Acidic texturing solution for texturing of polycrystalline silicon chip and using method thereof

A technology of polycrystalline silicon wafers and texturing liquid, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems such as uneven texture, environmental pollution, etc., increase absorption area, avoid control requirements, and have stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

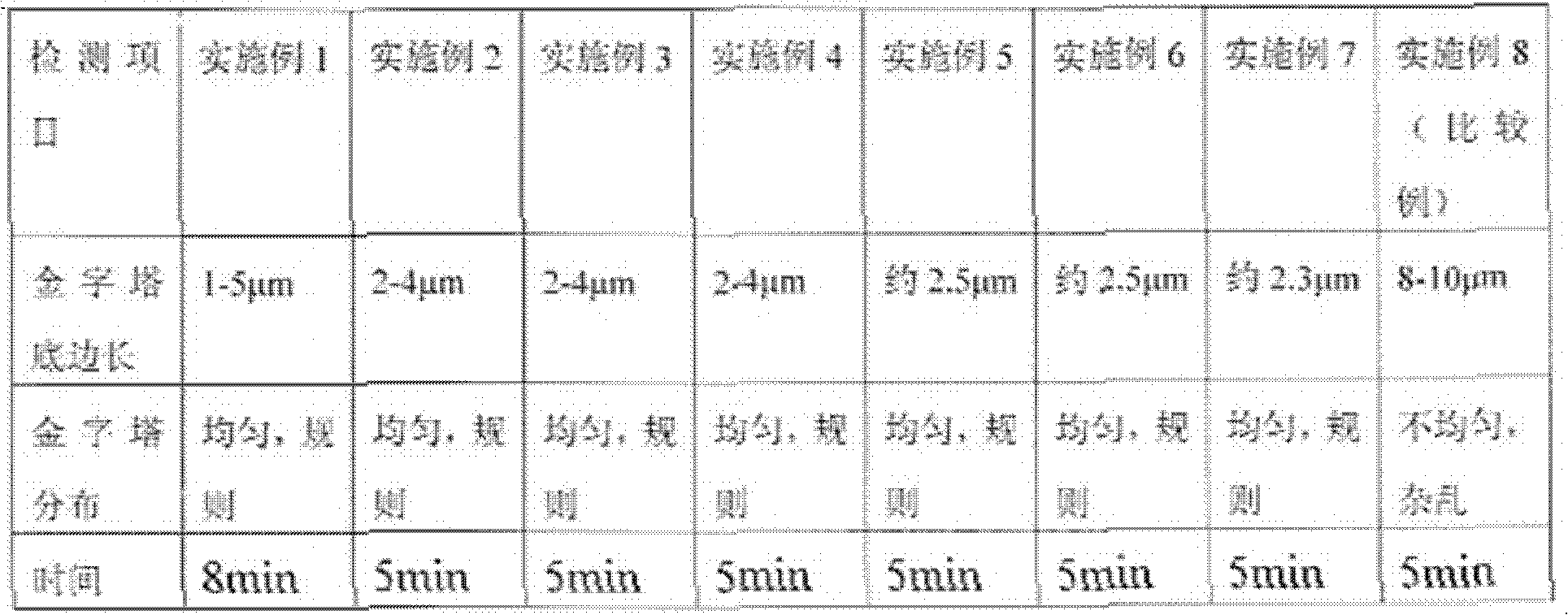

[0023] Take the following process steps: 1) configure acidic texturing solution: dissolve 5 mol / liter of sodium perchlorate and 1 mol / liter of hydrofluoric acid in deionized water; 2) immerse the polycrystalline silicon wafer for solar cells in the solution The surface is textured, the texture temperature is 7°C, and the texture time is 8 minutes.

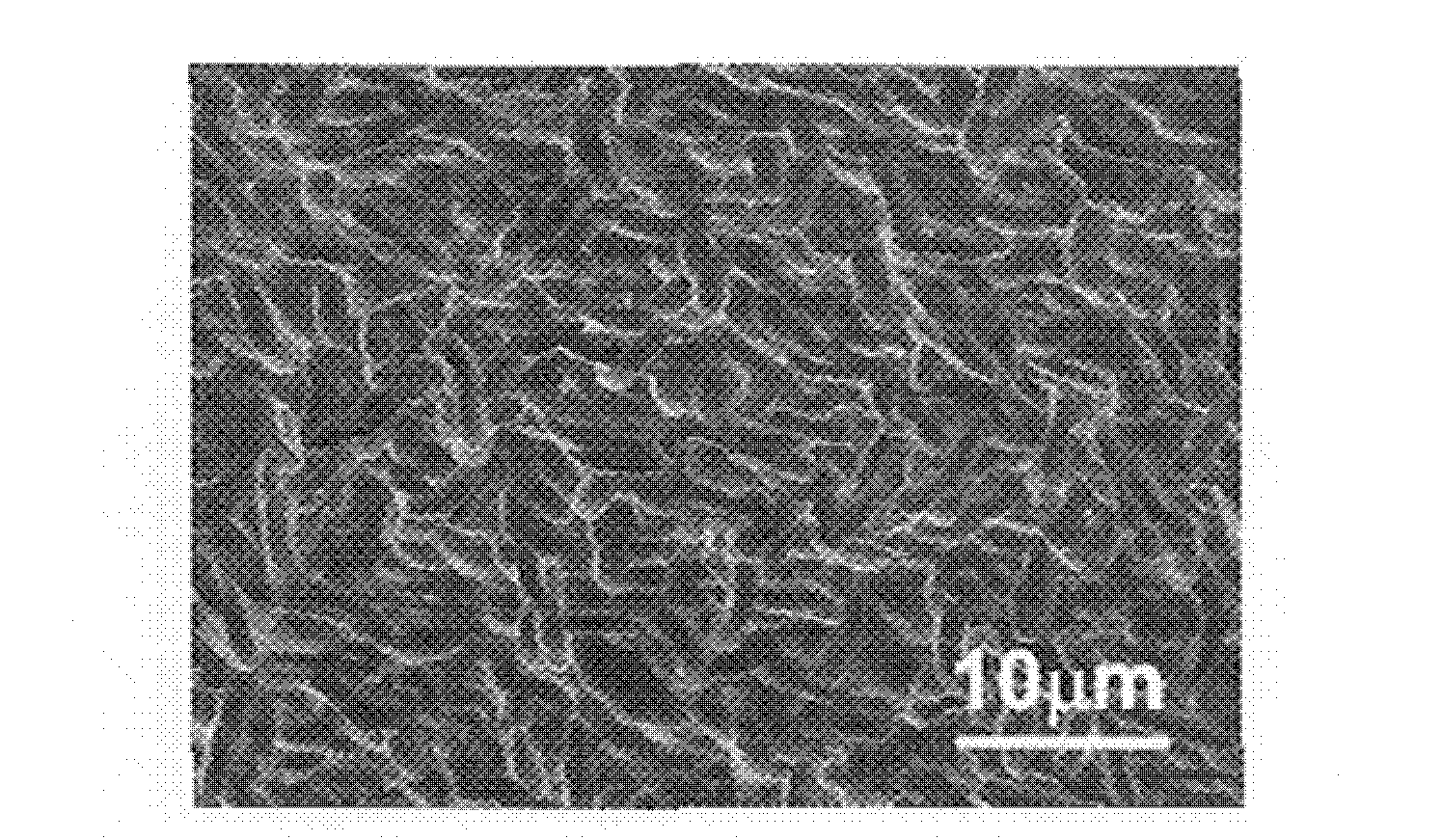

[0024] figure 1 A scanning electron microscope plane photo of the textured surface of the obtained polycrystalline silicon wafer is given. From the figure, it can be seen that a uniform pit-shaped textured surface is formed on the surface of the silicon wafer, and the textured surface has a size of about 1-5 μm.

Embodiment 2

[0026] Take the following process steps: 1) configure acidic texturing solution: dissolve the polymethylsiloxane of 30 mol / liter of sodium perchlorate and 20 mol / liter of hydrofluoric acid, 0.05% (percentage by weight) in deionized in water; 2) immerse the polysilicon wafer for solar cells in the solution for surface texturing, the texturing temperature is 10° C., and the texturing time is 5 minutes.

Embodiment 3

[0028] Take the following process steps: 1) configure acidic cashmere liquid: the octylphenol polyoxyethylene ether of 10 mol / liter of sodium perchlorate and 5 mol / liter of hydrofluoric acid, 0.2% (percentage by weight) is dissolved in Ionized water: 2) Immerse the polysilicon wafer for solar cells into the solution for surface texturing, the texturing temperature is 10° C., and the texturing time is 5 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com