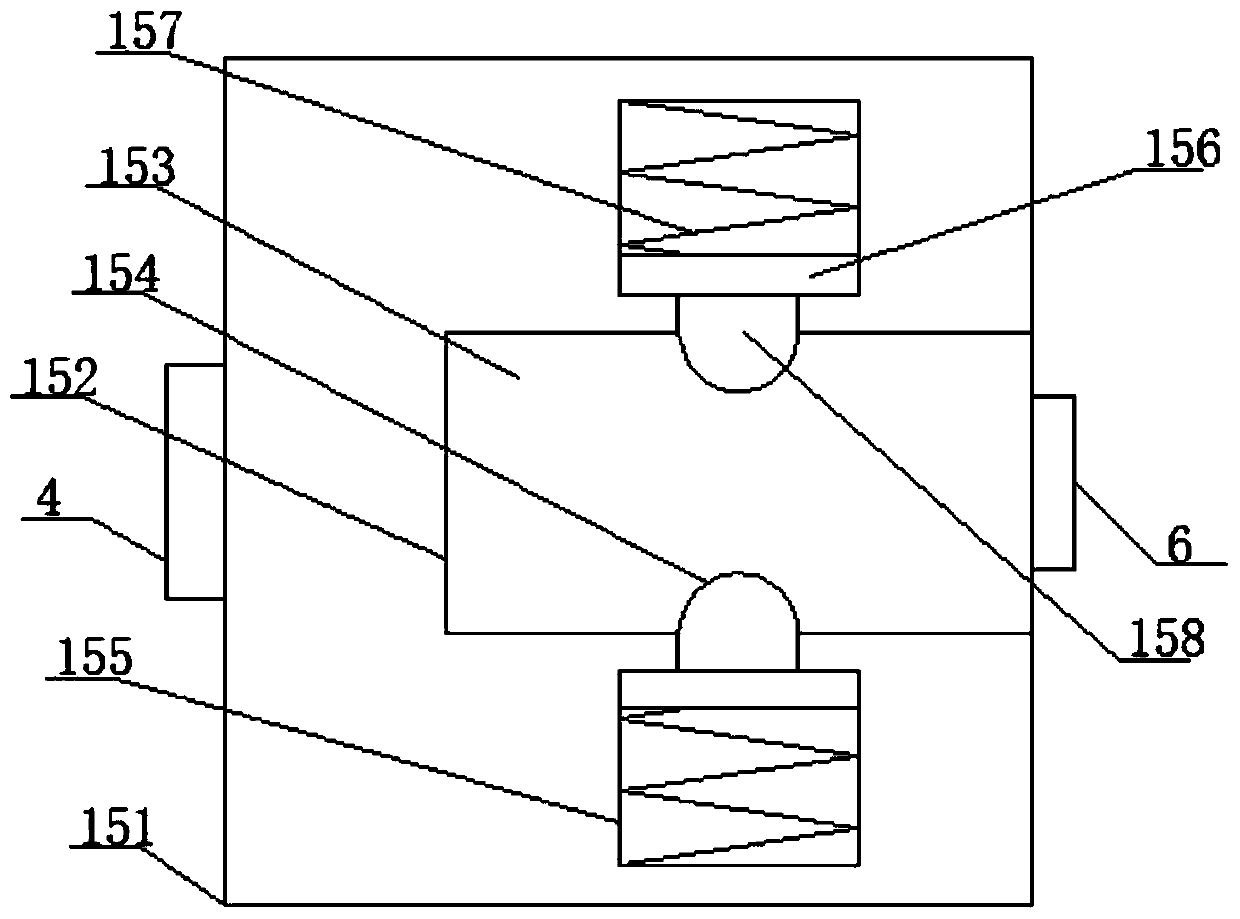

Power generation device for ship by utilizing wave energy

PendingCN111472922ASolve the problem that it is difficult to use wave energyReduce fuel consumptionMachines/enginesEngine componentsOn boardGenerating capacity

The invention discloses a power generation device for a ship by utilizing wave energy. The device mainly comprises a wave energy collecting device and a hydraulic system. The device is symmetrically installed on a larboard and a starboard of the ship, the wave energy of the left and right sides of the ship is utilized by the wave energy collecting device and converted into pressure energy in hydraulic oil, and then the pressure energy is converted into electric energy through the hydraulic system to provide part of power for the ship, so that the effective utilization of the wave energy in thesailing process of the ship is realized. In addition, the existence of an energy collecting plate in the device plays a role in buffering the impact of waves, and the rolling degree of the ship can be properly reduced; more importantly, the ship length of the ship is long, the area of the left and right sides impacted by the waves is large, multiple sets of devices can be installed on the ship, and larger power generation quantity can be generated; and the device is simple in method and wider in application range.

Owner:QINGDAO UNIV OF SCI & TECH

Friction inserting type clutch and its mfg. method

A friction-jaw clutch. Driving disc is equipped on the driving wheel, and driven disc is equipped on the driven shaft. The driven disc and the driven shaft are tabled at radial direction, and skidding bond at axial direction; and driven spring is equipped on the driven shaft. The character is that dogtooth or beard is equipped on the driving disc, the correspondent is equipped on the driven disc, but they are asymmetrical shape. Backlash of the dogtooth and beard is less than four millimeter, or fit angle is less than four degree. The invention has the advantage of friction and jaw clutch.

Owner:葛玉明

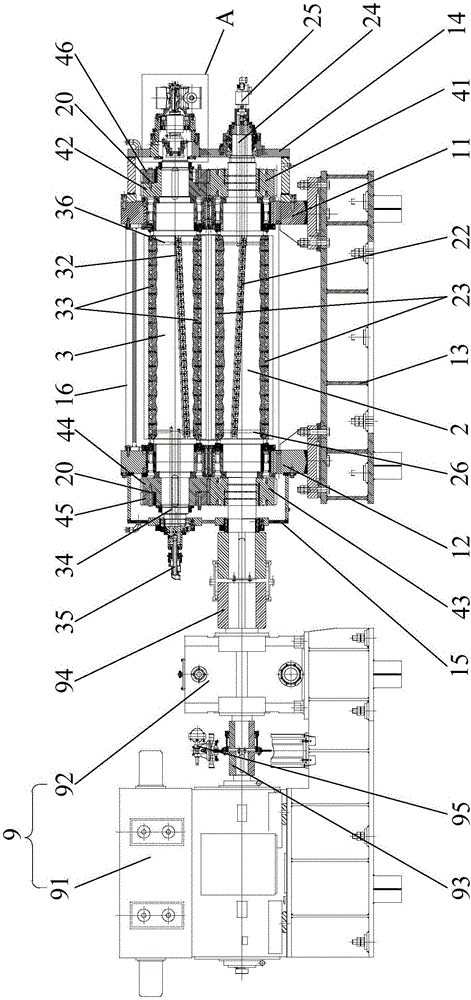

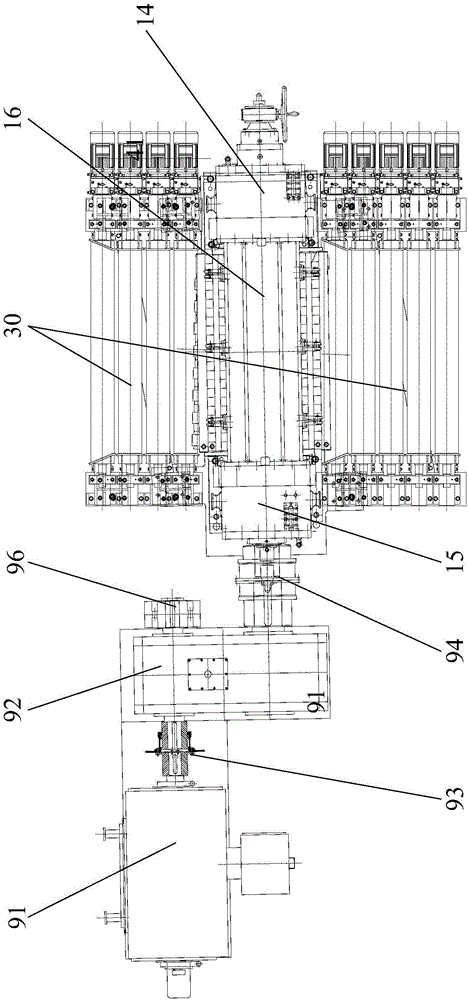

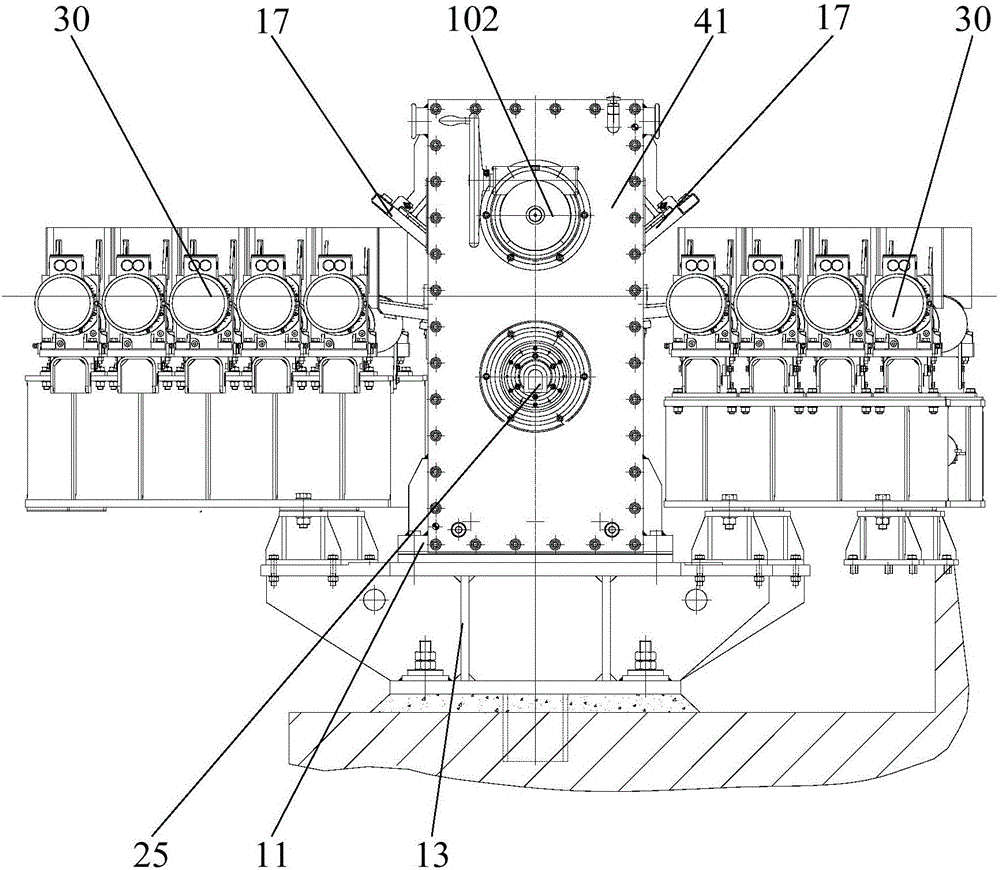

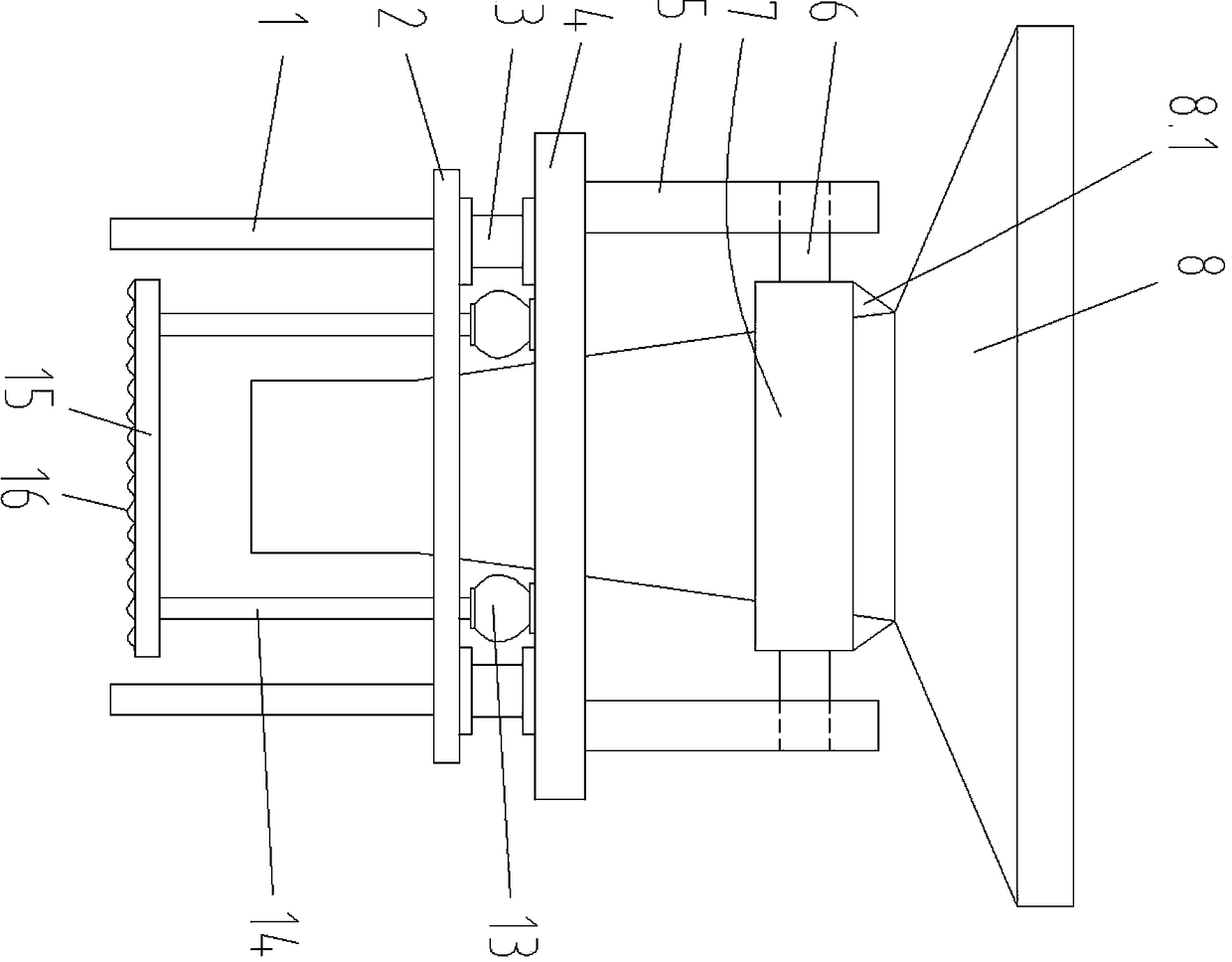

Drum flying shears

ActiveCN106363229AReduce weightMeet the cutting precision requirementsStock shearing machinesEngineeringHelix angle

The invention provides drum flying shears. The drum flying shears comprise a rack, wherein the upper part of the rack is rotationally connected with a driving cutter shaft and a driven cutter shaft which are parallel and overlaid in a spaced manner, the driving cutter shaft and the driven cutter shaft have equal diameter and are connected through a transmission mechanism, a linear first cutter groove and a cylindrical-helix-shaped second cutter groove are formed in a spaced manner in the outer surface of the driving cutter shaft in the axial direction, a linear third cutter groove and a cylindrical-helix-shaped fourth cutter groove are formed in a spaced manner in the outer surface of the driven cutter shaft in the axial direction, the fourth cutter groove and the second cutter groove have identical helix angle and opposite rotating directions, and shear blades are arranged in the first cutter groove, the second cutter groove, the third cutter groove and the fourth cutter groove respectively; a drive mechanism is connected with the driving cutter shaft and drives the driving cutter shaft to rotate, and the driving cutter shaft drives the driven cutter shaft through the transmission mechanism to rotate synchronously in the opposite direction. According to the provided drum flying shears, thick and thin strips with large thickness change ranges are sheared, the shearing precision is guaranteed, and the shearing impact is reduced.

Owner:CERI TECH +1

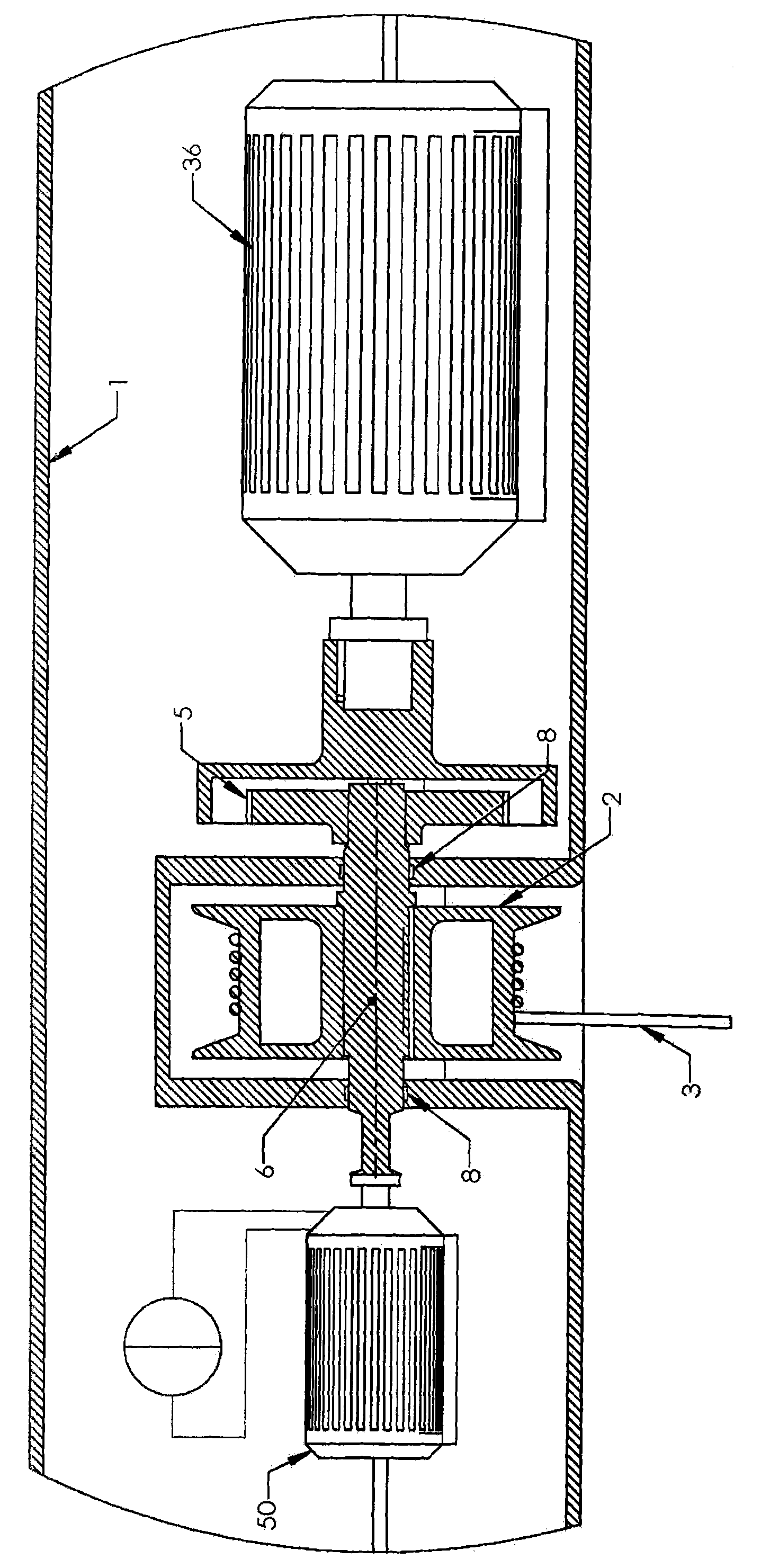

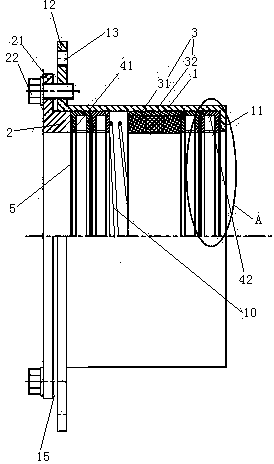

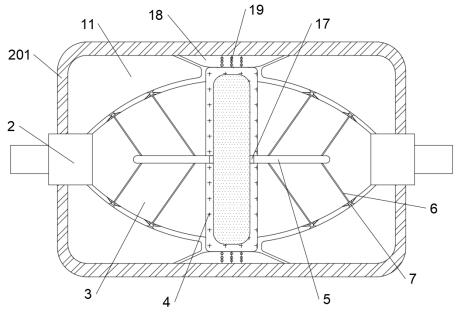

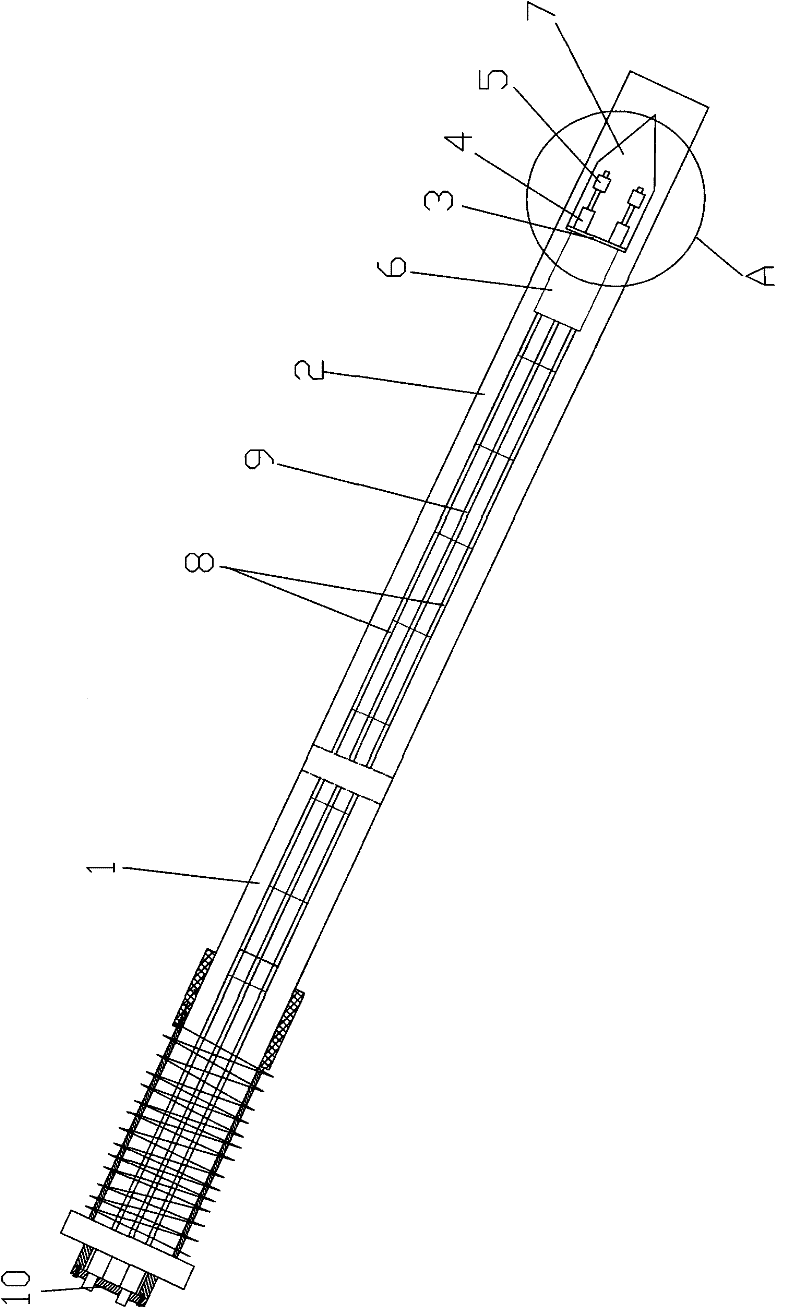

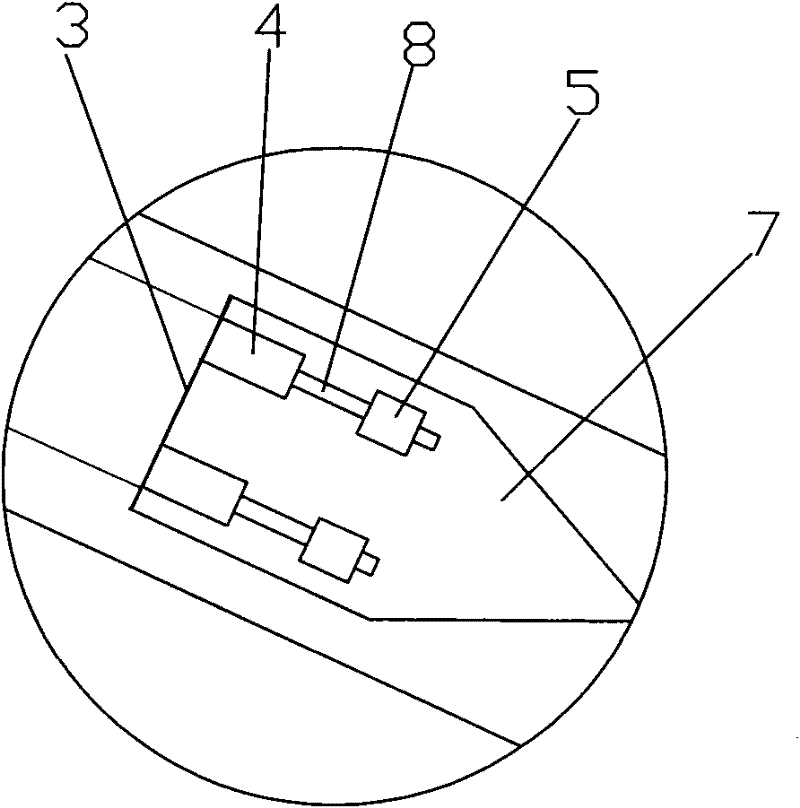

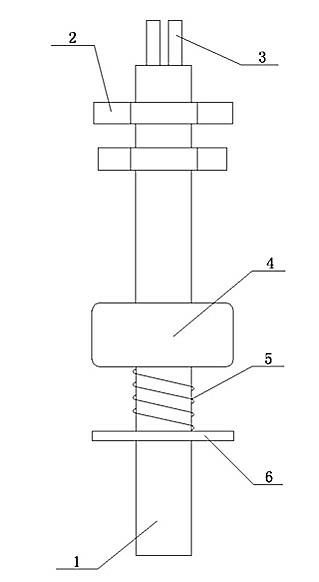

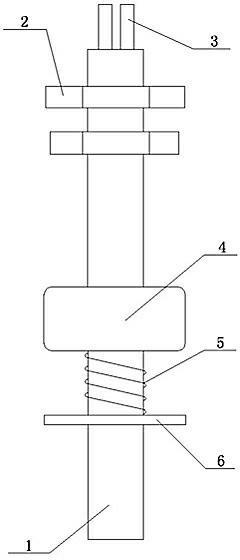

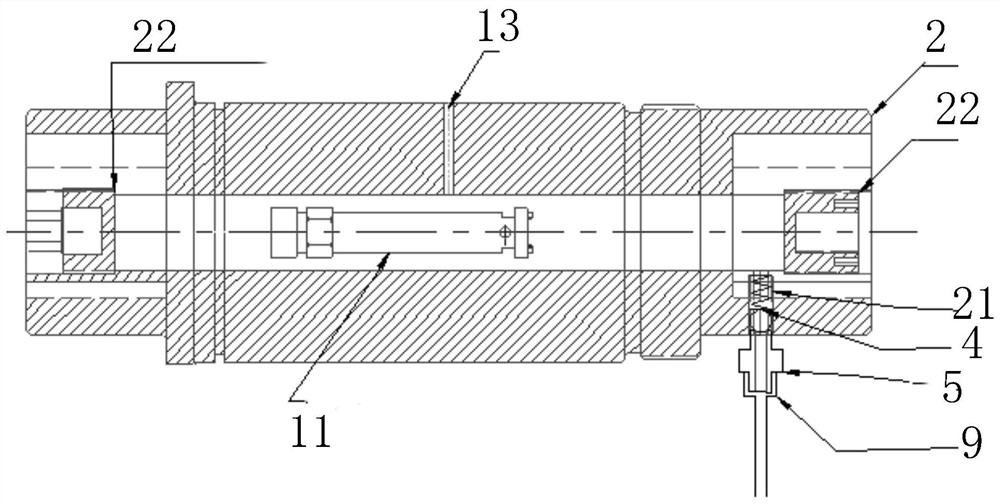

Damped sensor for detecting oil quantity of oil tank

InactiveCN102426045AReduce the momentary impactAvoid stickingLevel indicators by floatsFuel tankPetroleum engineering

The invention discloses a damped sensor for detecting the oil quantity of an oil tank. The damped sensor is provided with a measuring tube (1), wherein a fixed end (2) and a wiring terminal (3) are arranged at the upper end of the measuring tube (1); a magnetic floating fall (4) is sleeved outside the measuring tube (1); the lower part of the magnetic floating ball (4) is connected with a damping fin (6) through a spring (5); and the spring (5) and the damping fin (6) are respectively sleeved outside the measuring tube. According to the damped sensor disclosed by the invention, the transient impact force of the liquid level for the magnetic floating ball during shake in a wide range can be effectively relived; the locking or damaging of the magnetic floating ball is avoided; the service life of the sensor is prolonged (can reach about one year); the loss and the cost are reduced; the detection precision of the oil quantity is increased; and the reliable detection of the oil quantity of locomotives such as forklift trucks and the like in a work state is realized.

Owner:DALIAN AULEI TECH

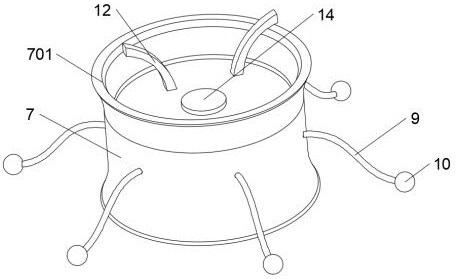

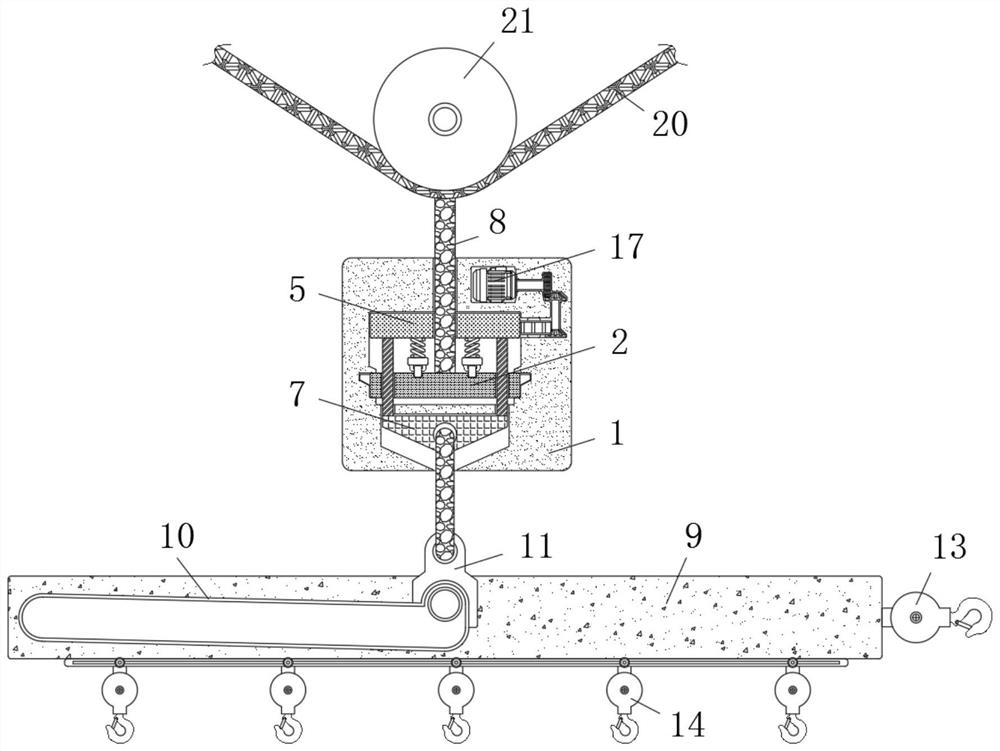

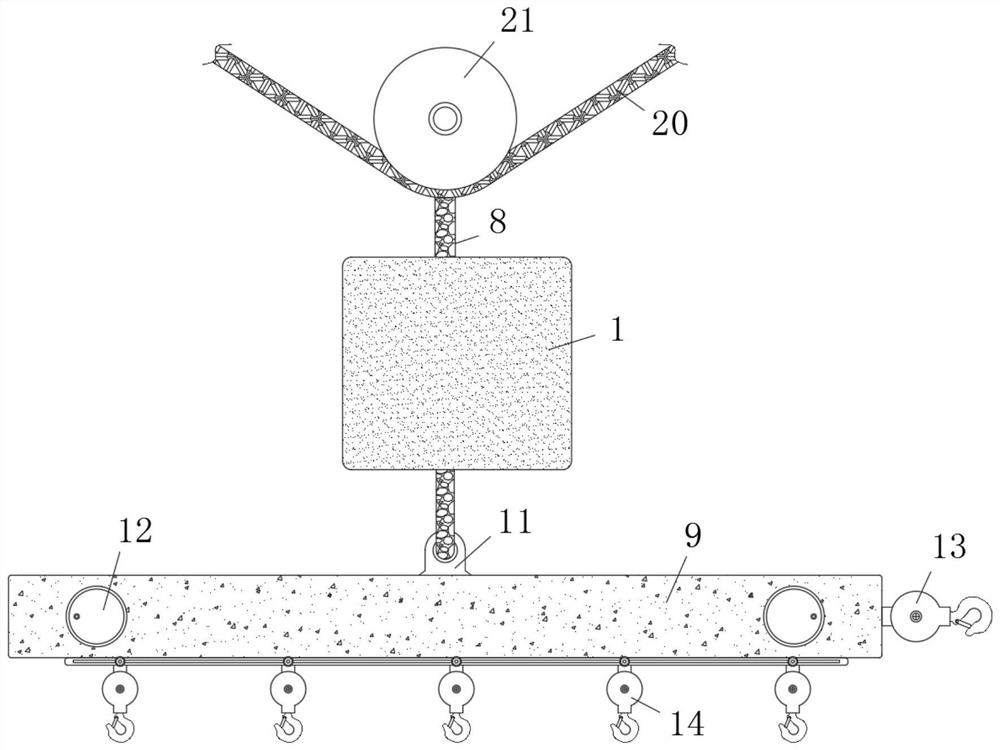

Adjustable import and export cargo hoisting structure with buffering effect

InactiveCN113233314AEasy to share gravityPrevent the rope from breakingVibration suppression adjustmentsLoad-engaging elementsStructural engineeringMarine engineering

The invention provides an adjustable import and export cargo hoisting structure with a buffering effect, and relates to the technical field of import and export cargo transportation. The adjustable import and export cargo hoisting structure with the buffering effect comprises a mounting shell, a fixing plate is fixedly mounted inside the mounting shell, a strip-shaped through hole is formed in the surface of the fixing plate, limiting stop blocks are fixedly mounted on the two sides of the fixing plate, and a pressing plate is arranged in the position, above the fixing plate, of the mounting shell. According to the adjustable import and export cargo hoisting structure with the buffering effect, through the unique design of a hoisting frame, in the actual use process of the hoisting structure, regular objects can be hoisted through a second suspension hook, gravity is conveniently shared, irregular cargoes can be suspended and hoisted through a first suspension hook, by arranging a spring damping structure, the structure can reduce instantaneous impact force generated during hoisting in actual use, and can also reduce shaking of the cargoes during hoisting.

Owner:广州玖玖捌建筑劳务有限公司

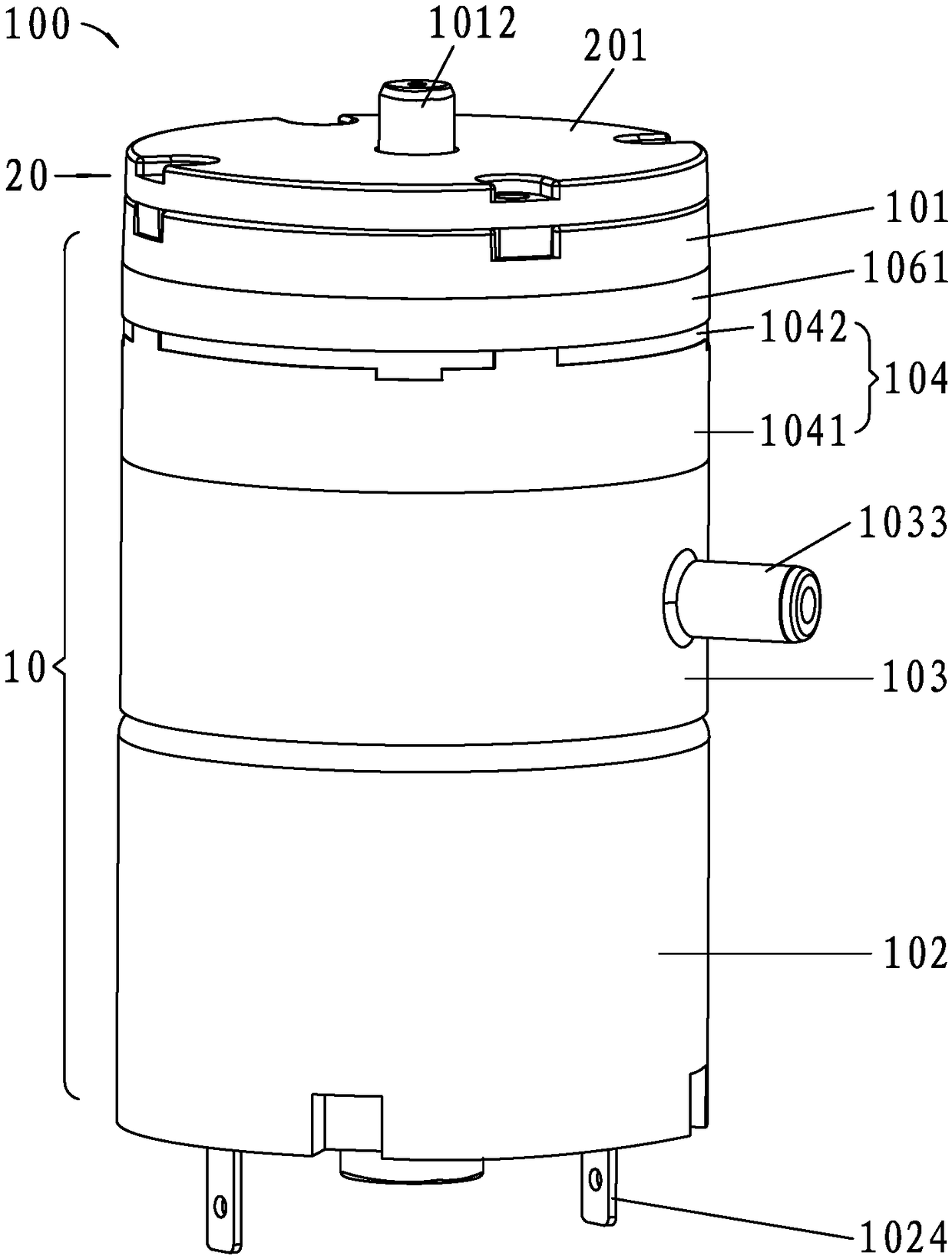

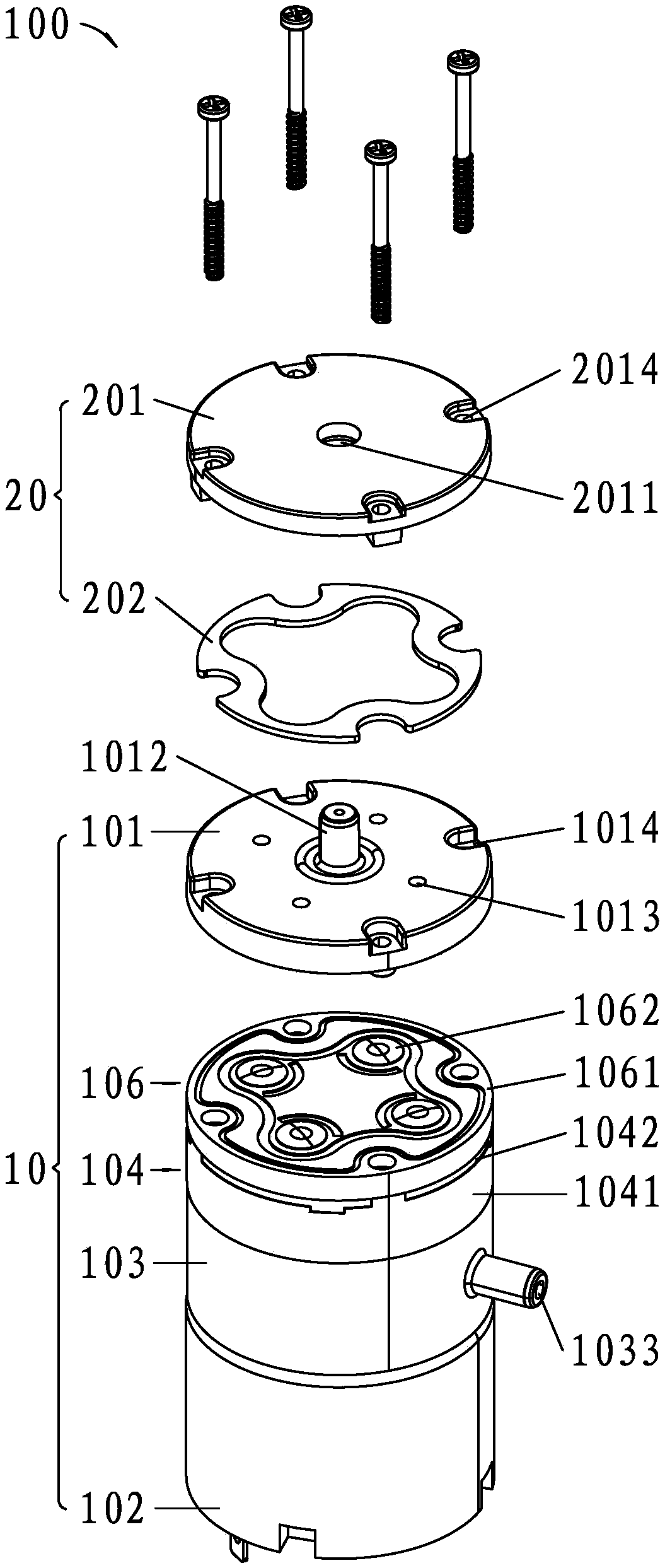

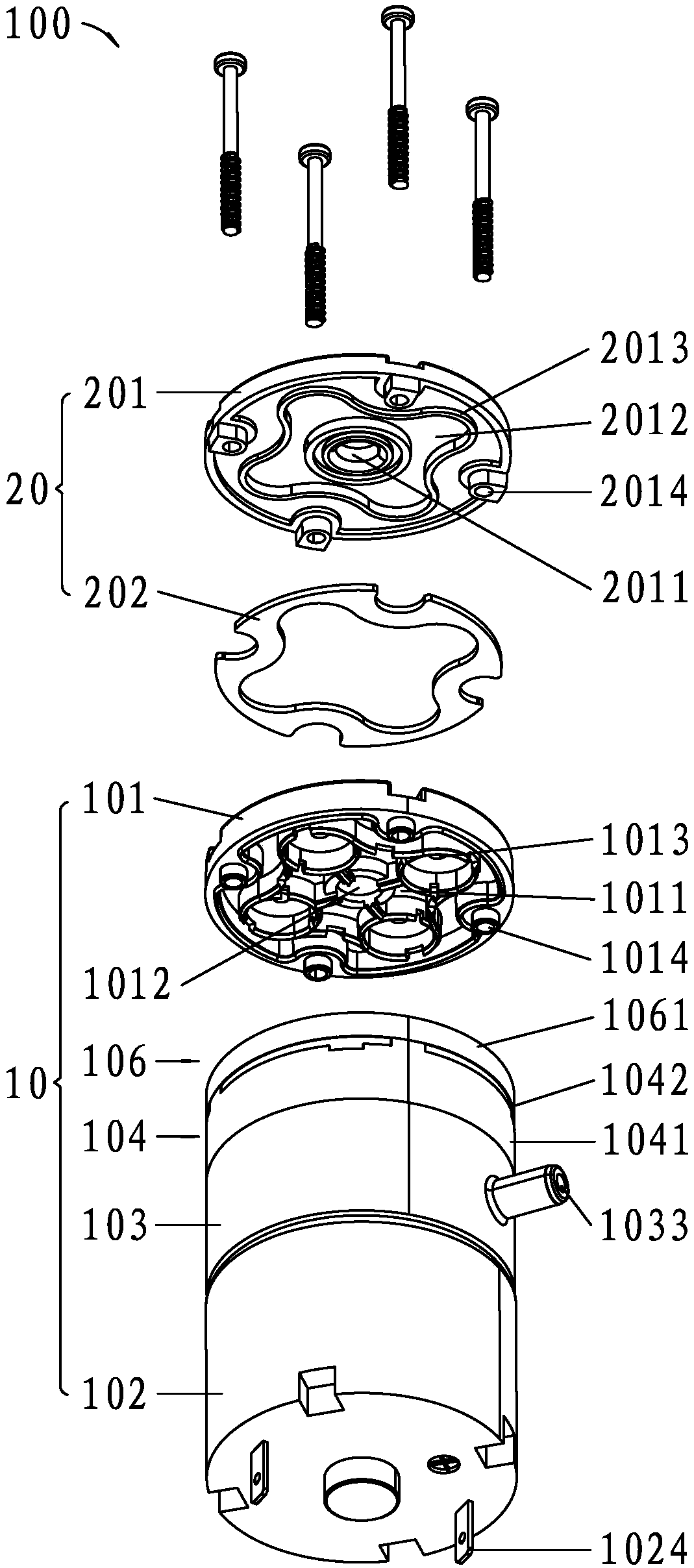

Low-noise air pump

PendingCN108119346AReduce the momentary impactIncrease outflow strokePositive displacement pump componentsFlexible member pumpsLow noiseAir pump

The invention discloses a low-noise air pump, comprising an air pump body. The air pump body comprises a pump head cover. The bottom of the pump head cover is provided with a relief chamber; the upperend face of the pump head cover is provided with an exhaust head. The low-noise air pump also comprises an air flow buffer device that comprises a buffer cover; the buffer cover hermetically covers the upper end face of the pump head cover; the upper end face of the buffer cover is provided with a via hole allowing passage of the exhaust head; the bottom face of the buffer cover is provided withan air flow buffer chamber; the upper end face of the pump head cover is provided with an air flow through hole that communicates the relief chamber with the air flow buffer chamber. The low-noise airpump has the advantages that part of air in the relief chamber is discharged into the air flow buffer chamber via the air flow through hole so that transient impact of air discharged from the exhausthead can be effectively relieved; noise due to outflow impact of air at the exhaust head can be effectively reduced, and two-stage denoising is achieved; when the air in the air flow buffer chamber reflows into the relief chamber and flows out of the exhaust head, outflow travel of the air can be greatly extended, and noise can be further reduced; therefore, the low-noise air pump has good denoising effect.

Owner:SHENZHEN SKOOCOM ELECTRONICS CO LTD

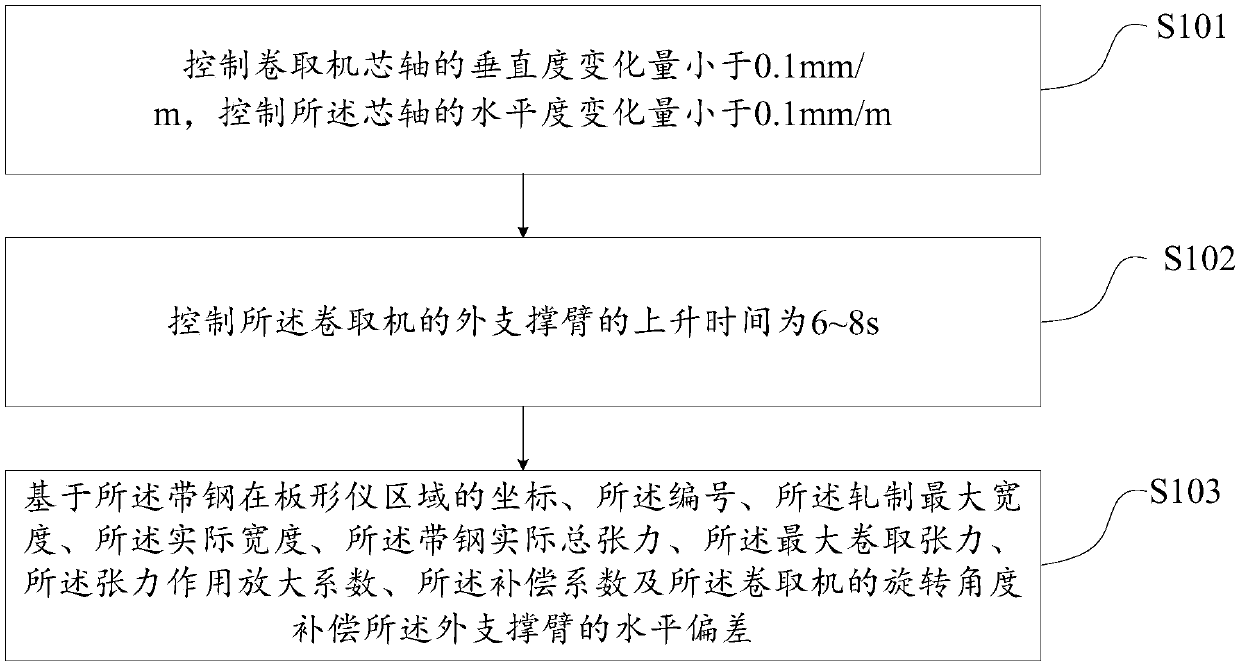

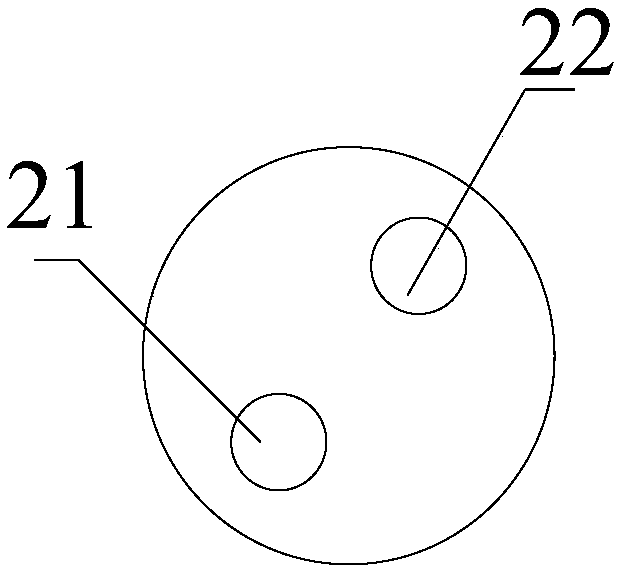

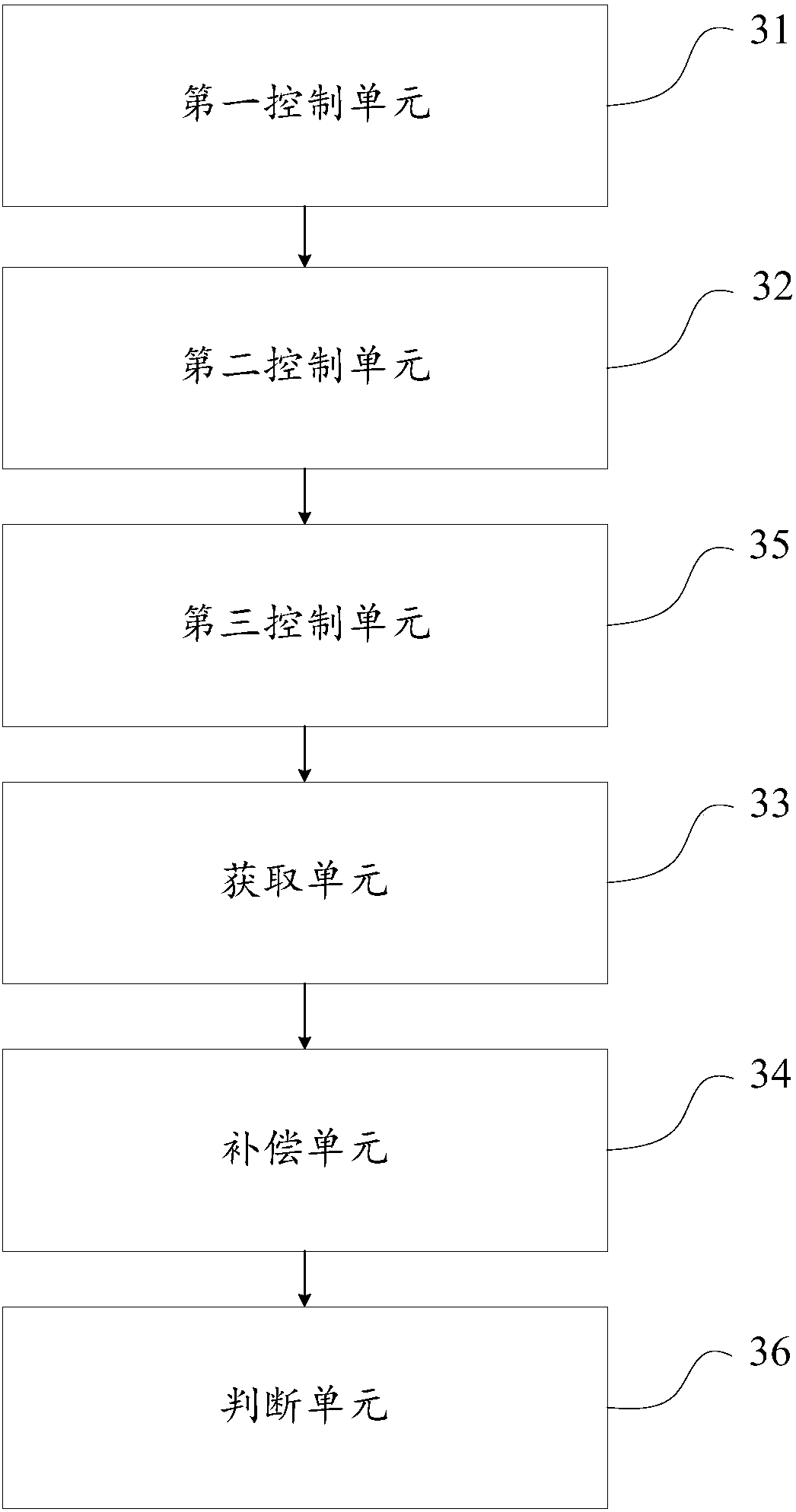

Method and device for controlling strip shape of strip steel

ActiveCN107900109AControl the amount of verticality changePrevent deviationProfile control deviceRise timeSerial code

The invention provides a method and device for controlling the strip shape of strip steel. The method comprises the steps of controlling the variable quantity of the perpendicularity of a center spindle of a coiling machine to be less than 0.1 mm / m and controlling the variable quantity of the levelness of the center spindle to be less than 0.1 mm / m; controlling the rising time of an outer supporting arm of the coiling machine to be 6-8 s; acquiring coordinates, the serial number, the maximum rolling width, the practical width, the practical strip steel total tension, the maximum coiling tension, the tension effect amplification coefficient and the compensation coefficient of the strip steel in a strip shape instrument region and the rotating angle of the coiling machine; compensating for the horizontal deviation of the outer supporting arm according to the coordinates, the serial number, the maximum rolling width, the practical width, the practical strip steel total tension, the maximum coiling tension, the tension effect amplification coefficient and the compensation coefficient of the strip steel in the strip shape instrument region and the rotating angle of the coiling machine;conducting compensation adjustment on the horizontal deviation of the outer supporting arm in the coiling process in real time. The stability of the coiling process is improved. The straightness of the strip shape is further improved. Deviation of the strip steel during on a subsequent treatment line is avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Base mounting structure with weighing sensors being convenient to dismount

ActiveCN108709070AReduce the momentary impactExtended service lifeNon-rotating vibration suppressionStands/trestlesRough surfaceEngineering

The invention discloses a base mounting structure with weighing sensors being convenient to dismount. The base mounting structure comprises a support. The upper portion of the support is connected with a base plate through the set of weighing sensors in a supporting mode. Vertical plates are connected with the centers of the two sides of the upper portions of the base plate in a matched mode. A horizontal plate is connected between the two vertical plates through a rotary shaft in a rotating fit mode. A mounting hole is formed in the center of the upper side of the horizontal plate. A materialhopper is arranged at the mounting hole. A set of jacks are evenly arranged on the lower side of the base plate. A supporting column is fixedly connected with the lower end of a telescopic rod of each jack. The lower ends of the supporting columns are connected with an earth plate jointly and fixedly. The lower surface of the earth plate is a wavy rough surface. The base mounting structure has the advantages that the structure is simple, up-down and left-right instantaneous impact force on weighing sensing devices in the material pouring process can be effectively buffered, the service life of the weighing sensing devices is prolonged, when the weighing sensing devices need to be detected and calibrated, the earth plate is pushed by the jacks, and the weighing sensors can be dismounted conveniently.

Owner:BENGBU WANDA ELECTRONICS

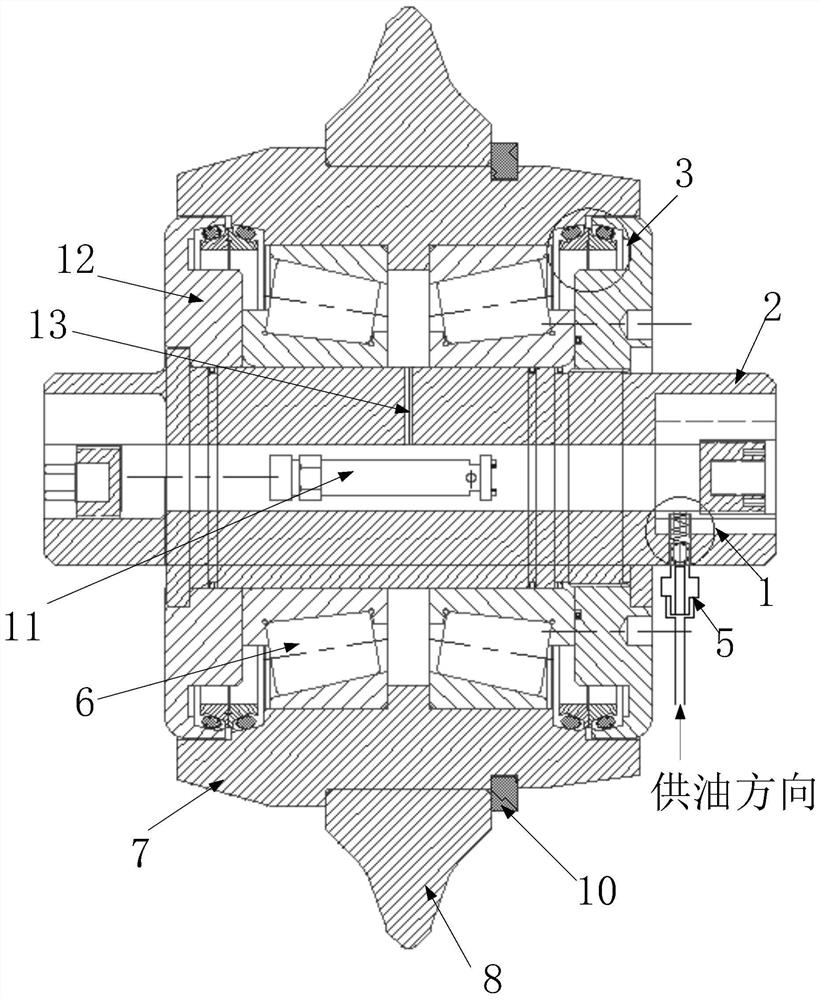

External oil filling type shield hob

The invention discloses an external oil filling type shield hob. The external oil filling type shield hob comprises a hob hub, two bearings are arranged in the hob hub, a hollow hob shaft is arranged in the bearings, end covers are arranged at the two ends of the hob hub, the two ends of the hollow hob shaft penetrate through the end covers, and a hob ring is arranged outside the hob hub; a grease supplementing through hole communicated with the interior of the hollow hob shaft is formed at one end of the hollow hob shaft, and the grease supplementing through hole is provided with a supplementary lubrication system; the supplementary lubrication system comprises a first one-way valve arranged in the grease supplement through hole, an oil pipe joint and an oil pipe; the hollow hob shaft is provided with a lubricating oil cavity communicating hole communicating with the area between the two bearings, a wireless temperature and pressure sensor is arranged in the hollow hob shaft, and shaft end oil plugs are arranged at the two ends of the hollow hob shaft. a floating sealing system is arranged between the end covers and the hob hub; and the problems that a shield tunneling machine is prone to sealing failure in the composite stratum tunneling process, mud and sand enter a lubricating oil cavity to damage a bearing, and consequently a hob loses efficacy are solved.

Owner:广州市力劲机电有限公司 +1

Energy consumption buffer type high-pressure nozzle fixing device

The invention discloses an energy consumption buffer type high-pressure nozzle fixing device. The device comprises a bottom mounting substrate provided with a bolt hole inside and a 3 / 4 sphere outer shell. The device is used for fixing a handheld part of a high-pressure water gun or a high-pressure spraying pipe; such parts as a spiral spring and hydraulic oil are used for reducing instant impactforce of high-pressure impact force to mounting parts, so that the parts are protected, and the service life of the parts is prolonged; the device can achieve a free adjustment function of spraying angles to achieve high practicability; the device is provided with a spiral spring elastic compression butted highest liquid pressure control mechanism for preventing the damage phenomenon of internal parts caused by higher liquid pressure; and in addition, the device is provided with a spiral spring compression elastic telescopic liquid control mechanism for controlling flowing liquid to achieve the effects of timely liquid returning and timely guidance and prestorage.

Owner:东台市高科技术创业园有限公司

Precision forging mold capable of conducting automatic lateral pressing and vibration reducing and vibration reducing method for forging mold

InactiveCN105458143AReduce the momentary impactExtended service lifeForging/hammering/pressing machinesForgingImpact energy

The invention relates to the technical field of precision forging, in particular to a precision forging mold capable of conducting automatic lateral pressing and vibration reducing and a vibration reducing method for the forging mold. An upper movable block (a lower movable block) is driven by a first oil cylinder (a second oil cylinder) to get away from an upper fixed block (a lower fixed block), an upper mold body (a lower mold body) can be put into an upper installing groove (a lower installing groove) of an upper mold base (a lower mold base) accordingly, then the first oil cylinder (the second oil cylinder) stops driving, the upper movable block (the lower movable block) presses the upper mold body (the lower mold body) under the effect of a compression spring, the upper mold body (the lower mold body) is fixed accordingly, and the upper mold body (the lower mold body) is quite convenient to replace. When forging is carried out, as one side of the upper mold body and one side of the lower mold body abut against the upper fixed block and the lower fixed block respectively, automatic positioning can be achieved, large instantaneous impact force is generated when forging is carried out, and the impact energy can cause mold vibration; and due to the effect of the compression spring, the horizontal direction impact energy is absorbed, the instantaneous impact force is reduced accordingly, automatic resetting is achieved, and the service life of the mold is prolonged.

Owner:HUBEI TRI RING FORGING

Production method of striker board of ice hockey stick

The invention discloses a production method of a striker board of an ice hockey stick. The production method includes the steps of cutting a sheet of striker board filler with a tool; connecting the filler with a handle preforming tool and attaching carbon fiber or glass fiber yarn to the front and back of each of the handle preforming tool and the striker board layer by layer; cutting a buffer film into strips; pricking the buffer film to obtain a plurality of evenly arranged air holes; attaching the buffer film to one side surface on the side of the striker board; attaching release cloth to the striker board to obtain a preformed striker board body; and forming the preformed striker board body in a striker board forming die. The production method has the advantages that transient impact of a puck upon the sticker board is reduced, the sticker board is resistant to damage, and the service life of the striker board is prolonged; shock transmitted from the ice hockey stick to hands of a user is reduced; and the puck rebounded by the striker board is well controllable, and better striking can be obtained.

Owner:包爾曲棍球有限公司

Synchronous wrench for bolts arranged in annular array

InactiveCN110977848AImprove protectionReduce the level of security risksSpannersWrenchesWrenchContact friction

The invention discloses a synchronous wrench for bolts arranged in an annular array mode. The synchronous wrench comprises a main body shell. According to the invention, a plurality of bolts can be rotated to bolt holes in which the bolts need to be mounted at the same time under the effect of synchronous rotation, therefore, the phenomena that due to the fact that a single bolt is stressed, the fastening angle of a connecting part deviates and the threads are damaged, the service life is short can be effectively prevented. The protection capability on the bolt structure is improved; potentialsafety hazard degree reduction, an annular array type longitudinal and transverse staggered rod body linkage mechanism is arranged; longitudinal and transverse cross arrangement is utilized; therefore, the transmission effect of rotation is realized; meanwhile, due to point contact and small friction force, longitudinal movement is not greatly affected, the efficiency is improved, and potential safety hazards in use are reduced; and in addition, the wrench is provided with an annular array spiral spring type maximum rotating strength control mechanism, and the phenomenon that a threaded structure is damaged due to the fact that the rotating strength is too large is avoided.

Owner:薛春红

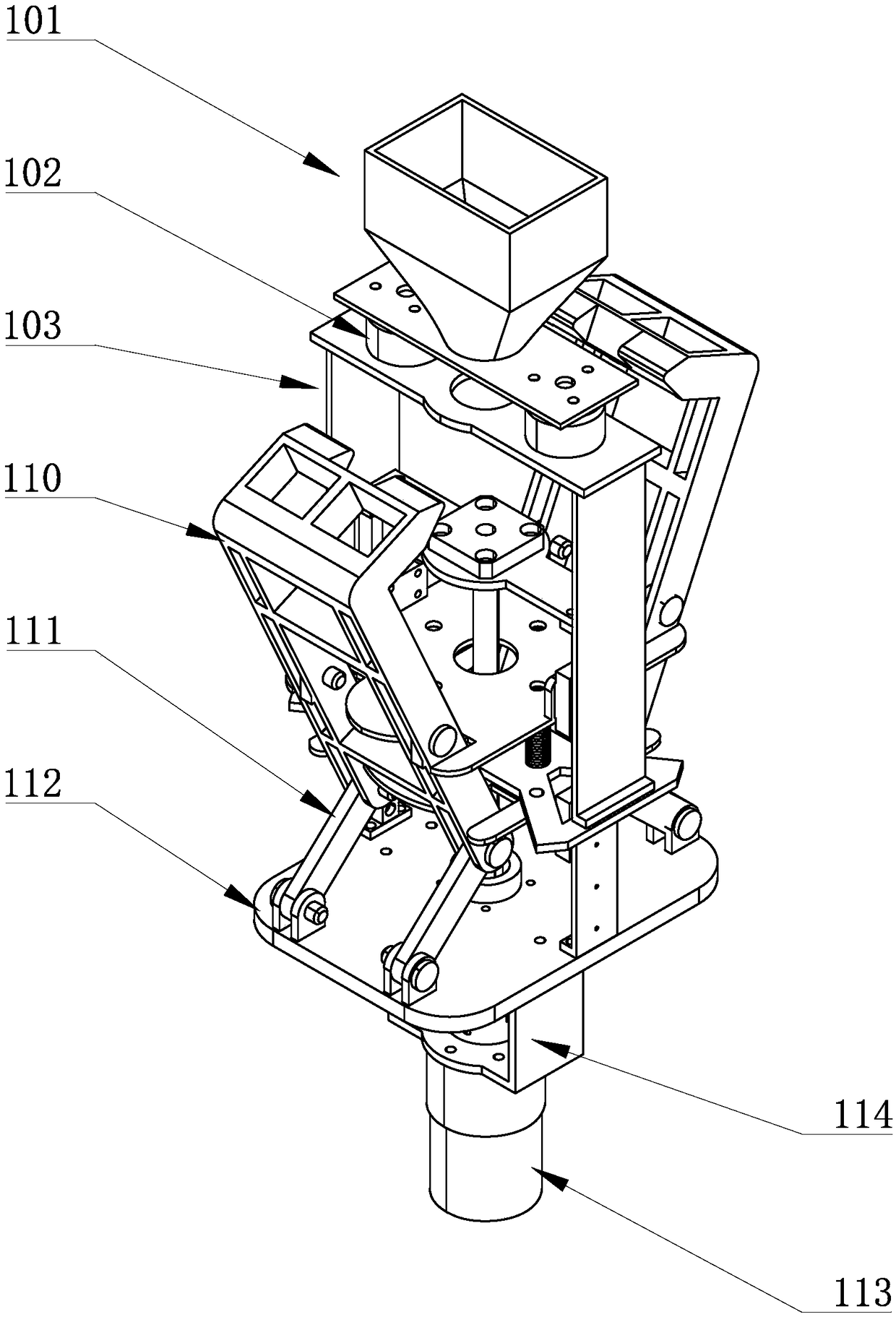

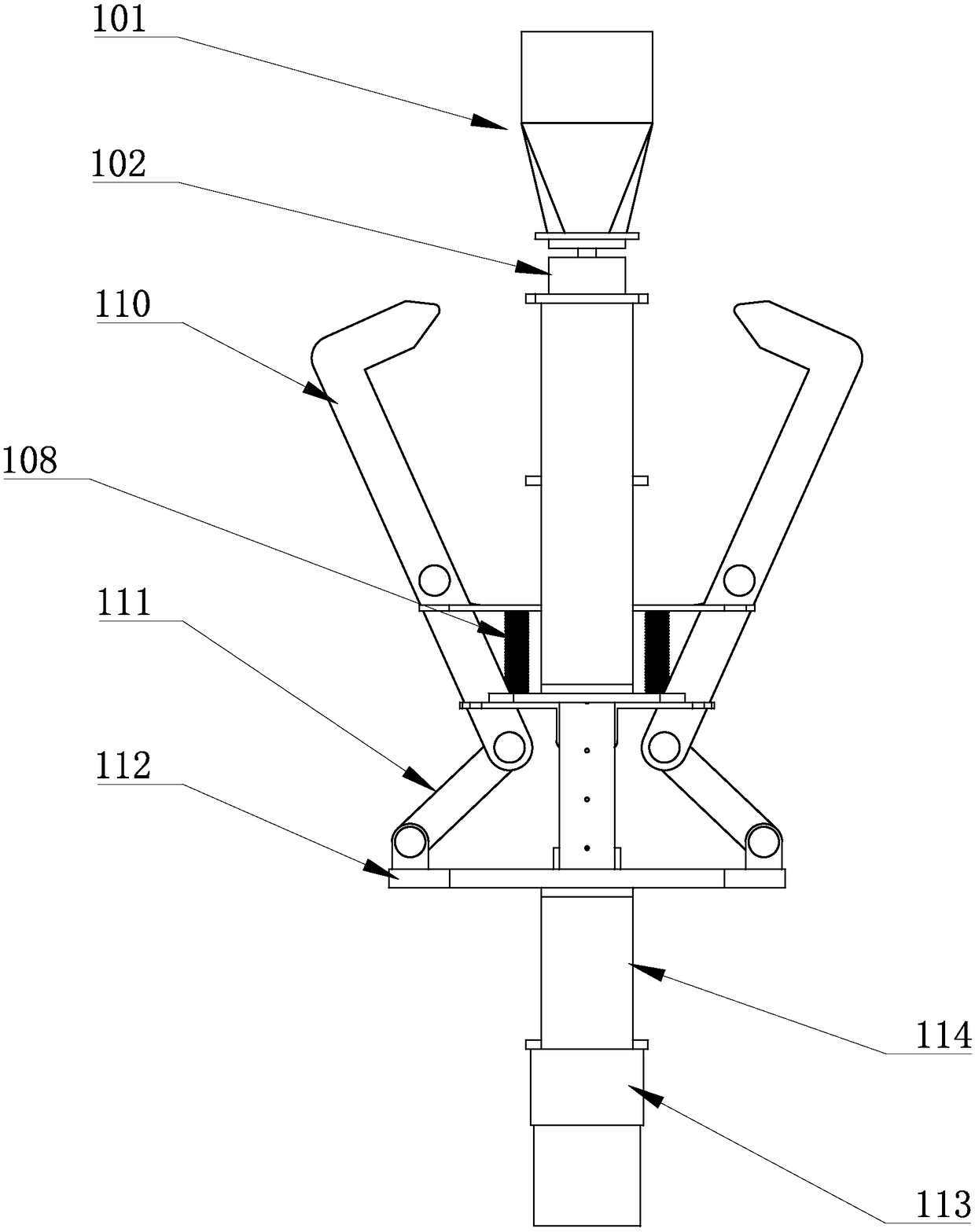

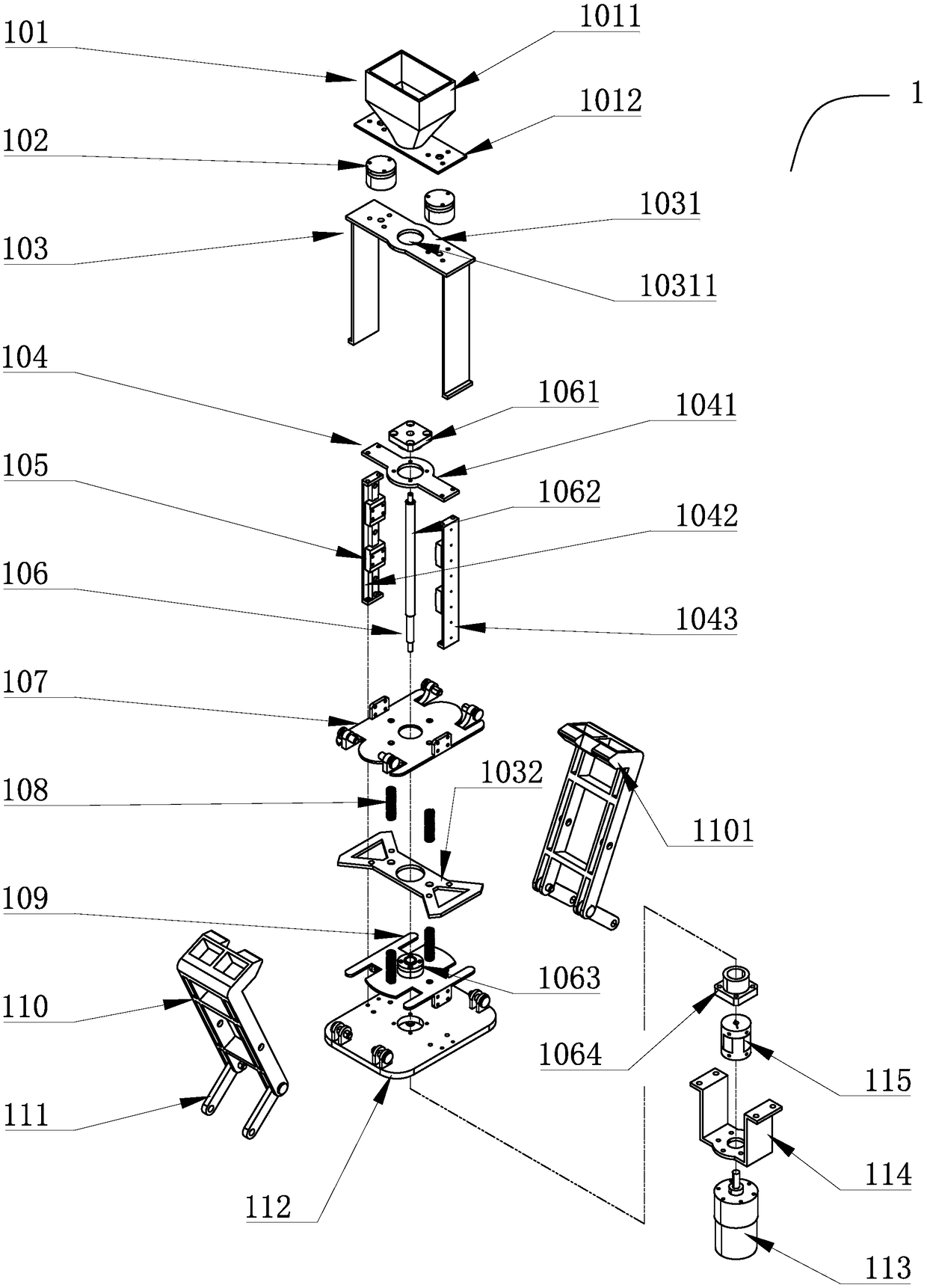

Jaw clamping mechanism of separated action and robot thereof

ActiveCN108908389AExtended service lifeReduce the momentary impactGripping headsEngineeringMechanical engineering

The invention relates to a jaw clamping mechanism of separated action. The jaw clamping mechanism of the separated action comprises a jaw, a connecting rod, a fixing plate, a driving plate, a driven plate, a connector fixing base and a driving device. One end of the jaw is hinged with the connecting rod. One end, away from the connecting rod, of the jaw is provided with a clamping part. The jaw ishinged with the driven plate in a middle position of the jaw. One end, away from the jaw, of the connecting rod is hinged with the fixing plate. The driven plate is elastically connected with the driving plate. The connector fixing base is fixed on the driving plate. There are two pairs of the jaws and the connecting rods. While the driving device drives the driving plate to be away from / adjacentto the fixing plate, the jaws are relatively gathered / separated. While the jaws are impacted by an external force, the driving plate can be elastically moved relative to the driven plate. The invention further relates to a robot. The jaw clamping mechanism is capable of solving an instant impact problem of the jaws in a clamping process, so the jaws of the robot have a function of preventing instant impact.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com