Plunger type coiler mandrel

A plunger-type, machine-coiling technology, applied in the field of plunger-type coiler reels, can solve the problems of shortening the service life of hot-rolled reels, prone to fatigue fracture of springs, and deformation of plunger bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

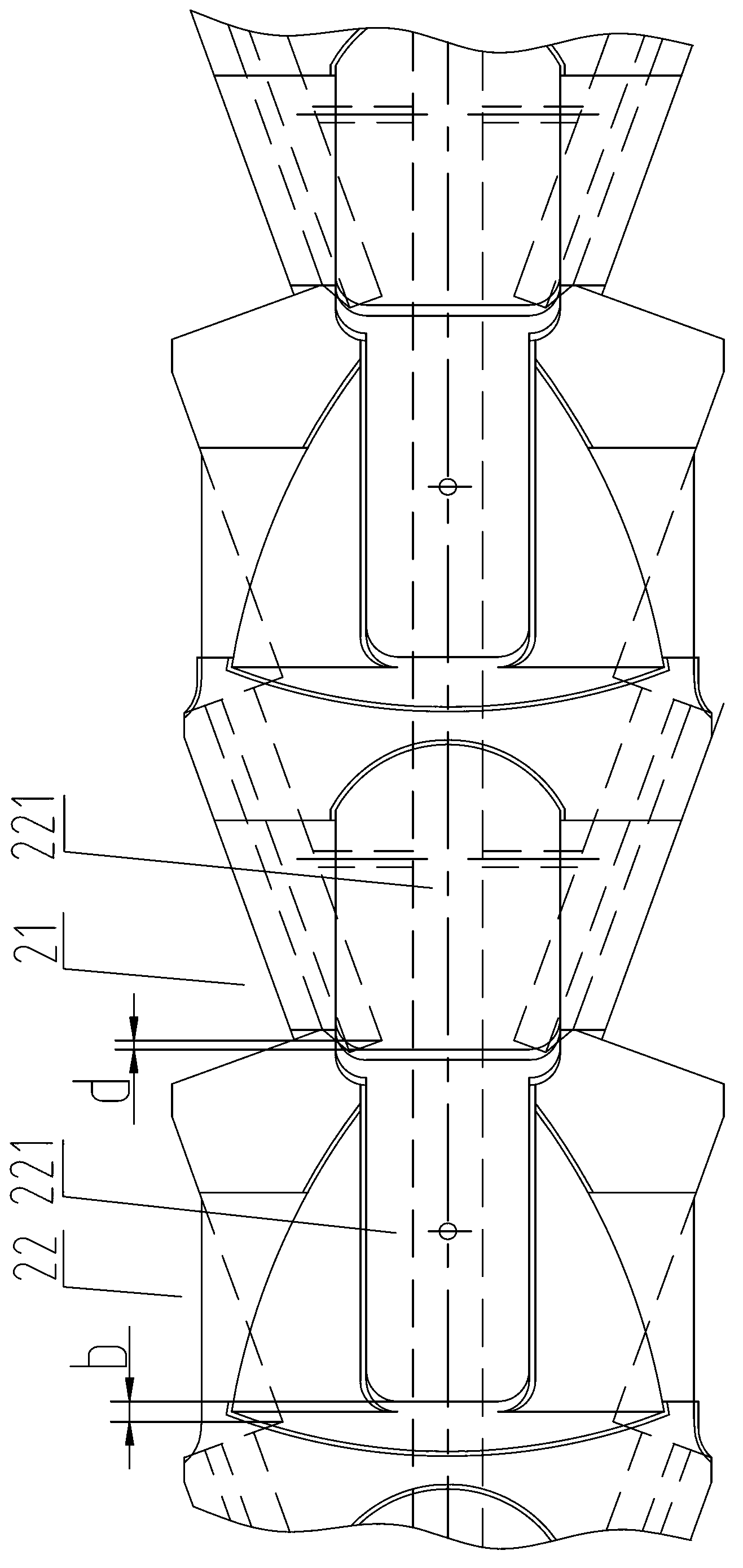

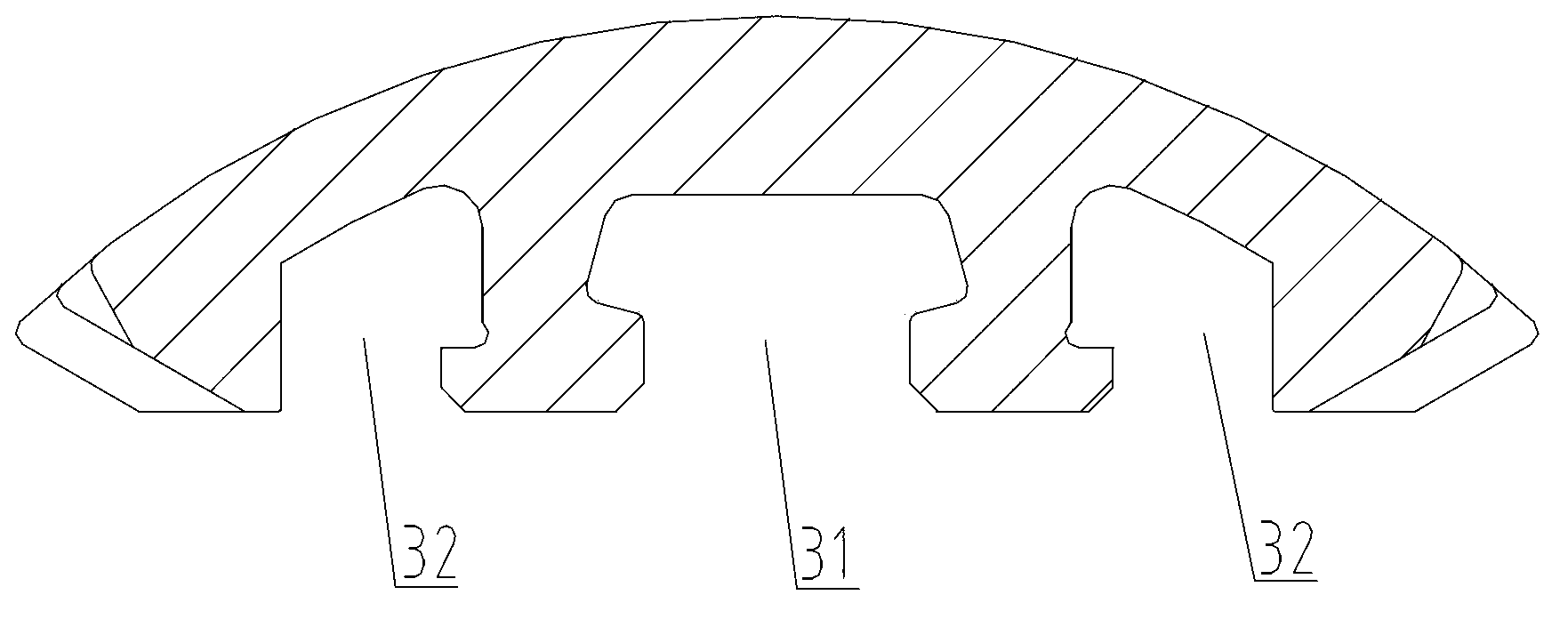

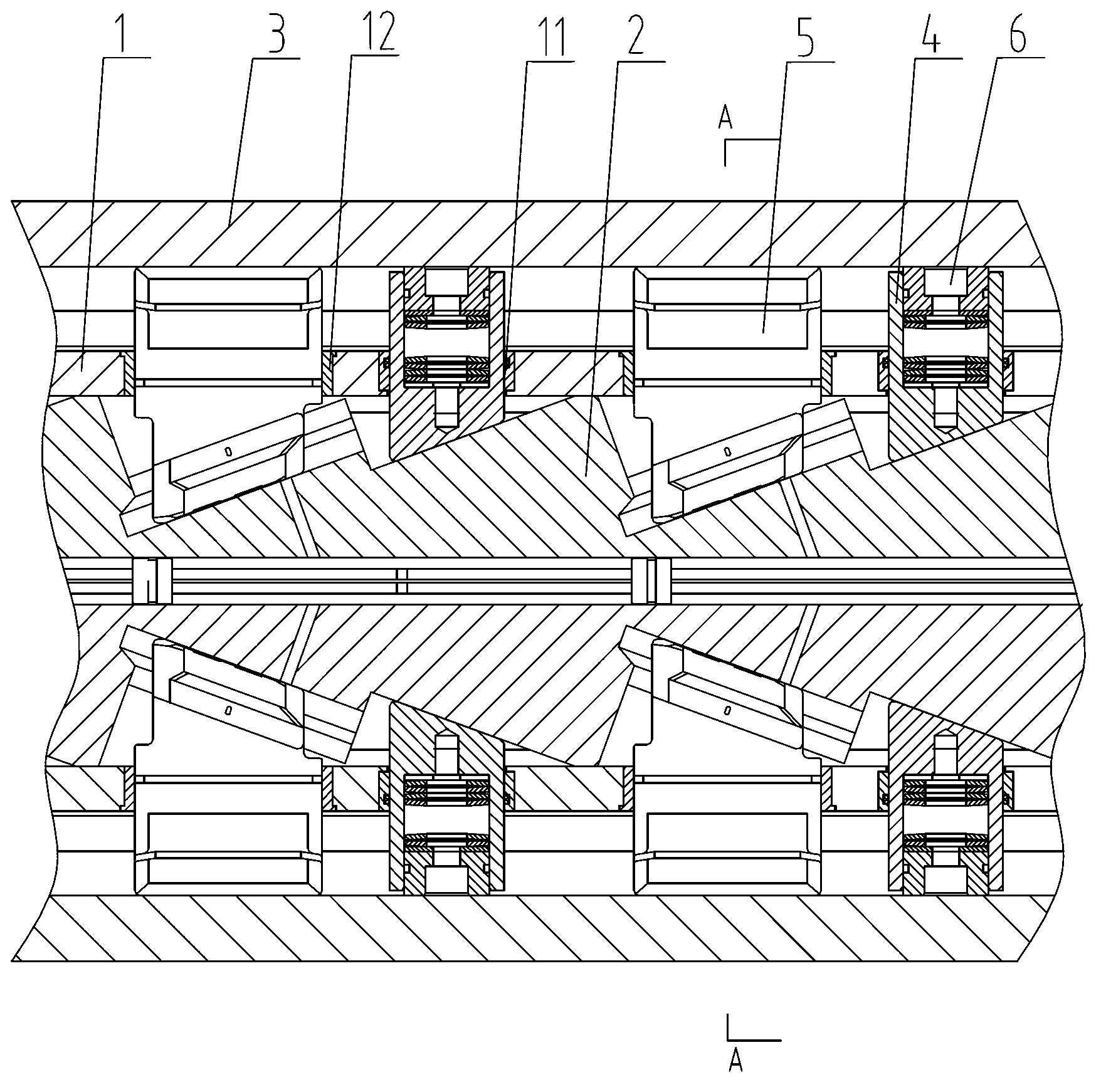

[0024] Such as figure 1 As shown, the pull rod 2 of the plunger-type coiler reel involved in the present invention is formed by several groups of wedge-shaped protrusions sequentially connected in the axial direction, and each group of wedge-shaped protrusions is composed of the first wedge-shaped protrusions 21 Composed of the second oblique wedge protruding block 22, the first oblique wedge protruding block 21 is provided with four oblique sides that are symmetrical along the axis of the reel, and the side of the second oblique wedge protruding block 22 is provided with four bottom surfaces along the axis of the reel The chute 221 is symmetrical, and the bottom surface of the chute 221 of the second wedge protrusion 22 is inclined toward the axis of the reel. One set of opposite inclined sides 211 of the first oblique wedge protrusion 21 is axially staggered by a certain distance b relative to the other set of opposite oblique sides 211 thereof, and one set of opposite obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com