Drum flying shears

A technology of flying shears and rollers, which is applied in the field of steel rolling machinery, can solve the problems of large shear impact force of thick materials, and achieve the effects of small shear impact force, reduced instantaneous impact force, and large system inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

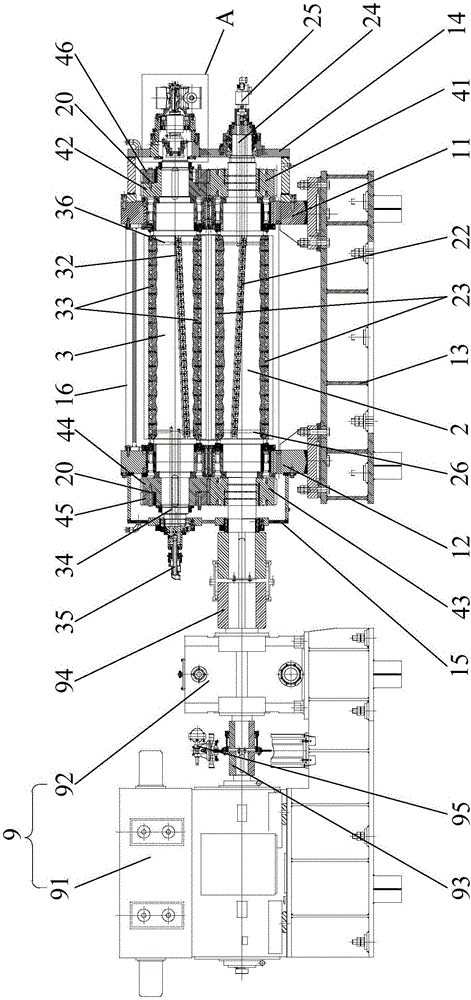

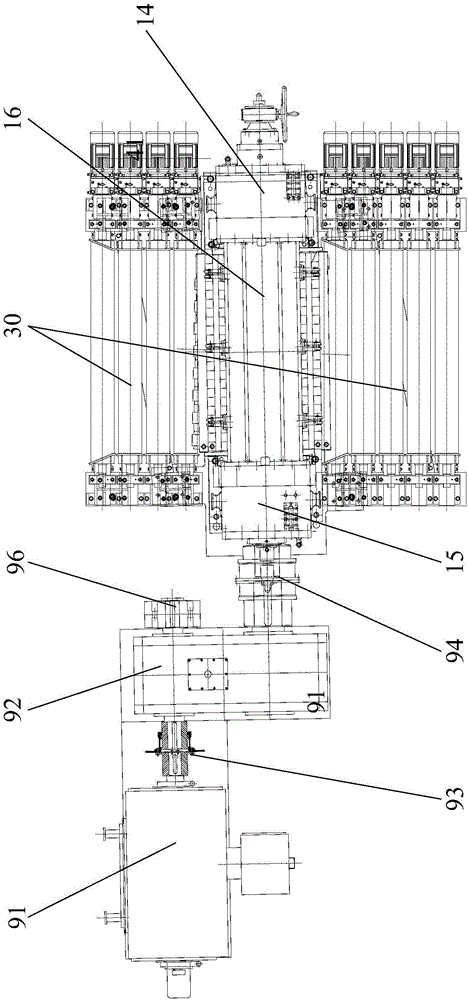

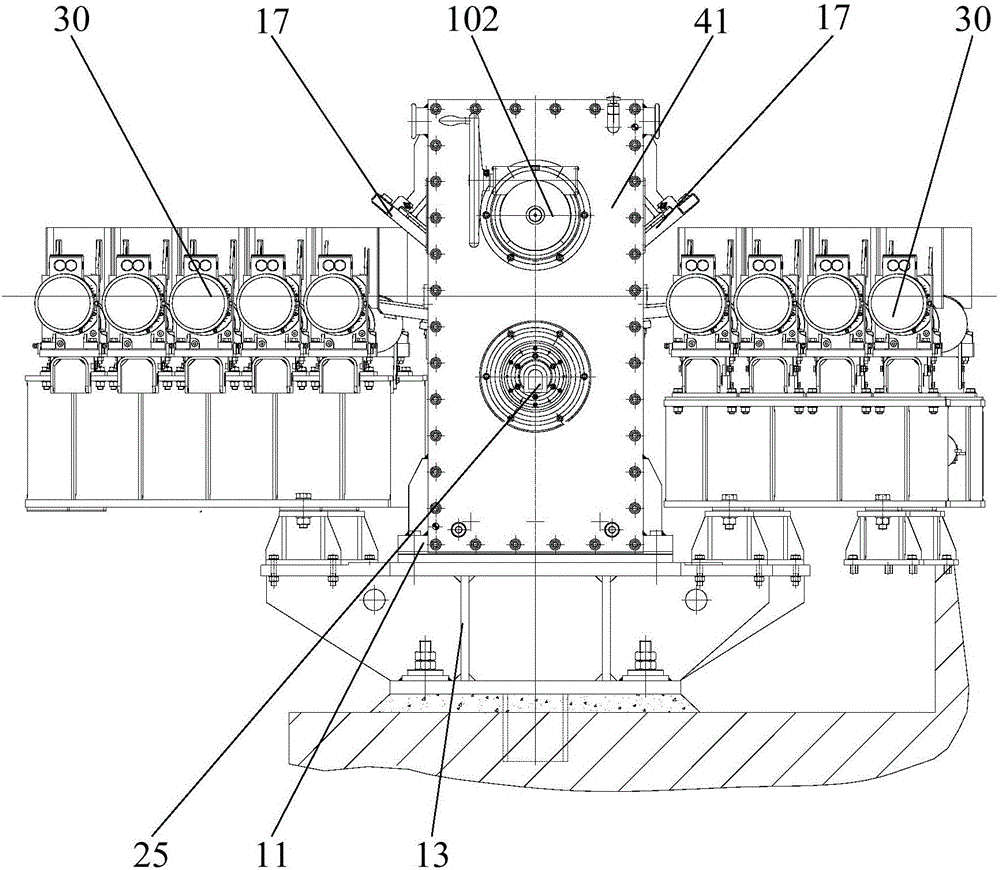

[0041] Such as figure 1 As shown, the present invention provides a drum flying shear, which includes: a frame 1 and a drive mechanism 9, wherein the upper part of the frame 1 is rotatably connected with parallel and spaced stacked driving knife shafts 2 and driven knives Axis 3, driving knife shaft 2 and driven knife shaft 3 are equal in diameter and connected by a transmission mechanism, which can drive the driven knife shaft 3 and the driving knife shaft 2 to rotate in reverse synchronously, as Figure 4 and Figure 5 As shown, the outer surface of the active cutter shaft 2 is provided with a linear first sipe 21 and a cylindrical helical second sipe 22 at intervals along the axial direction, that is, the first sipe 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com