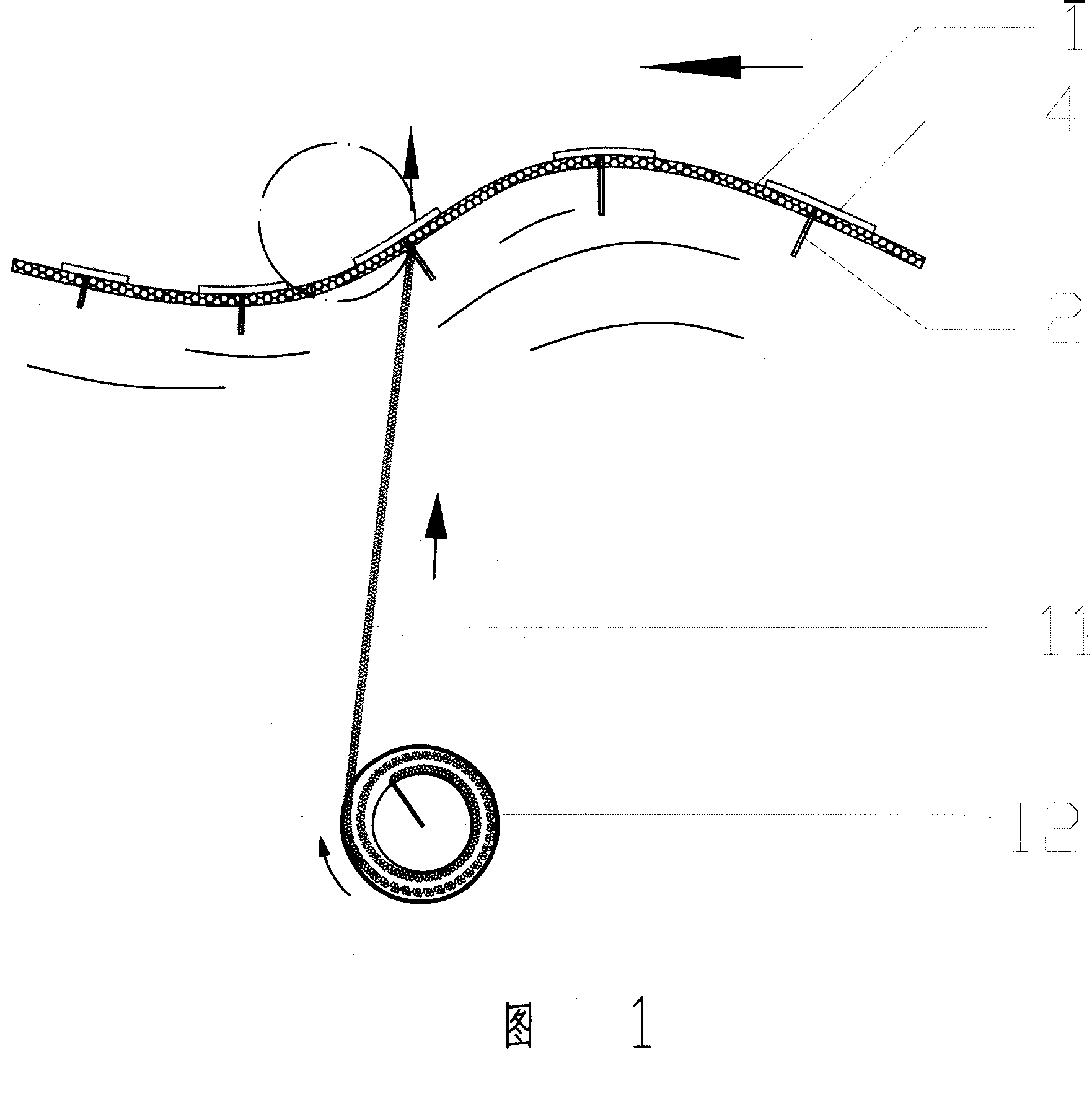

Curved rope wheel wave energy conversion and power generating system

A power generation system and wave energy technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve problems such as poor wave capability, poor wind and wave resistance, and low wave energy absorption efficiency, and achieve strong wave adaptability, Increased absorption area and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

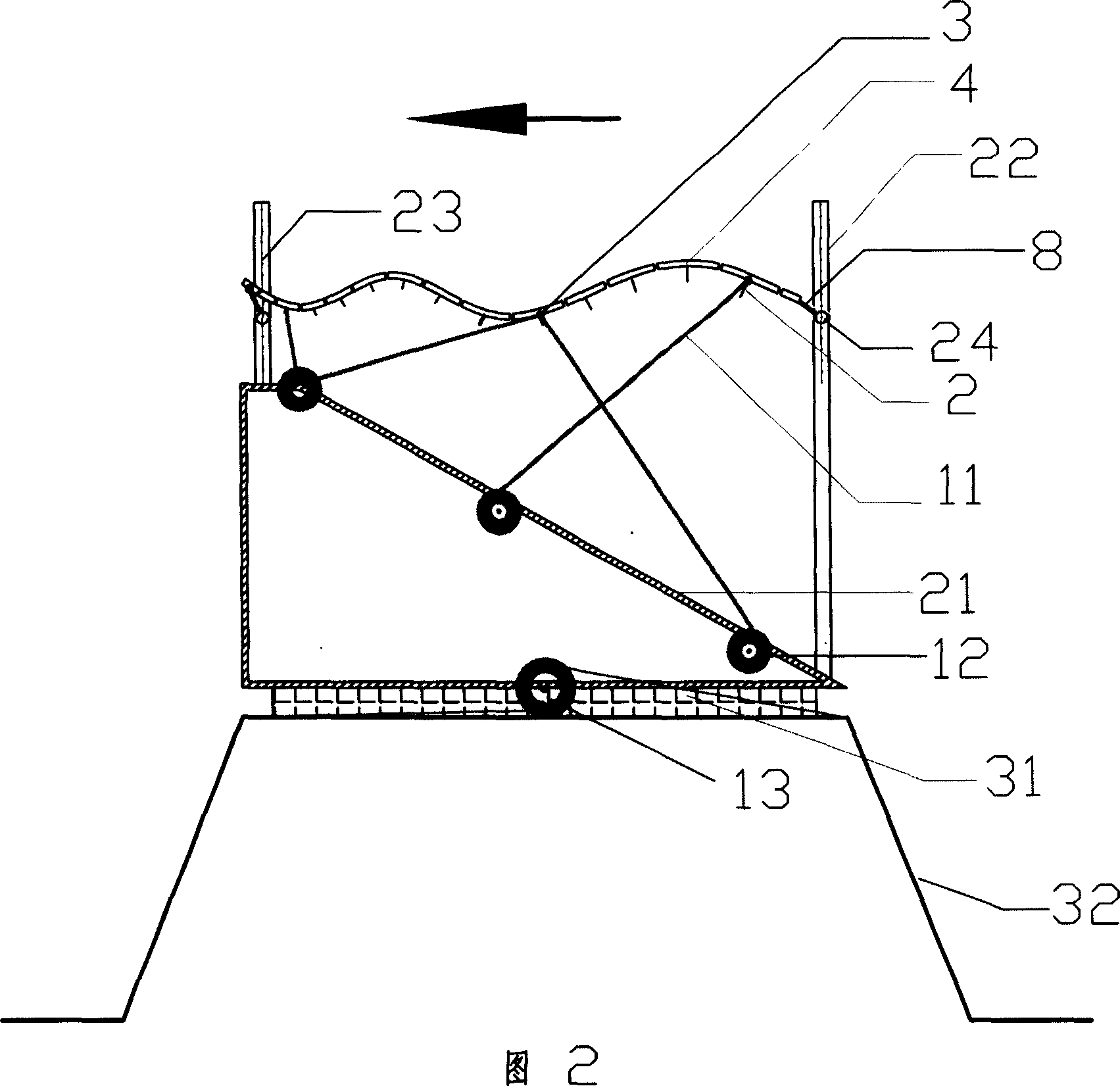

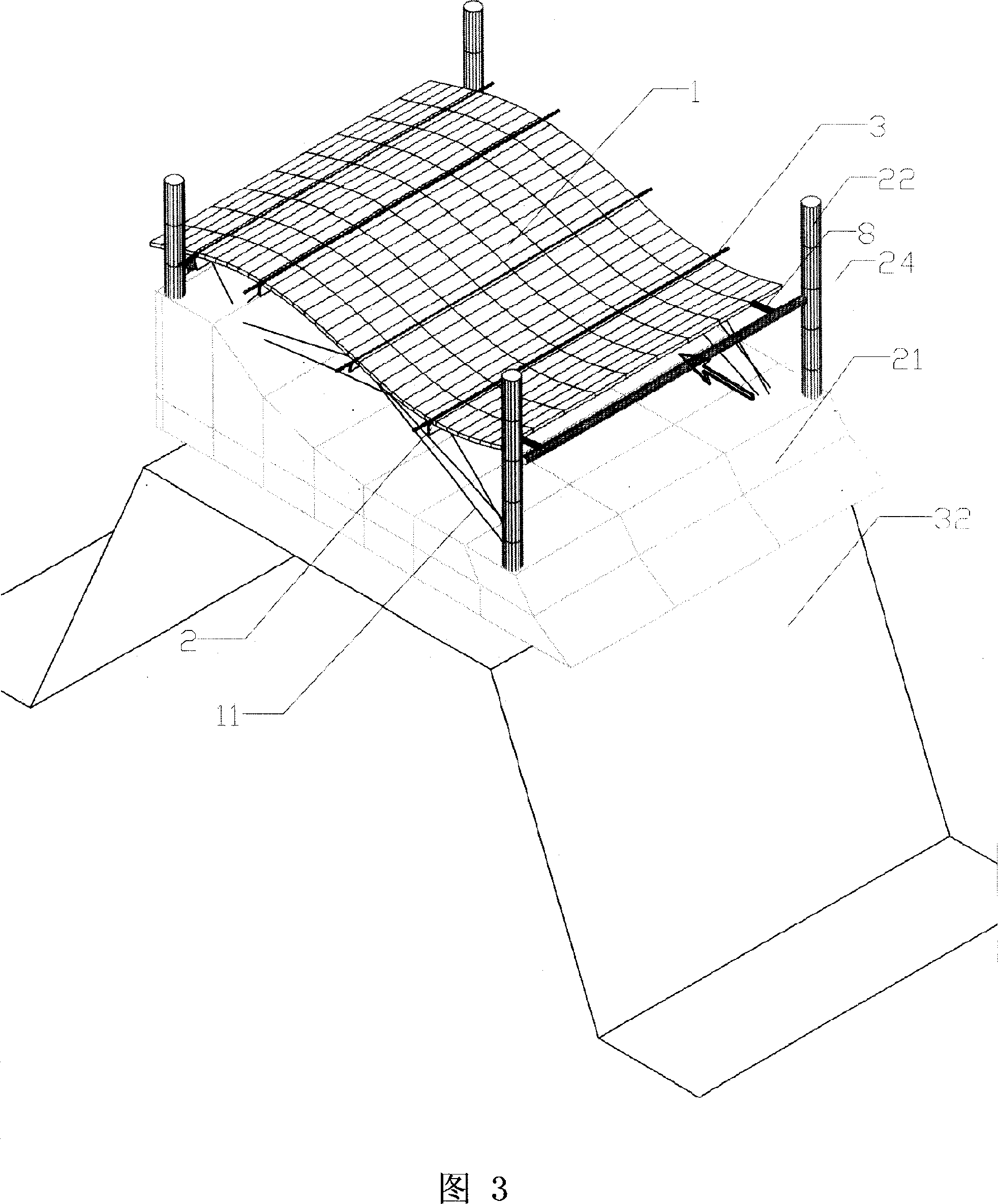

[0082] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0083] (1) Manufacture of easy bending surface (see Figure 4, Figure 5, Figure 6, Figure 7):

[0084] The first kind of easy-bending surface can be made of elastic plastic material, but the cost is relatively high.

[0085] For multi-plate form easy-bending surfaces:

[0086] The size of a single plate (4) on the easy-bending surface can be selected according to the average wave size at the location of the device. generally can is long 6 meters, 2.5 meters wide About, the thickness can meet the working intensity requirement. The board is lighter than water, but it must be guaranteed to have a certain strength, and a high-strength plastic board can be added with foam plastic.

[0087] The partition plate (2) has the same length as the single plate it is affixed to, is vertically affixed under the plate, and has a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com