A double-protection connection device with buffer overhead ground wire

A connection device and overhead ground wire technology, which is applied in overhead installation, cable suspension device, cable installation, etc., can solve the problems of bad social impact, reduced reliability of overhead ground wire connection, loss of personnel and property, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

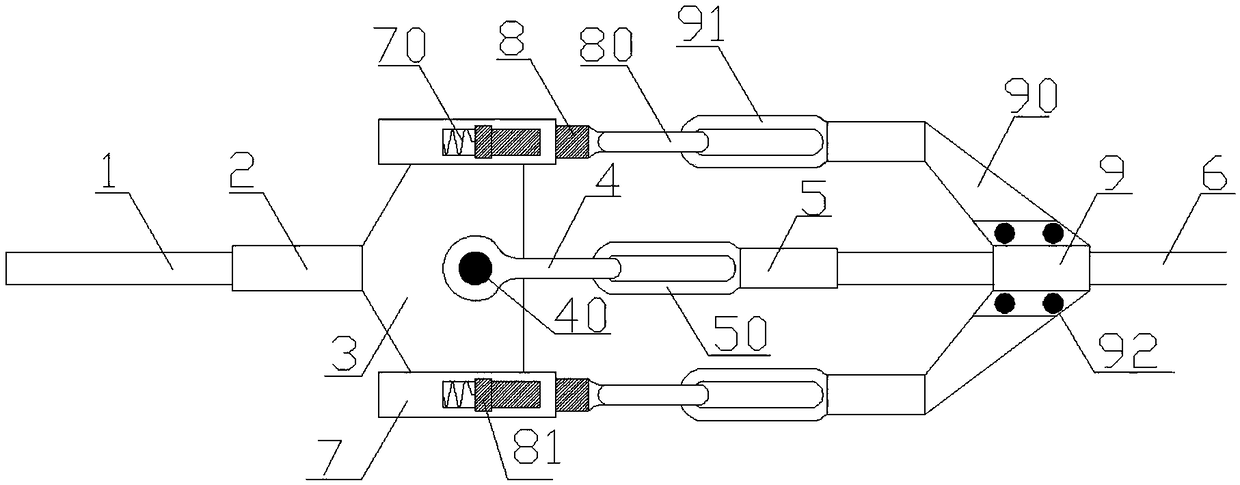

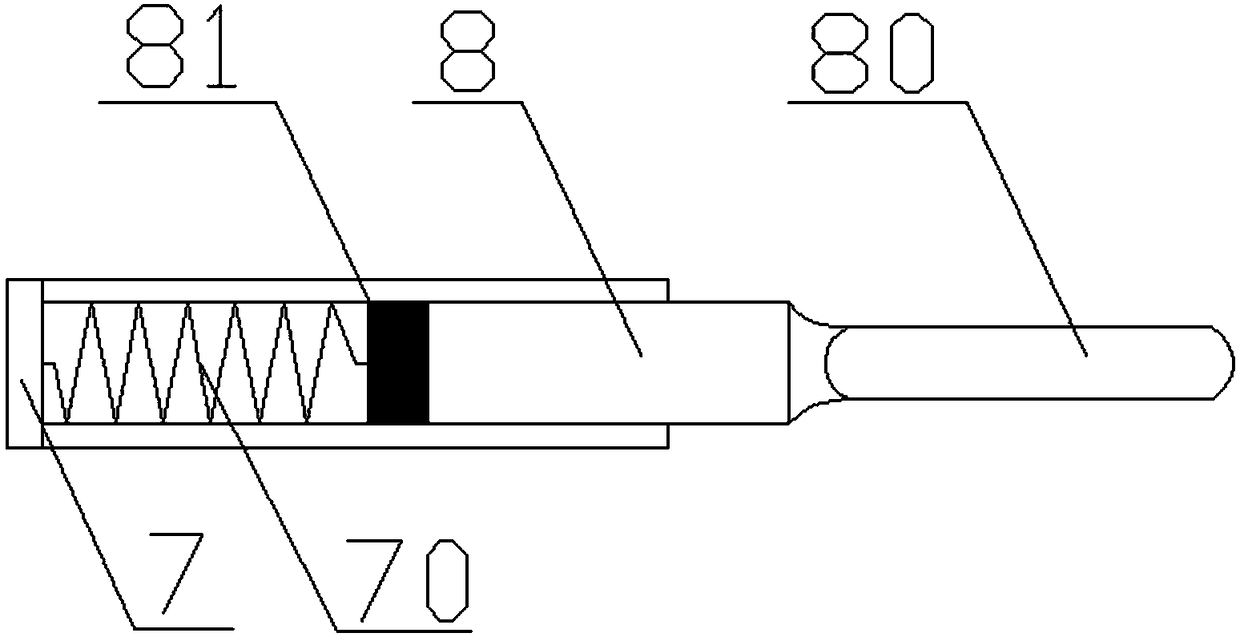

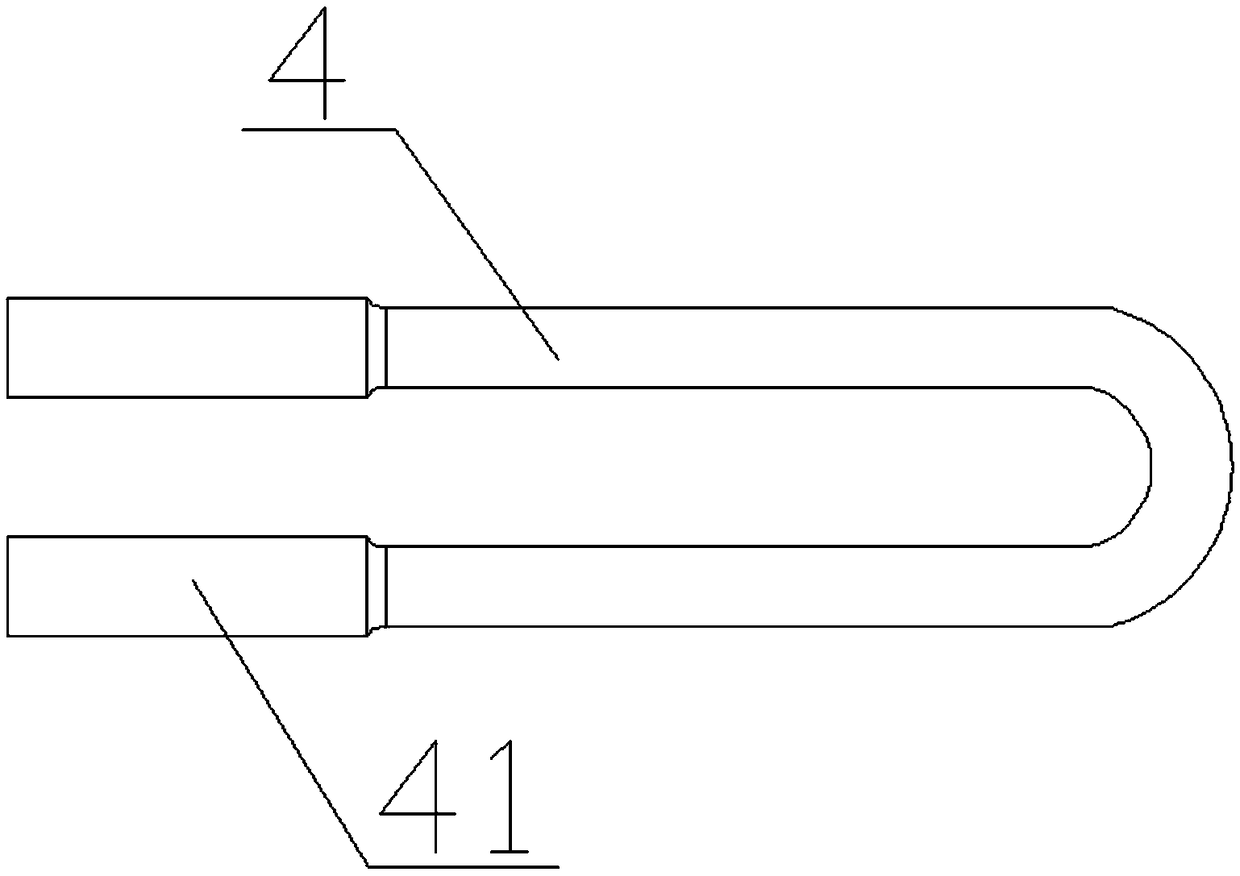

[0021] like Figure 1 to Figure 4 As shown, a double protection connection device for overhead ground wires with a buffer, including a connecting rod 1, a fixing piece 2, a triangular connecting plate 3, a main bearing connection ring 4, a main bearing clamp 5, a spare connection guide sleeve 7, a spare Connect the guide post 8 and the spare wire clip 9;

[0022] The fixed part 2 is fixedly connected with the connecting rod 1, and the right end of the fixed part 2 is fixedly connected to the left end of the triangular connecting plate 3, and the upper and lower ends of the triangular connecting plate 3 are fixedly connected with a spare connecting guide sleeve 7. The load-bearing connection ring 4 is fixedly connected to the middle of the right side of the triangular connecting plate 3 through the fixing bolt 40. The clip 5 is fixedly connected, and the main load-bearing wire clamp 5 is fixedly connected to the overhead wire 6; the main load-bearing connection ring 4 plays a ...

Embodiment 2

[0025] like Figure 1 to Figure 4 As shown, a double protection connection device for overhead ground wires with a buffer, including a connecting rod 1, a fixing piece 2, a triangular connecting plate 3, a main bearing connection ring 4, a main bearing clamp 5, a spare connection guide sleeve 7, a spare Connect the guide post 8 and the spare wire clip 9;

[0026] The fixed part 2 is fixedly connected with the connecting rod 1, and the right end of the fixed part 2 is fixedly connected to the left end of the triangular connecting plate 3, and the upper and lower ends of the triangular connecting plate 3 are fixedly connected with a spare connecting guide sleeve 7. The load-bearing connection ring 4 is fixedly connected to the middle of the right side of the triangular connecting plate 3 through the fixing bolt 40. The clamp 5 is fixedly connected, and the main bearing clamp 5 is fixedly connected to the overhead wire 6;

[0027] The spare connection guide sleeve 7 is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com