Damped sensor for detecting oil quantity of oil tank

A detection sensor and damping technology, applied in the field of damping fuel tank fuel quantity detection sensors, can solve the problems of magnetic floating ball stuck, affecting accuracy, damage, etc., to avoid stuck or damaged, prolong service life, and improve detection. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

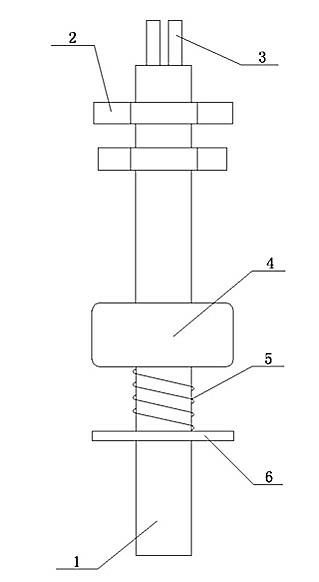

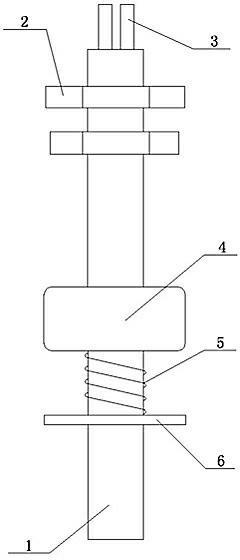

[0008] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: the same as the prior art, there is a measuring tube 1, the upper end of the measuring tube 1 has a fixed end 2 and a terminal 3, and a magnetic floating ball 4 is connected outside the measuring tube 1, which is different from the prior art What is more important is that the underside of the magnetic floating ball 4 is connected to the damping sheet 6 through the spring 5, and the spring 5 and the damping sheet 6 are both sleeved outside the measuring tube 1. The number of spring coils of the spring 5 is 3, the material diameter is 0.6mm, and the material is carbon spring steel wire IIa group. The damping sheet (6) is made of EPDM (ethylene propylene diene monomer), preferably circular and equal in diameter to the magnetic float 4, and the weight to volume ratio of the magnetic float 4 is preferably 1 mg: 1 cubic mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com