Electrochemical preparation method of BiOBr/Bi12SiO20 composite film photocatalyst and application of BiOBr/Bi12SiO20 composite film photocatalyst

A technology of composite thin film and photocatalyst, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc. It can solve the problems of high energy consumption powder catalyst and difficult separation of reaction system , to achieve controllable and easy-to-operate reaction conditions, improve the photocatalytic activity of the film, and achieve mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A BiOBr / Bi 12 SiO 20 The electrochemical preparation method of composite film photocatalyst comprises the steps:

[0019] The first step is to polish the Bi and Ti plates, wash them with absolute ethanol and distilled water, dry them for later use, and prepare them with a concentration of 5-20% NaBr and NaBr. 2 SiO 3 9H 2 A mixed solution of 90-600 mL distilled water and ethylene glycol with different volume ratios of O is used as the electrolyte, and the pH is adjusted to 8-14 with nitric acid or sodium hydroxide solution to obtain the electrolyte solution A required for the reaction. Among them, distilled water and B The volume ratio of diol is 3:1~5:1;

[0020] In the second step, the Bi plate and Ti plate treated in the first step are used as anode and cathode materials respectively and placed in the electrolyte solution A. The distance between the two electrodes is 3-8 cm, and the current density is 0.5-5.0 A / dm 2 , reacted at room temperature under magnetic...

Embodiment 1

[0023] 1) After polishing the Bi and Ti plates, wash them with absolute ethanol and distilled water, and dry them for later use. Mix 12 mmoL NaBr and 6 mmoL Na 2 SiO 3 9H 2O was dissolved in 120 mL of water / EG (volume ratio 5:1) mixed solution, and the nitric acid solution adjusted the pH to 8 to obtain the electrolyte solution A required for the reaction;

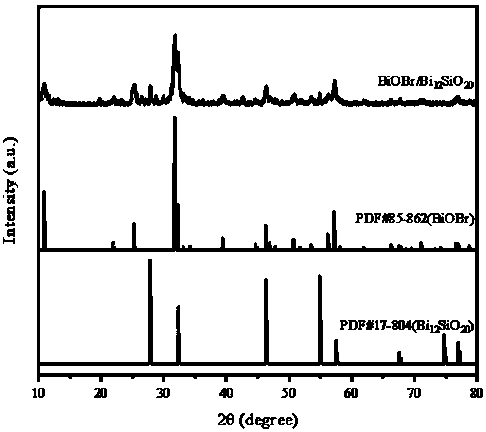

[0024] 2) The Bi plate and Ti plate treated in step 1) were used as anode and cathode materials respectively in solution A, the distance between the two electrodes was 8 cm, and the current density was 1.5 A / dm 2 React with magnetic stirring at room temperature for 3 h, the surface of the Bi plate forms a thin film, rinse with absolute ethanol and distilled water three times, and then dry in an oven at 60 °C to prepare BiOBr and Bi 12 SiO 20 Immobilized BiOBr / Bi with Bilayer Structure and Photocatalytic Activity 12 SiO 20 Composite film;

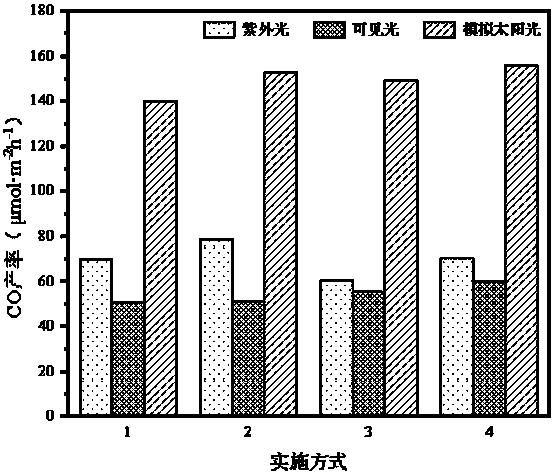

[0025] 3) The prepared BiOBr / Bi 12 SiO 20 Composite thin films for photoredu...

Embodiment 2

[0027] 1) After polishing the Bi and Ti plates, wash them with absolute ethanol and distilled water, and dry them for later use. Mix 36 mmoL NaBr and 18 mmoL Na 2 SiO 3 9H 2 O was dissolved in 360 mL water / EG (3:1 volume ratio) mixed solution, and the sodium hydroxide solution adjusted the pH to 14 to obtain the electrolyte solution A required for the reaction;

[0028] 2) The Bi plate and Ti plate treated in step 1) were used as anode and cathode materials respectively in solution A, the distance between the two electrodes was 4 cm, and the current density was 3 A / dm 2 React with magnetic stirring at room temperature for 3 h, the surface of the Bi plate forms a thin film, rinse with absolute ethanol and distilled water three times, and then dry in an oven at 60 °C to prepare BiOBr and Bi 12 SiO 20 Immobilized BiOBr / Bi with Bilayer Structure and Photocatalytic Activity 12 SiO 20 Composite film;

[0029] 3) The prepared BiOBr / Bi 12 SiO 20 Composite thin films for photor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com